Kitchen waste disposal device

A kitchen garbage and processor technology, which is applied in grain processing, indoor sanitary pipeline installations, water supply installations, etc., can solve the problems of crushing quality limitation, large particles, easy to block sewers, etc., and achieve the effect of ensuring crushing quality and avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the content of the present invention more clear and understandable, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

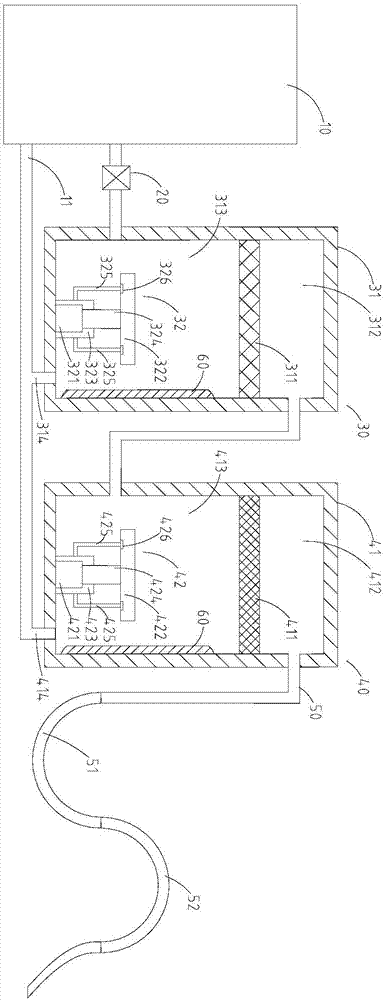

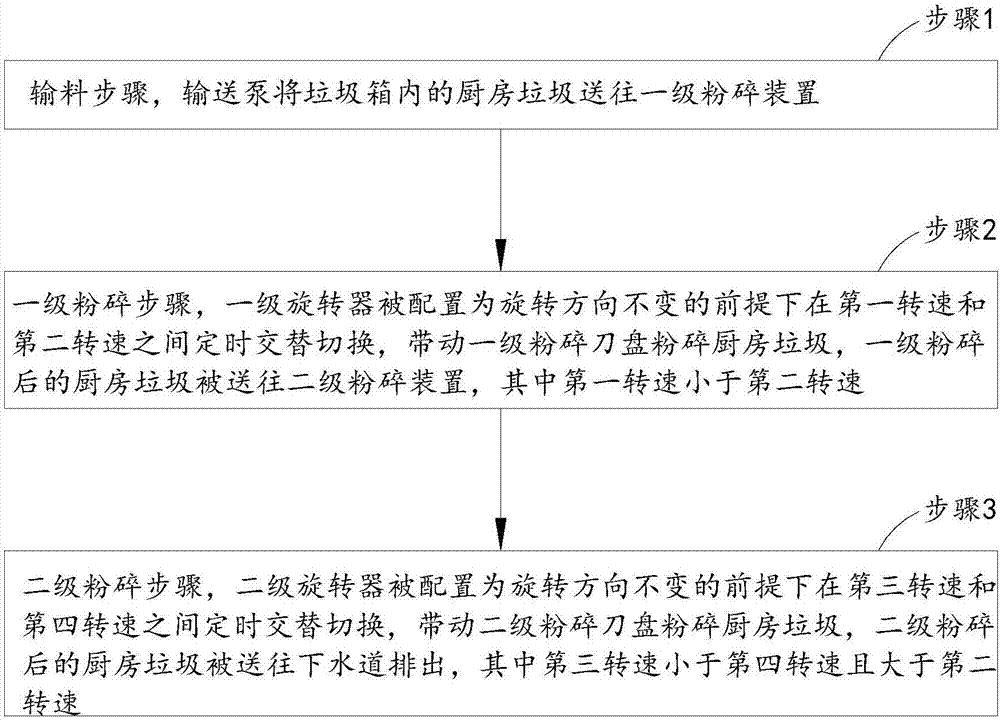

[0021] Such as figure 1 As shown, the structure of the kitchen garbage disposer of the present invention includes a garbage bin 10, a delivery pump 20, a primary crushing device 30 and a secondary crushing device 40.

[0022] The dustbin 10 is provided with a coarse filter, and the coarse strainer separates the dustbin 10 into an upper feeding area and a lower discharge area, the feeding area is provided with a mixing knife, and the mixing knife is used to stir the kitchen waste into fluid, and enter the discharge area through the coarse filter, and the discharge area is connected to the delivery pump 20. In the actual operation process, for relatively viscous kitchen waste, an appropriate amount of water or garbage sewage can be matched, so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com