Patents

Literature

33results about How to "Efficient stirring and mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

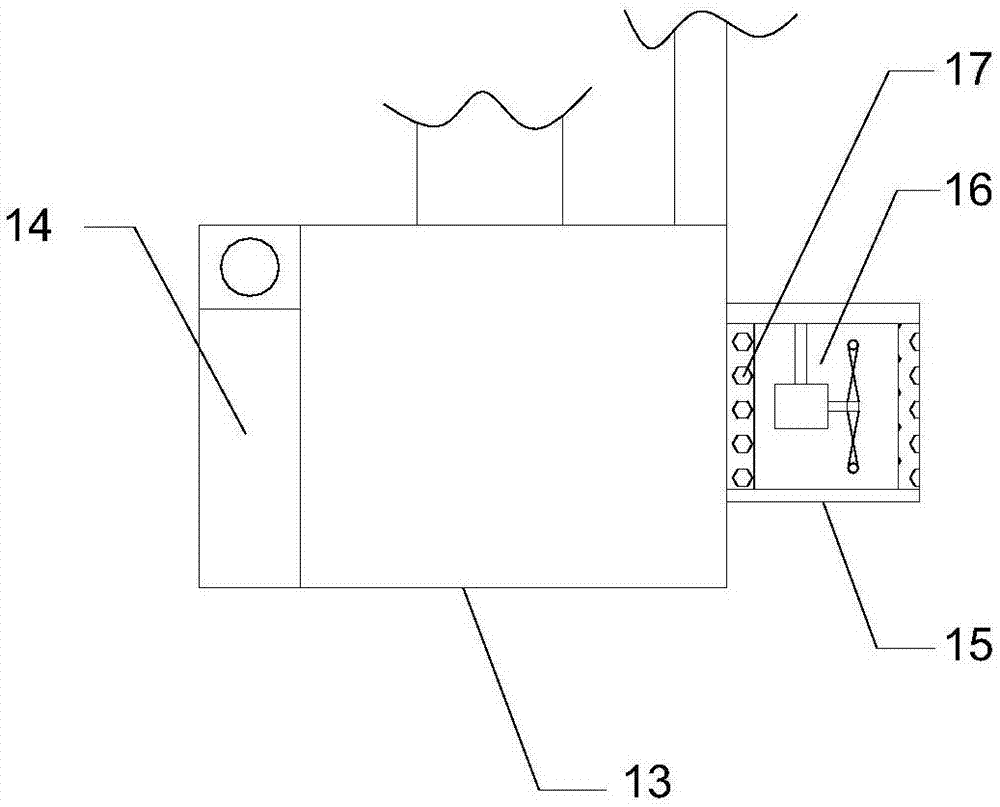

Application Year

Inventor

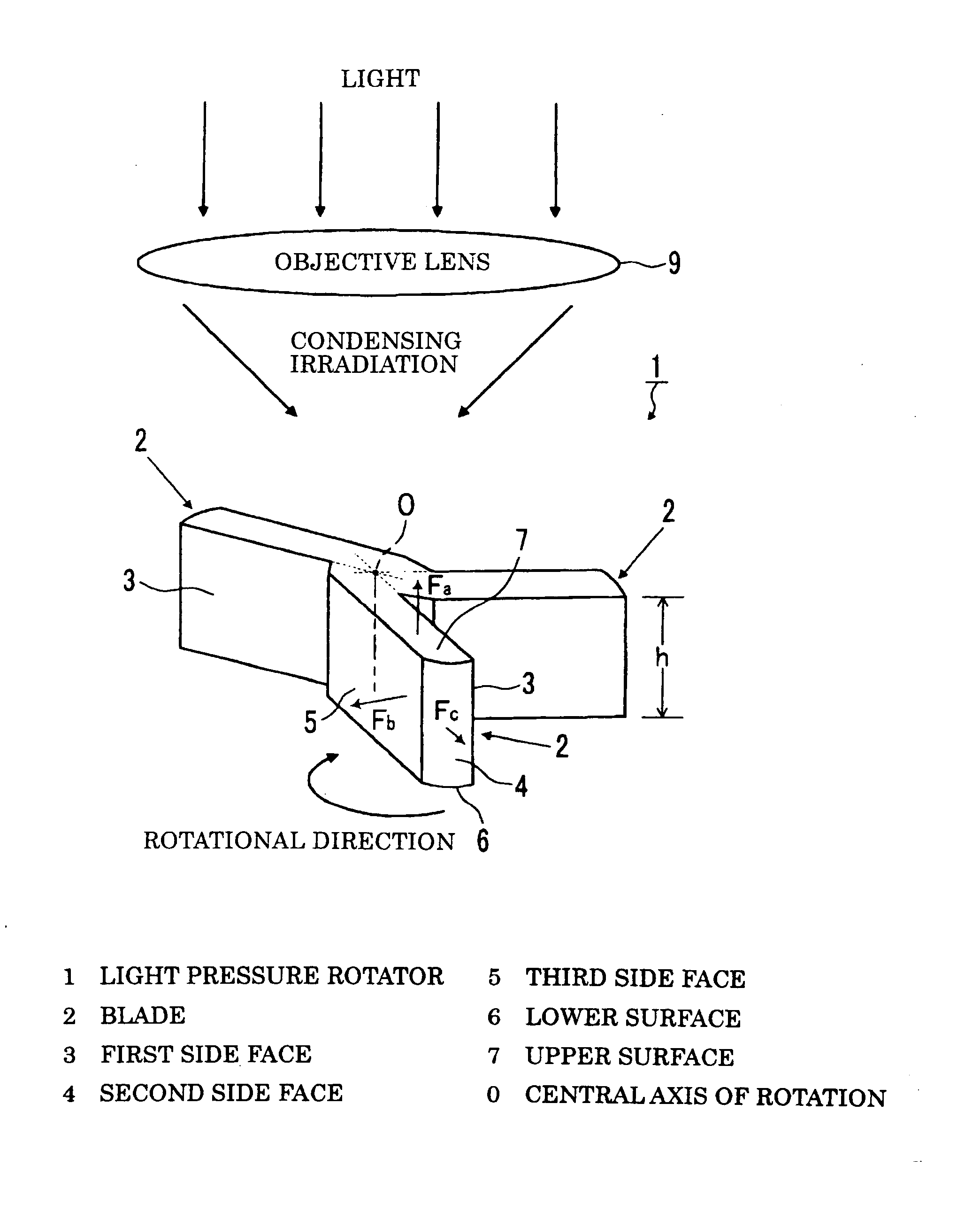

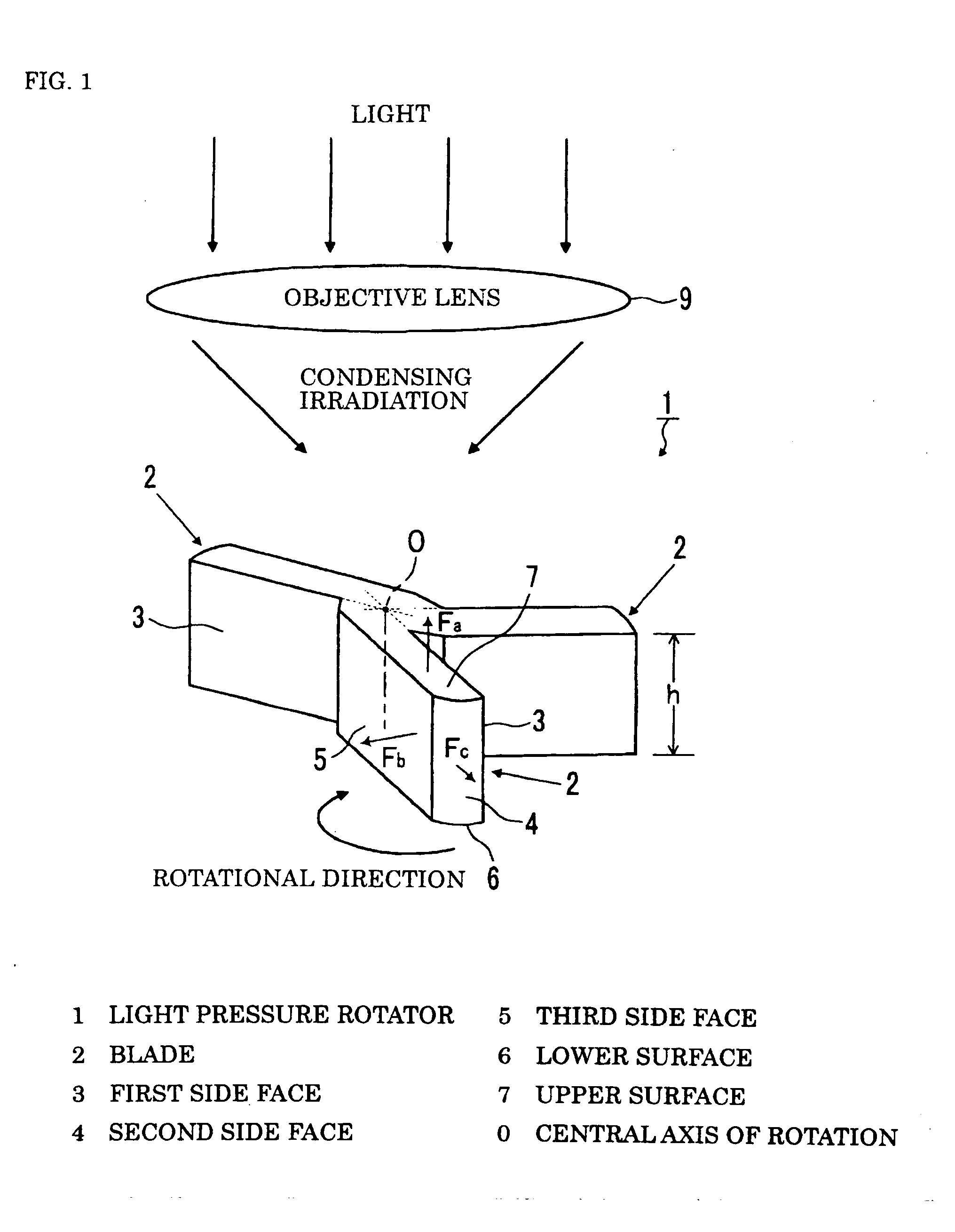

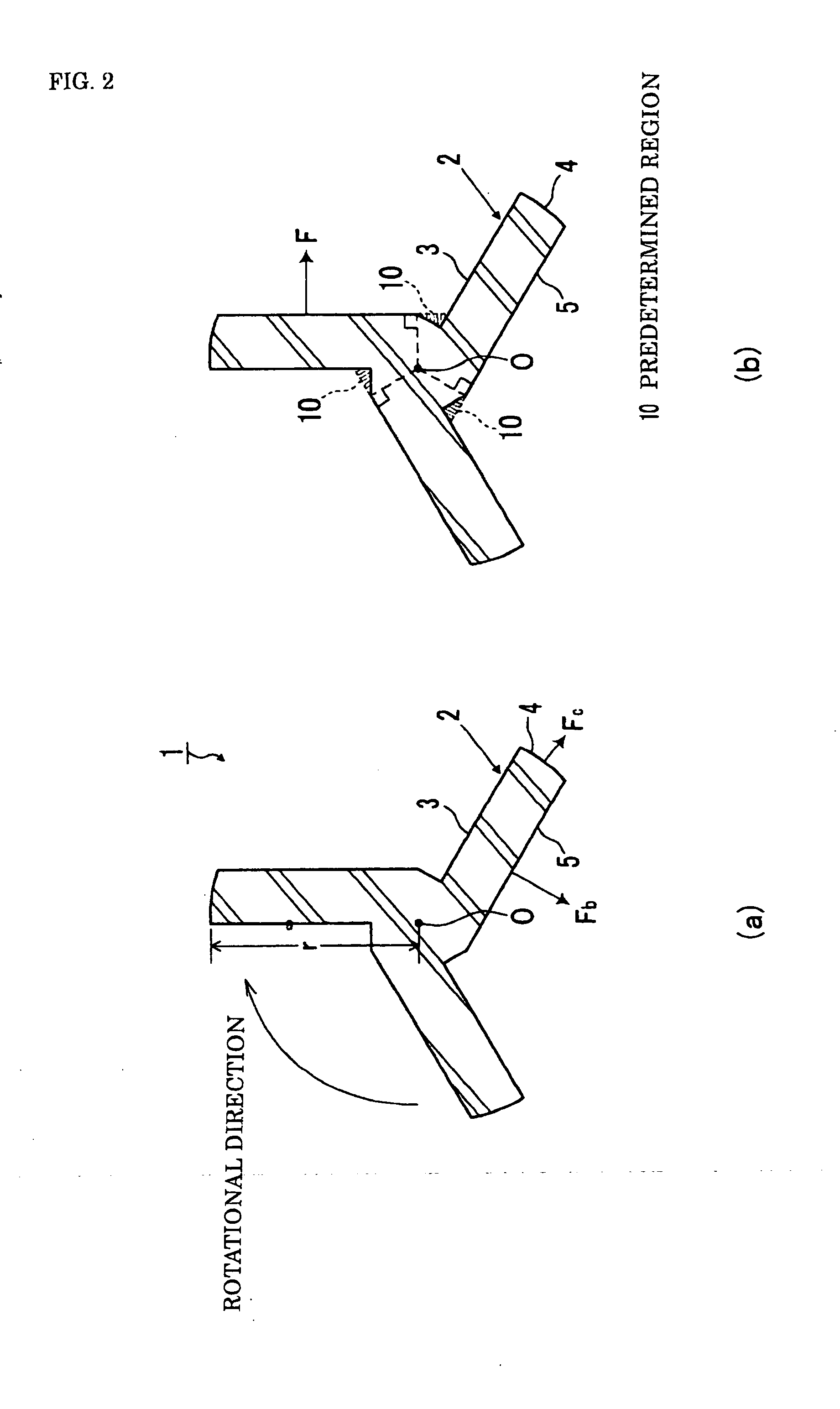

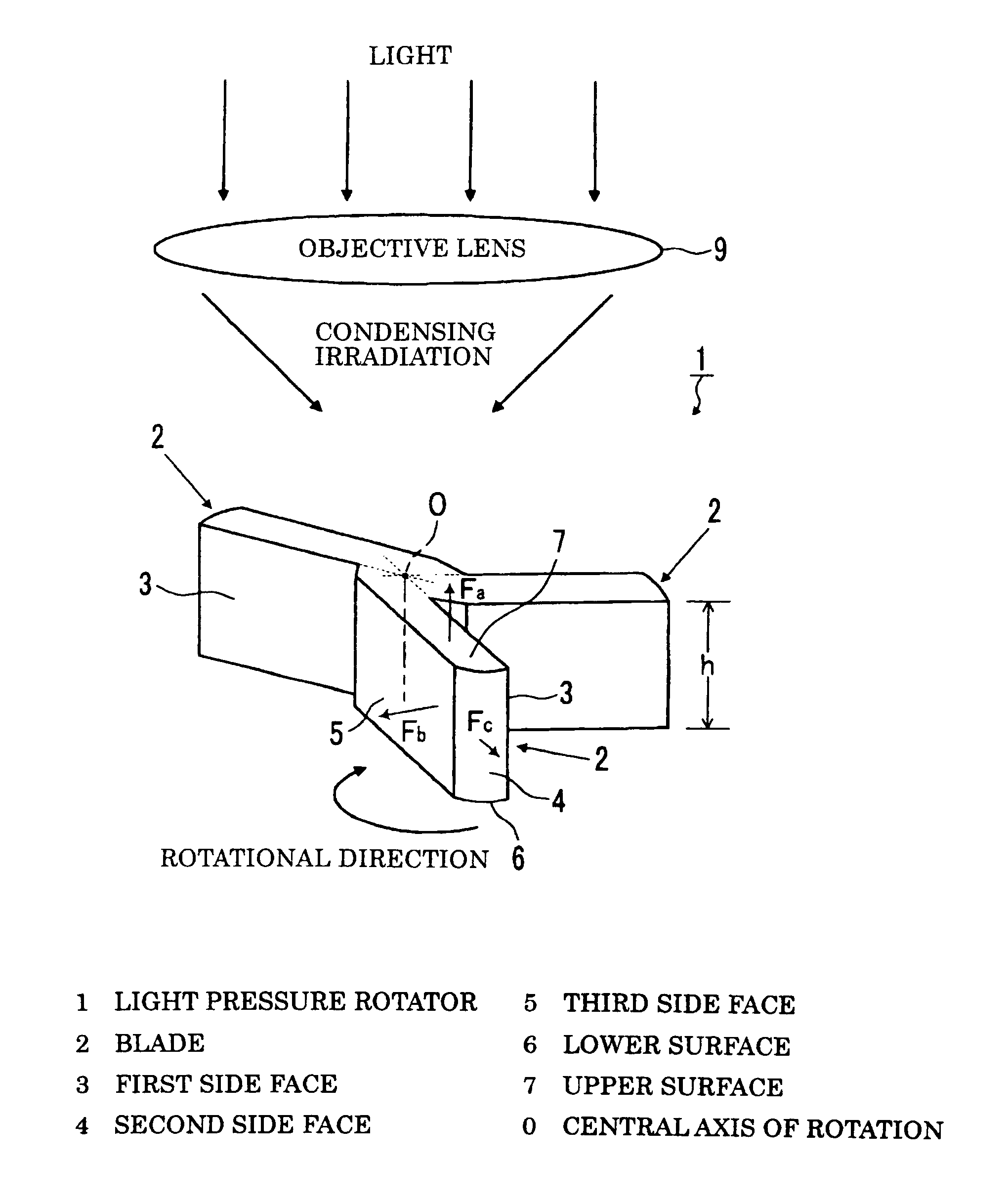

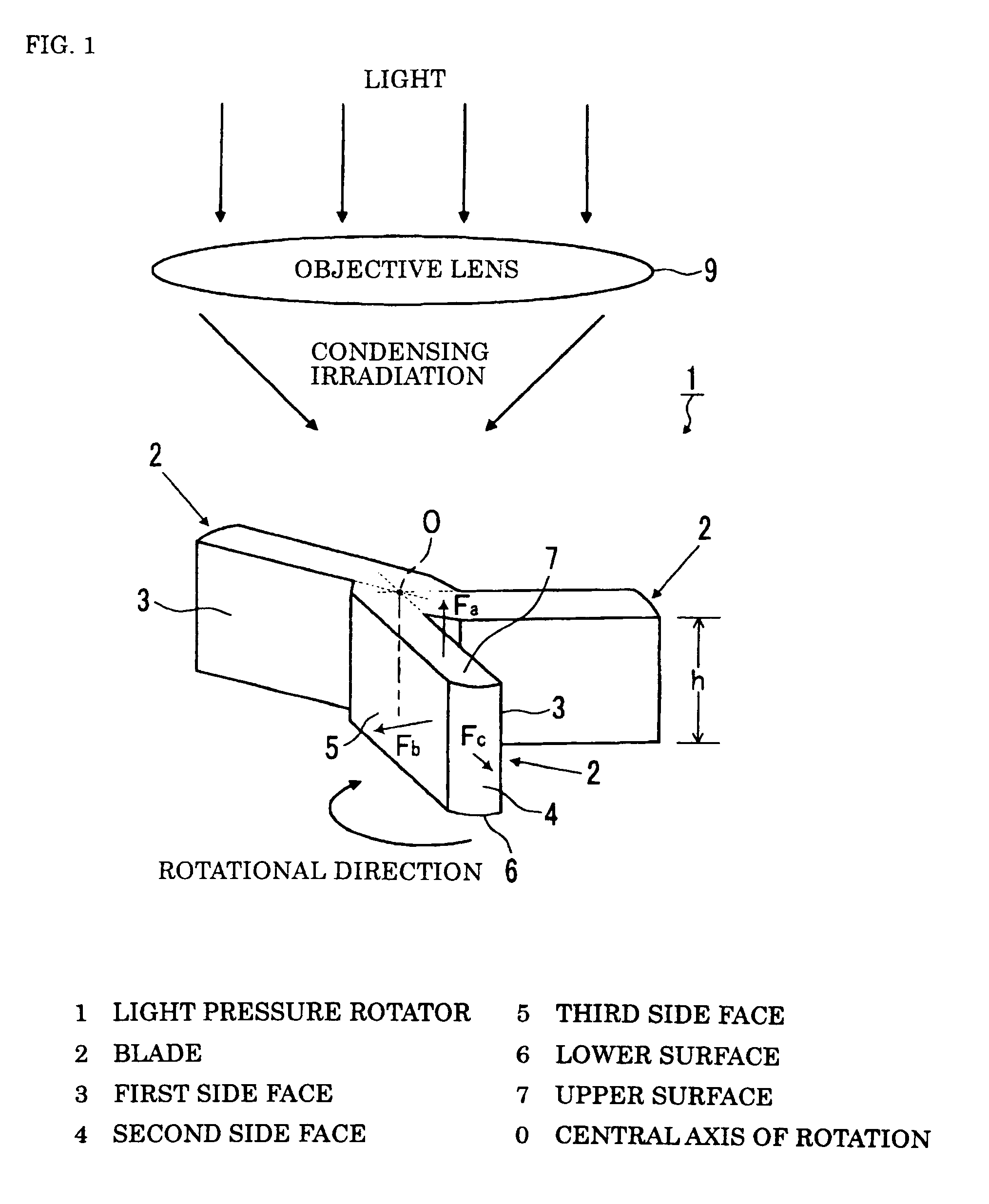

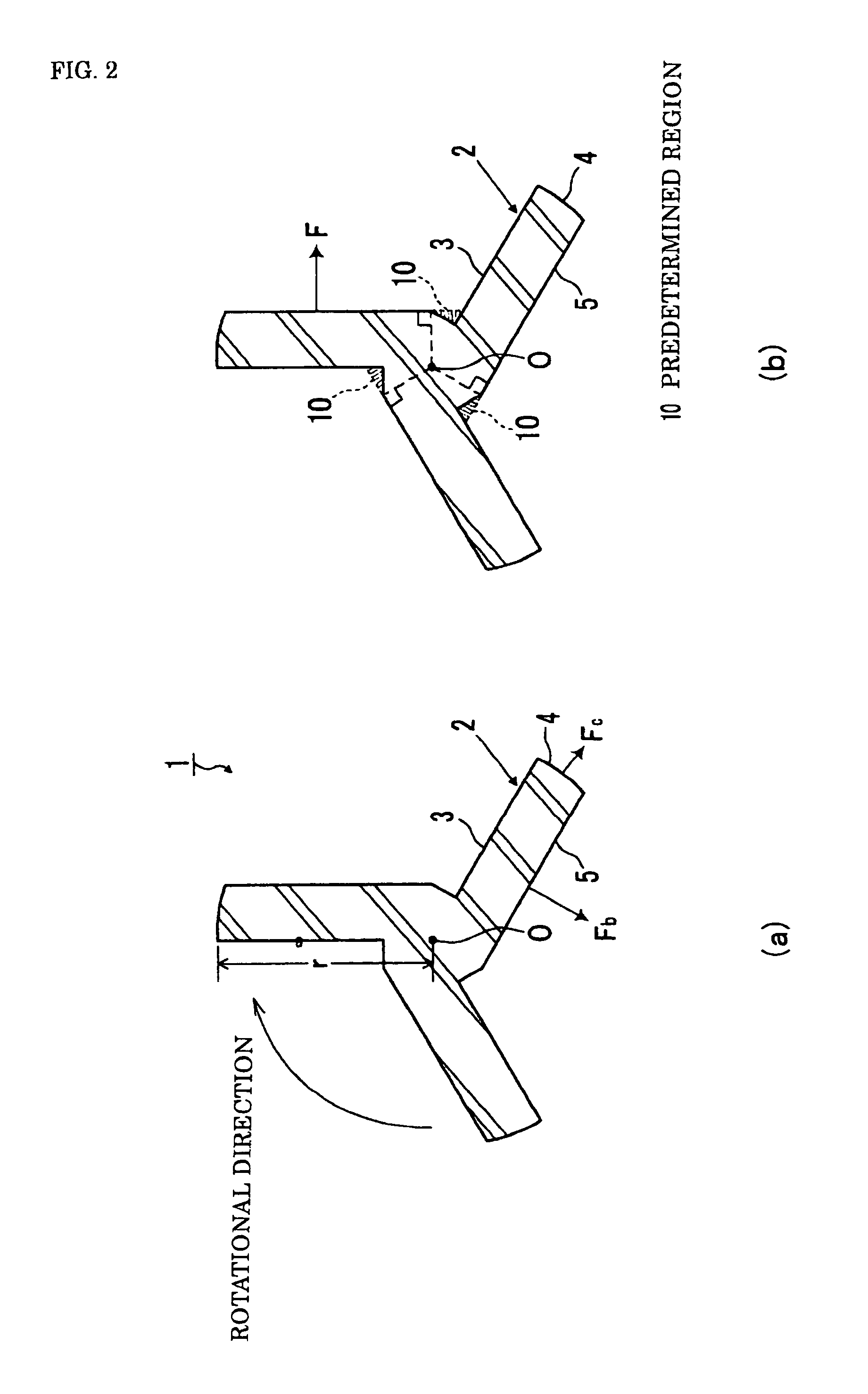

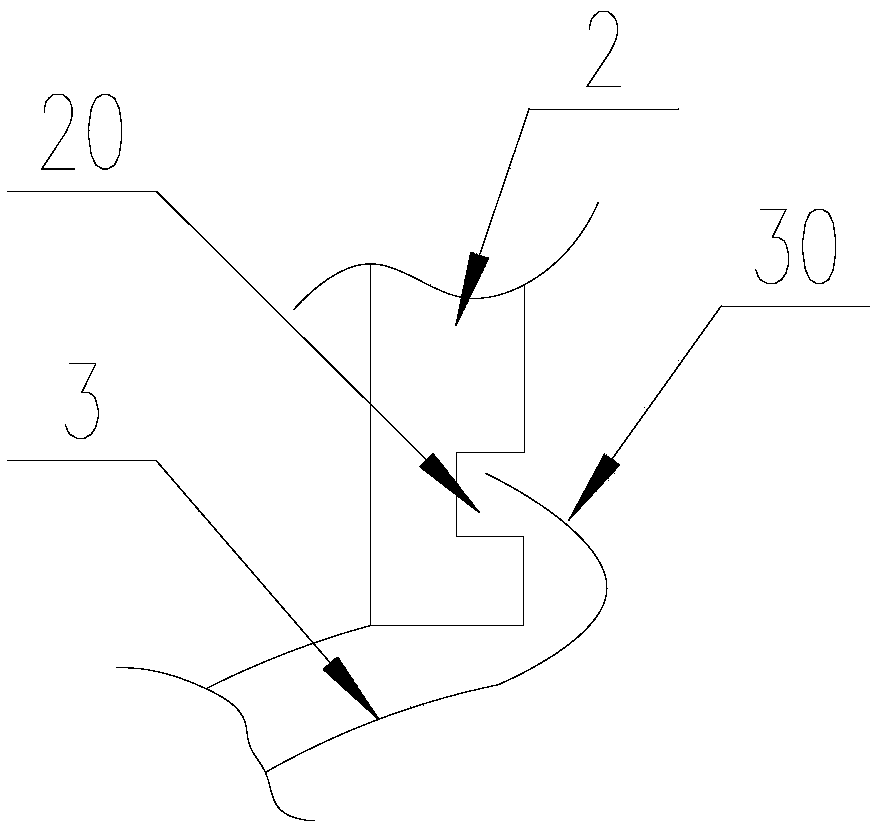

Light Pressure Rotator and Light Pressure Rotating Device

InactiveUS20080031088A1Faster light pressure rotationEffective stirringShaking/oscillating/vibrating mixersFrom solar energyEngineeringIrradiation

