Method for operating a workstation of an open end rotary spinning machine and corresponding workstation

A rotor spinning machine, free-end technology, applied in open-end spinning machines, spinning machines, spinning machines with continuous winding, etc., can solve problems such as uncertain operating conditions, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

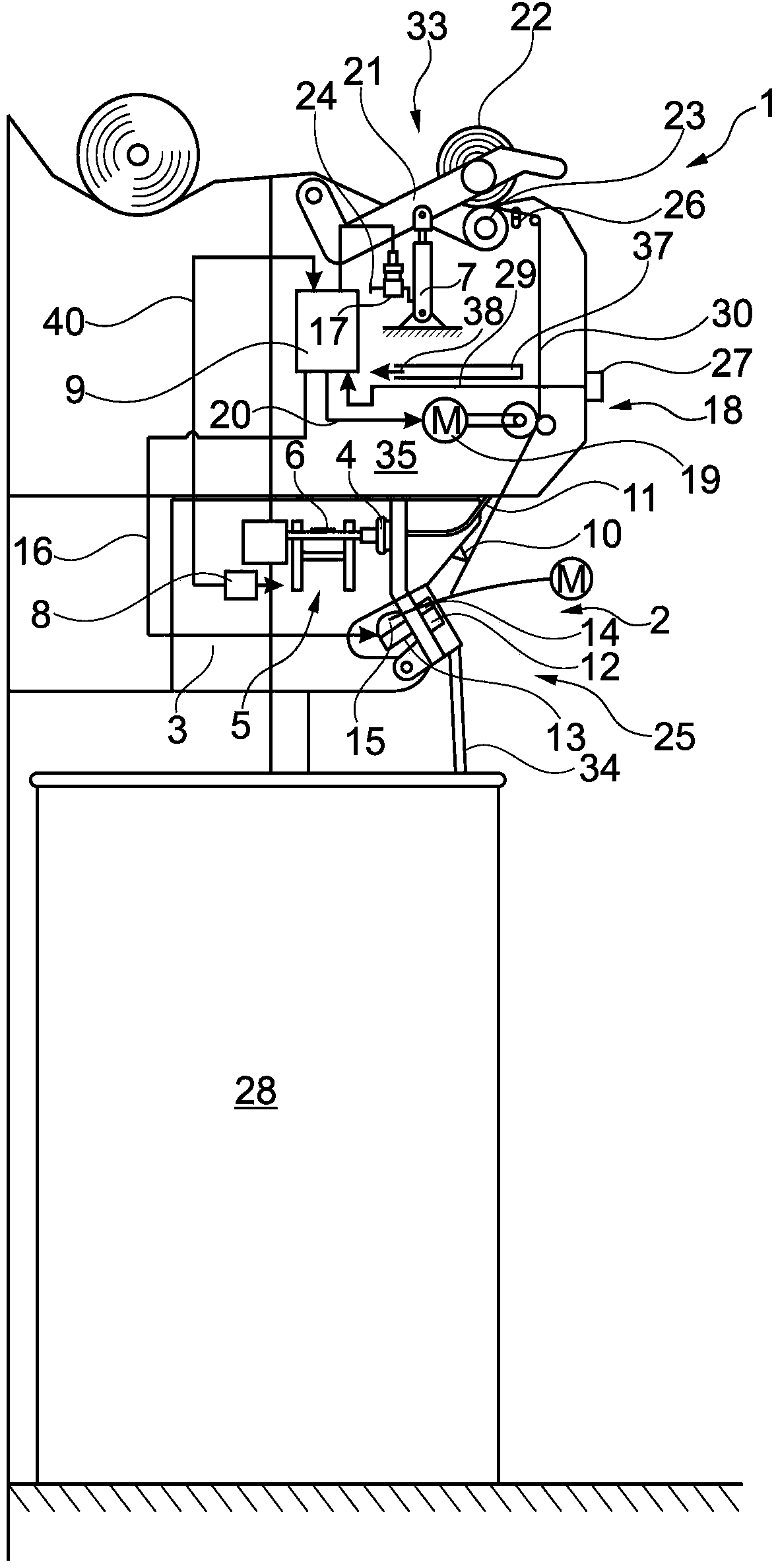

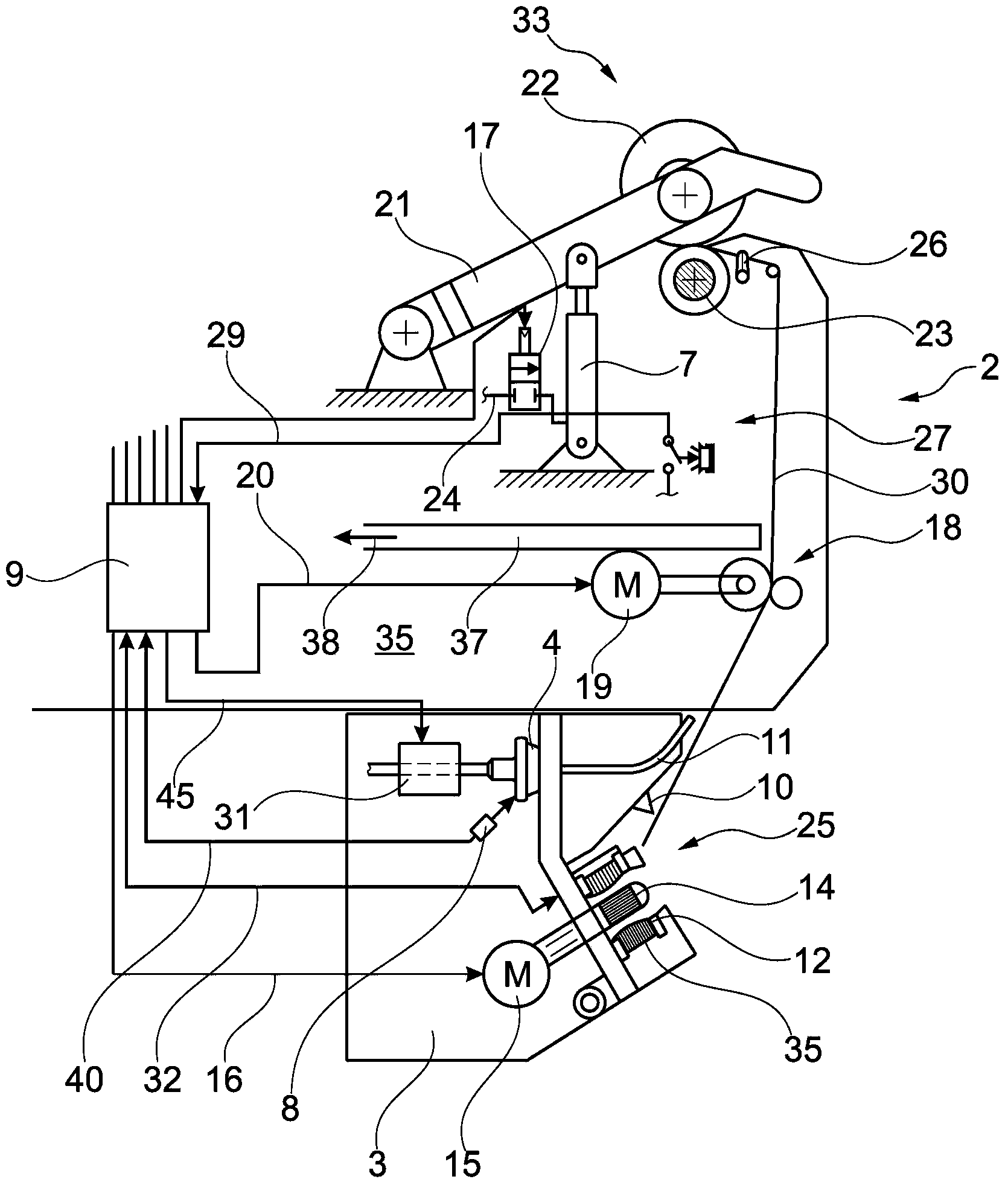

[0035] figure 1 Half of station 2 of semi-automatic open-end rotor spinning machine 1 is shown. As is known, this type of textile machine usually has a large number of stations 2 equipped with an open-end spinning device 3 and a winding device 33, respectively.

[0036] In the open-end spinning device 3, the fiber ribbon 34 supplied in the spinning bobbin 28 is spun to form the yarn 30, and the yarn 30 is wound on the winding device 33 to form a cross-wound bobbin 22. As known per se, the winding device 33 respectively has a creel 21 for holding the bobbin of the cross-wound bobbin 22 in a rotatable manner, a bobbin driving roller 23, a yarn traverse mechanism 26, and a yarn traverse mechanism 26 for winding the cross-wound bobbin 22. The bobbin 22 is lifted away from the mechanism 7 of the bobbin driving roller 23. The mechanism 7 is, for example, configured as a push rod transmission, which is connected to an overpressure source (not shown) via a pneumatic line 24, in which a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com