High-concentration activated sludge sewage disposal process

A technology for activated sludge and sewage treatment, applied in water/sludge/sewage treatment, biological water/sewage treatment, sustainable biological treatment, etc. The problem of high cost, to achieve the effect of short residence time, easy transformation, and saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

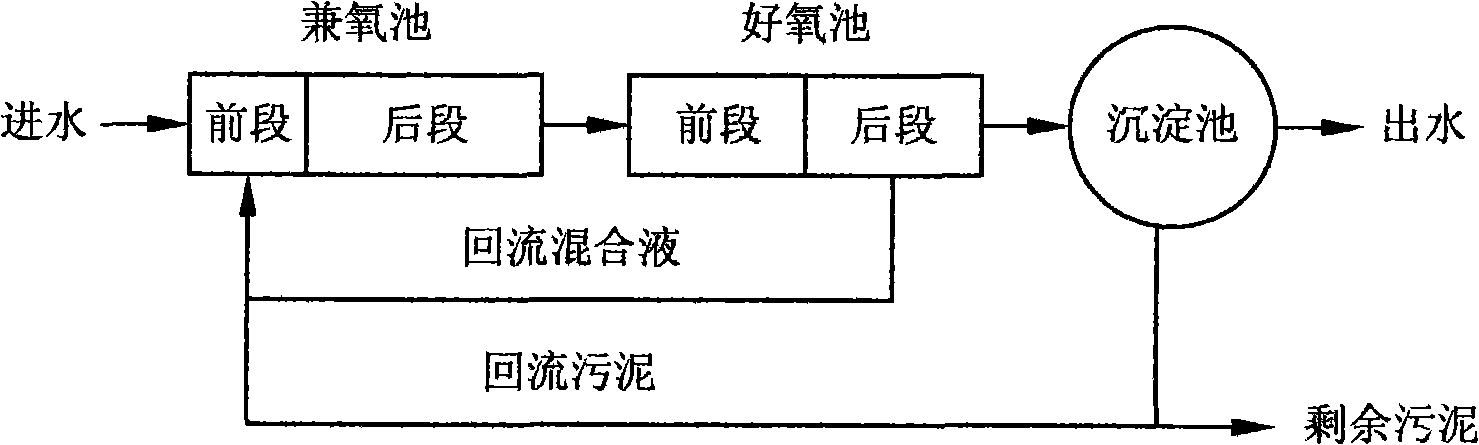

Method used

Image

Examples

Embodiment Construction

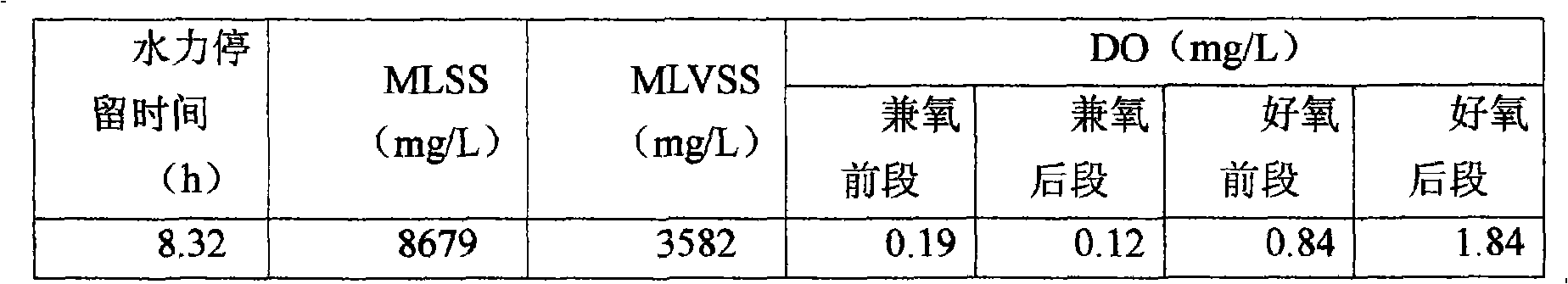

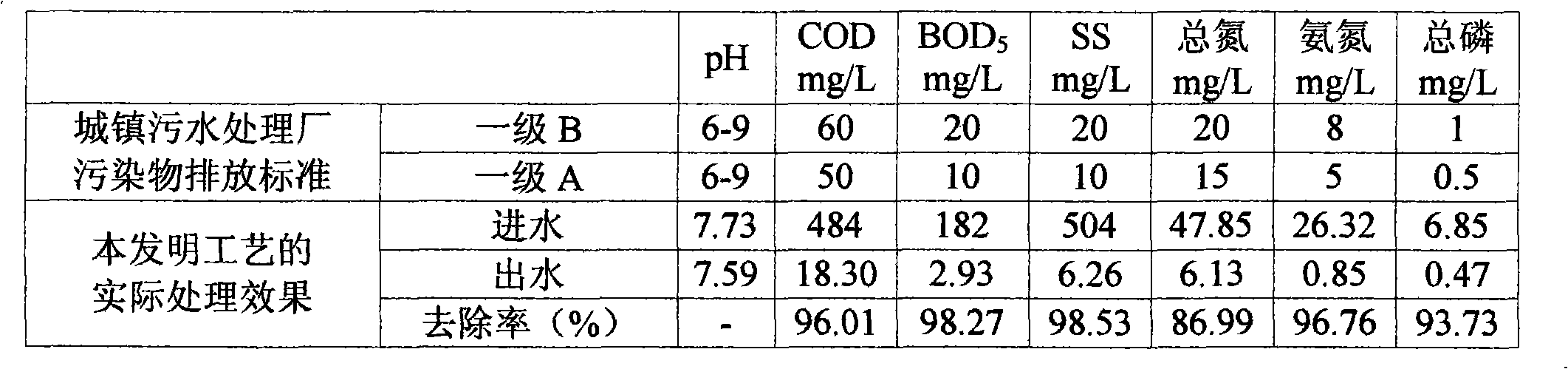

[0022] A certain urban sewage treatment project requires the effluent to reach the level of 8mg / L total nitrogen and 3mg / L ammonia nitrogen after transformation, but the hydraulic retention time of the whole process is only 8.7 hours. It is impossible to meet such strict water discharge requirements.

[0023] According to the process of the present invention, the process is transformed, and the existing common sedimentation tank is adopted, and the main operating parameters are as follows.

[0024]

[0025] the mud

age

d

total nitrogen load

(kgTN / kgMLSS / d)

Ammonia load

(kgAN / kgMLSS / d)

BOD 5 the load

(kg

BOD 5 / kgMLSS / d)

total

back

Sedimentation tank surface

(m 3 / m 2 / d)

7.03

0.0165

0.0090

0.0628

3.85

0.99

[0026] It can be seen from the above table that the hydraulic retention time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com