Sewage treatment method based on improved A2O process

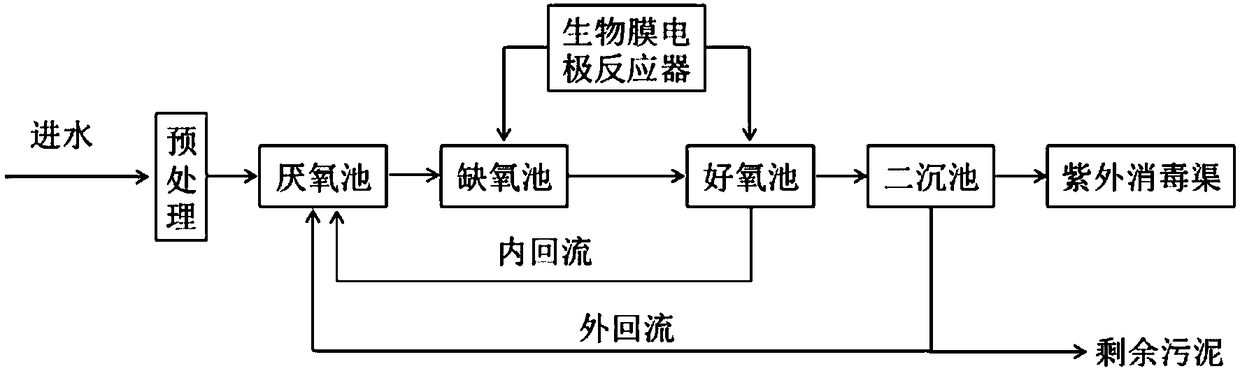

A sewage treatment method and improved technology, applied in biological water/sewage treatment, light water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of insufficient denitrification reaction, insufficient carbon source, influence, etc. Achieve the effect of solving carbon source competition and sludge age difference, shortening reaction time and improving phosphorus removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A modified A 2 The sewage treatment method of O process, in the traditional A 2 Improvement is made on the basis of the O process, and the sewage passes through the anaerobic tank, the anoxic tank, the aerobic tank and the secondary sedimentation tank in turn, and the anaerobic tank is inoculated with domesticated anaerobic sludge, and the anaerobic sludge in the anaerobic sludge is inoculated. The dominant bacteria include Anammox bacteria, Anaerolinea, Bifidobacterium, Clostridium, Methanogenus, Moraxella, Serratia marcescens, Phycisphaerae, and Flavobacteriales. The Anammox bacteria include Candidatus Kuenenia, Scalindua, Anammoxoglobuspropionicus, and there are biofilm electrode reactions in the aerobic and anoxic pools The anode uses a cylindrical nickel electrode, and a layer of jade that can radiate far-infrared rays with a wavelength of 6 to 14 μm is glued inside the cylinder. It is located in the aerobic pool, and the cathode uses an activated carbon fiber elec...

Embodiment 2

[0059] A modified A 2 The sewage treatment method of the O process is improved on the basis of the traditional AO process. The sewage passes through the anaerobic tank, the anoxic tank, the aerobic tank and the secondary sedimentation tank in turn, and the anaerobic tank is inoculated with domesticated anaerobic sludge. , the dominant bacteria in the anaerobic sludge include Anammox bacteria, Anaerolinea, Bifidobacterium, Clostridium, Methanogenus, Moraxella, Serratia marcescens, Phycisphaerae and Flavobacteriales, the Anammox bacteria include Candidatus Kuenenia, Candidatus Brocadia, Anammoxoglobuspropionicus, and the aerobic tank and There is a biofilm electrode reactor in the anoxic pool, the anode is a cylindrical copper electrode, and a layer of biochar that can radiate far-infrared rays with a wavelength of 6-14 μm is bonded inside the tube, which is located in the aerobic pool, and the cathode is graphite carbon felt. The electrode, with denitrifying bacteria biofilm fi...

Embodiment 3

[0067] A modified A 2 The sewage treatment method of O process, in the traditional A 2 Improvement is made on the basis of the O process, and the sewage passes through the anaerobic tank, the anoxic tank, the aerobic tank and the secondary sedimentation tank in turn, and the anaerobic tank is inoculated with domesticated anaerobic sludge, and the anaerobic sludge in the anaerobic sludge is inoculated. The dominant bacteria include Anammox bacteria, Anaerolinea, Bifidobacterium, Clostridium, Methanogenus, Moraxella, Serratia marcescens, Phycisphaerae, and Flavobacteriales, and the Anammox bacteria include Candidatus Jettenia, Candidatus Brocadia, Scalindua, and there are biofilm electrodes in the aerobic and anoxic pools The anode of the reactor is a cylindrical titanium electrode, and a layer of far-infrared ceramics that can radiate far-infrared rays with a wavelength of 6-14 μm is bonded inside the cylindrical shape. It is located in the aerobic pool, and the cathode is a ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com