Scaffold screen grinding and leveling machine

A scaffolding and leveling machine technology is applied in the field of grinding and processing, which can solve the problems of low work efficiency and large labor consumption, and achieve the effects of improving work efficiency, reducing consumption and ensuring health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

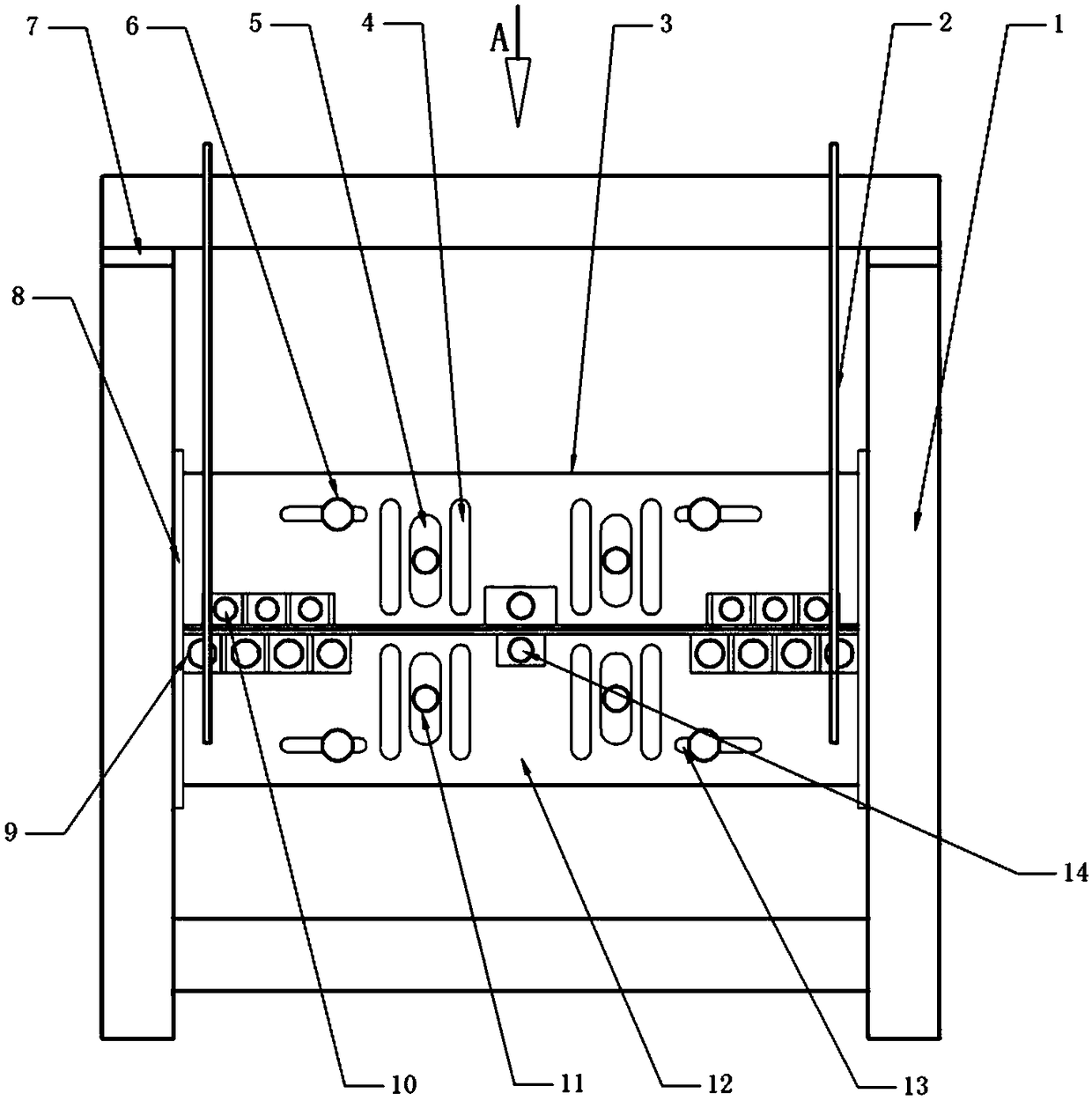

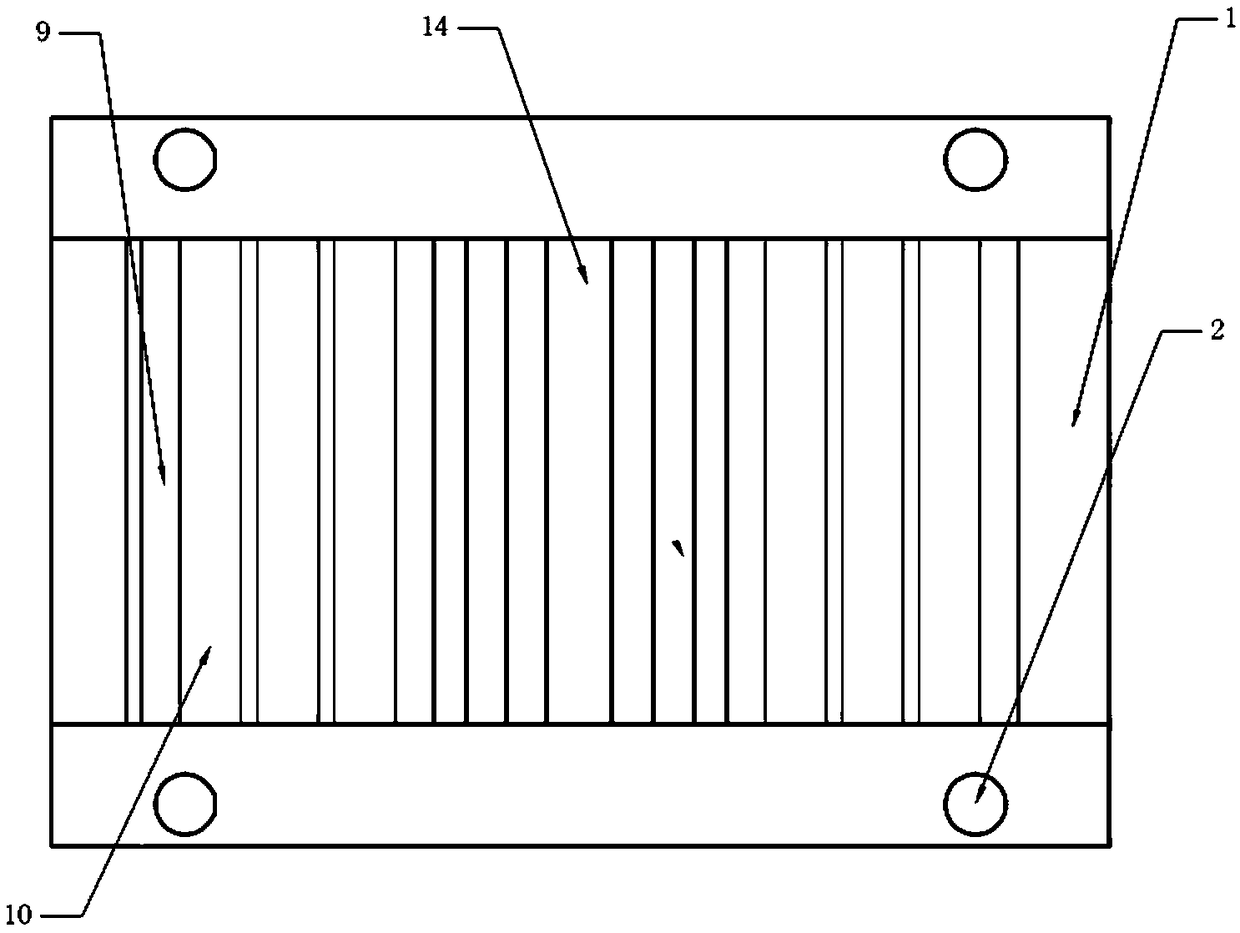

[0032] Scaffold net plate grinding and leveling machine, basically as attached figure 1 And attached figure 2 As shown, the frame 1 is included, the front and back of the frame 1 are provided with clamping mechanisms, and the clamping structures include an upper clamping plate 3 and a lower clamping plate 12 . The upper part of the frame 1 is provided with a spacer 7 for stabilizing the frame structure of the frame 1 .

[0033] Both the upper clamping plate 3 and the lower clamping plate 12 are vertically slidingly connected with the frame 1, and the guide rail 8 is also fixed on the frame 1, and the two ends of the upper clamping plate 3 and the lower clamping plate 12 are located in the guide rail 8, The upper clamping plate 3 and the lower clamping plate 12 are guided by the guide rail 8, four lead screws 2 are fixed on the frame 1, and the nut seats of the lead screw 2 are respectively connected with the corresponding upper clamping plate 3 and the lower clamping plate ...