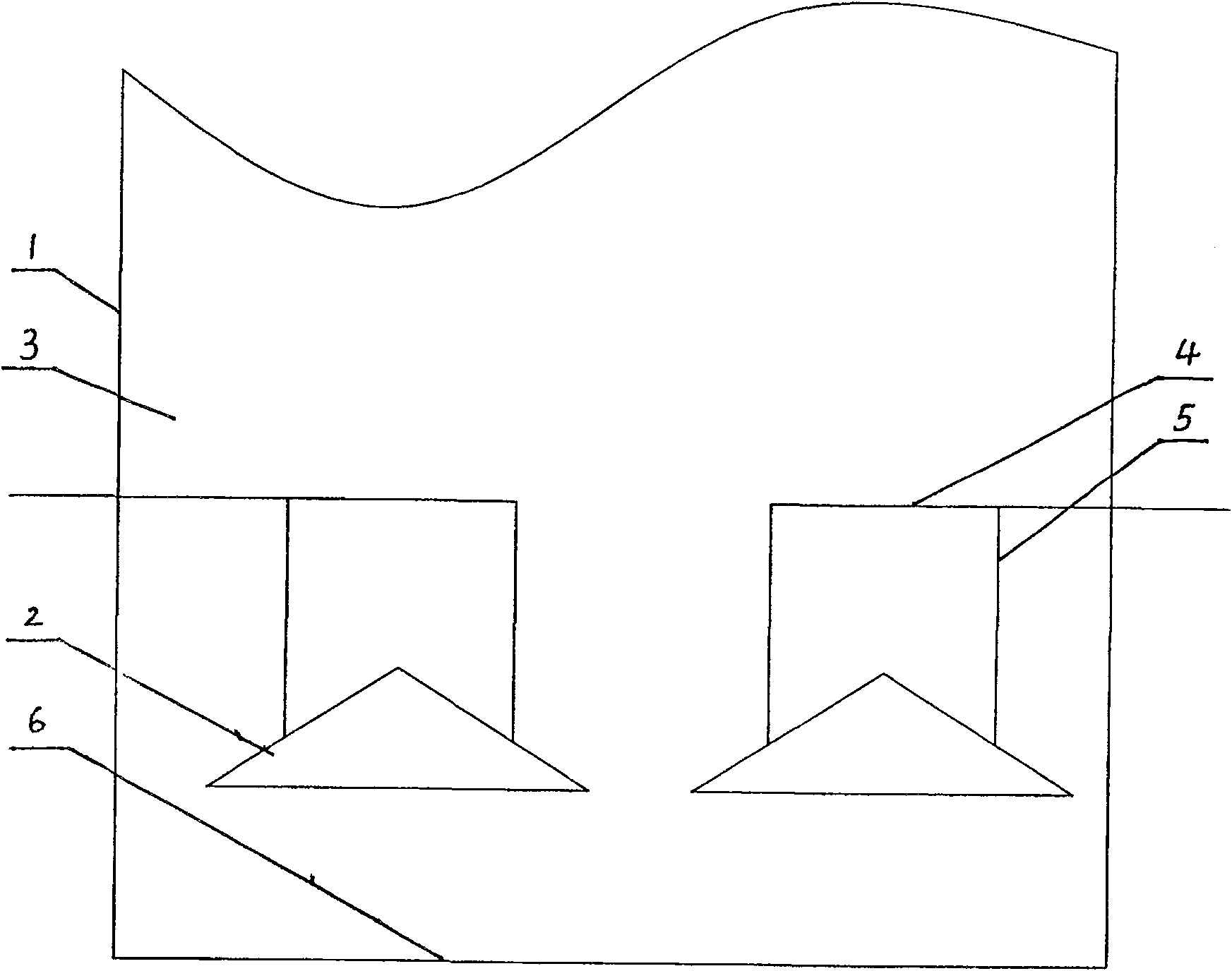

The light pressure rotator (1) is the light pressure rotator being light pressure trapped by irradiation with light and light pressure rotating about the central axis O of rotation, characterized in that a reverse torque generating section generating a torque for rotating the rotator in the direction reverse to the predetermined direction is removed from a section arranged with three blades (2) each having a first side face (3) extending in the radial direction from the central axis O of rotation, a second side face (4) facing the central axis O of rotation, a third side face (5) facing the first side face (3), a lower surface (6) intersecting the central axis O of the rotation, and an upper surface (7) facing the lower surface (6). The light pressure rotating device comprises the light pressure rotator (1), a light source (C), and an objective (condenser) lens D.

Owner:THE RITSUMEIKAN TRUST

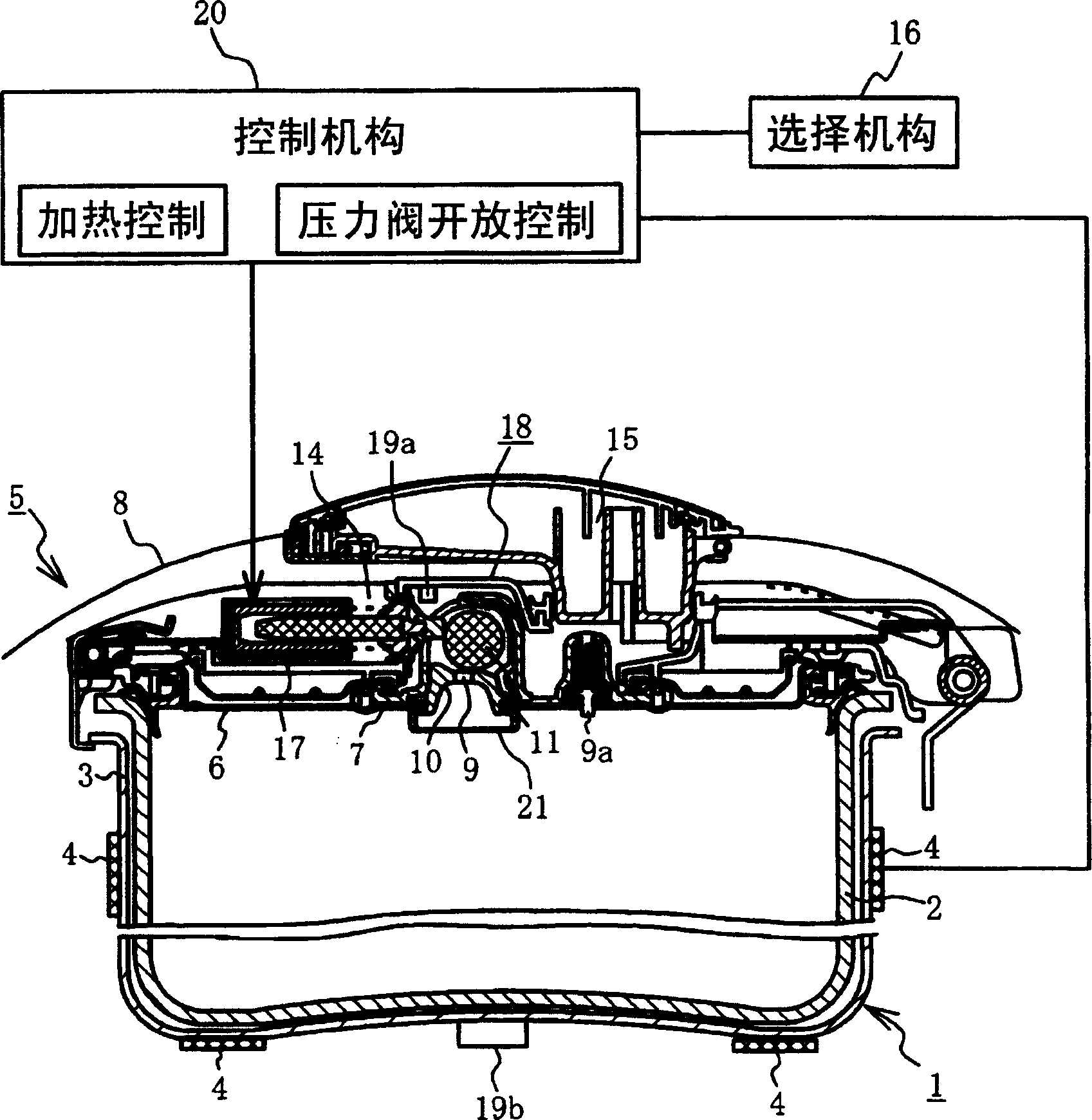

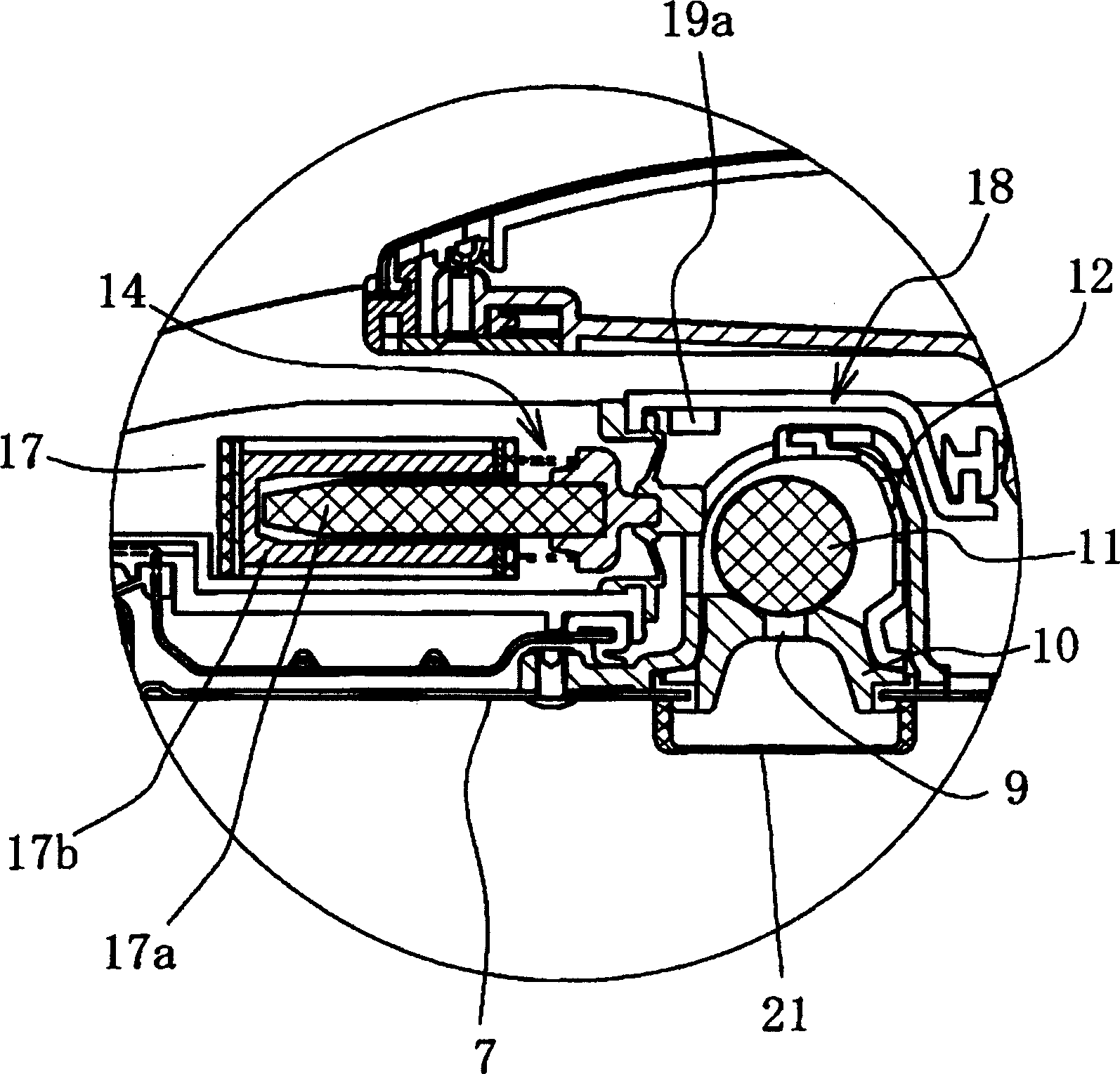

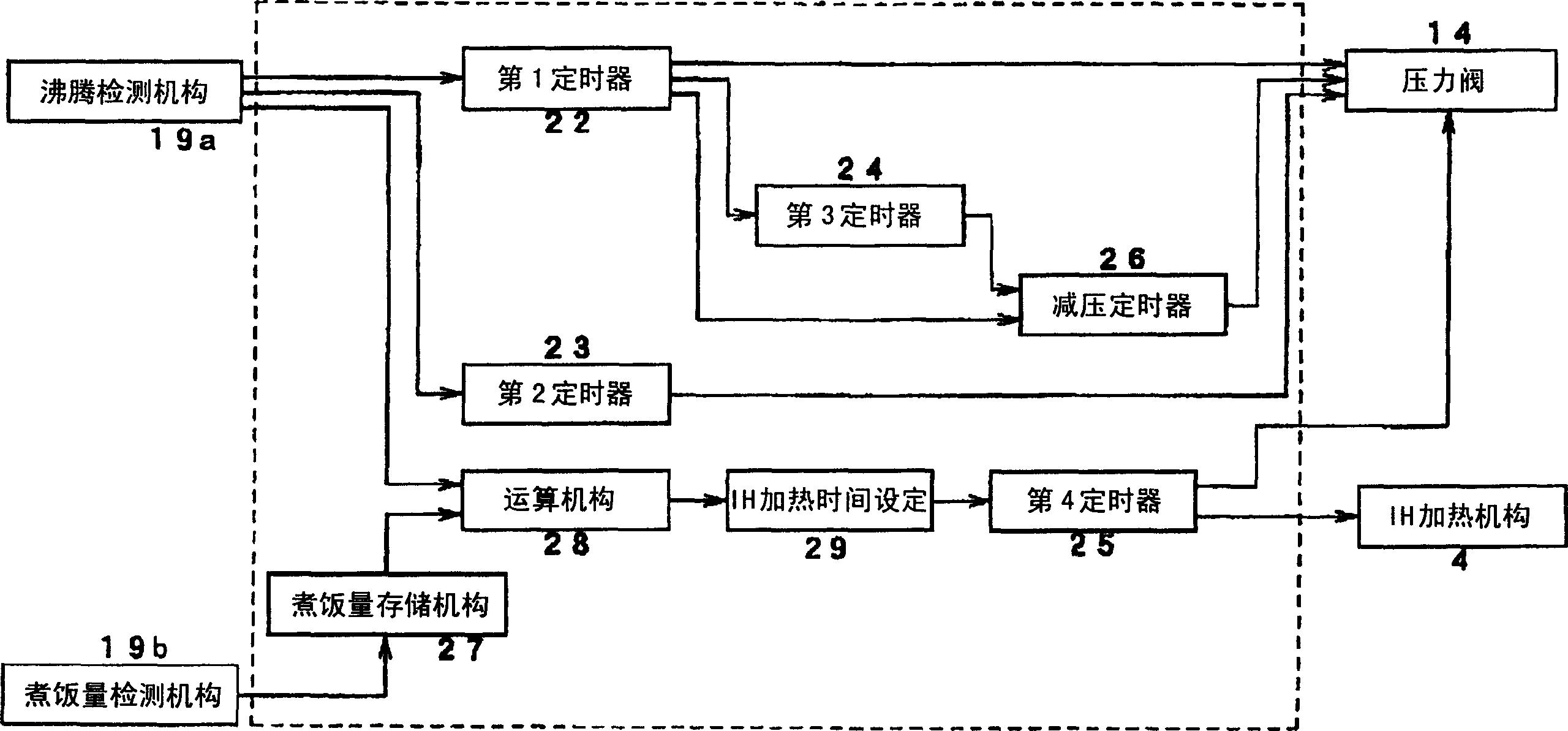

Rice cooker

This rice cooker is equipped with a pot to house water and rice, a heating means, a pressure valve to make the inside of the pot communicate with the outside air or cut off, and a control means for the heating means and the pressure valve. The rice to be cooked is processed by a starting-up process to rapidly heat rice and then a boiling keeping process wherein the rice to be cooked is heated by the heating means when the pressure valve is open.The invention provides a rice cooker in which rice can be sufficiently agitated during boiling and uniformly cooked, and the upper face of cooked rice is flat causing visual artistic effect after rice is completely cooked.

