Gangue crushing and screening device for mine production

A screening device and a technology for gangue, applied in the field of minerals, can solve the problems of waste of resources, inability to screen and process gangue coal, and equipment not being screened, and achieve the effect of convenient screening and saving coal resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

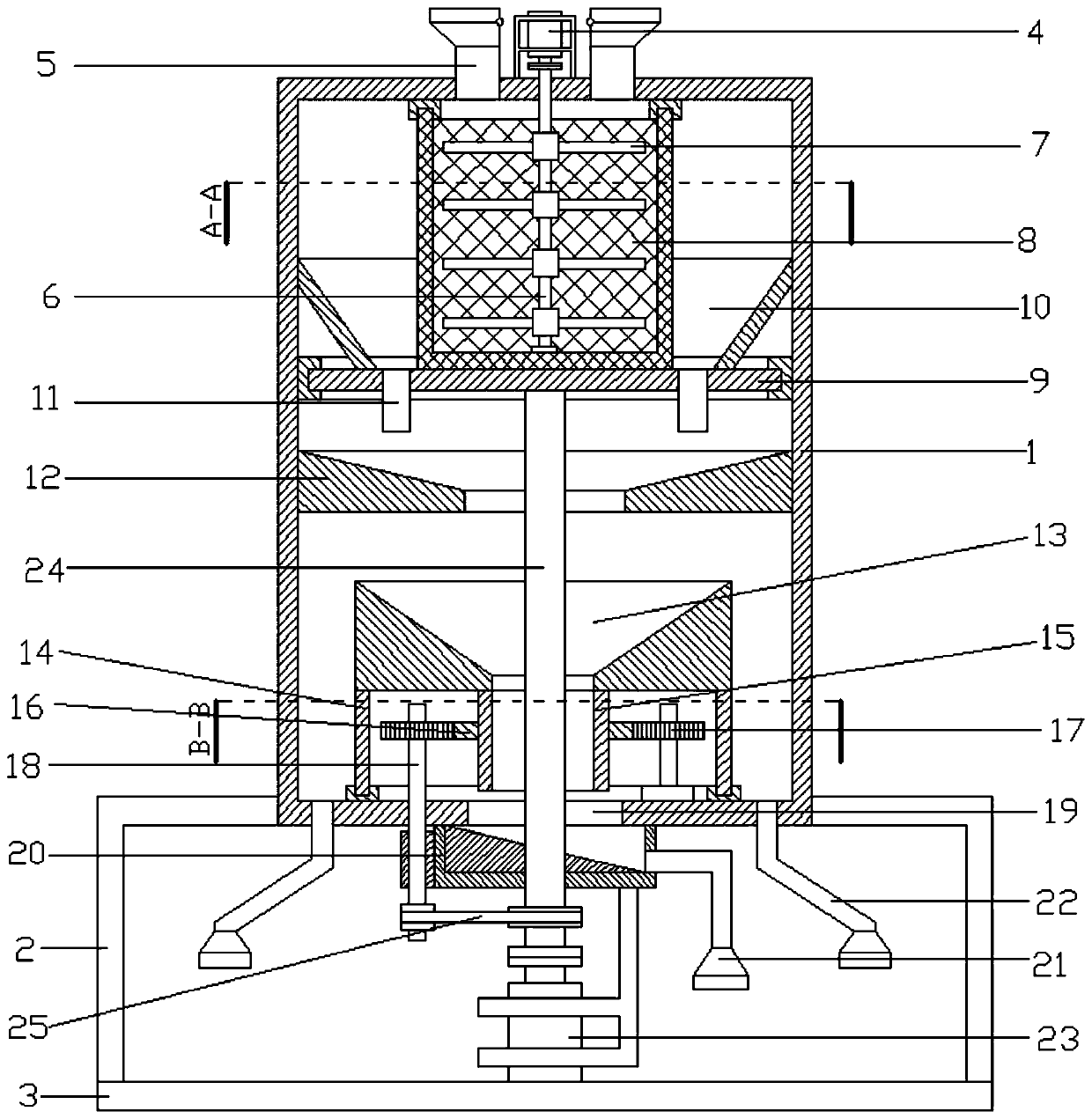

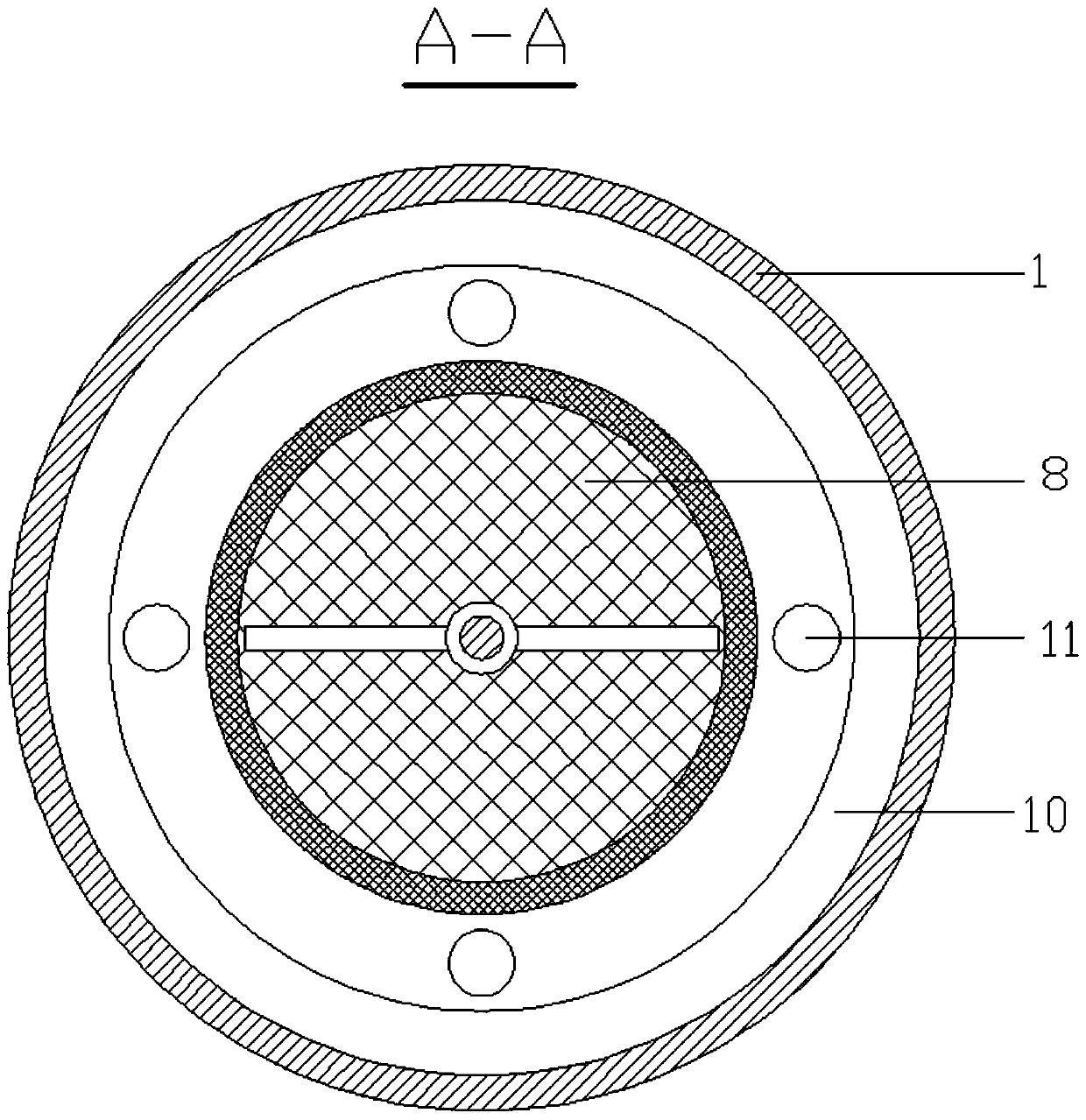

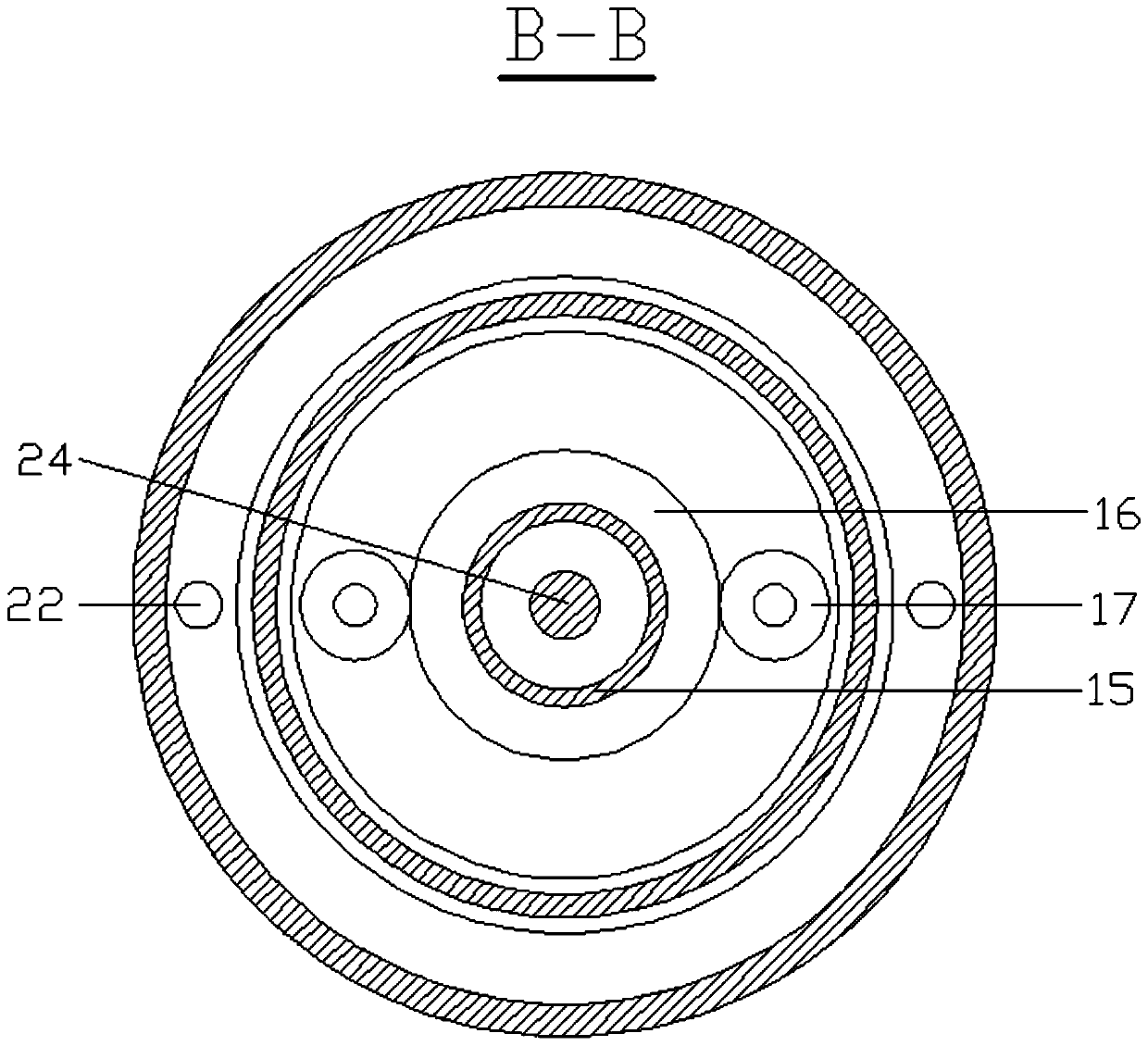

[0025] refer to Figure 1~3 , in an embodiment of the present invention, a gangue crushing and screening device for mine production includes a processing chamber 1, the upper middle of the processing chamber 1 is connected with a first motor 4 through a connecting piece, and the left and right sides of the first motor 4 are installed There is a feeding port 5, which can facilitate the equipment to adjust gangue. The upper side of the feeding port 5 is connected with a sealing plate through a hinge, which can effectively ensure the sealing of the equipment. The lower side of the first motor 4 is connected with a crushing shaft through a coupling. 6. The left and right ends of the lower side of the crushing shaft 6 are equipped with crushing blades 7 through the installation sleeve, and the crushing shaft 6 and the crushing blade 7 are driven by the first motor 4 to rotate and crush, so that gangue can be effectively crushed, which can To facilitate the crushing process of the e...

Embodiment 2

[0029] The difference from Embodiment 1 is: the lower ends of the left and right sides of the storage chamber 1 are fixedly installed with a support plate 2, and the lower side of the support plate 2 is fixedly installed with a bottom plate 3, which is fixedly connected with the processing chamber 1 through the support plate 2, This can effectively support the equipment, and the base plate 3 fixedly installed at the bottom can ensure the overall stability of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com