Environmentally-friendly solid waste treatment device based on cyclic crushing technology

A technology for recycling crushing and solid waste, applied in grain processing, etc., can solve problems such as poor crushing quality and reduced processing effect, and achieve the effect of ensuring crushing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

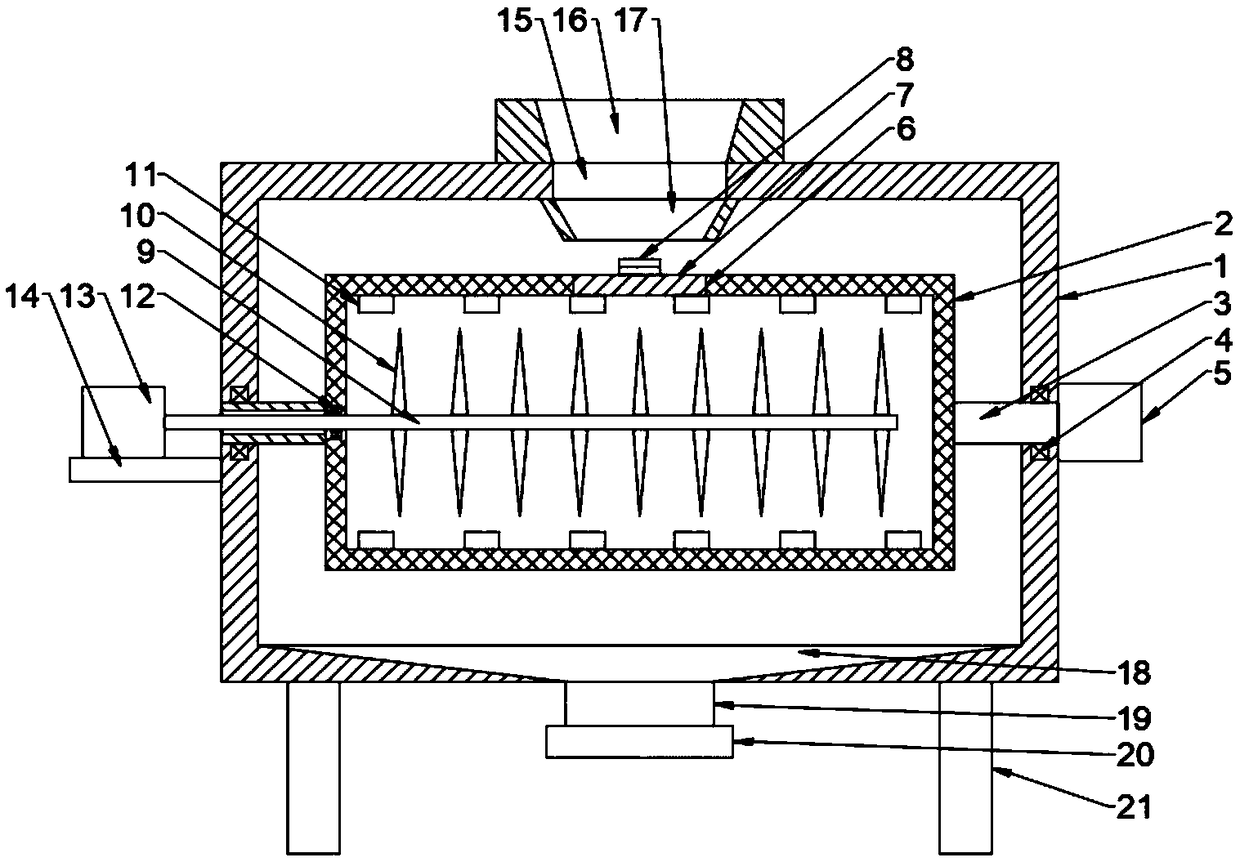

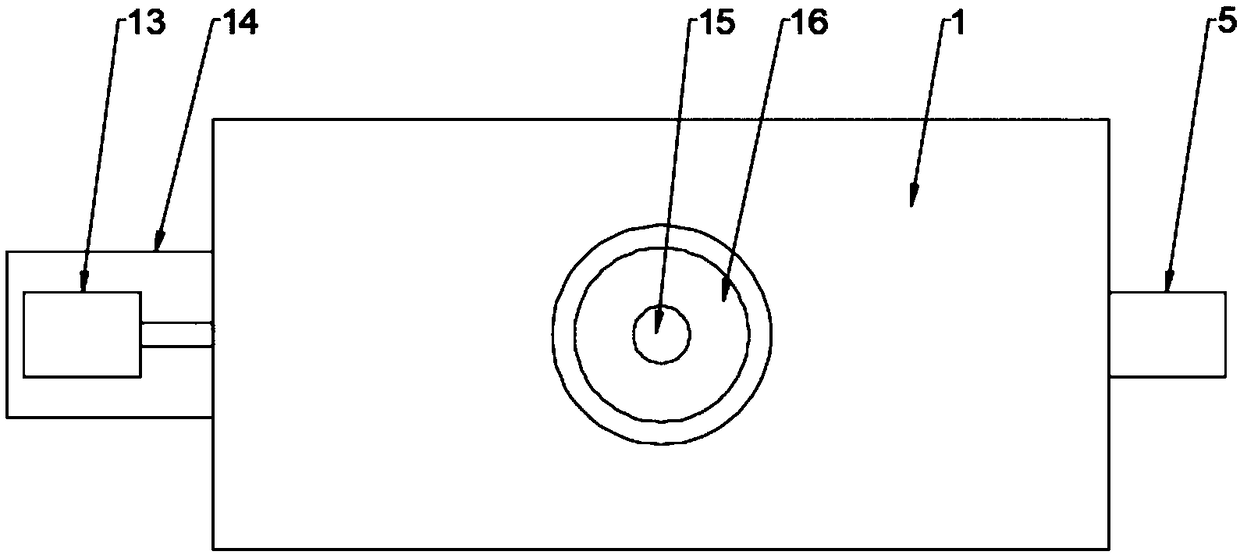

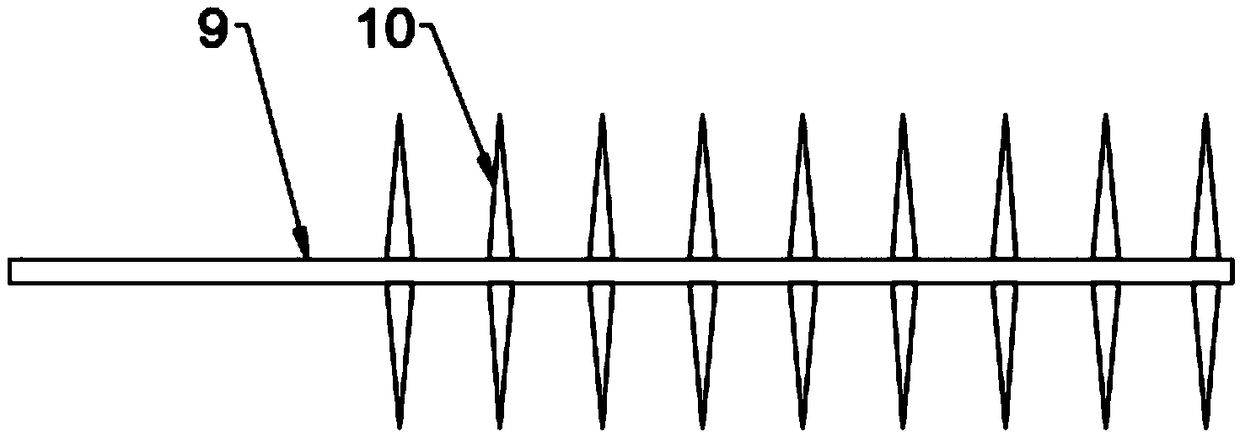

[0026] see Figure 1~3 , an environment-friendly solid waste treatment device based on cyclic crushing technology, comprising an outer casing 1 and a crushing cylinder 2, the outer casing 1 is a cylindrical structure, and the outer casing 1 is provided with a crushing cylinder 2, and the crushing cylinder 2 is Cylindrical barrel structure, the crushing barrel 2 is made of metal mesh, the axis of the crushing barrel 2 coincides with the axis of the outer shell 1, and the crushing barrel 2 is connected to the outer shell 1 through the rotating shaft 3, the rotating shaft 3 is a hollow shaft, and the rotating shaft The right end of 3 runs through the side wall of the outer casing 1 and is fixedly connected to the motor shaft of the first motor 5, the rotating shaft 3 is connected to the outer casing 1 through the first bearing 4 in rotation, and the inner chamber of the pulverizing cylinder 2 The wall is evenly provided with a number of shifting plates 11, and the inner cavity of...

Embodiment 2

[0028] This embodiment is a further elaboration on the basis of Embodiment 1. One end of the crushing cylinder 2 is provided with a feed hole 6, and a seal cover 7 is hinged in the feed hole 6, and the seal cover 7 There is a handle 8 on the top, through which the sealing cover 7 is opened, and the material enters the crushing cylinder 2 through the feed hole 6 .

[0029] The center of the top surface of the outer shell 1 is provided with a feeding hole 15, the bottom end of the feeding hole 15 is connected with a diversion bucket 17 matched with the feeding hole 6, and the top of the feeding hole 15 is connected with a feeding hopper 16. When feeding is required, adjust the crushing cylinder 2 so that the feeding hole 6 corresponds to the feeding hole 15 (the position adjustment of the crushing cylinder 2 can be considered using laser position sensing positioning, so as to determine the positional relationship between the feeding hole 6 and the feeding hopper 16 , but this po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com