Owner:SANYO ELECTRIC CO LTD +1

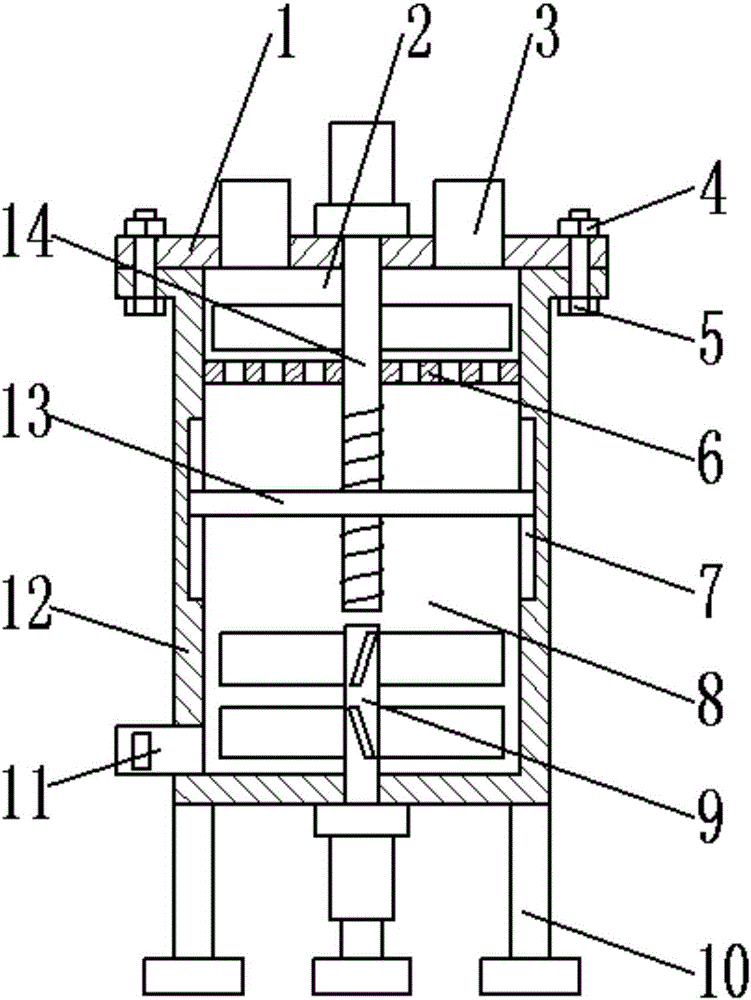

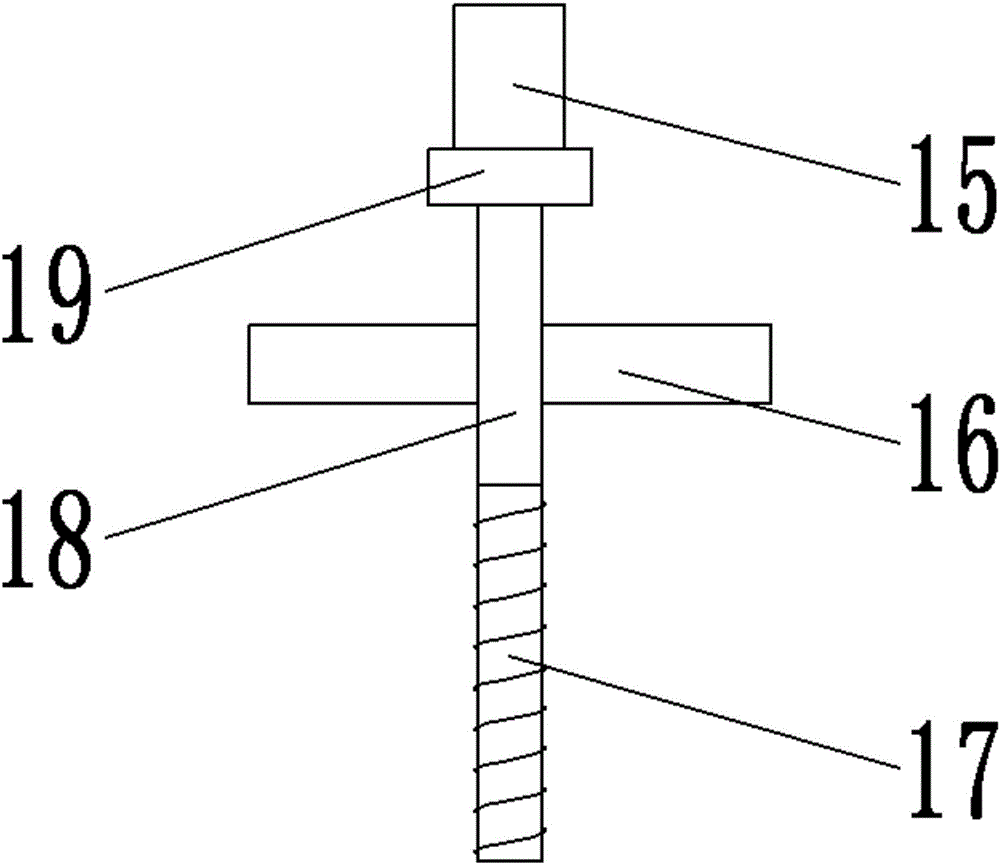

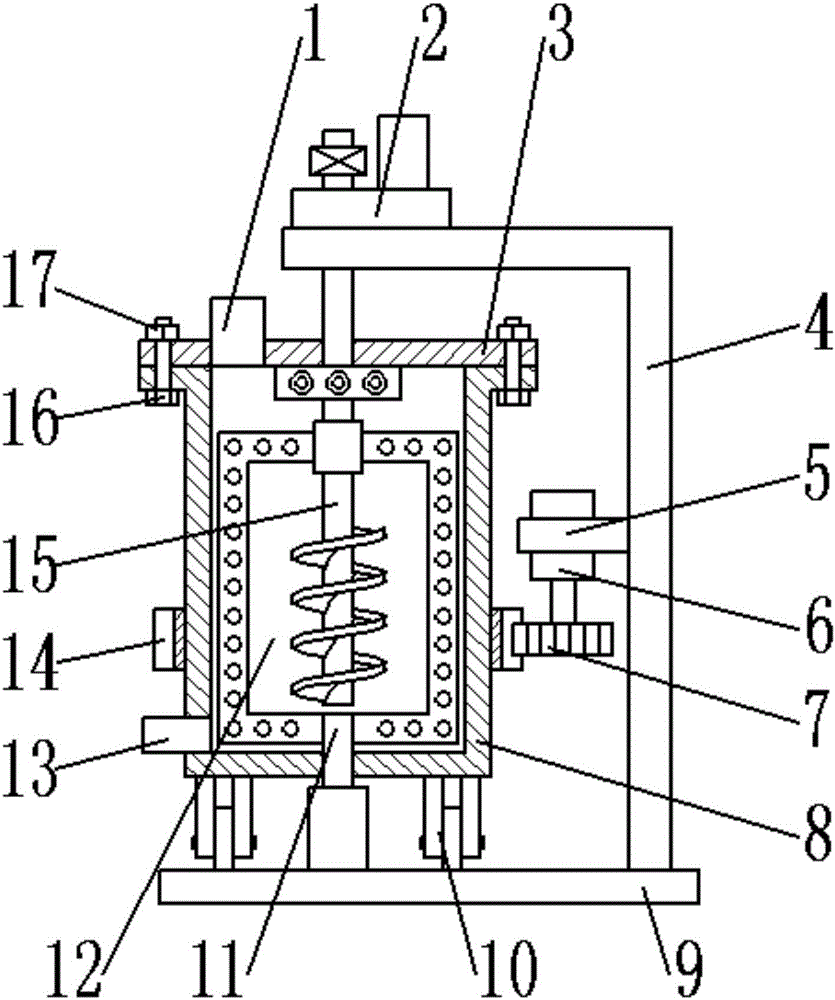

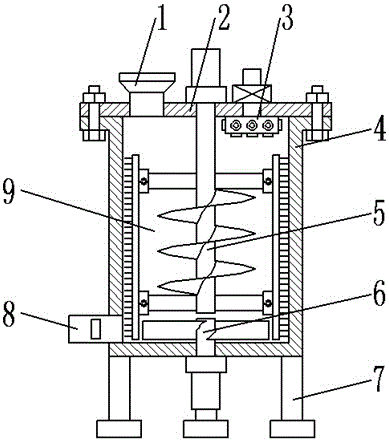

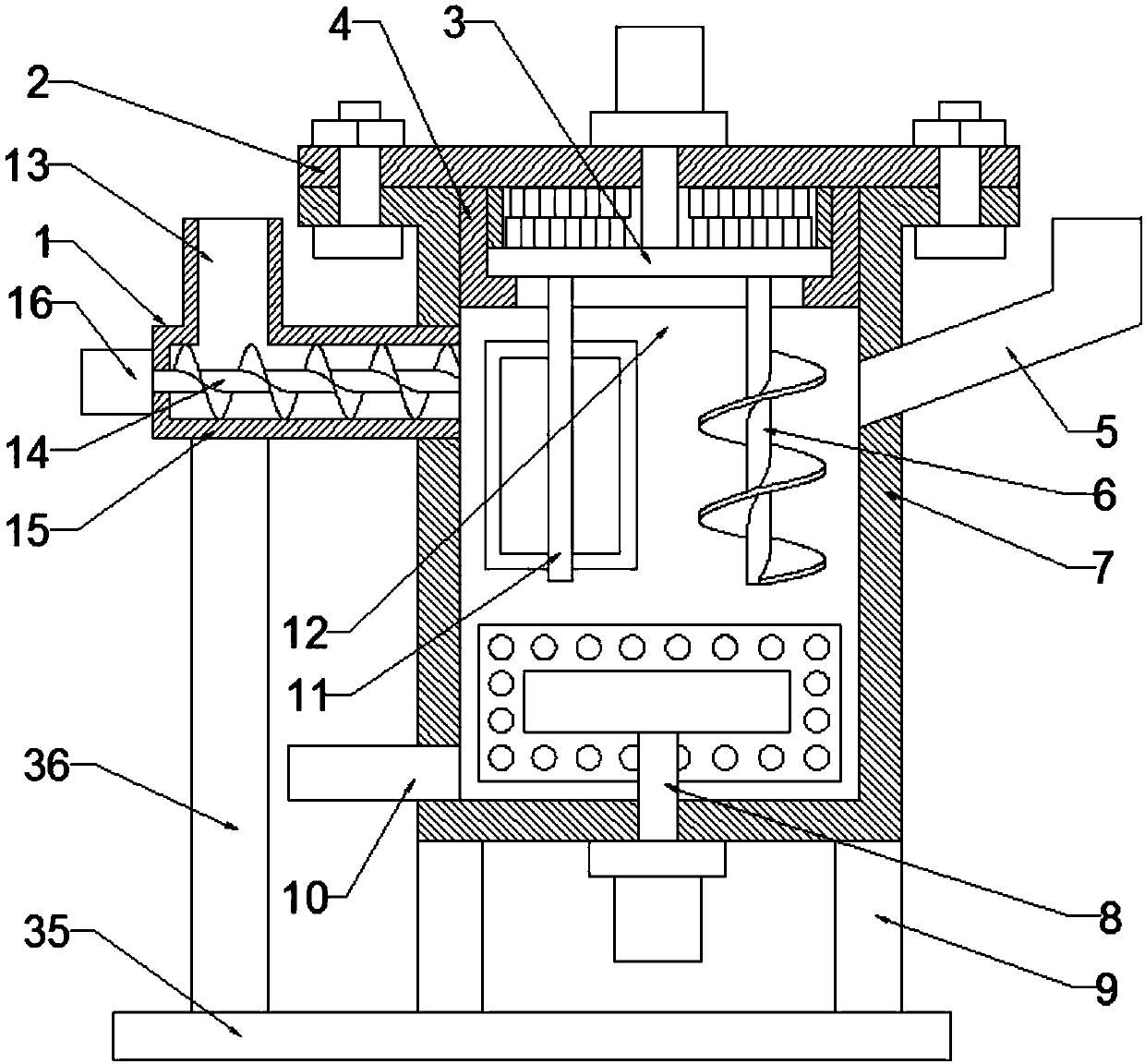

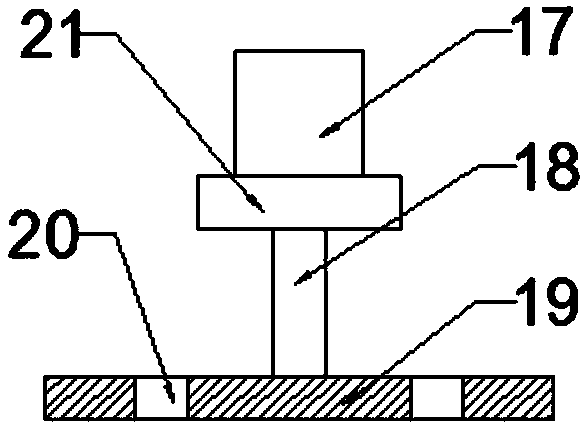

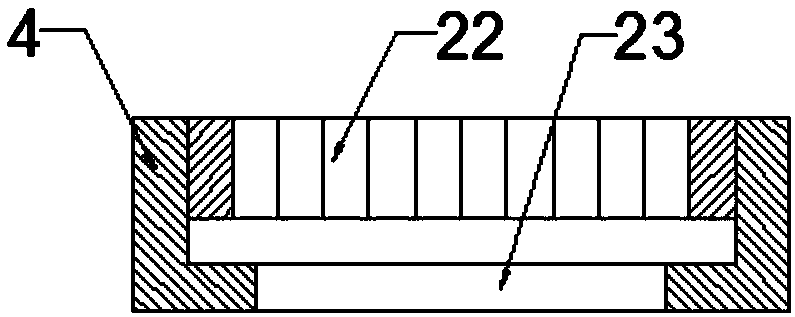

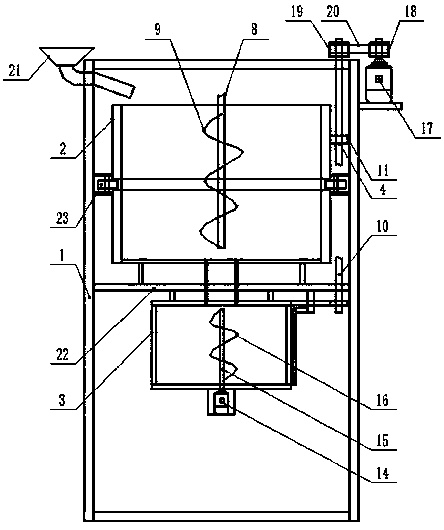

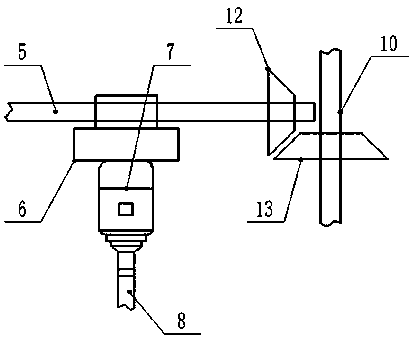

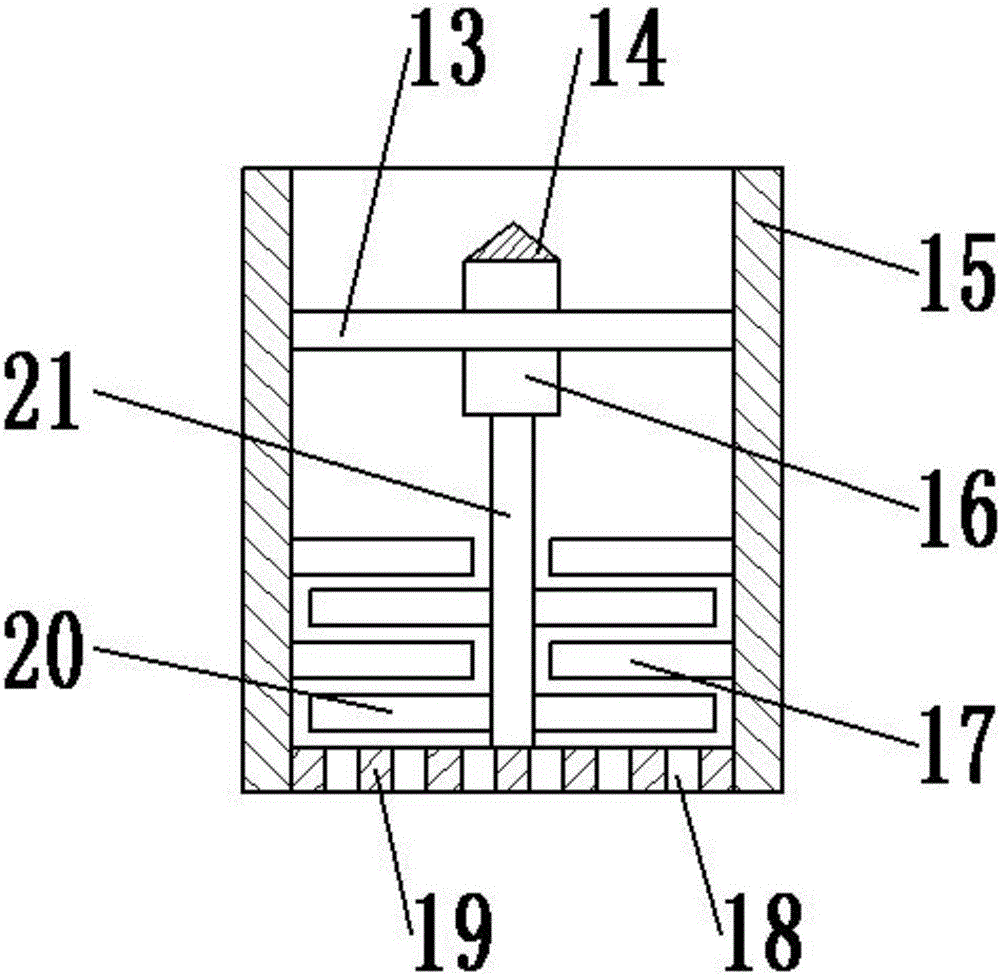

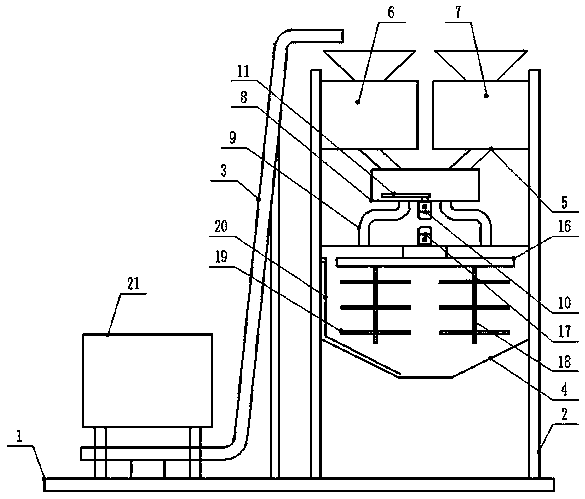

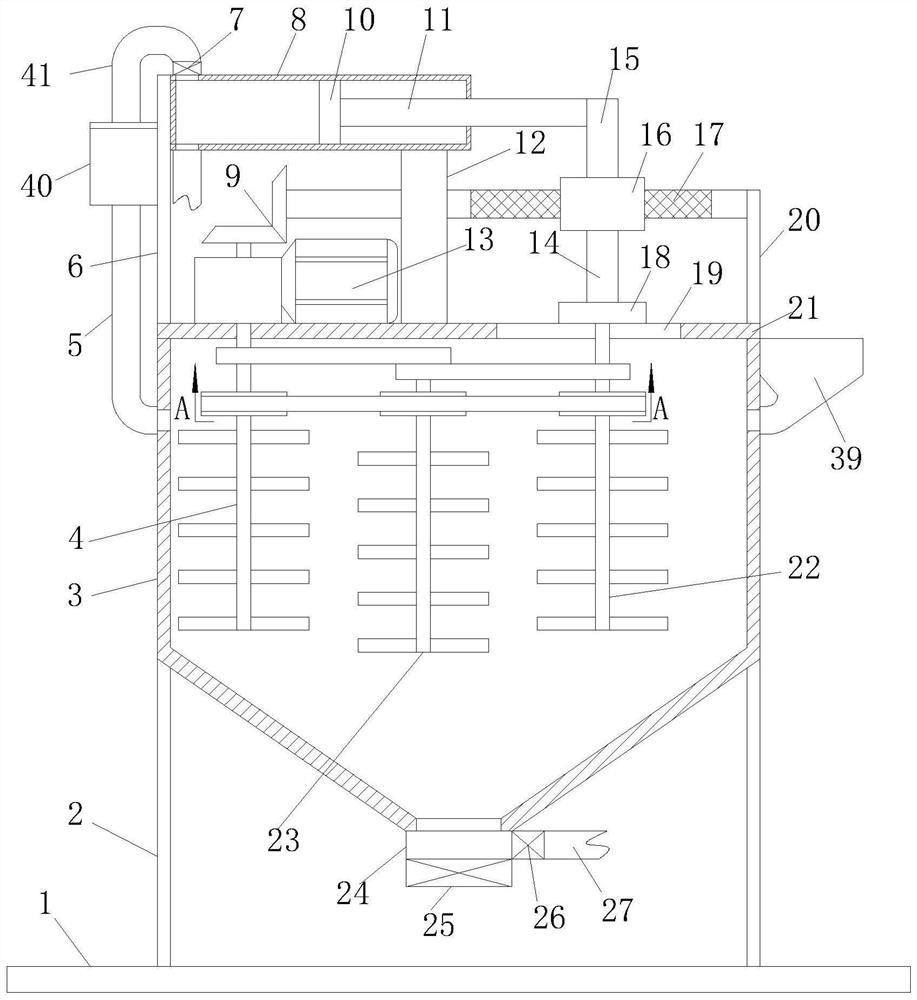

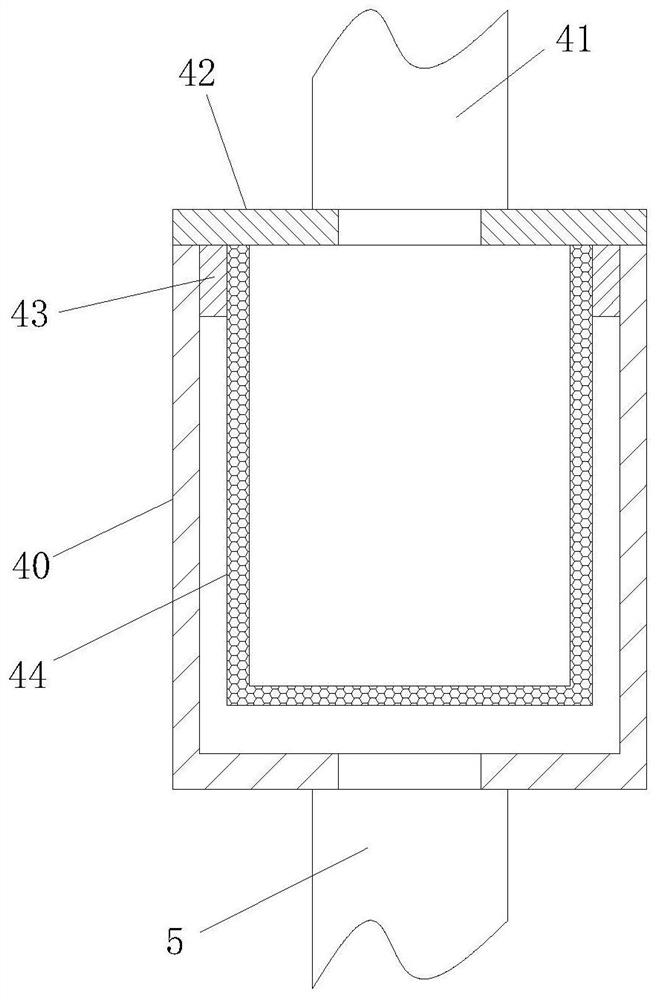

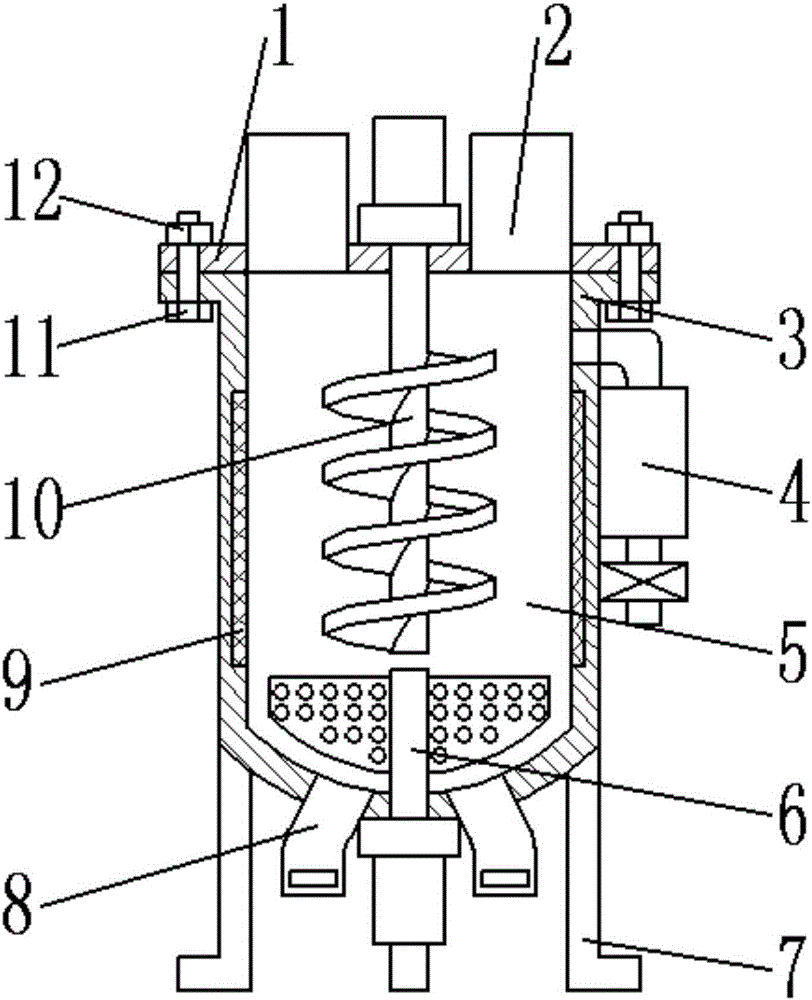

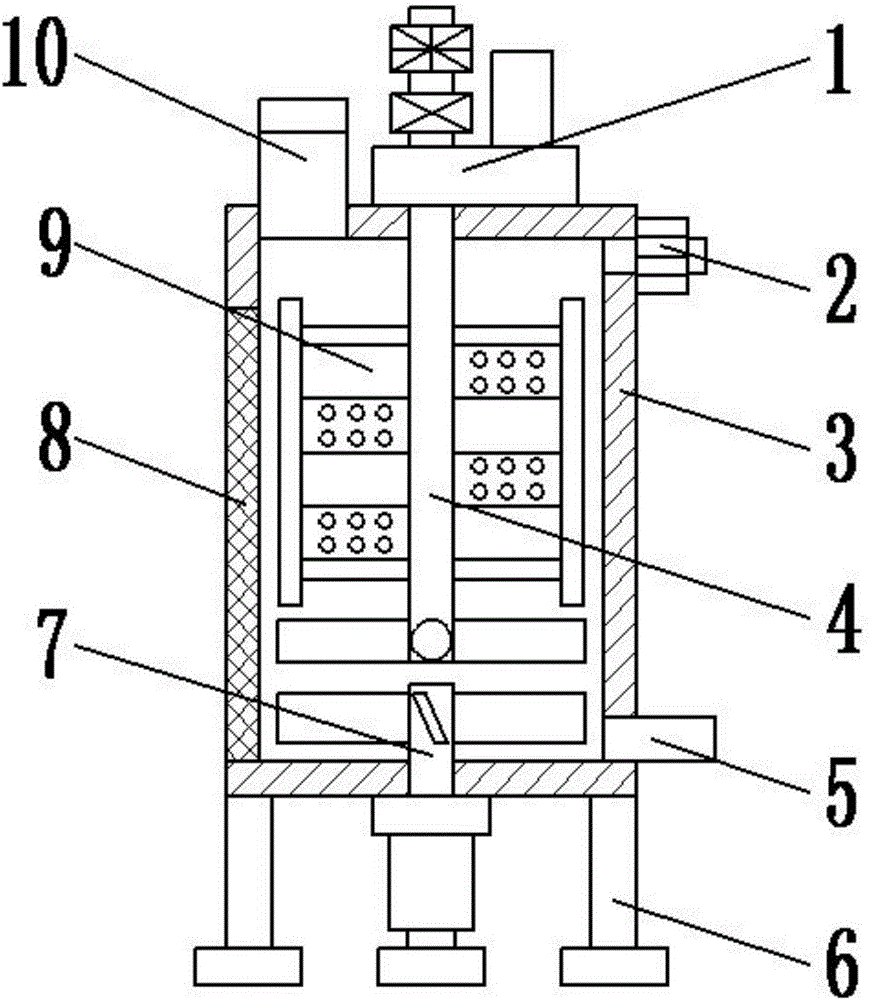

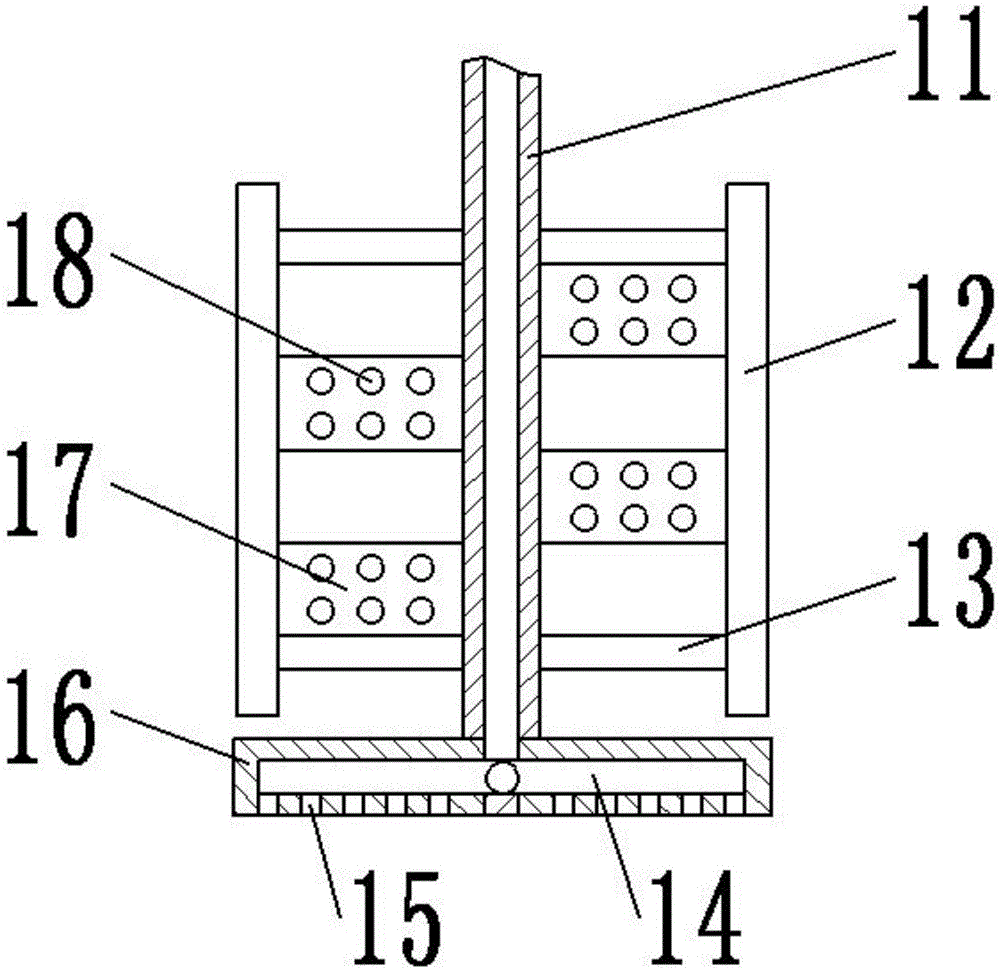

