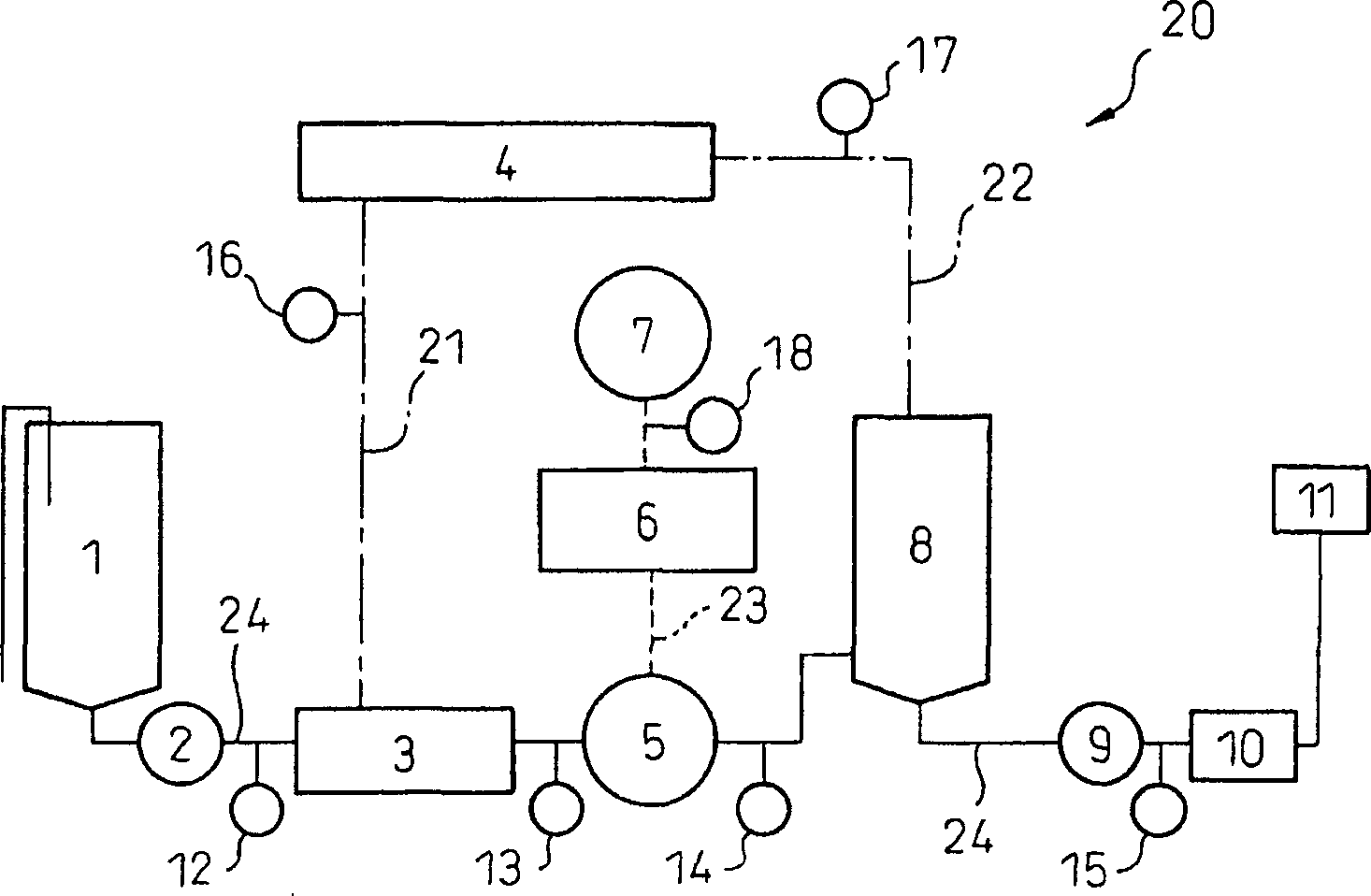

Method and apparatus for manufacturing beverage

A manufacturing method and manufacturing device technology, applied to beverage preparation devices, separation methods, chemical instruments and methods, etc., can solve the problems of not being able to use and obtain defoaming effects, so as to prevent damage to the flavor of beverages and reduce dissolved gases. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

