Double-arm large-stroke bidirectional fork device

A large-stroke, bidirectional technology, applied in the field of double-arm large-stroke bidirectional fork devices, can solve the problems of limited handling stroke and handling range, falling of the goods to be handled, low handling efficiency, etc., and achieves simplified drive and fork structure, The effect of protecting the motor, easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

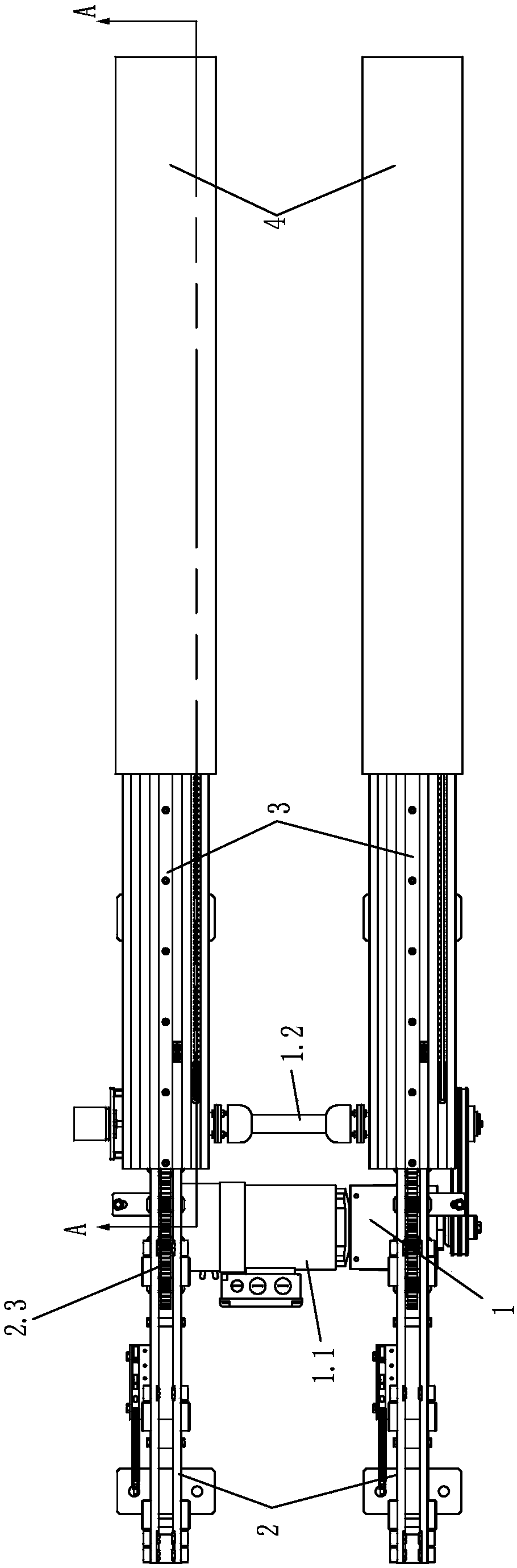

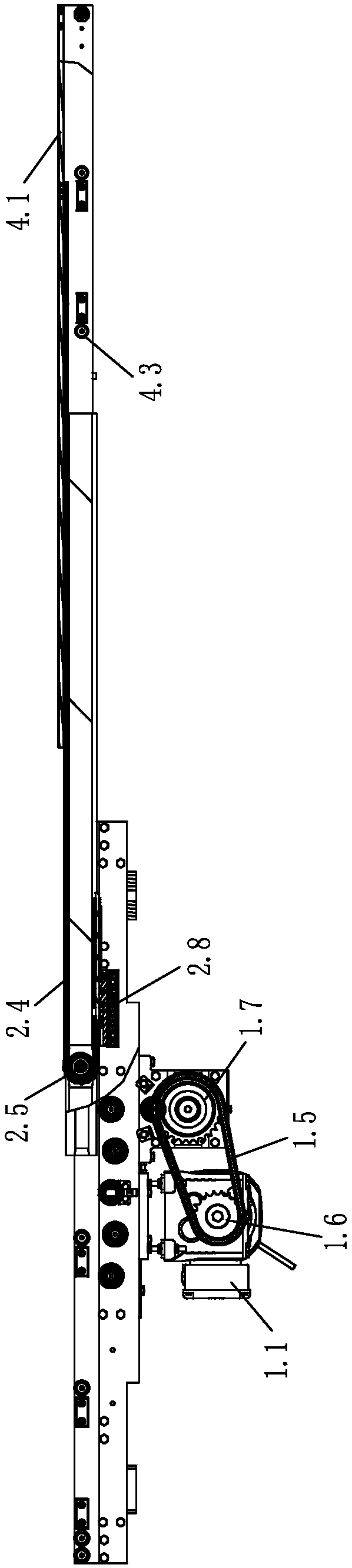

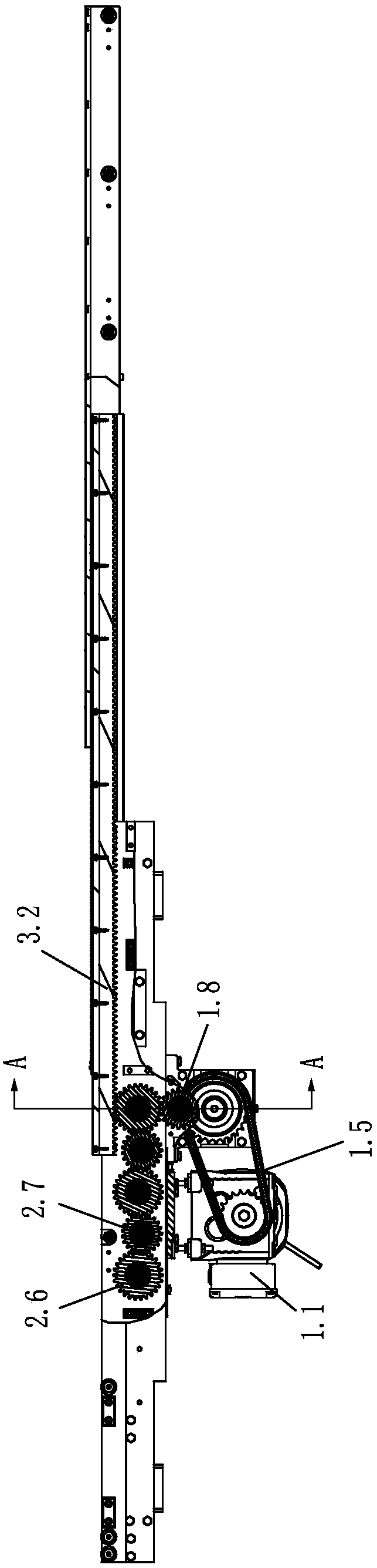

[0031] Embodiment one: see Figure 1~4 As shown, a double-arm large-stroke two-way fork device includes two fork units, left and right, and each fork unit includes an upper fork unit 4, a middle fork unit 3, and a lower fork unit 2. , the left and right fork units are synchronously driven by a drive unit 1,

[0032] The lower fork unit 2 includes a base and several intermeshing gear sets 2.3 arranged in the base, and the drive unit 1 is meshed with the gear set 2.3 through a transmission gear 1.8;

[0033] The middle fork unit 3 is arranged above the lower fork unit 2, which includes a body 3.1 and a rack 3.2 arranged under the body 3.1 and meshed with the gear set 2.3;

[0034] The upper fork unit 4 is located above the middle fork unit 3, and includes a platform plate 4.1, an outer guide roller 4.3 arranged below the platform plate 4.1, and the body 3.1 of the middle fork unit 3 is provided with A groove, the outer guide roller 4.3 of the upper fork unit 4 is rollingly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com