Embodiment 2

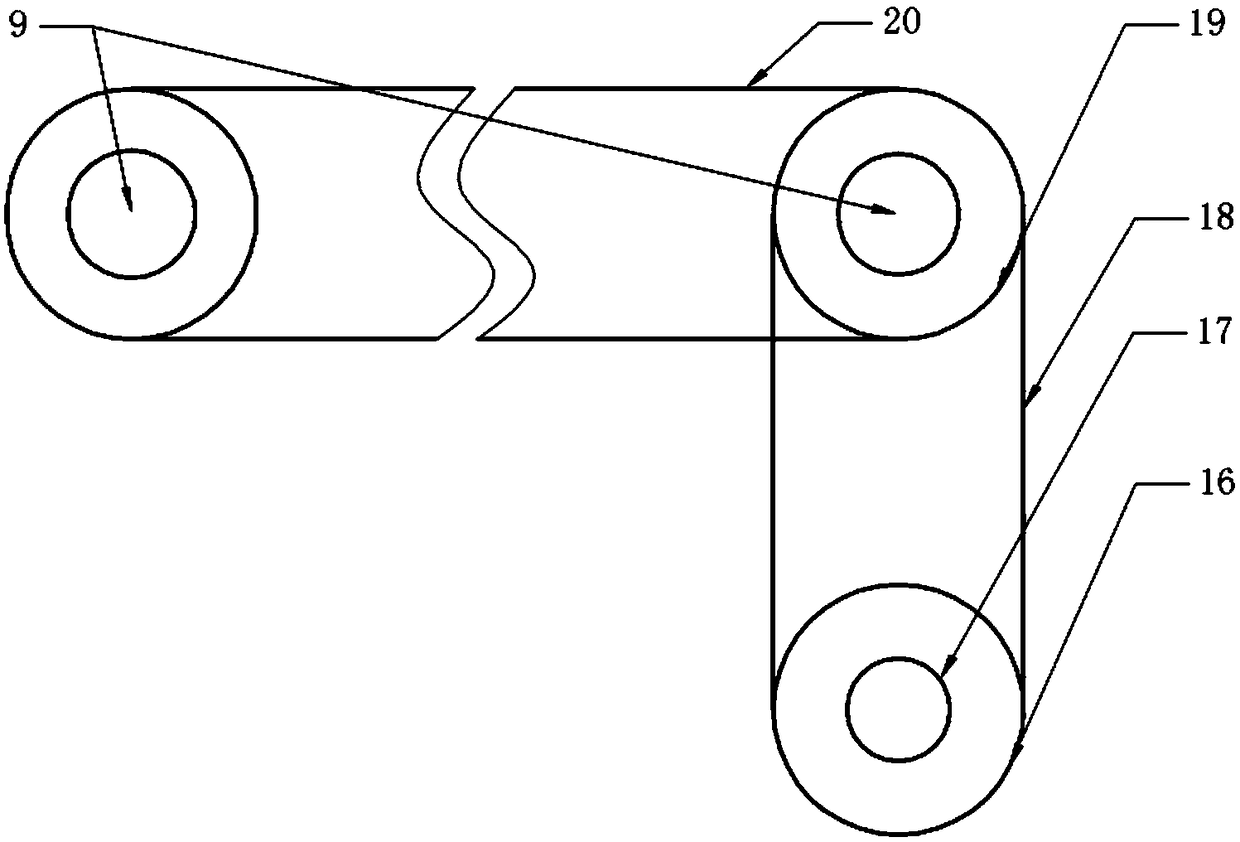

[0045] The difference from Embodiment 1 is that, as attached Image 6 As shown, the connecting end of the tensioning wheel 6 is slidably connected with the chute 13, and the side of the tensioning wheel 6 away from the guide groove 5 is provided with an air box 26 installed on the frame 1, and the air box 26 is horizontally slidably connected with The piston plate is fixed with the piston rod 261 fixedly connected with the tensioning wheel 6, and the air box 26 on the left side of the piston plate is connected with an air intake check valve 263 and an air outlet check valve 262, and the intake check valve 263 Under the action of pressure, the gas outside the gas box 26 enters the gas box 26 through the intake check valve 263, and the gas outlet check valve 262 is subjected to pressure, and the gas inside the gas box 26 will be discharged through the gas outlet check valve 262, and the tensioner 6. A spring against the sliding groove 13 is provided on one side close to the moun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com