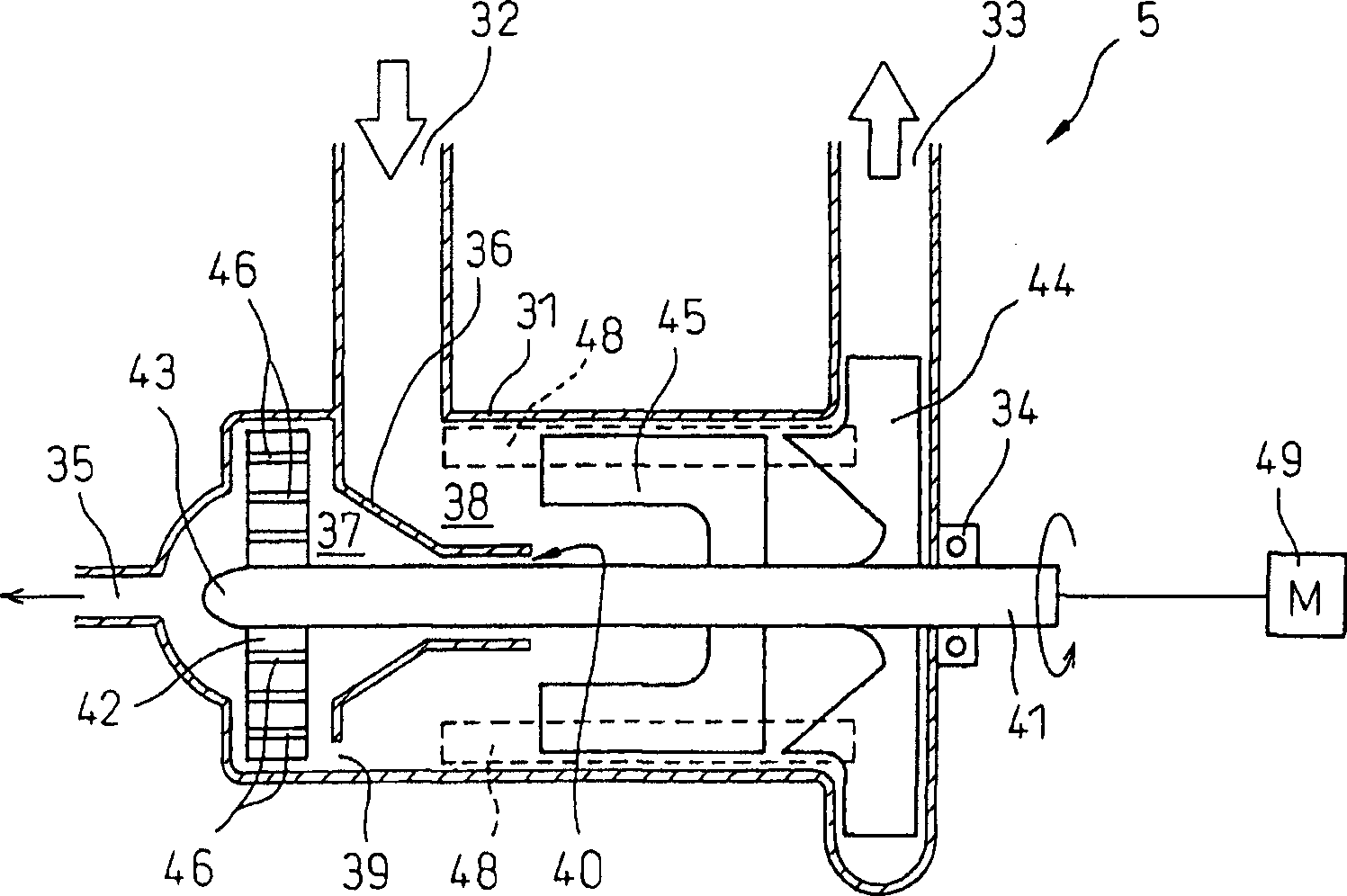

Method used

Image

Examples

Embodiment

[0055] 30 g of green tea leaves were extracted within 5 minutes with 1050 g of pure water at 75° C., the tea leaves were removed from the extract, and after cooling, centrifugal separation was performed, and then L-ascorbic acid, sodium bicarbonate, and pure water were added to adjust to 4 L. Afterwards, using nitrogen (N2 ) as the inert gas stripping part of the inert gas as the degassing device 3, filling and sealing under nitrogen flow, and in the sterilization device 10, sterilizing at 120° C. for 1 minute to produce a product. Table 1 shows the amount of dissolved oxygen, the amount of vitamin C, and sensory evaluation at this time.

[0056] level

Degassing conditions

Dissolved oxygen (ppm)

Vitamin C(ppm)

sensory evaluation

1

no degassing

7.93

350

△

2

N 2 Stripping for 15 minutes

1.76

399

○

3

N 2 Stripping for 60 minutes

0.4

416

◎

[0057] ◎: Very ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com