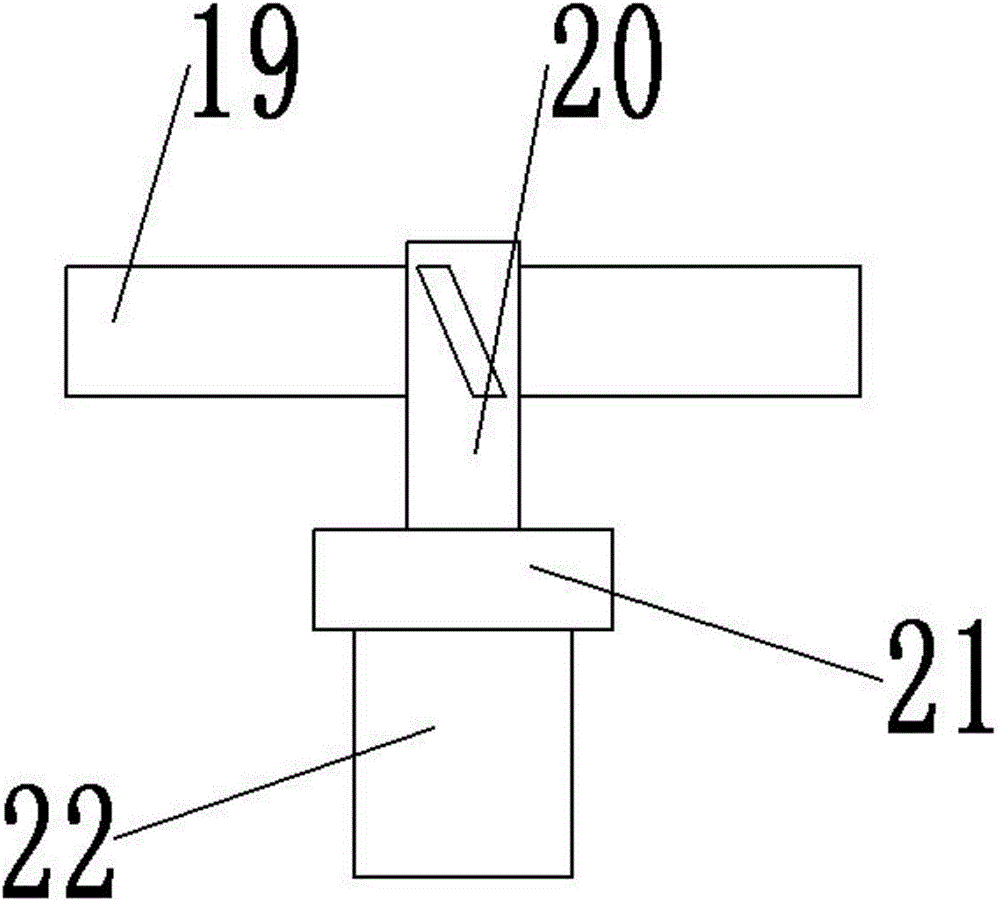

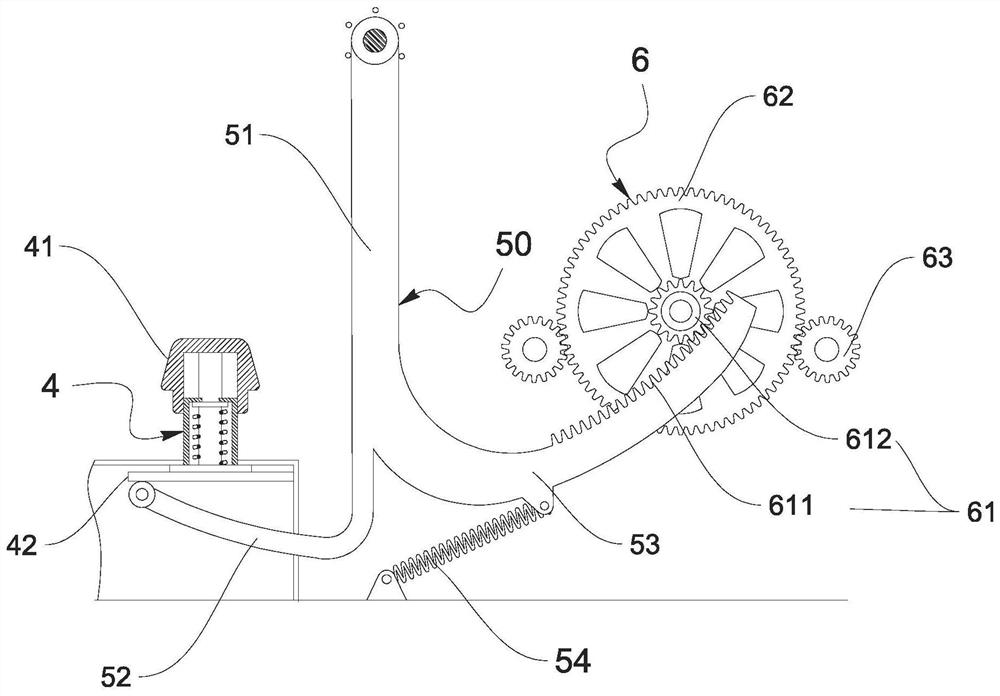

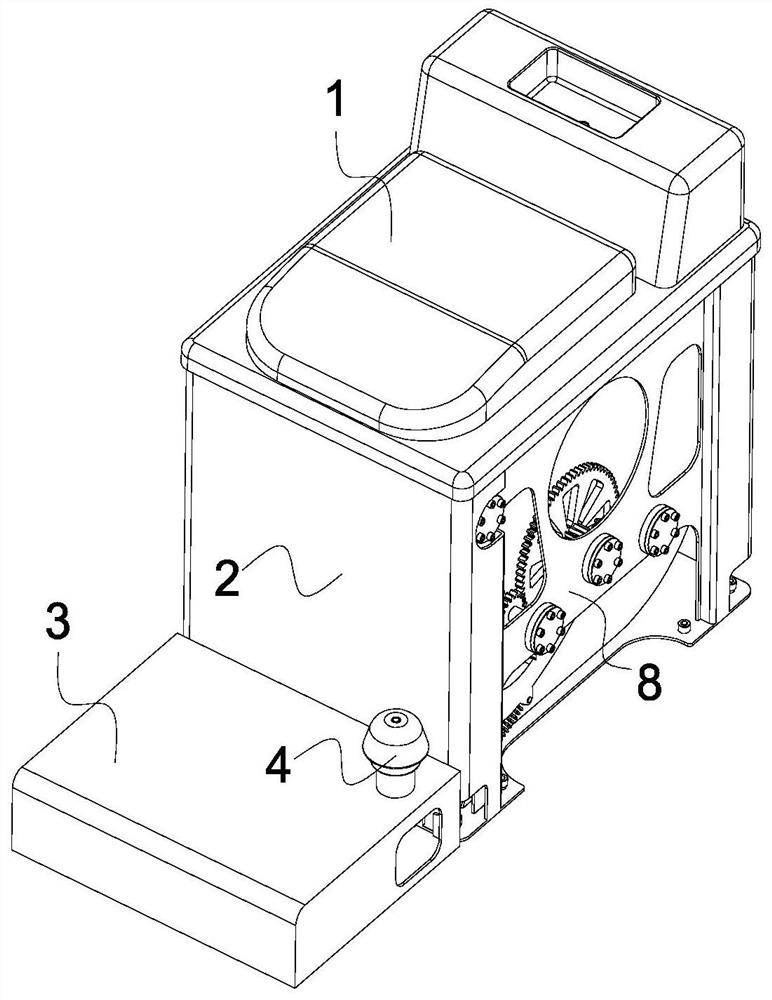

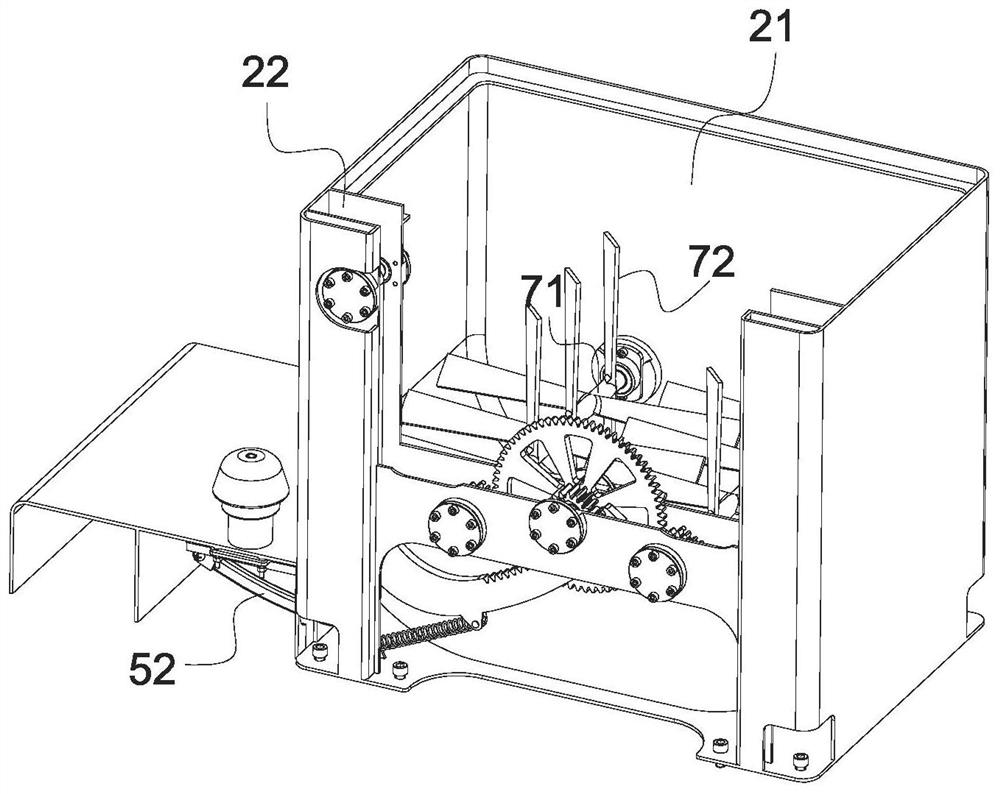

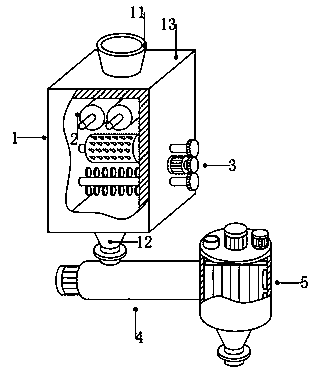

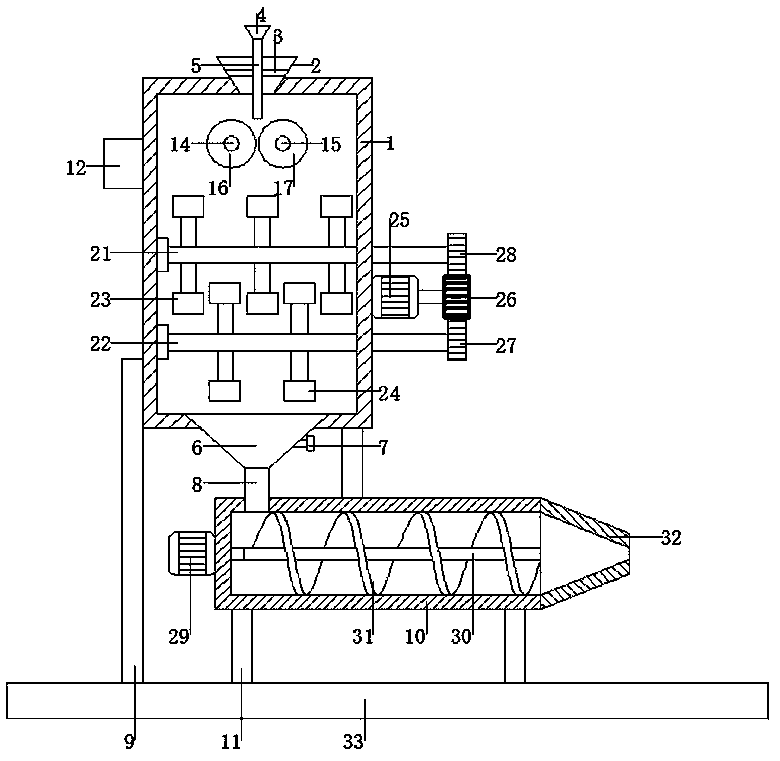

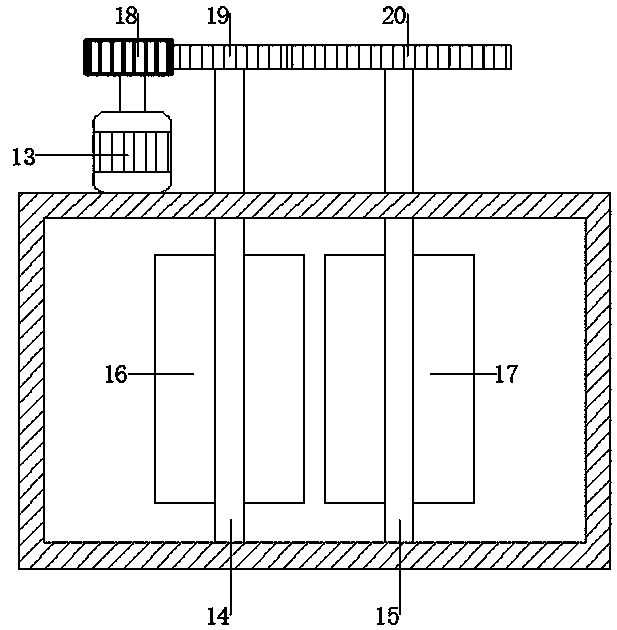

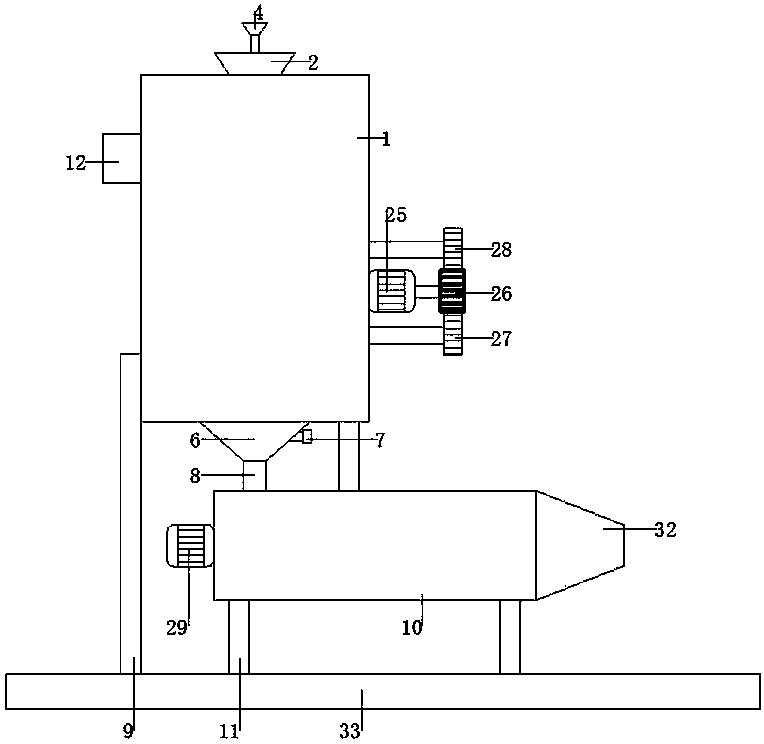

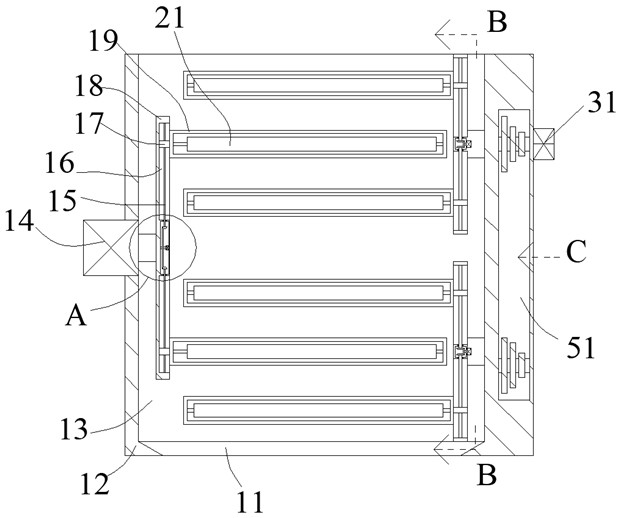

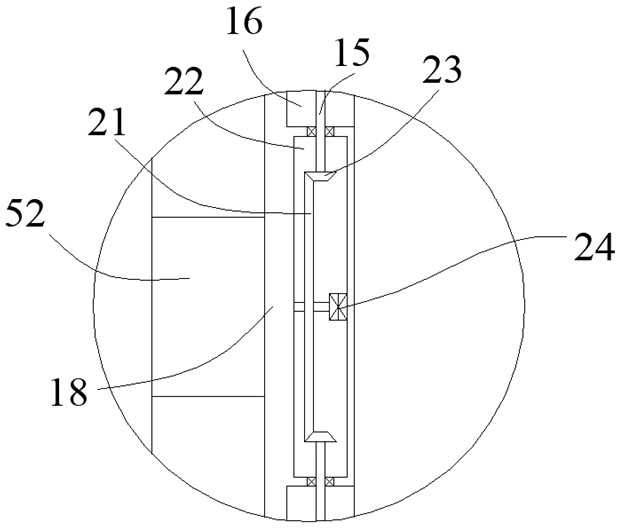

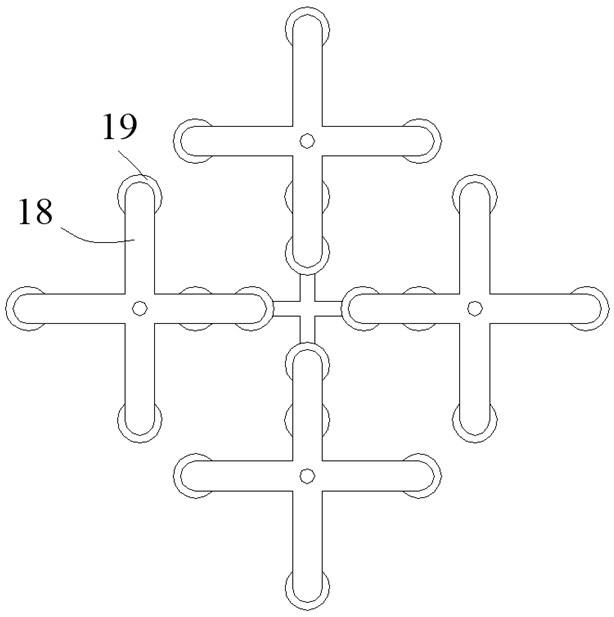

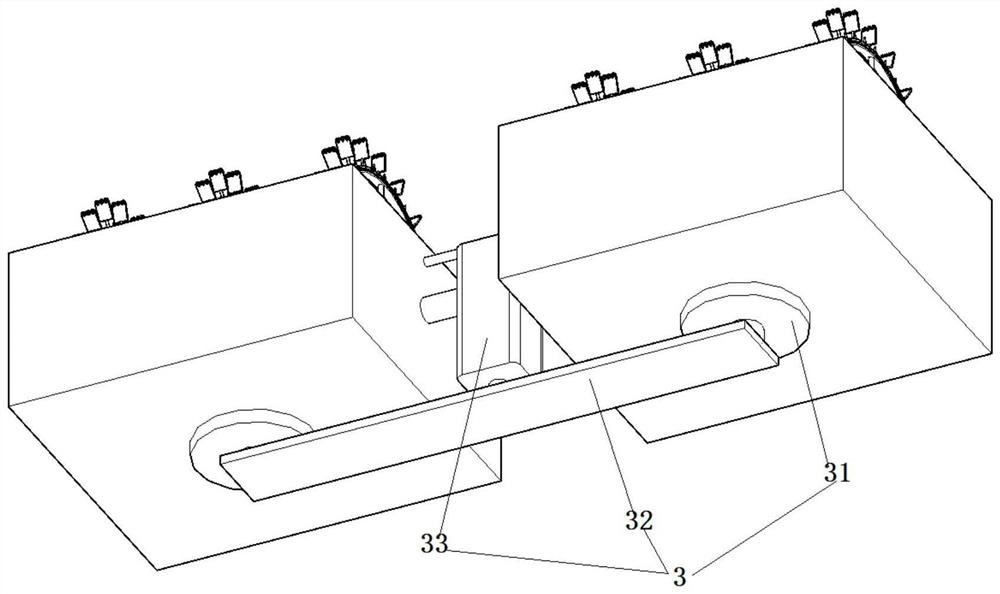

High-efficiency stirring and mixing equipment for chemical engineering

InactiveCN106621911AEfficient stirring and mixingAvoid cloggingRotary stirring mixersTransportation and packagingHybrid deviceChemical engineering

