Biomass particle smashing device

A biomass particle and crushing device technology, applied in grain processing and other directions, can solve the problem that the crushing effect of materials cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

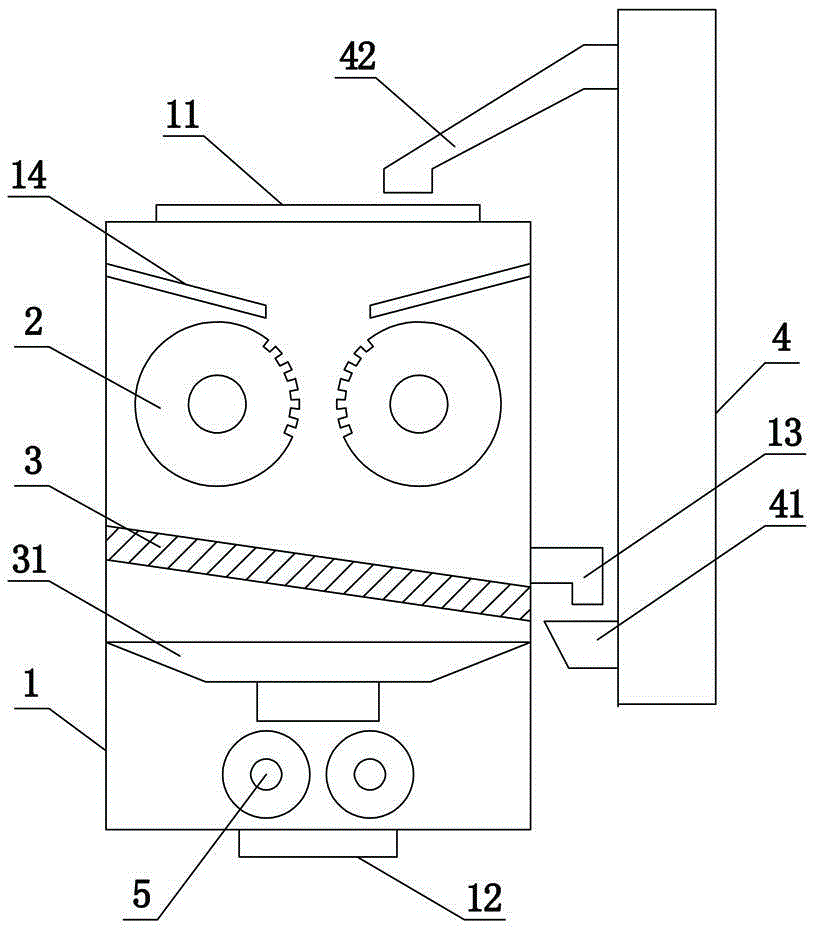

[0013] Such as figure 1 As shown, a biomass particle crushing device includes a frame, a crushing shell 1 arranged on the frame, and a crushing motor. Crushed, the pulverized raw material is used to make biomass pellets.

[0014] A pair of crushing rollers 2 are arranged horizontally in the crushing shell 1, and the pair of crushing rollers 2 are respectively densely covered with crushing teeth that interlock with each other, and the raw materials entering the crushing shell are squeezed and crushed by using the crushing teeth; The roller shafts of a pair of crushing rollers 2 protrude from the crushing housing 1 respectively, the roller shafts of a pair of crushing rollers 2 are meshed by gears, and the output shaft of the crushing motor is connected to one of the crushing rollers. The roller shaft adopts the above method to set the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com