Round pipe grinding method

A round tube and grinding wheel technology, which is applied to the grinding machine, grinding feed motion, grinding workpiece support, etc., can solve the problems of poor grinding effect and inaccurate positioning of the round tube, and achieve the effect of saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

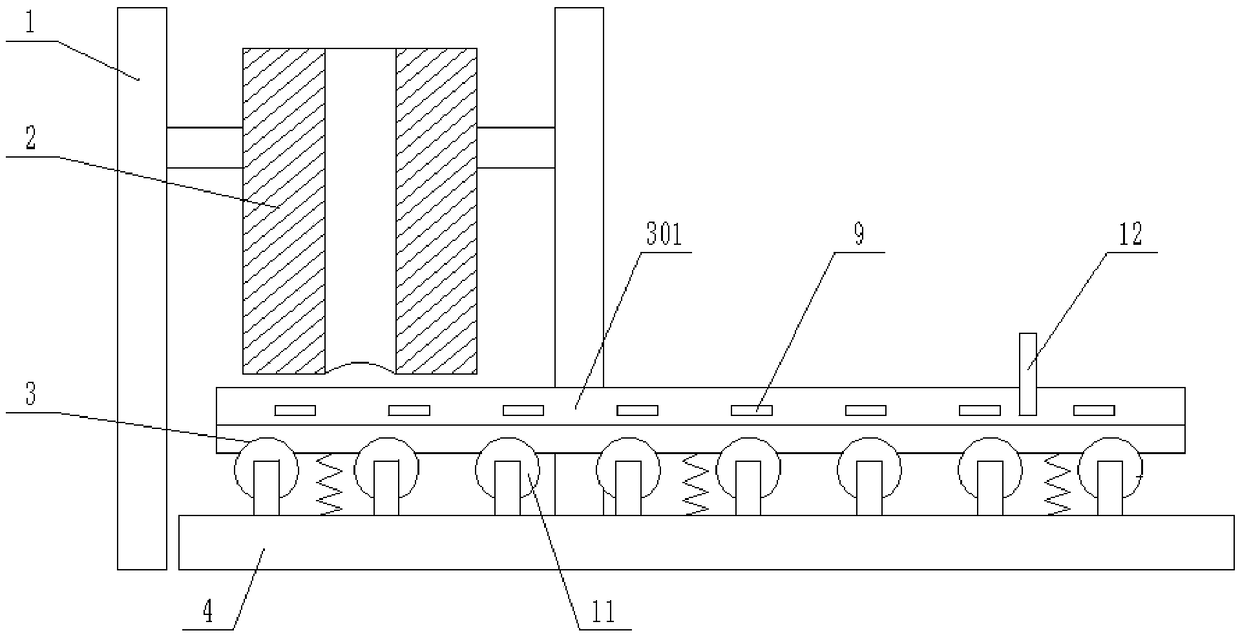

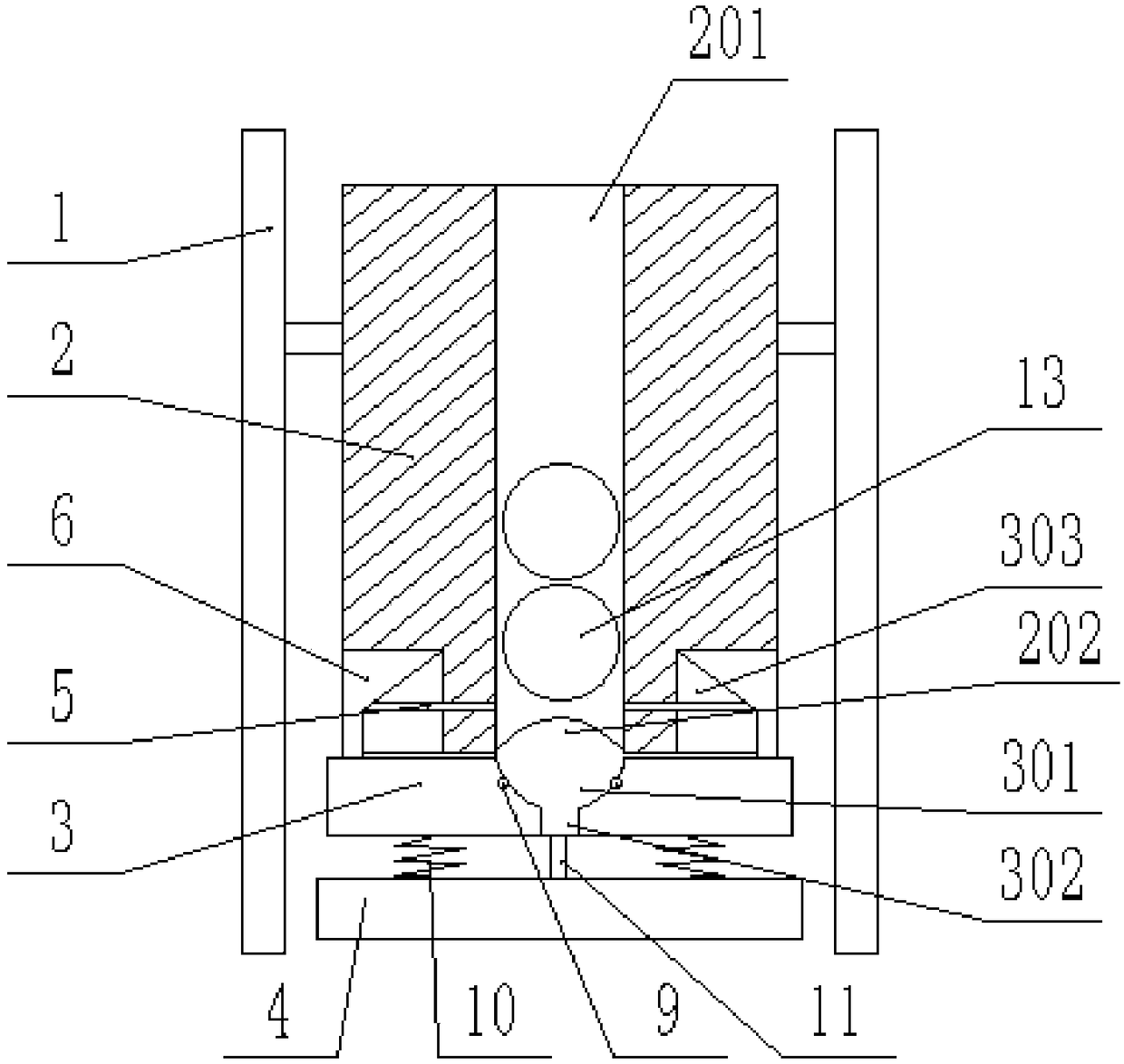

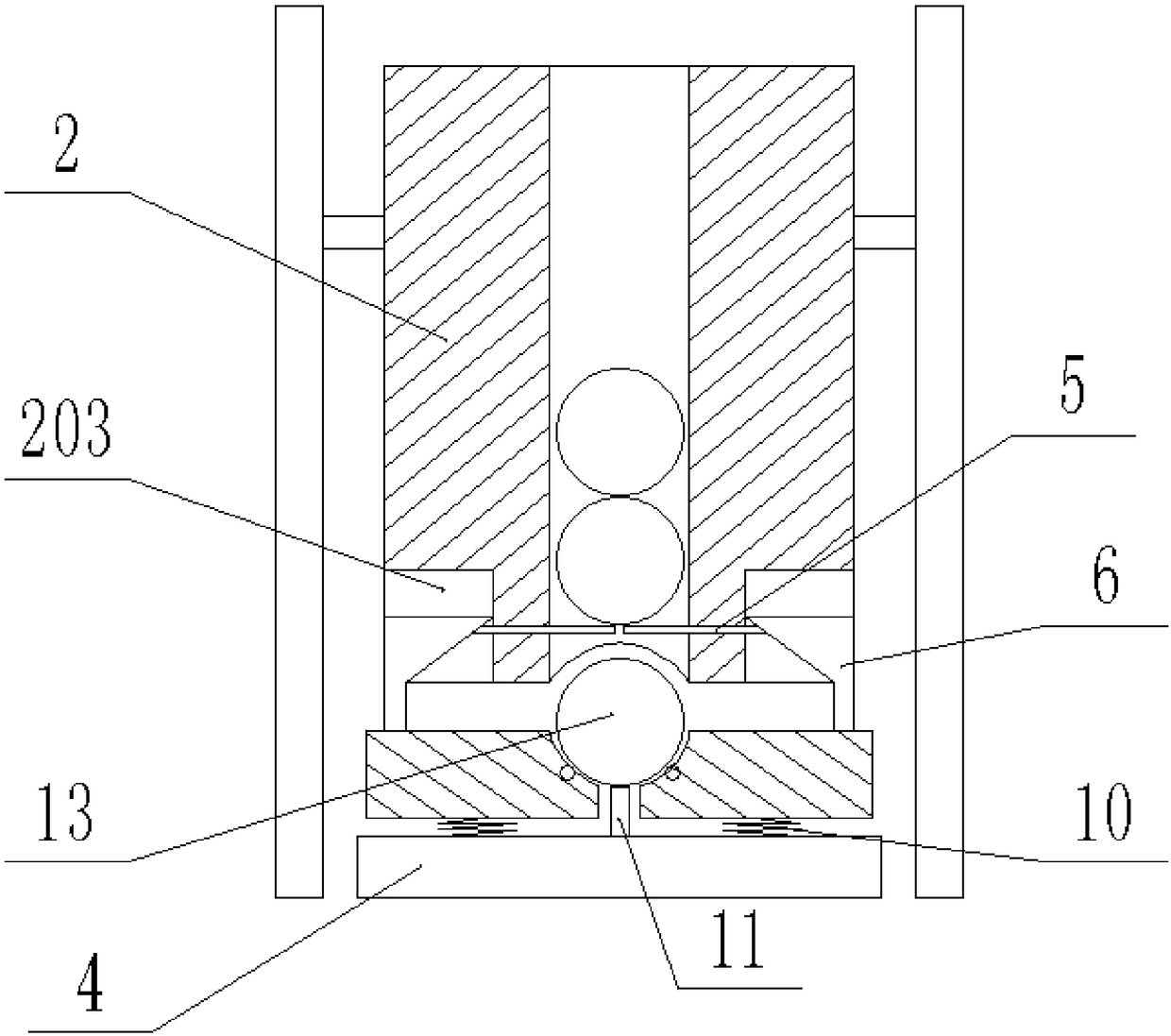

[0029] The reference signs in the drawings of the description include: feeding frame 1, feeding pipe 2, feeding port 201, feeding port 202, chute 203, positioning table 3, positioning slot 301, cavity 302, grinding slot 303, base 4 , support plate 5, pull bar 6, extension spring 7, rotating shaft 8, rotating roller 9, stage clip 10, transmission roller 11, grinding wheel 12, circular pipe 13.

[0030] The round pipe grinding method comprises the following steps:

[0031] Step 1: Prepare the round pipe and grinding device to be polished.

[0032] In order to better illustrate the specific steps of this method, the specific structure of the grinding device used is as follows:

[0033] like figure 1 , figure 2 and Figure 4 As shown, the grinding device includes a feeding frame 1, a feeding tube 2, a positioning platform 3 and a base 4, wherein the feeding tube 2 is vertically fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com