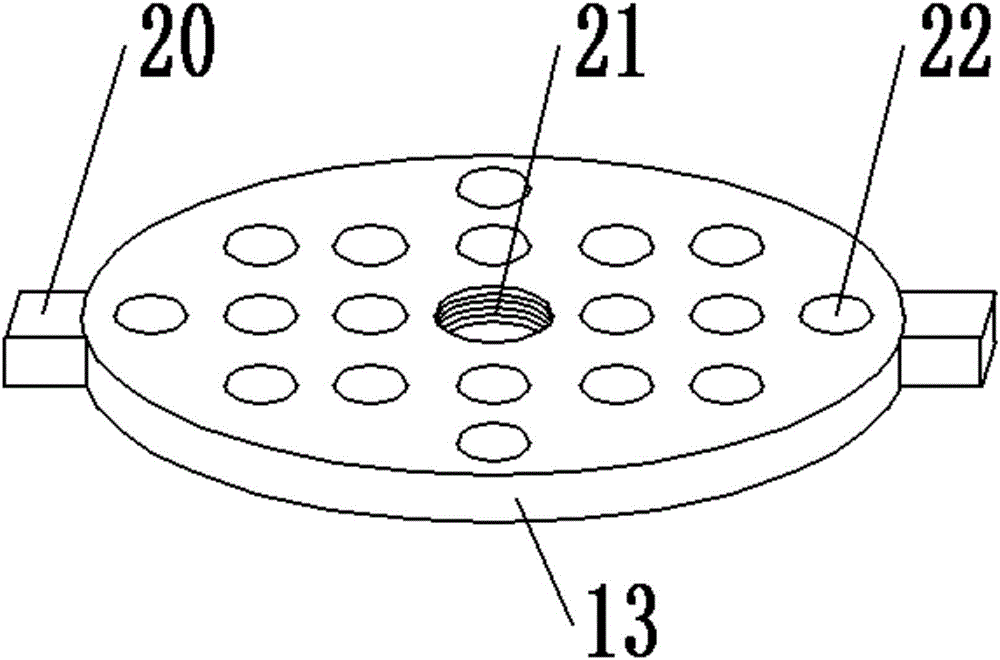

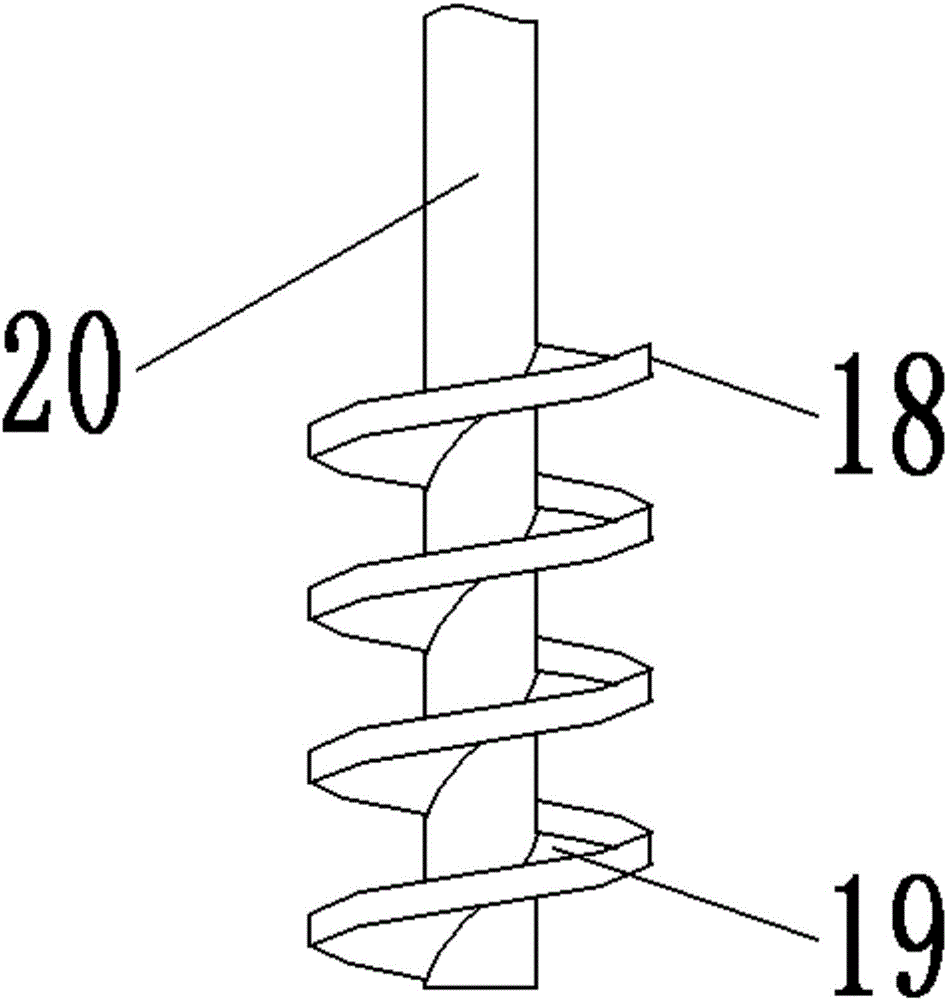

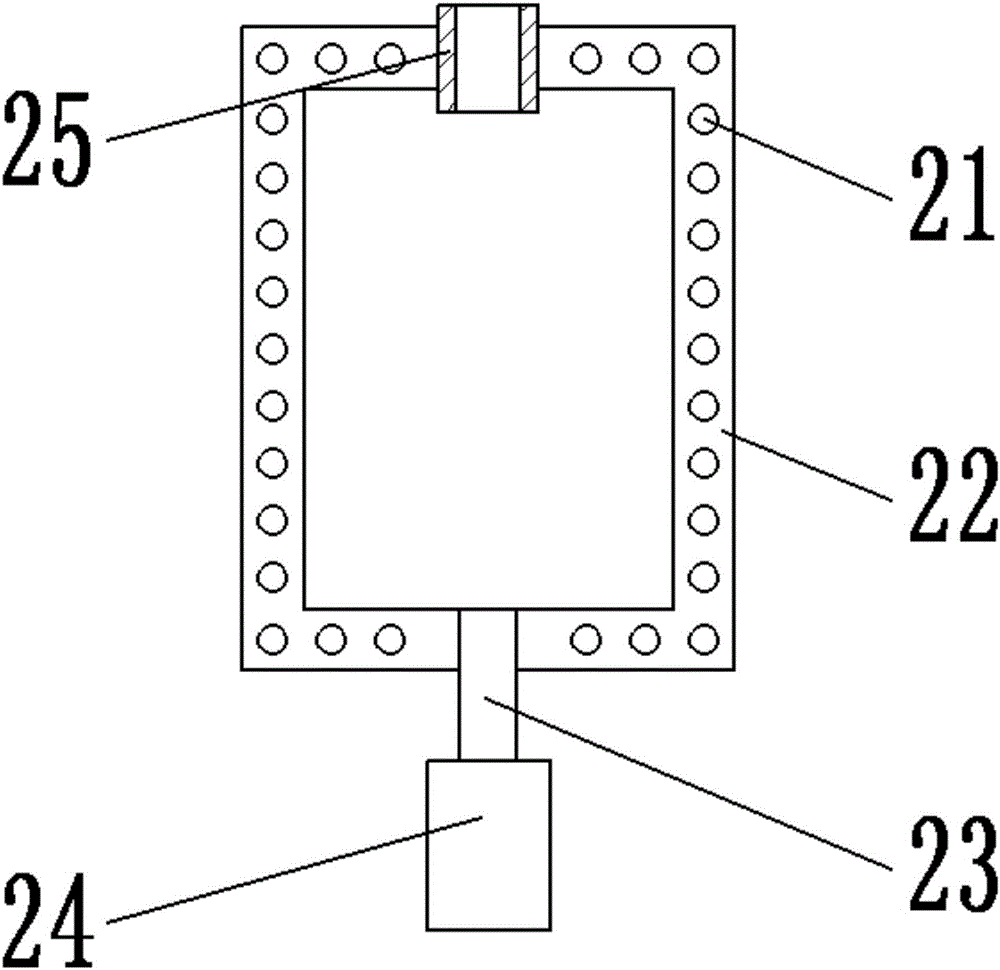

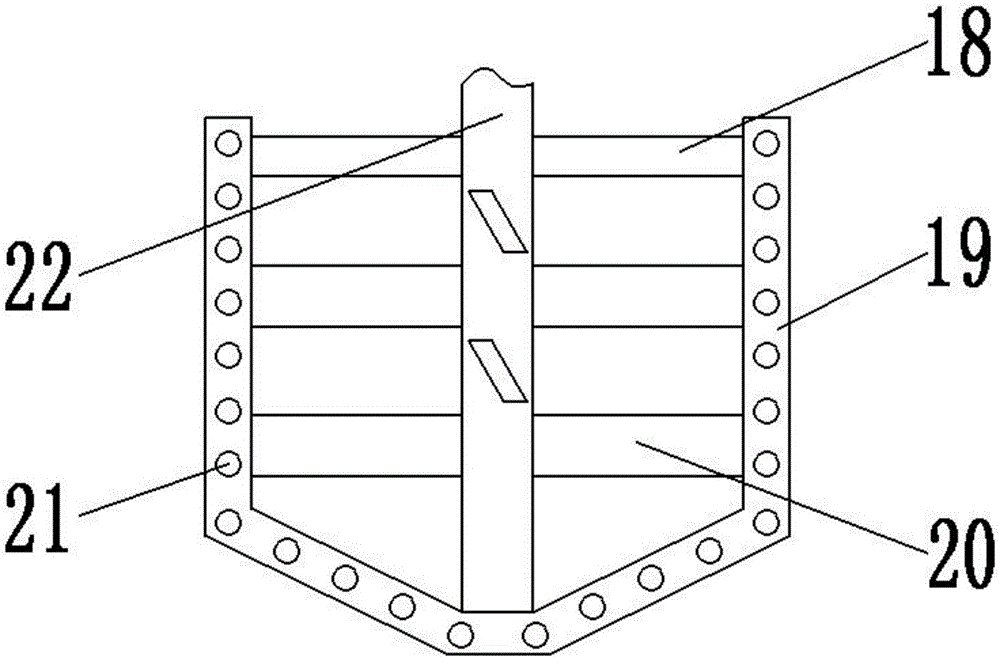

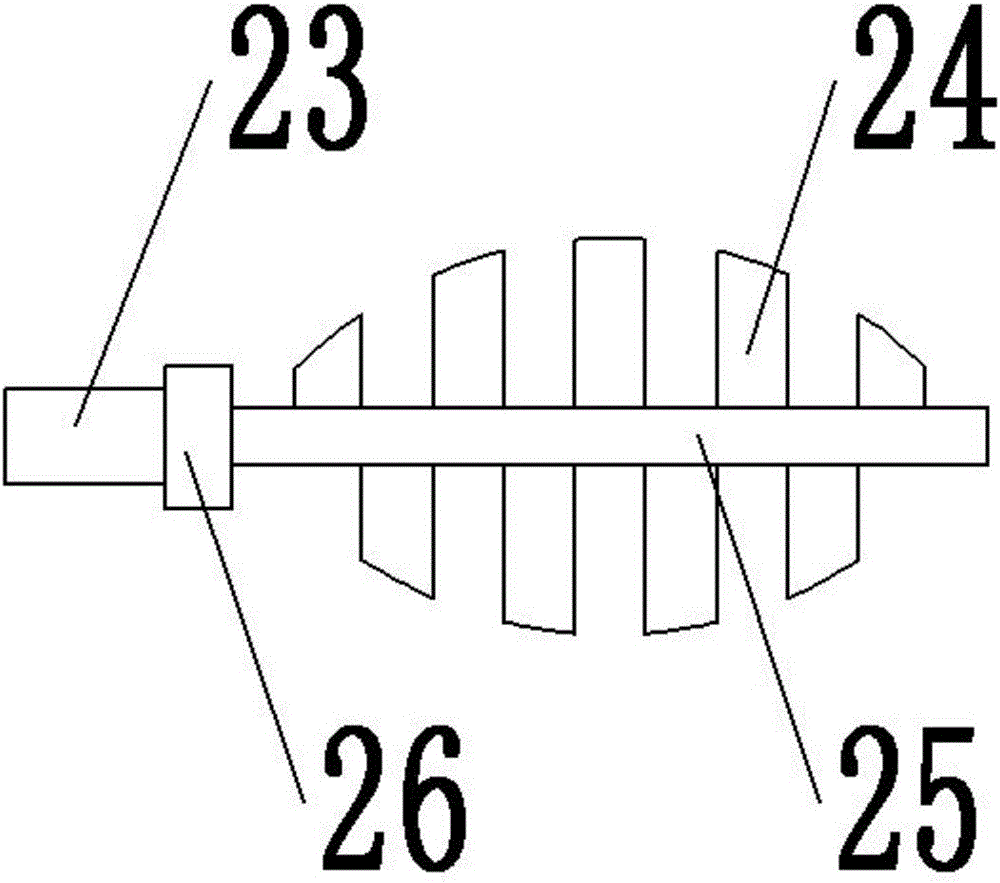

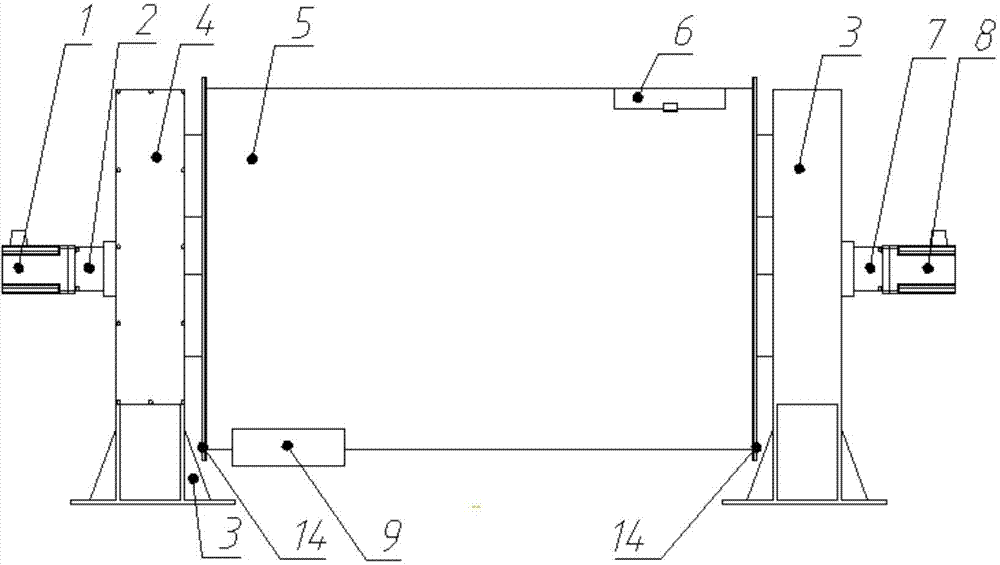

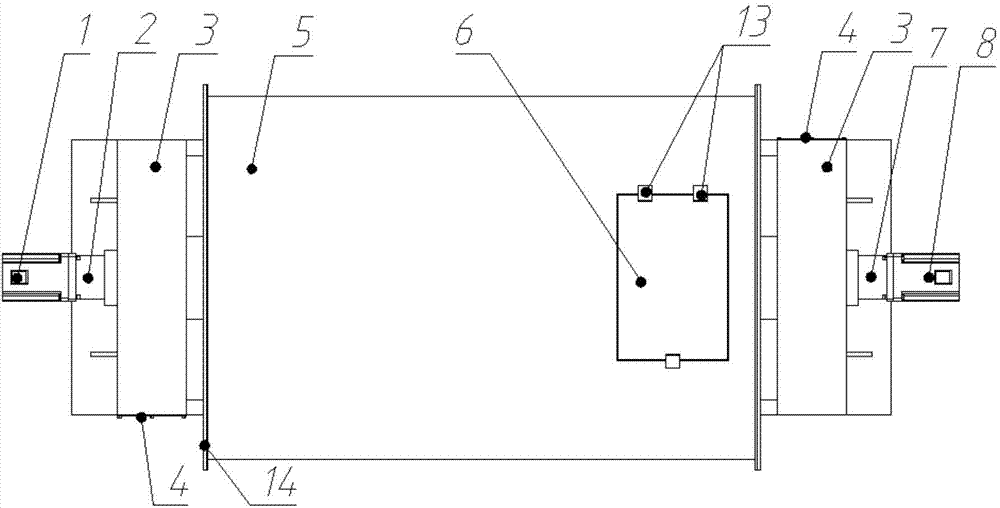

The invention provides high-efficiency stirring and mixing equipment for chemical engineering. The high-efficiency stirring and mixing equipment comprises a tank body, wherein the interior of the tank body is separated into a material equalizing cavity and a stirring cavity by a separating plate, and an upper cover is arranged at a top opening; a material inlet pipe is arranged on the upper cover; a material equalizing device is arranged in the material equalizing cavity, and consists of a first motor, a material equalizing shaft and a material equalizing plate; the material equalizing shaft penetrates through the separating plate, and is connected with a threaded screw rod; a lifting plate is arranged on the threaded screw rod; a stirring device is arranged at the bottom part of the stirring cavity, and consists of a second motor, a stirring shaft and stirring blades. The high-efficiency stirring and mixing equipment has the advantages that multiple types of materials are uniformly equalized in the material equalizing cavity by the material equalizing device, and are primarily mixed, so as to smoothly pass through falling holes in the separating plate; by utilizing the positive and reverse rotation of the threaded screw rod, the lifting plate is driven to do lifting motion, and the material in the middle part of the tank body is stirred and mixed in the vertical direction; by arranging the stirring device, the material is stirred and mixed at high efficiency, and the working efficiency is improved.

