Air rapid cycle device within plant for metallurgical steelmaking

A technology of rapid circulation and air circulation device, applied in mechanical equipment, air humidification system, lighting and heating equipment, etc., can solve problems such as inability to reasonably adjust the use range of equipment, difficulty in increasing air humidity, and inability to quickly adjust the speed of air convection circulation. , to achieve the effect of speeding up the air convection circulation, facilitating rapid exchange, and a comfortable and safe working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

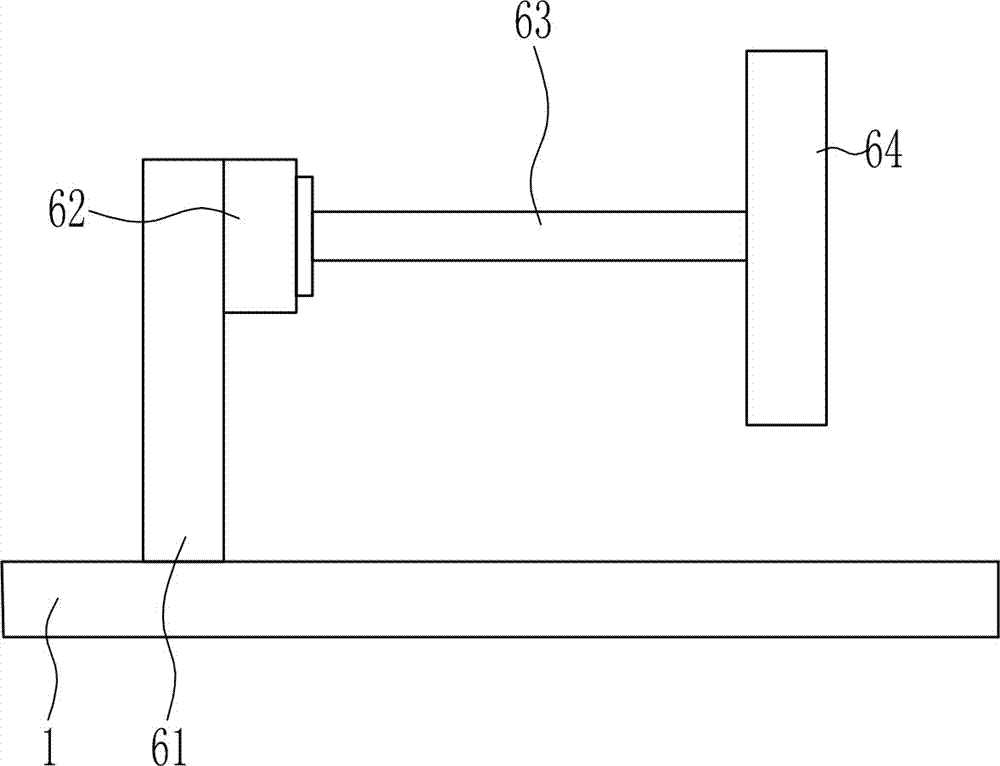

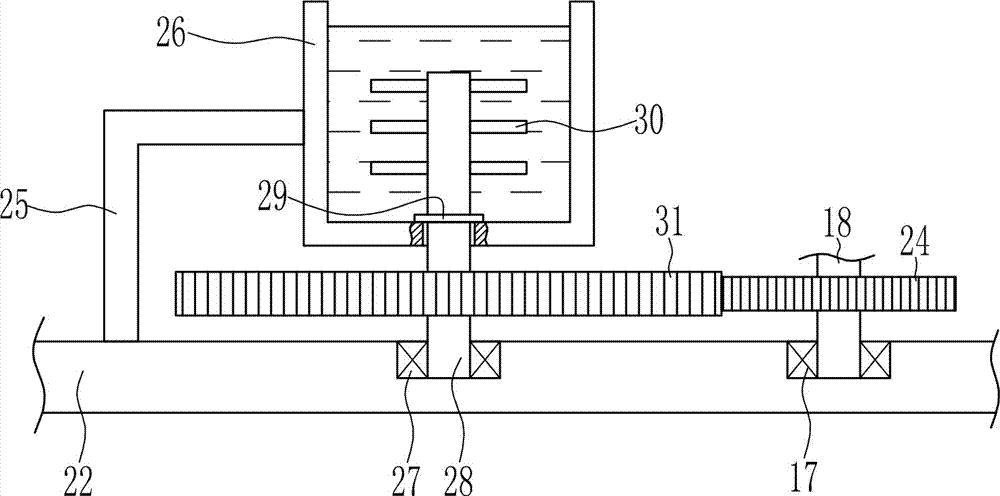

[0037] A kind of rapid air circulation equipment in a metallurgical steelmaking workshop, such as Figure 1-9 As shown, it includes a first mounting plate 1, a slide rail 2, a slider 3, a second mounting plate 4, an air circulation device 5, and a left and right moving device 6. The top left side of the first mounting plate 1 is inlaid with a slide rail 2, and the sliding The top of the rail 2 is connected with a slider 3 in a left-right symmetrical sliding manner, and the top of the slider 3 on the left and right sides is provided with a second mounting plate 4, and the top of the second mounting plate 4 is provided with an air circulation device 5, and the top right side of the first mounting plate 1 is provided with a There is a left and right moving device 6, and the left part of the left and right moving device 6 is connected with the right side of the second mounting plate 4.

