Sewage treatment system for improved A<2>O process

A sewage treatment system, an improved technology, applied in biological water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve insufficient denitrification reaction, hinder anaerobic phosphorus release, difficult To achieve simultaneous denitrification and phosphorus removal effects and other issues, to solve carbon source competition and sludge age differences, to increase the amount of sewage treatment, and to facilitate the effect of system denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

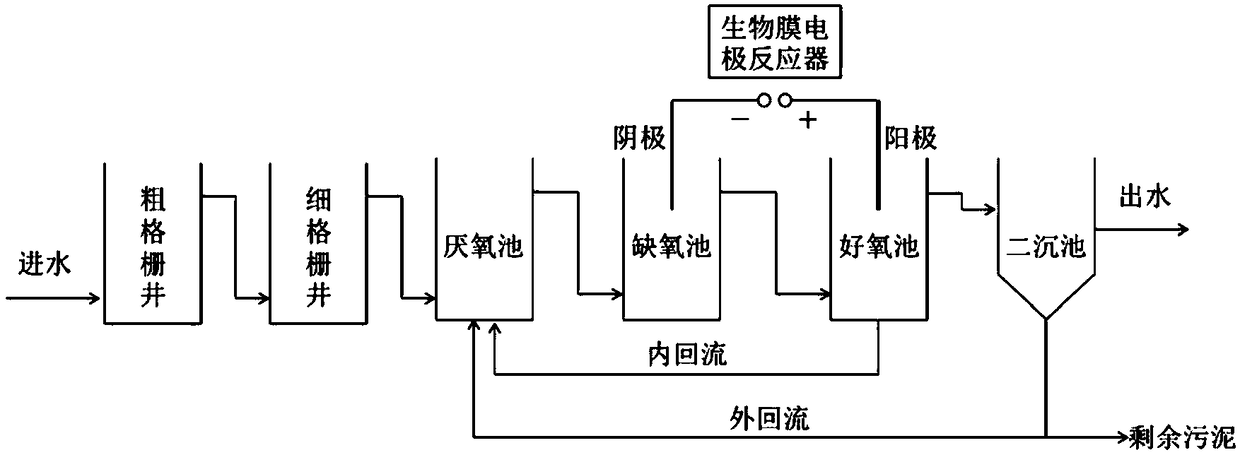

[0054] A modified form of A 2The sewage treatment system of O process, comprises the coarse grid well, fine grid well, anaerobic tank, anoxic tank, aerobic tank and secondary settling tank connected successively, and described anaerobic tank inoculates through domesticated anaerobic sewage Sludge, the dominant bacteria in the anaerobic sludge include Anammox bacteria, Anaerolinea, Bifidobacterium, Clostridium, Methanogenus, Moraxella, Serratia marcescens, Phycisphaerae and Flavobacteriales, the Anammox bacteria include Candidatus Kuenenia, Scalindua, Anammoxoglobus propionicus, can perform anaerobic ammonia Oxidation reaction, the top of the anaerobic tank is provided with an exhaust port, and an internal reflux mixed liquid pipeline is arranged between the aerobic tank and the anaerobic tank to make the nitrification liquid reflux, and the reflux ratio of the internal reflux is 300%. An external reflux sludge pipeline is set between the secondary settling tank and the anaerob...

Embodiment 2

[0057] A modified form of A 2 The sewage treatment system of O process, comprises the coarse grid well, fine grid well, anaerobic tank, anoxic tank, aerobic tank and secondary settling tank connected successively, and described anaerobic tank inoculates through domesticated anaerobic sewage Sludge, the dominant bacteria in the anaerobic sludge include Anammox bacteria, Anaerolinea, Bifidobacterium, Clostridium, Methanogenus, Moraxella, Serratia marcescens, Phycisphaerae and Flavobacteriales, the Anammox bacteria include Candidatus Kuenenia, Candidatus Brocadia, Anammoxoglobus propionicus, can perform anaerobic Ammoxidation reaction, the top of the anaerobic tank is provided with an exhaust port, and an internal reflux mixed liquid pipeline is arranged between the aerobic tank and the anaerobic tank, so that the nitrifying liquid can be refluxed, and the reflux ratio of the internal reflux is 400%. An external return sludge pipeline is arranged between the secondary settling ta...

Embodiment 3

[0060] A modified form of A 2 The sewage treatment system of O process, comprises the coarse grid well, fine grid well, anaerobic tank, anoxic tank, aerobic tank and secondary settling tank connected successively, and described anaerobic tank inoculates through domesticated anaerobic sewage Sludge, the dominant bacteria in the anaerobic sludge include Anammox bacteria, Anaerolinea, Bifidobacterium, Clostridium, Methanogenus, Moraxella, Serratia marcescens, Phycisphaerae and Flavobacteriales, the Anammox bacteria include Candidatus Jettenia, Candidatus Brocadia, Scalindua, can carry out anaerobic Ammoxidation reaction, the top of the anaerobic tank is provided with an exhaust port, an internal reflux mixed liquid pipeline is arranged between the aerobic tank and the anaerobic tank, so that the nitrifying liquid can be refluxed, and the reflux ratio of the internal reflux is 500%. An external return sludge pipeline is arranged between the secondary settling tank and the anaerobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com