Owner:郑州吉音动漫科技有限公司

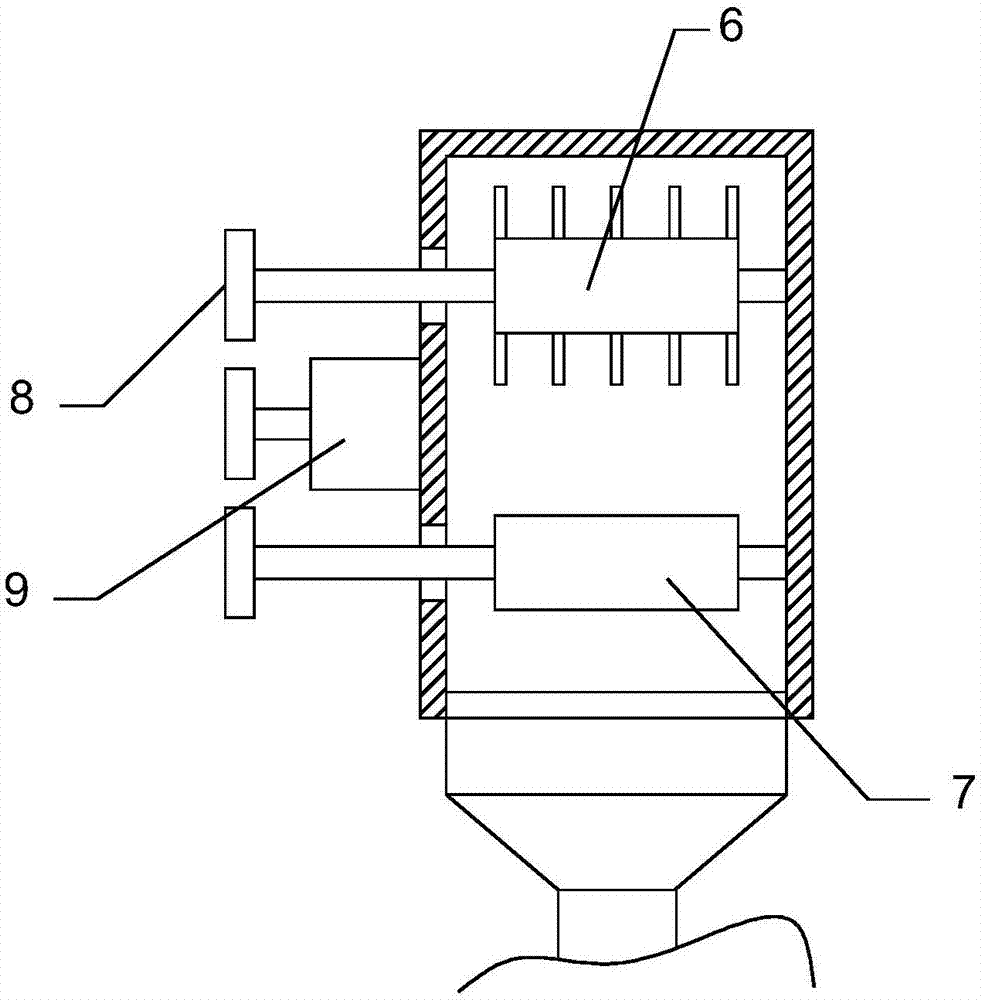

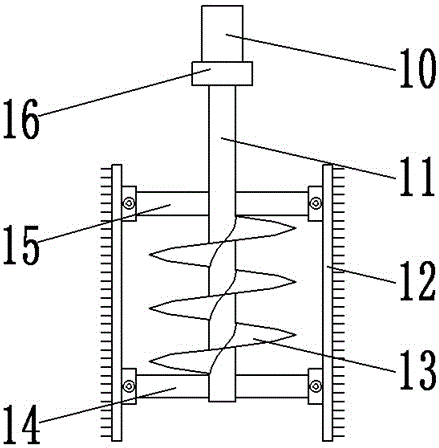

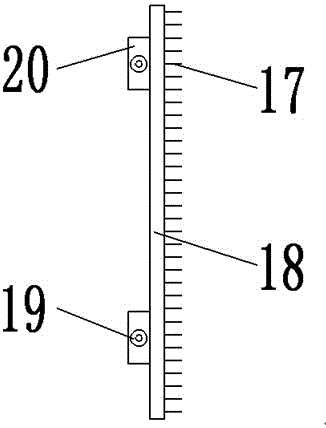

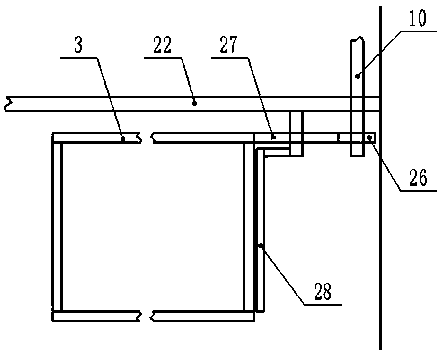

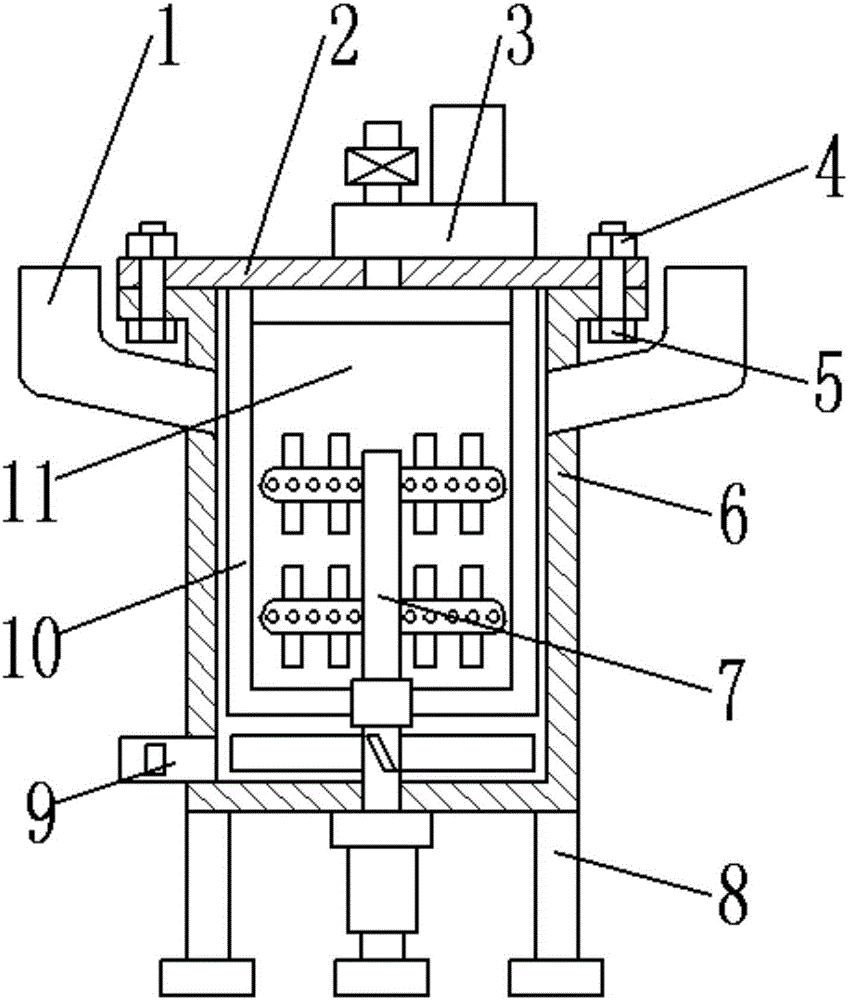

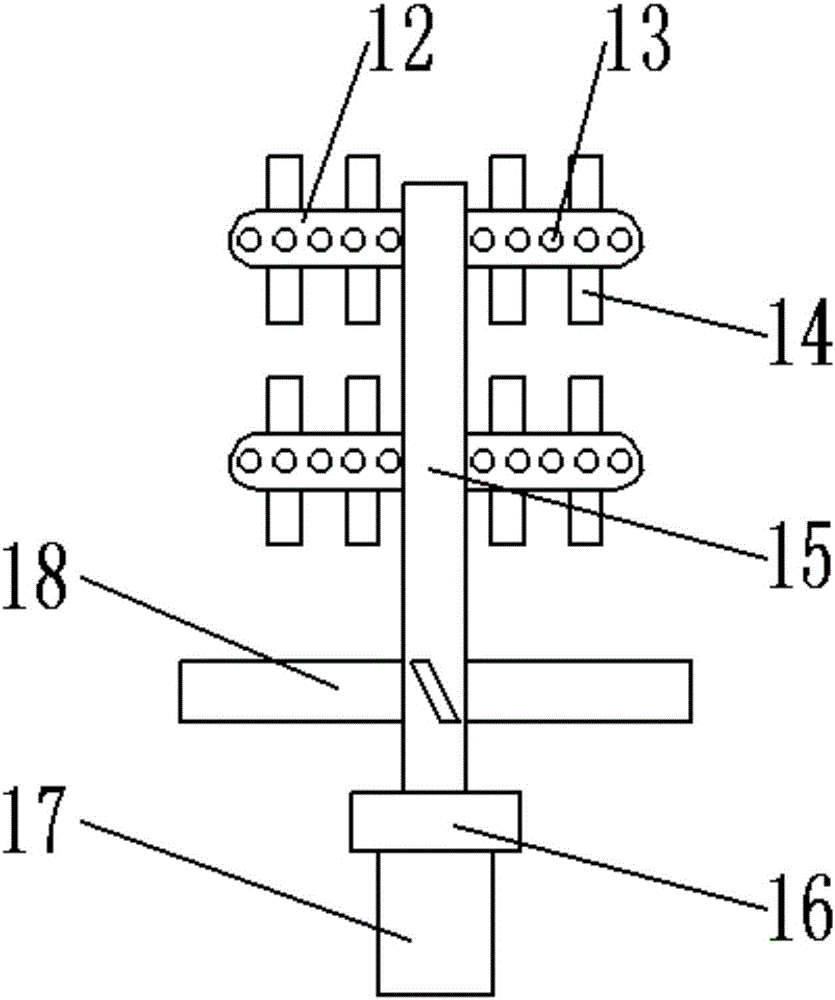

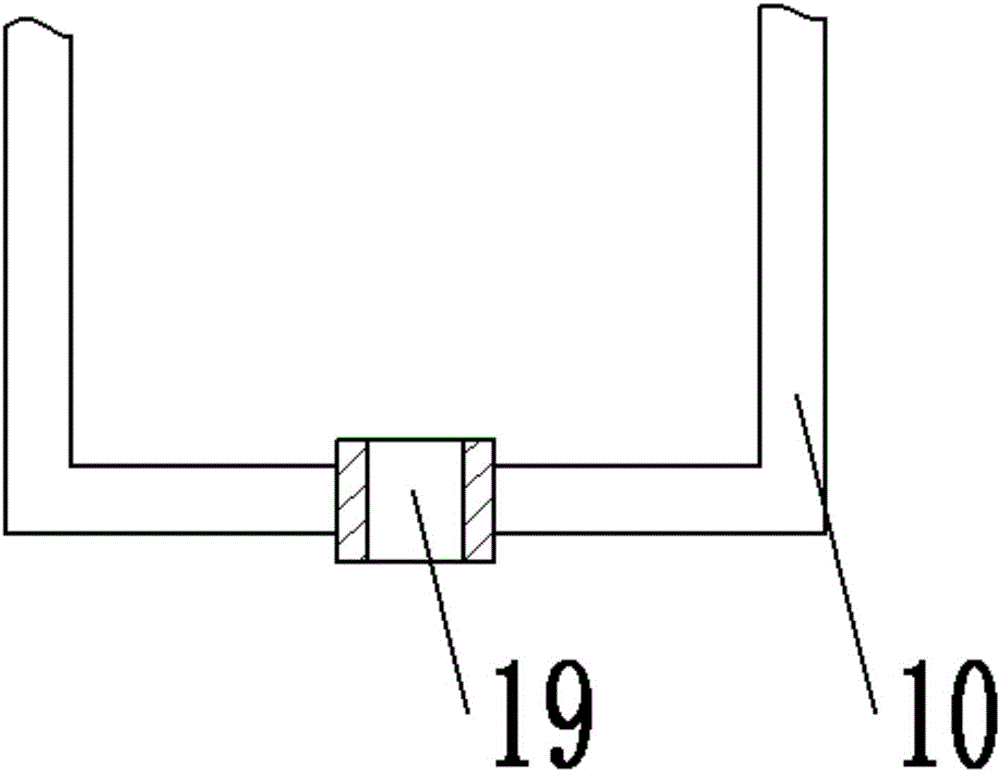

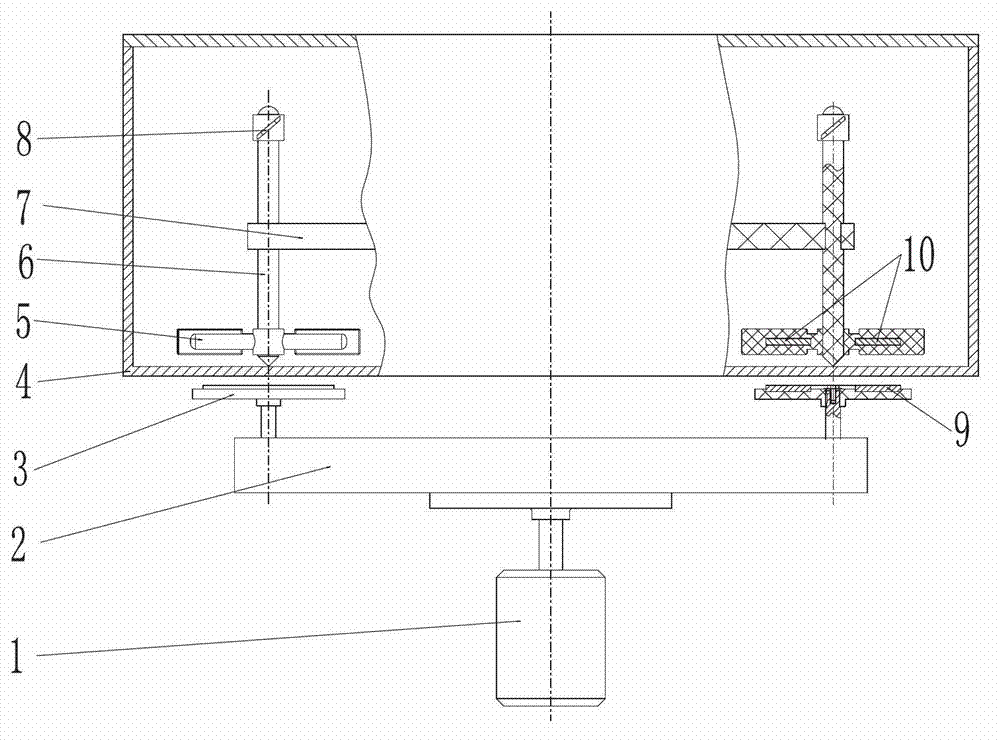

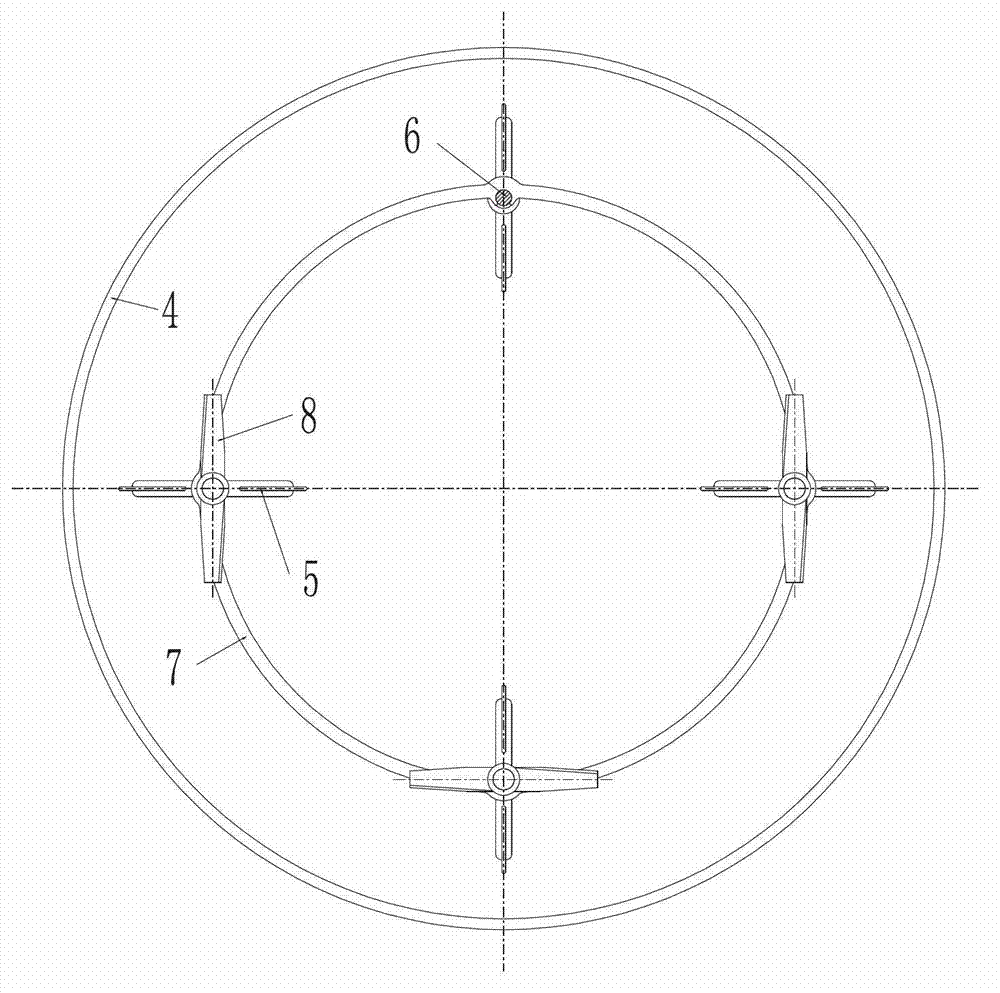

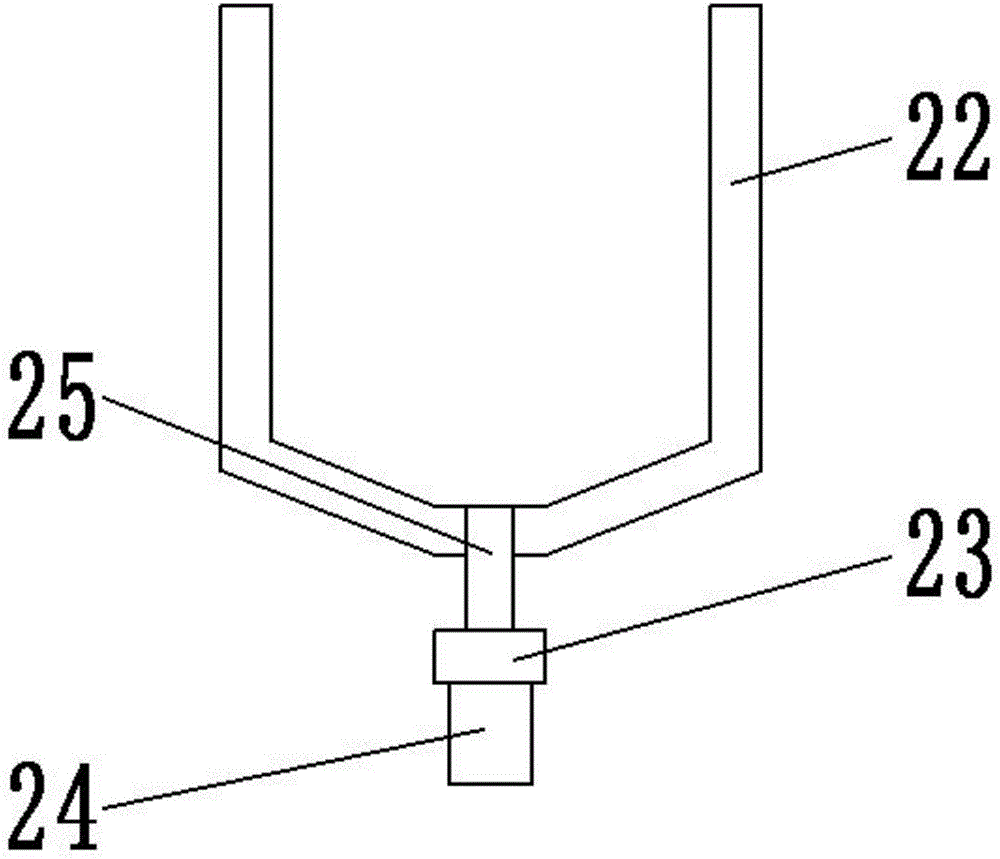

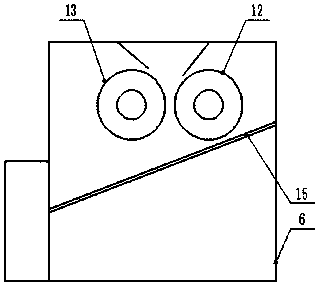

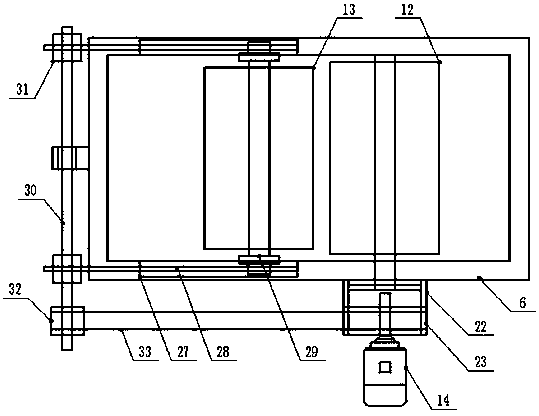

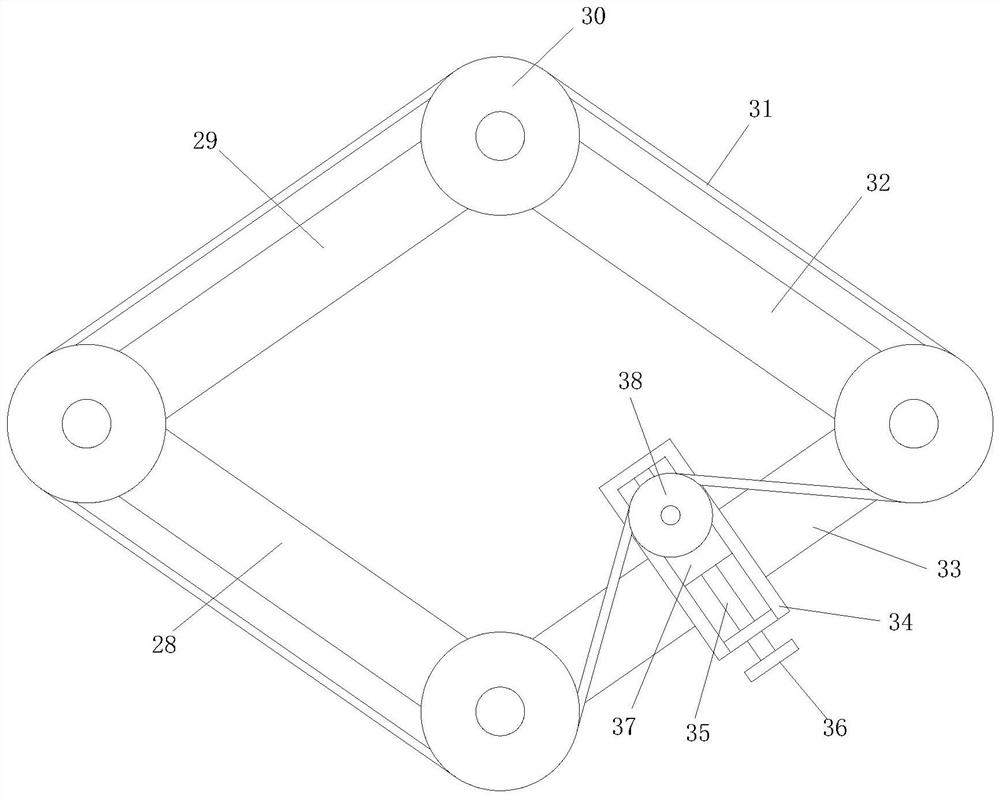

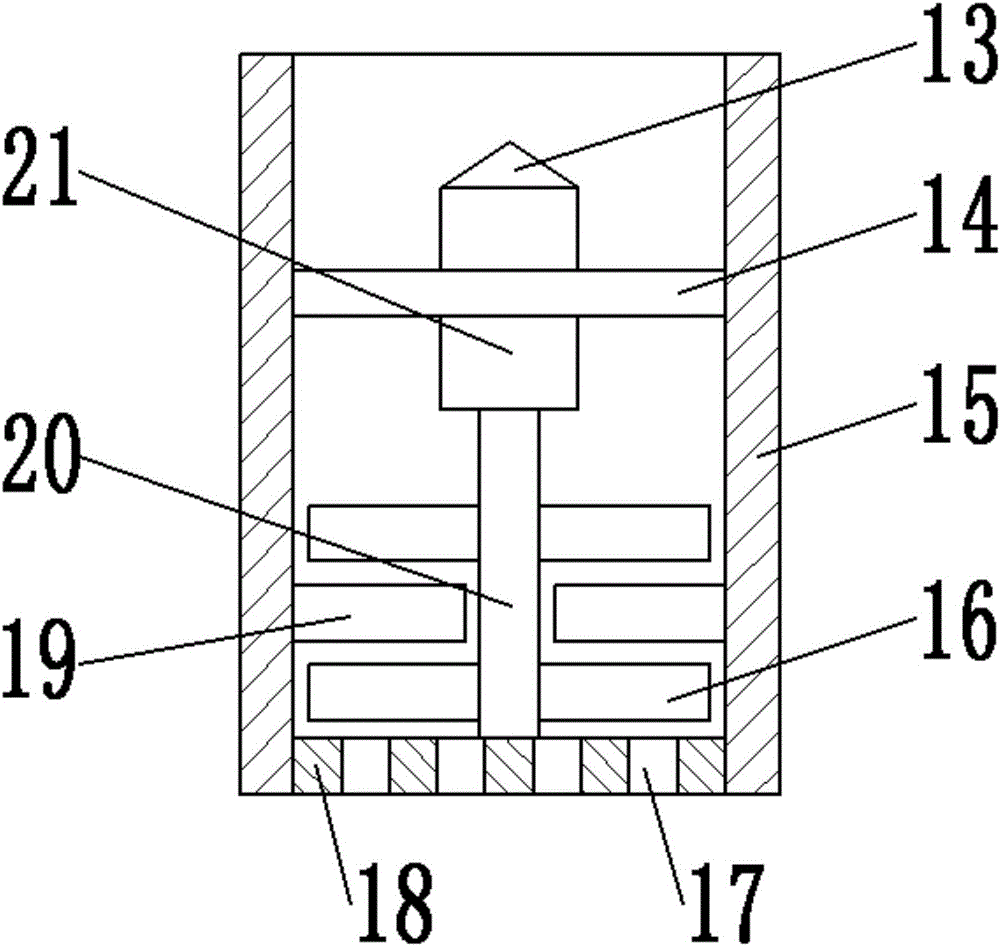

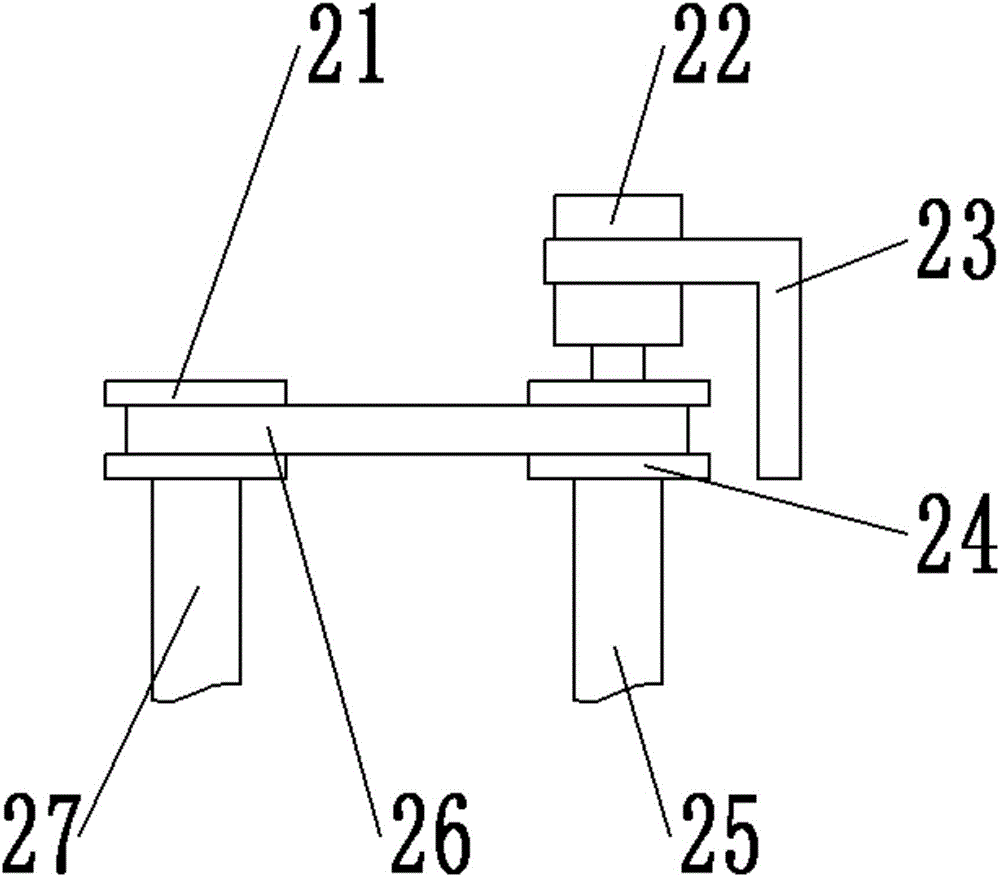

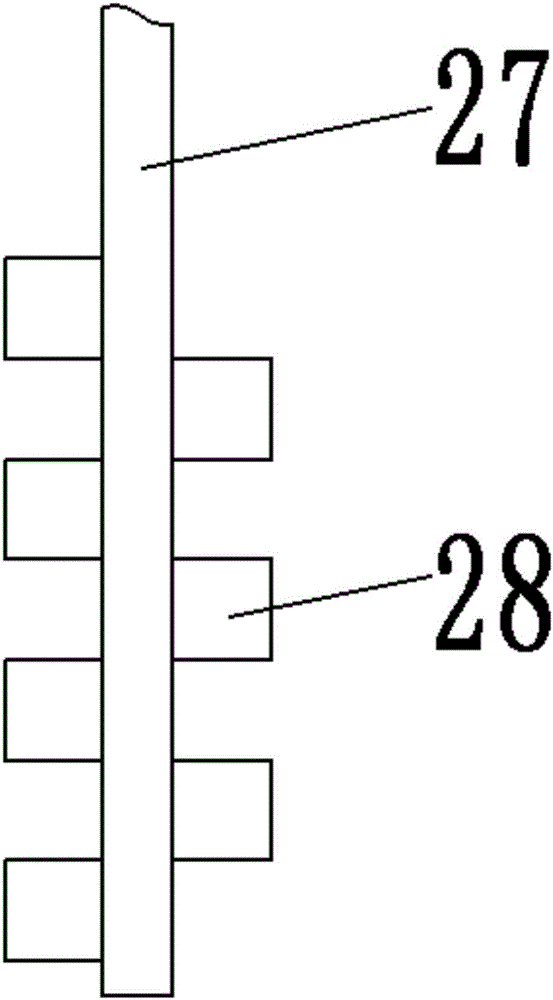

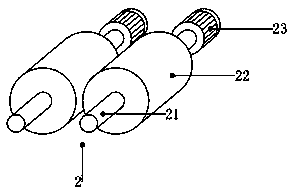

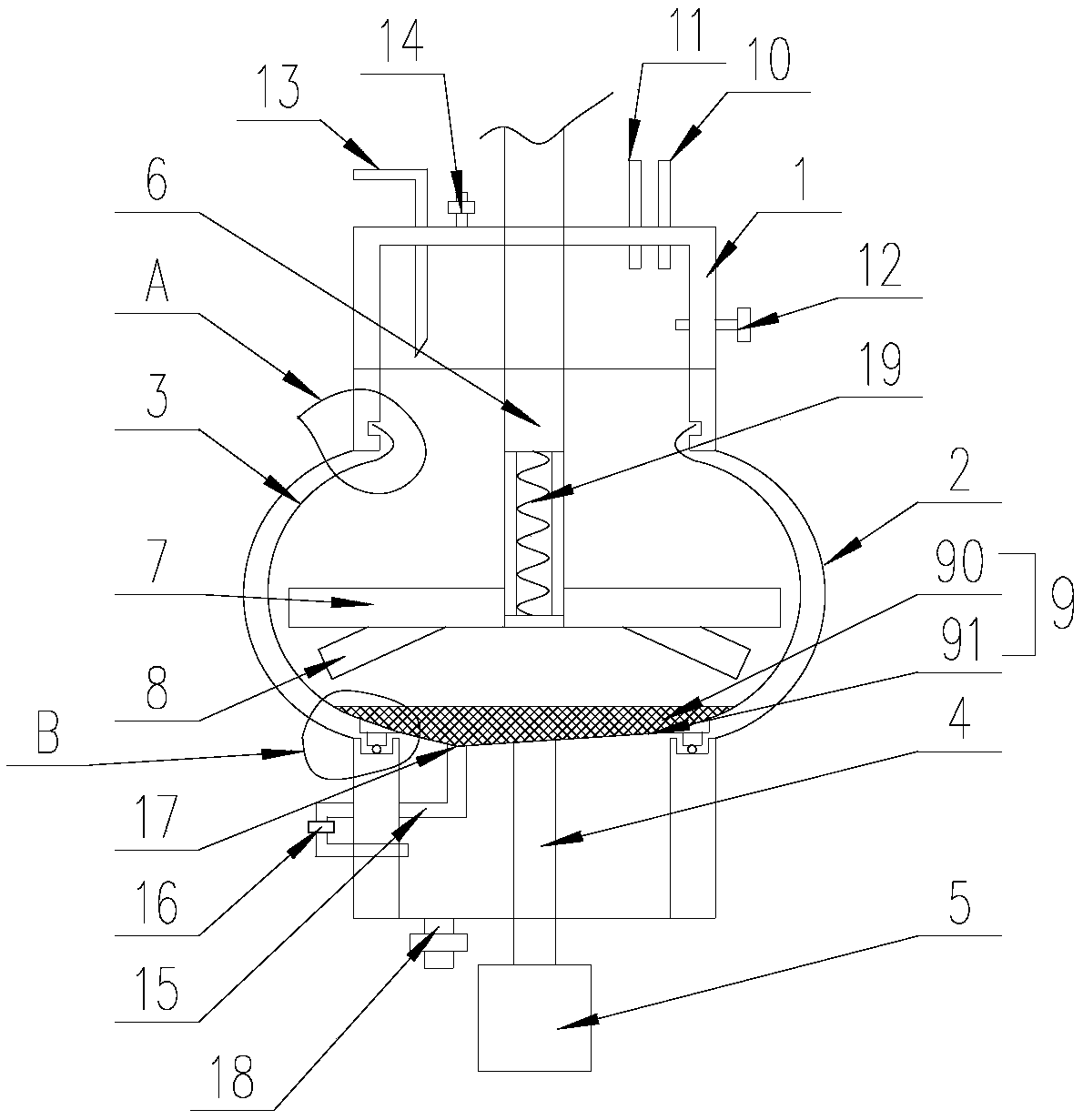

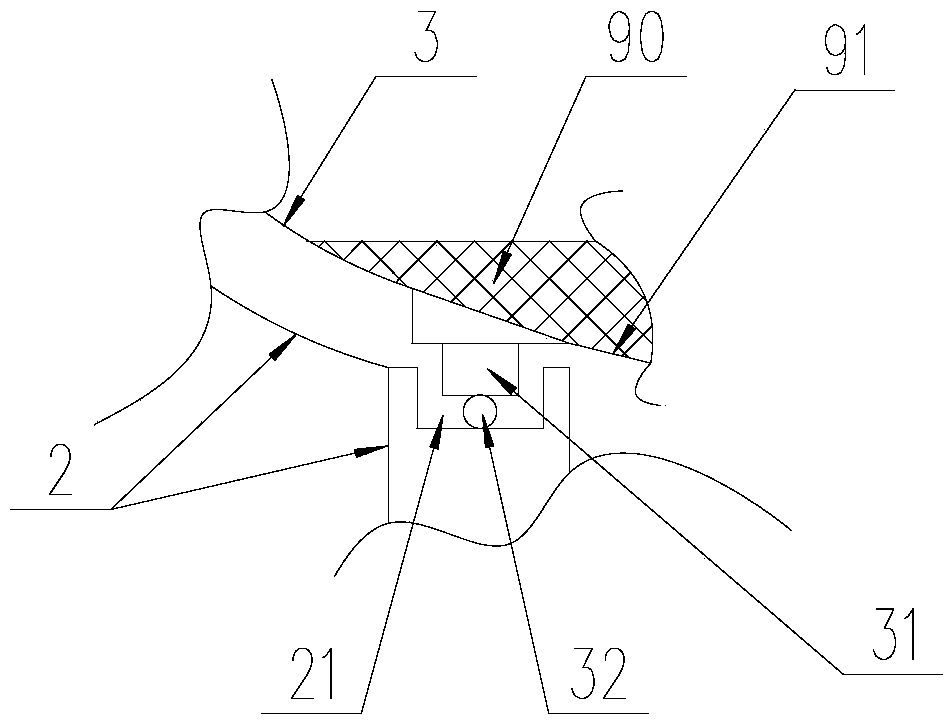

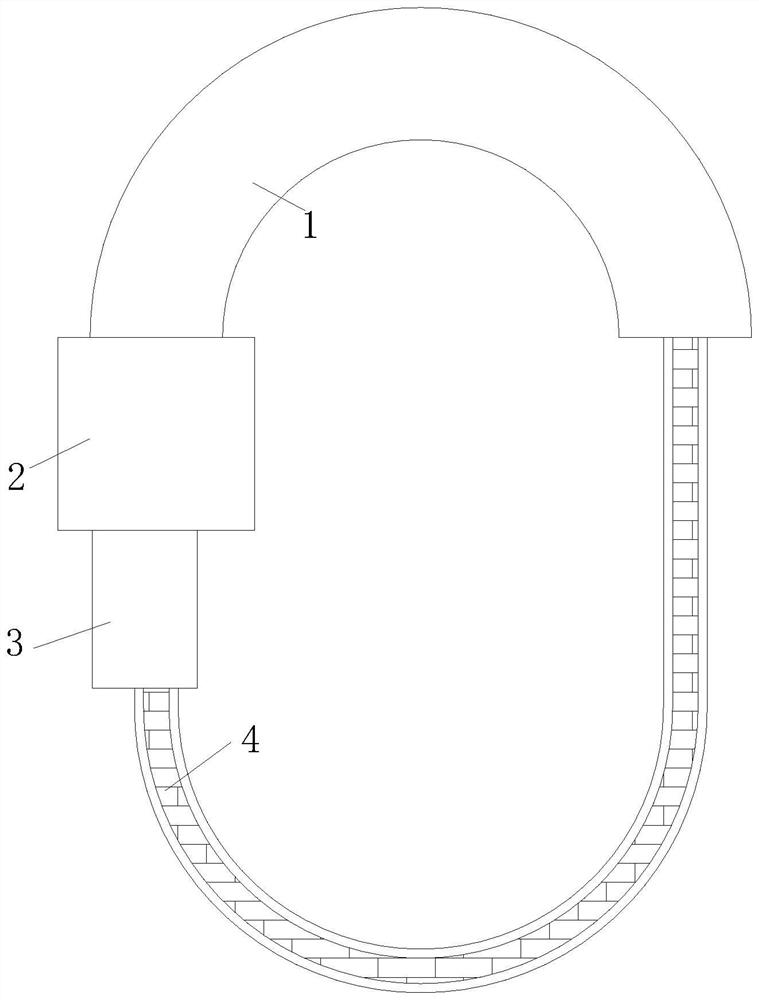

Efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering

InactiveCN106582389AEnsure mixing uniformityMixing uniformity does not existRotating receptacle mixersRotary stirring mixersElectric machineryRaw material

The invention provides efficient stirring and mixing equipment of solid-liquid raw materials for chemical engineering. The efficient stirring and mixing equipment comprises a tank body; a stirring cavity is formed in the tank body, an upper cover is installed on an opening formed in the top of the tank body, and four sets of rollers are installed on the lower surface of the tank body; the rollers are installed in a sliding groove formed in a base plate, a support is installed at the end of the base plate, and the vertical portion of the support is fixedly connected with a second motor through a fixing plate; a liquid feeding device is installed on the upper surface of the horizontal portion of the support, the liquid feeding device is composed of a transmission box, a first motor, a liquid feeding pipe, a connecting pillar and a spraying disc, and a first stirring device and a second stirring device are installed in the stirring cavity. According to the efficient stirring and mixing equipment of the solid-liquid raw materials for chemical engineering, through the liquid feeding device, the spraying area and speed of liquid materials are enlarged, so that the liquid materials make sufficient contact with solid materials; through the first stirring device, circulating stirring and mixing of the materials are achieved, so that the spraying speed of the liquid materials is improved; and through arrangement of the second stirring device, the materials are further stirred and mixed.

Owner:郑州吉音动漫科技有限公司

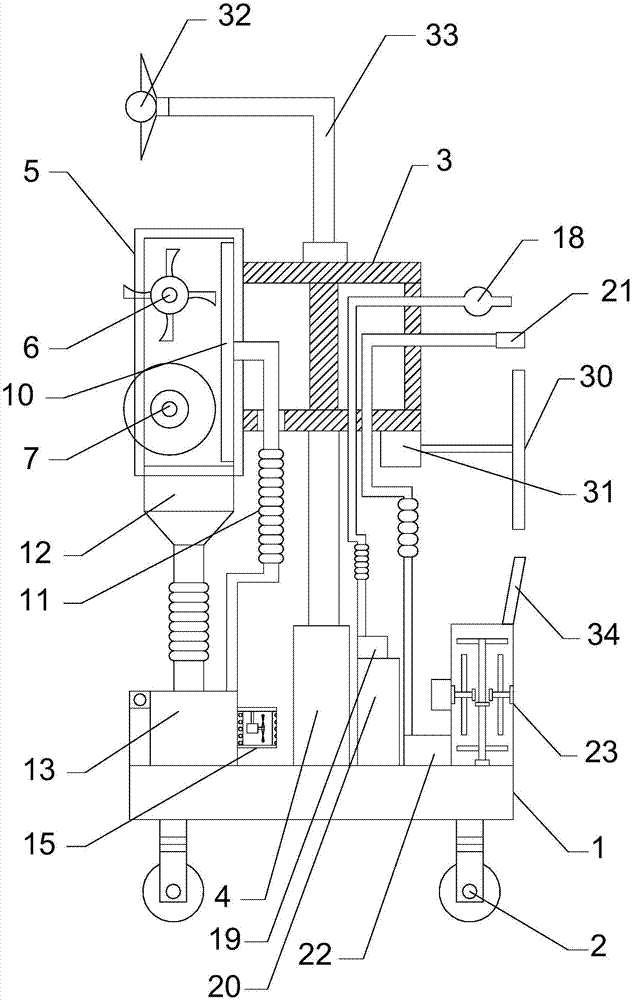

Multifunctional wall surface processing device

InactiveCN107882300AImprove mixing qualityImprove stirring efficiencyRotary stirring mixersTransportation and packagingSlagMultiple function

The invention discloses a multifunctional wall surface processing device which comprises a movable flat plate, universal wheels and a hydraulic cylinder. The universal wheels are arranged at the bottom of the movable flat plate. A lifting table is arranged above the movable flat plate and connected with the hydraulic cylinder through a piston rod. The left side of the lifting table is fixedly connected with a grinding box. By means of a horizontal stirring plate and a vertical stirring plate, putty paste is efficiently stirred and mixed, and the putty stirring quality and stirring efficiency are improved; by means of a scraper roller and a grinding wheel roller, scraping and grinding are efficiently conducted on a wall body, and wall peel is more thoroughly cleaned away; by means of a dustsuction cover, a dreg collecting hopper and a slag box, dust and slag produced in the operating process are efficiently collected, dust pollution is avoided, and slag is more easily cleaned away; bymeans of a material guide plate, dripped putty paste is collected and prevented from contaminating the ground, and raw materials are saved.

Owner:杭州智仁信息科技有限公司

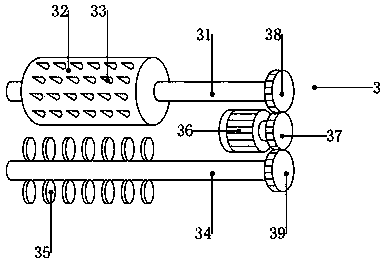

Self-washed type feed stirring, mixing and drying integral equipment

ActiveCN106387966AEasy to passEfficient mixingFeeding-stuffCleaning using liquidsEngineeringFeeding tube