Embodiment 2

[0039] A kind of rapid air circulation equipment in a metallurgical steelmaking workshop, such as Figure 1-9 As shown, it includes a first mounting plate 1, a slide rail 2, a slider 3, a second mounting plate 4, an air circulation device 5, and a left and right moving device 6. The top left side of the first mounting plate 1 is inlaid with a slide rail 2, and the sliding The top of the rail 2 is connected with a slider 3 in a left-right symmetrical sliding manner, and the top of the slider 3 on the left and right sides is provided with a second mounting plate 4, and the top of the second mounting plate 4 is provided with an air circulation device 5, and the top right side of the first mounting plate 1 is provided with a There is a left and right moving device 6, and the left part of the left and right moving device 6 is connected with the right side of the second mounting plate 4.

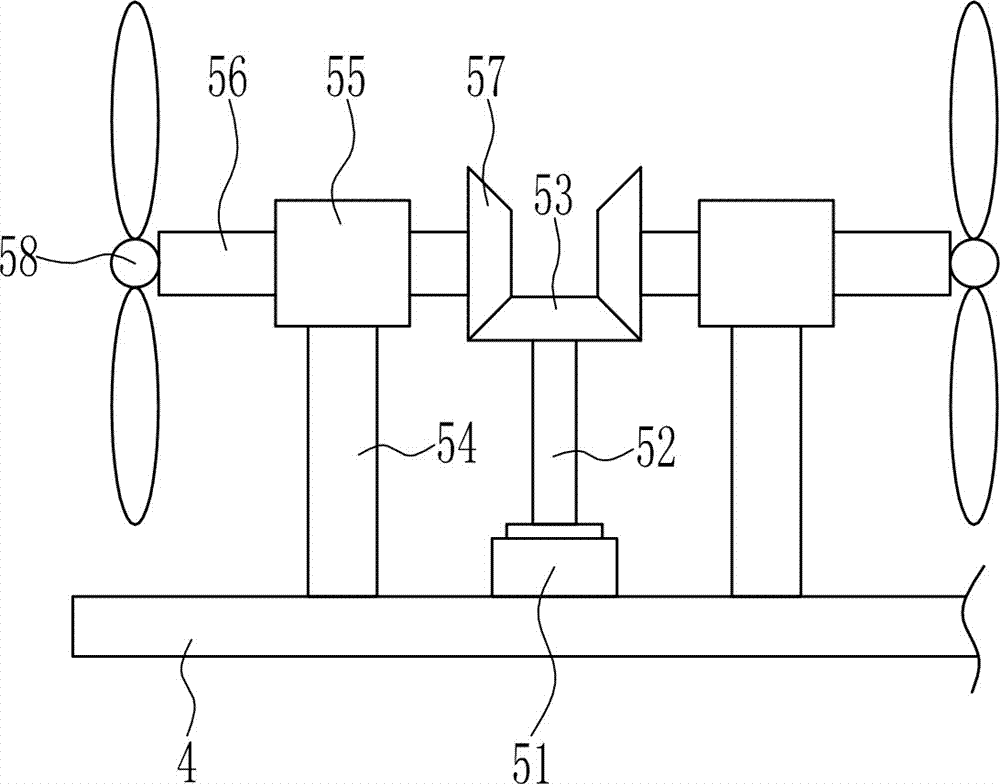

[0040] The air circulation device 5 includes a first motor 51, a first rotating shaft 52, a fi...

Embodiment 3

[0042] A kind of rapid air circulation equipment in a metallurgical steelmaking workshop, such as Figure 1-9 As shown, it includes a first mounting plate 1, a slide rail 2, a slider 3, a second mounting plate 4, an air circulation device 5 and a left and right moving device 6. The left side of the top of the first mounting plate 1 is inlaid with a slide rail 2, and the sliding The top of the rail 2 is connected with a slider 3 in a left-right symmetrical sliding manner, and the top of the slider 3 on the left and right sides is provided with a second mounting plate 4, and the top of the second mounting plate 4 is provided with an air circulation device 5, and the top right side of the first mounting plate 1 is provided with a There is a left and right moving device 6, and the left part of the left and right moving device 6 is connected with the right side of the second mounting plate 4.

[0043] The air circulation device 5 includes a first motor 51, a first rotating shaft 52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com