Two-stage water inlet weir plate

A water inlet weir and weir plate technology, which is applied in the direction of gravity filter, loose filter material filter, filtration separation, etc., can solve the problem of large inflow flow changes, water head loss, stainless steel or plastic water inlet weir plate is not uniform Water distribution and other problems, to achieve the effect of reducing flow rate, improving performance and reducing dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

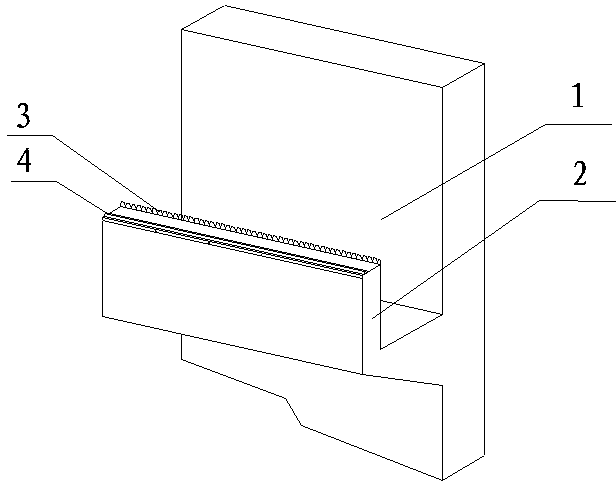

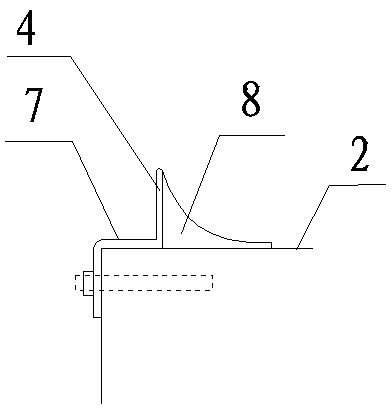

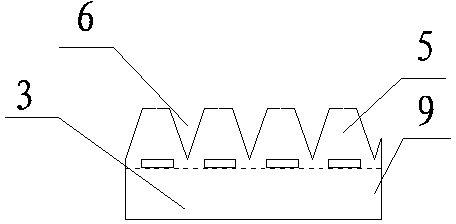

[0011] Such as figure 1 As shown, a two-stage water inlet weir plate includes a water inlet channel 1, and a water inlet weir 2 is provided on the water inlet channel 1. It is characterized in that a flow control weir plate 3 is provided on the inner side of the water inlet weir 2, The outer edge of the water inlet weir 2 is provided with a uniform water distribution weir plate 4 . Such as figure 2 As shown, the flow control weir plate 3 includes a base 9, on which several trapezoidal teeth 5 are arranged, and a weir opening 6 is arranged between two adjacent trapezoidal teeth 5, and the weir opening 6 is V-shaped, and the V-shaped weir opening 6 The trapezoidal teeth on both sides are hollowed out. Such as image 3 As shown, the uniform water distribution weir plate 4 is composed of a support 7 and a weir plate 8. The support 7 fixes the weir plate 8 on the outer edge of the water inlet weir 2. The weir plate 8 is arc-shaped, and the inner side of the weir plate 8 for th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com