The invention provides self-washed type feed stirring, mixing and drying integral equipment which comprises a stirring tank and a drying tank, wherein a stirring cavity is formed inside the stirring tank; an upper cover is arranged at the opening of the top of the stirring tank; a drying cavity is formed inside the drying tank; a feeding tube and a cleaning and driving device are arranged on the upper cover; the cleaning and driving device consists of a transmission box, a first motor, a water inlet tube and a rotating spraying disc; the lower surface of the rotating spraying disc is fixedly connected with a first stirring device; a second stirring device is arranged inside the drying tank; an electric heating net is arranged on the bottom surface of the drying tank; a dehumidification device is arranged on the side wall of the top of the drying tank. Due to adoption of the cleaning and driving device, the stirring tank and the drying tank can be efficiently cleaned after being used; due to adoption of the first stirring device, the quality of feed can be improved; due to adoption of the electric heating net, heat for drying materials can be provided; and moreover due to arrangement of the second stirring device, heat conduction can be facilitated, and the materials can be uniformly heated.

Owner:佛山市顺德区正宇饲料有限公司

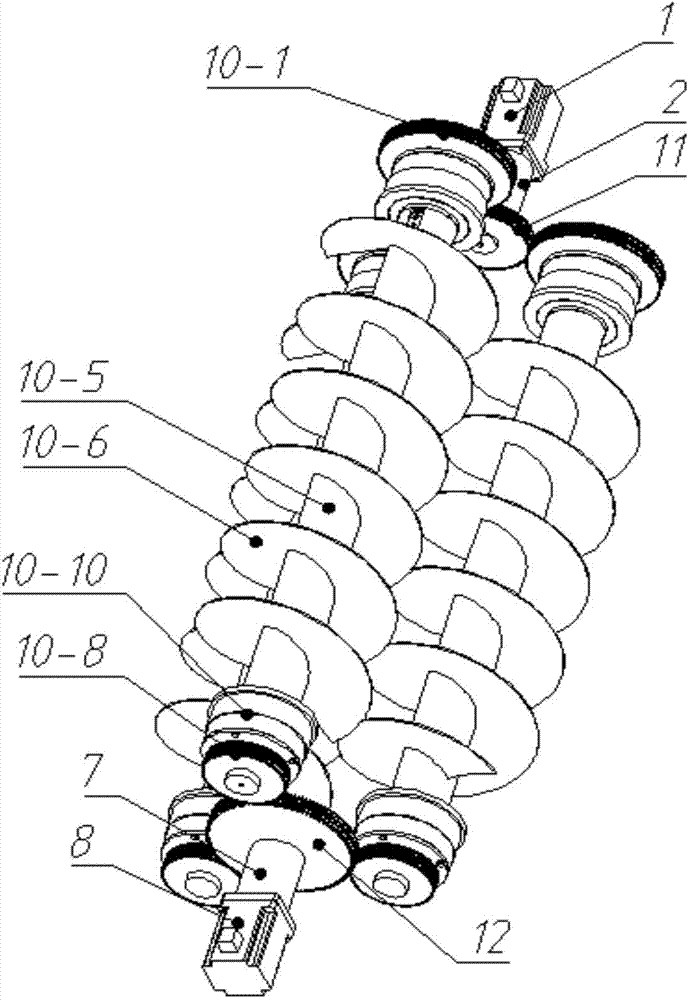

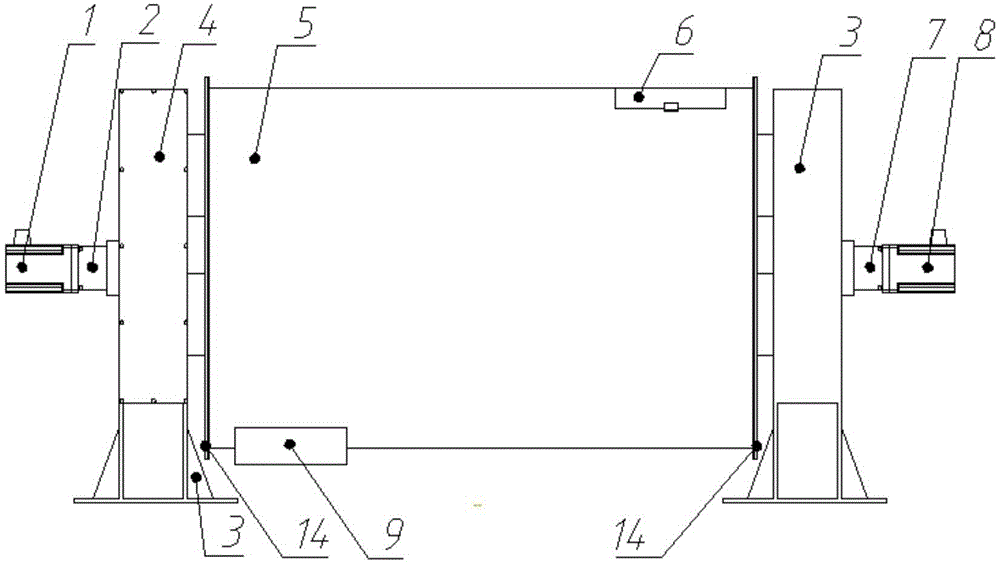

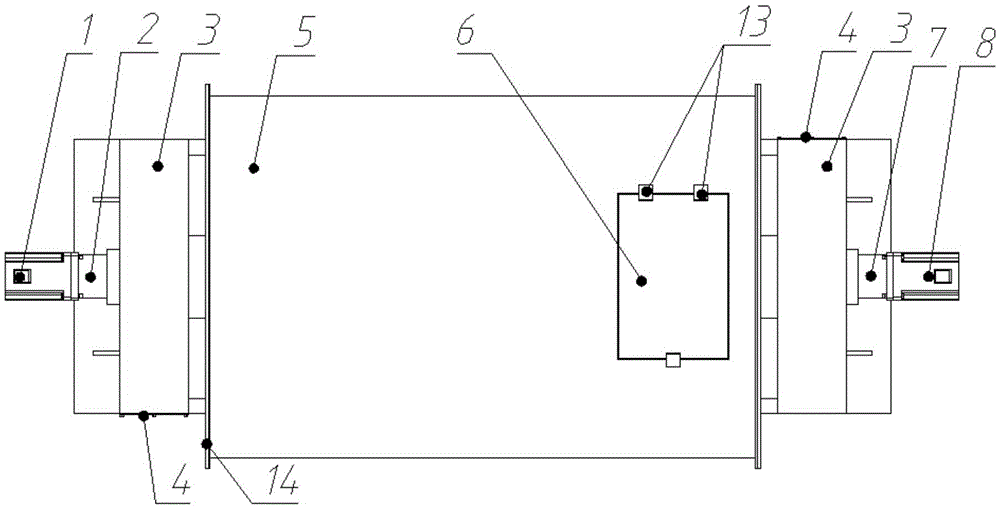

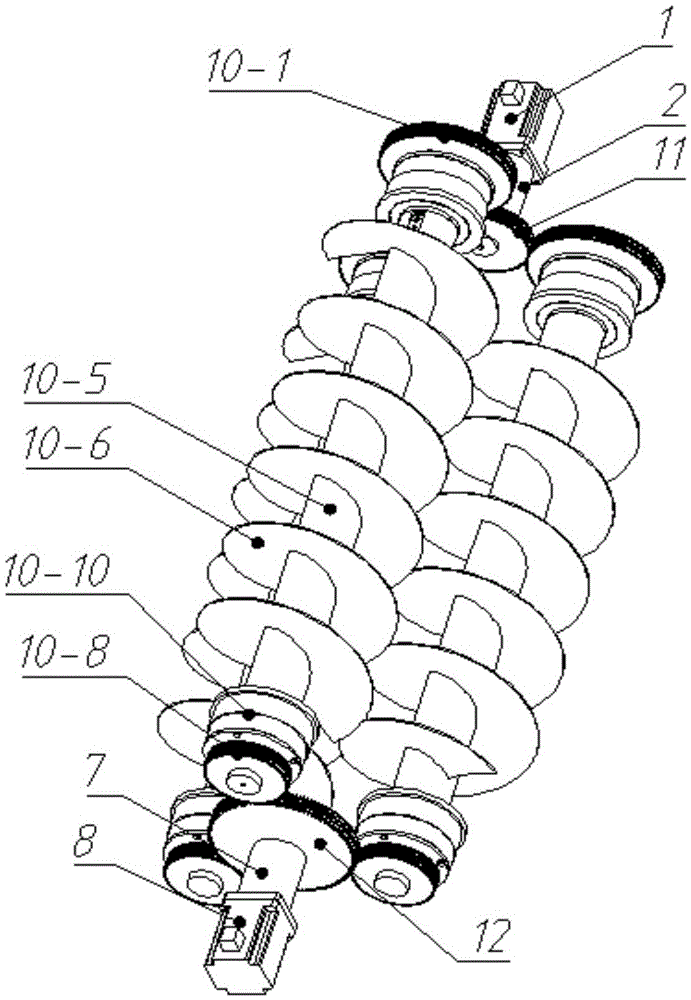

AC servo driven stirring-vibrating composite nanometer powder preparation ball mill

ActiveCN104324782AEfficient grindingEfficient stirring and mixingGrain treatmentsBall millControl theory

The invention provides an AC servo driven stirring-vibrating composite nanometer powder preparation ball mill, wherein the power is respectively provided by a first AC permanent magnetic synchronous servo motor for stirring and a second AC permanent magnetic synchronous servo motor for vibrating, the first AC permanent magnetic synchronous servo motor is engaged with the end rack wheels of three hollow stirring shaft groups through central pinions at the output end of a speed reducer, pinions used for driving eccentric vibrating shafts at the other end parts of the three hollow stirring shaft groups are connected with the second AC permanent magnetic synchronous servo motor through central rack wheels and accelerators, the eccentric vibrating shaft of each hollow stirring shaft group is provided with two groups of eccentric blocks, the eccentric vibrating shaft is supported in the inner hole of a hollow shaft, a helical stirring blade is welded on the hollow shaft, since the three controllable vibrating and stirring shaft groups are adopted, the AC servo driven stirring-vibrating composite nanometer powder preparation ball mill can be used for both stirring and vibrating on the eccentric vibrating shaft, reasonably controlling the stirring speed and improving the stirring efficiency.

Owner:北京润丰科技发展有限责任公司

Lithium battery electrode slurry stirring-mixing tank convenient to clean

InactiveCN106732009AEasy to cleanEasy dischargeRotary stirring mixersTransportation and packagingBiochemical engineeringSlurry

The invention provides a lithium battery electrode slurry stirring-mixing tank convenient to clean. The lithium battery electrode slurry stirring-mixing tank comprises a tank body and an upper cover, wherein the inside of the tank body is arranged as a mixing chamber; the upper cover is arranged on a top opening; the upper cover is provided with a charging pipe and a cleaning device; the cleaning device consists of a water inlet pipe, a water pump and a spraying disk; a stirring device and a discharging device are arranged in the mixing chamber; the stirring device consists of a first motor, a stirring shaft, an upper stirring blade, a lower stirring blade, a helical stirring plate and a hair brush; the discharging device consists of a second motor, a discharging revolving shaft and a discharging plate. The lithium battery electrode slurry stirring-mixing tank can be used for efficiently stirring and mixing slurry in the tank body by the stirring device, and the hair brush can be used for rapidly and efficiently cleaning the used tank body in cooperation with the cleaning device.

