Robot code scanning conveying line detection method, system and device and storage medium

A detection method and conveyor line technology, applied in the direction of conveyor control devices, conveyor objects, transportation and packaging, etc., can solve the problem that the product is difficult to be completely detected, and achieve the effect of reducing the possibility of omission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The following is attached Figure 1-6 The application is described in further detail.

[0067] The embodiment of the present application discloses a detection method, system, device and storage medium of a robot code scanning conveying line.

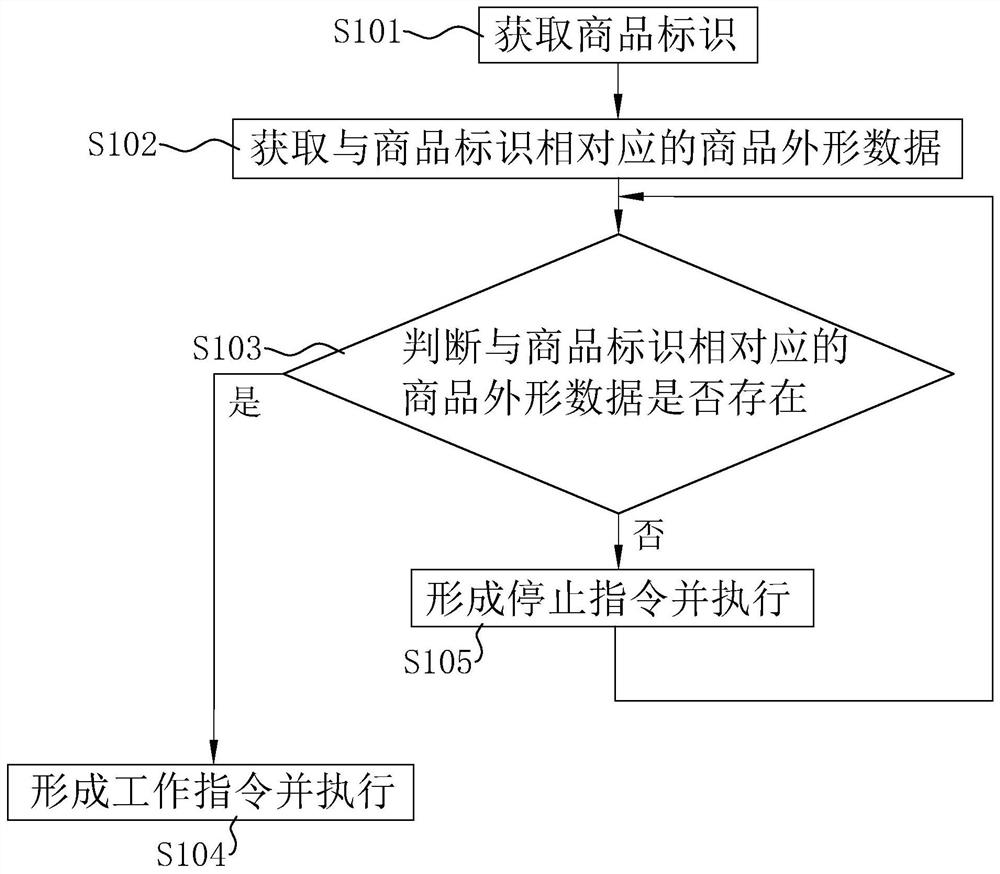

[0068] refer to figure 1 , a robot code scanning conveyor line detection method includes:

[0069] S101: Obtain a commodity identifier.

[0070] Specifically, after the relevant processing of the products is completed, the conveyor belt performs the operation of conveying the products out of the warehouse. At this time, the products are arranged along the length of the conveyor belt, and there is a certain distance between adjacent products. A detection device, when the conveyor belt transports the product to the location of the detection device, the detection device detects the product within the detection range, first identifies the identification number of the product, and obtains the product identification.

[0071] S102: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com