Owner:SHENZHEN JUOCAN TECH CO LTD

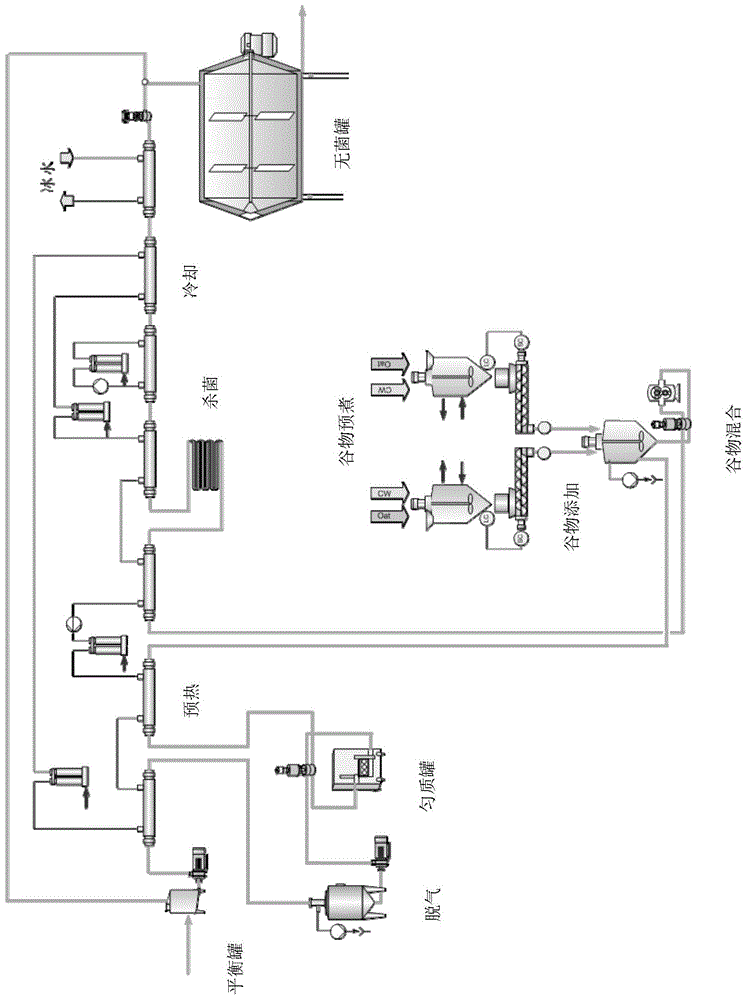

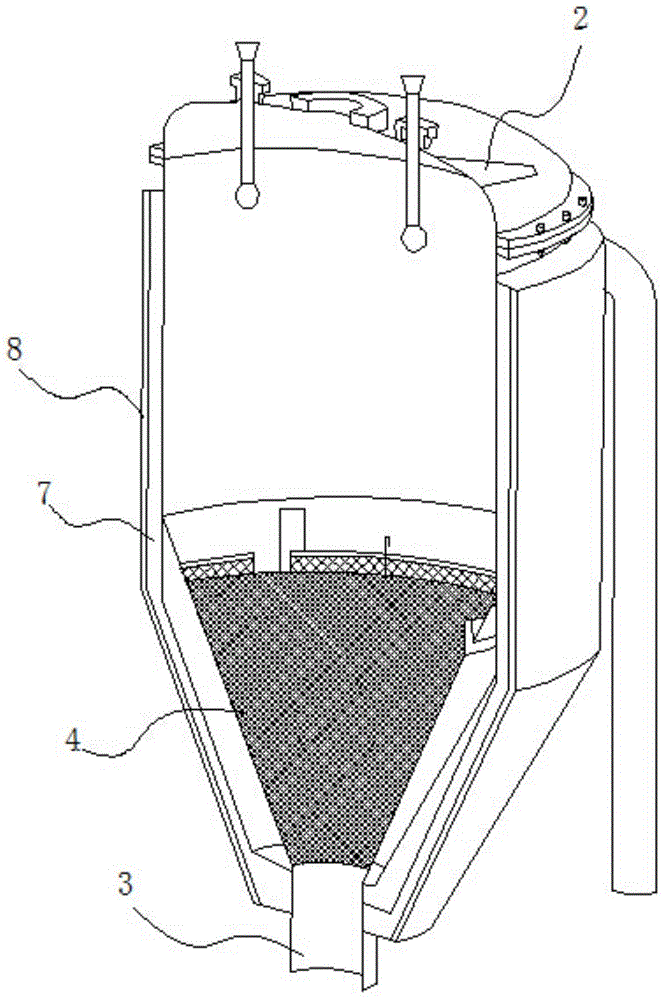

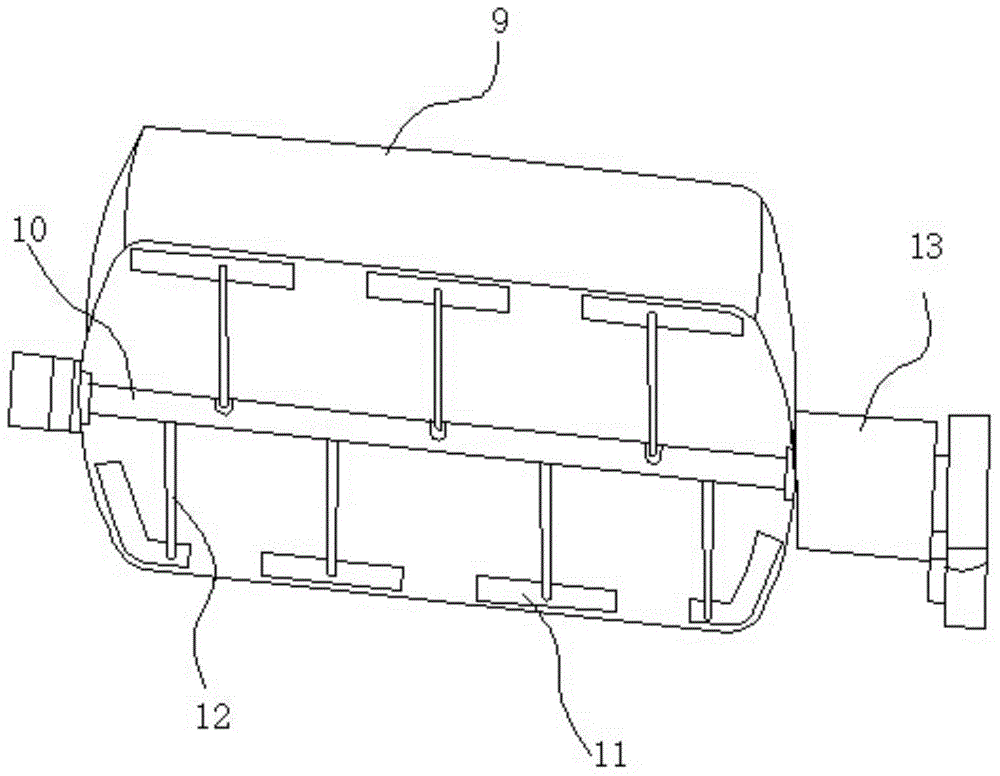

Continuous production process and devices of milk drink containing cereal grains

The present invention discloses a continuous production process and devices of milk drink containing cereal grains. The devices include an aseptic tank, a heat exchange sterilization conveying pipeline, and a grain adding device. The devices are characterized in that: the grain adding device includes a plurality of precooking tanks, mixing tanks and quantitative putting mechanisms. Cereals are put into the precooking tanks, water washing, draining, precooking, and cooling are carried out, the precooked cereal grains are continuously and quantitatively added into the mixing tanks through the quantitative putting mechanisms from the precooking tanks, at the same time, milk or drink is injected into the mixing tanks to be stirred and mixed together, then the mixture is subjected to heat sterilization, the sterilized mixture is cooled, the cooled mixture is injected into the aseptic tank to be stored and stirred, and finally the finished products are obtained by filling. The existing sterilization machine and aseptic tank structures are utilized, which achieves the production of the drink containing cereal grains or milk, online adding and continuous automatic filling, avoids pipeline blockage, improves productivity and reduces production costs.

Owner:GEA PROCESS ENG ASIA LTD

Stirring and mixing device for chemical fertilizer for crops

InactiveCN107583530AEfficient mixingStir wellRotary stirring mixersMixer accessoriesMotor driveReaction chamber

The invention provides a stirring and mixing device for chemical fertilizer for crops and belongs to the technical field of processing of chemical fertilizer for the crops. The stirring and mixing device comprises a tank body and an upper cover, wherein the tank body is arranged into a hollow cylinder; a reaction chamber is arranged inside the tank body; the upper cover is arranged at a top opening of the tank body; the upper cover is fixedly connected with the tank body by mutual screwing of bolts and nuts; in addition, the upper cover and the tank body are both made of steel materials. The stirring and mixing device provided by the invention is that a first motor in a driving device drives a rotary table to rotate; the rotary table drives a first stirring device and a second stirring device to revolve; the first stirring device and the second stirring device rotate in the meshing process of a first gear and a second gear and an inner gear ring; the revolution and the rotation are synchronously performed, so that efficient stirring and mixing of materials in the tank body are facilitated, and the stirring and mixing quality is improved; a third stirring device is arranged, a second motor drives a third stirring shaft to rotate, and the third stirring shaft drives a stirring frame to rotate, thereby stirring and mixing the materials at the bottom of the tank body.

Owner:李媛馨

Mixing equipment for polycarbonate modified material

PendingCN110252177AWell mixedEfficient stirring and mixingRotating receptacle mixersTransportation and packagingCouplingDrive shaft

The invention discloses mixing equipment for a polycarbonate modified material. The mixing equipment comprises a mixing box body; an inner cavity of the mixing box body is provided with a primary mixing barrel and a secondary mixing barrel; the upper end of the inner cavity of the mixing box body is provided with a mixing component; the mixing component is composed of a screw rod, a sliding seat, a first motor, a first stirring shaft, a first stirring blade, a transmission shaft, a first transmission gear, a driven gear and a driving gear; the middle of the outer bottom end of the secondary mixing barrel is provided with a second motor; the middle side of the inner end of the secondary mixing barrel is vertically provided with a second stirring shaft, and the end part of the bottom end of the second stirring shaft is connected with an output shaft of the second motor by a coupling; and the second stirring shaft is sleeved with a second stirring blade.

Owner:南京清研新材料研究院有限公司

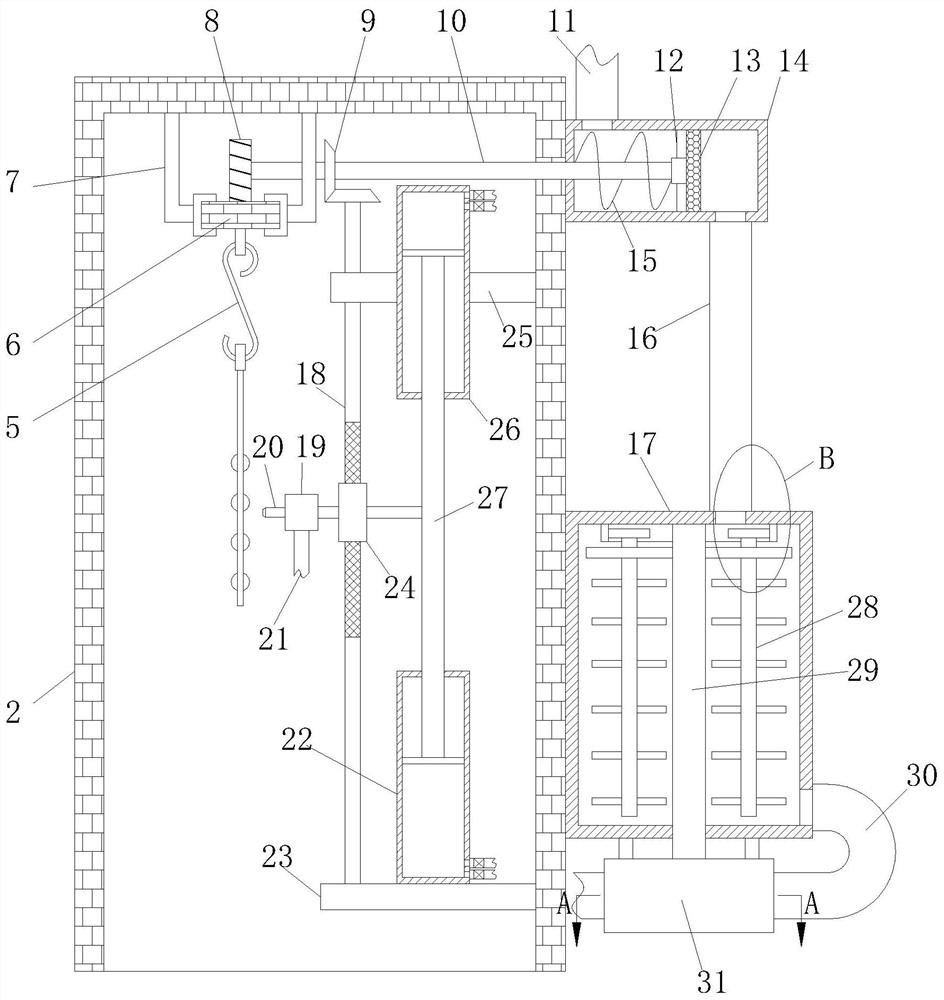

Chemical material stirring and mixing equipment with cleaning device

InactiveCN106693776AExpand the spraying areaSpraying speed is fastRotary stirring mixersTransportation and packagingEngineeringWater pipe

The invention provides chemical material stirring and mixing equipment with a cleaning device. The chemical material stirring and mixing equipment comprises a tank body; a mixing cavity is arranged in the tank body; an upper cover is arranged in an opening at the top part; the cleaning device is arranged on the upper cover; the cleaning device comprises a transmission case, a first motor, a water inlet pipe and a rotary spraying disc; a stirring device is arranged at the bottom part of the mixing cavity; the stirring device comprises a second motor, a stirring shaft, a horizontal stirring sheet, a vertical stirring sheet and a stirring plate; and the side wall of the rotary spraying disc is fixedly connected with a scraper plate. The spraying area and the spraying speed of clean water are increased and accelerated through the cleaning device, so that the used tank body can be conveniently efficiently cleaned; due to the arrangement of the stirring device, the material in the tank body is efficiently stirred and mixed through the horizontal stirring sheet, the vertical stirring sheet and the stirring plate; due to the arrangement of the scraper plate, the material adhered on the inner wall of the tank body is scraped, the material mixing accuracy is improved, the material can be completely discharged in the process of discharging the material, and the use ratio of the material is improved.

Owner:河南微服网络科技有限公司

Planetary magnetic stirring device

ActiveCN102861527AEfficient mixingEfficient stirring and mixingMixer accessoriesDriven elementMagnet

The invention provides a planetary magnetic stirring device. The planetary magnetic stirring device comprises a drive element, a planetary mechanism, a drive rotor, a material container, a lower stirring paddle, a paddle shaft, a paddle shaft support and an upper stirring paddle, the drive element is located below the planetary mechanism and drives the planetary mechanism to perform a planetary rotation, the drive rotor is located above the planetary mechanism connected with an extension shaft of the planetary mechanism, the material container is located above the drive rotor, a gap between the material container and the drive rotor is reserved, a ring-shaped magnet is fixed on the drive rotor, a stirring component is formed by combination of the lower stirring paddle, the paddle shaft, the paddle shaft support and the upper stirring paddle and arranged in the material container, the lower stirring paddle is installed at the lower end of the paddle shaft and fixed by a locating pin, a strip-shaped magnet is mounted in the lower stirring paddle, the upper stirring paddle is installed at the upper end of the paddle shaft and fixed by the locating pin, and the paddle shaft is in a clearance fit with the paddle shaft support. According to the planetary magnetic stirring device, a non-contact magnetic transmission is utilized, and problems of leakage, difficult connecting, sealing, installing and cleaning and the like during the stirring process are solved.

Owner:BEIJING UNIV OF CHEM TECH

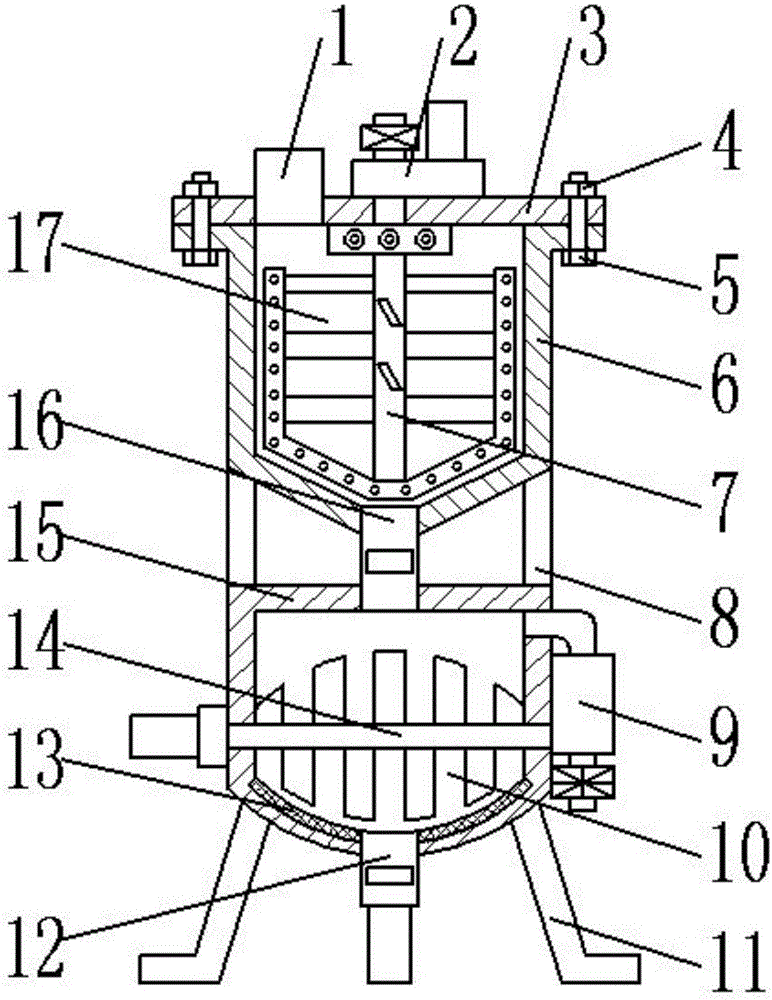

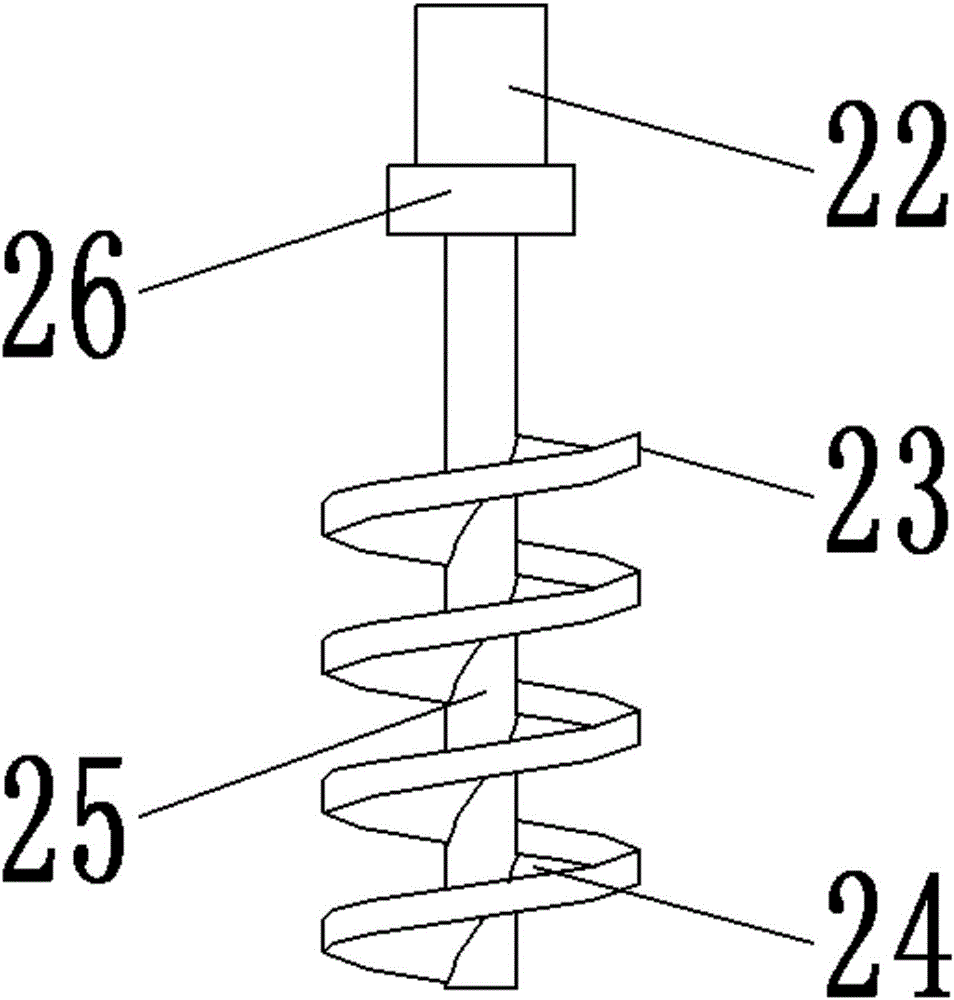

Chemical raw material smashing and stirring tank facilitating complete material discharge

InactiveCN106362636AImprove mix qualityEfficient stirring and mixingRotary stirring mixersTransportation and packagingRotational axisMotor drive

The invention provides a chemical raw material smashing and stirring tank facilitating complete material discharge. The tank comprises a tank body and an upper cover. A stirring cavity is formed in the tank body. The upper cover is provided with a feeding device and a water adding and driving device. The feeding device is composed of a feeding pipe, a smashing motor, a smashing rotary shaft, a fixed blade and a rotary blade. The water adding and driving device is composed of a transmission box, a first motor and a water inflow pipe. A material guiding pipe, a spiral stirrer and a scraping device are arranged in the stirring cavity. The spiral stirrer is composed of a stirring shaft and a spiral stirring blade. The scraping device is composed of a second motor, a rotary shaft and a scraper plate. The smashing motor drives the smashing rotary shaft to rotate, the smashing rotary shaft drives the rotary blade and the fixed blade to relatively rotate, and caked chemical raw materials are smashed. Through the arrangement of the water adding and driving device, the mixing quality of raw materials can be improved. Through the arrangement of the scraping device, the quality of products is improved, and complete material discharge is promoted during material discharge.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

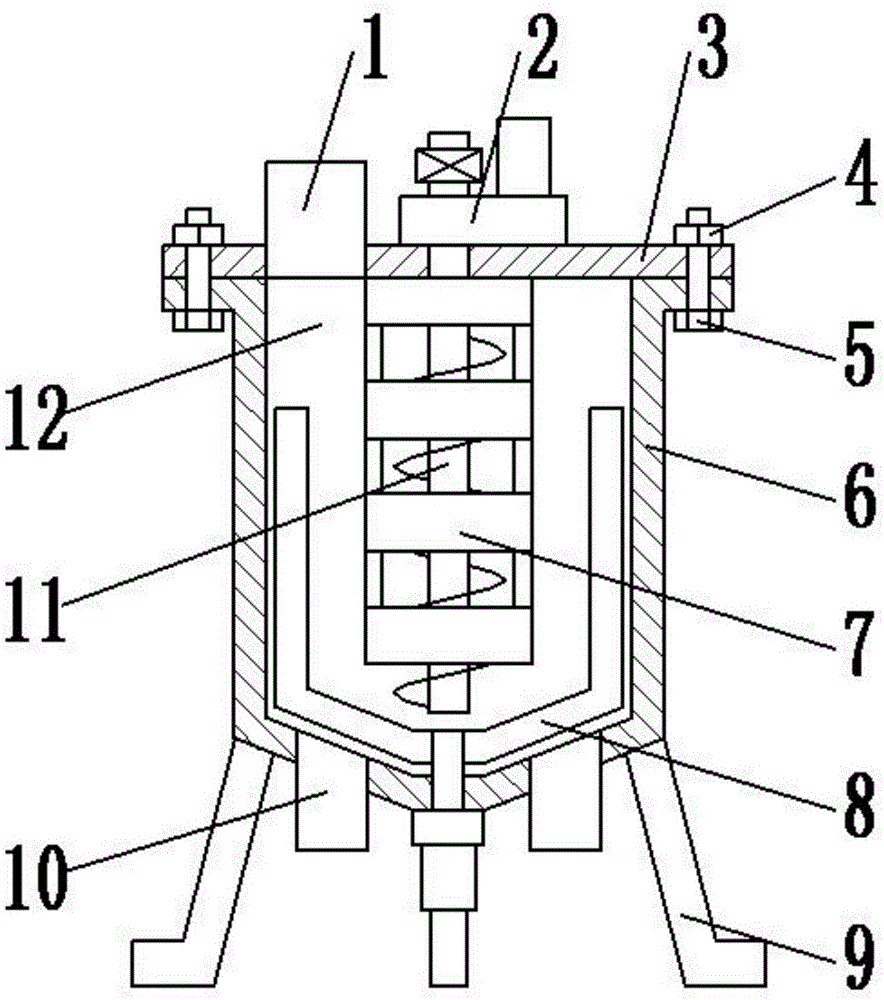

Pretreatment kettle for production of glass edge-wrapping material

PendingCN110302712APrevent concentrated accumulationReduce cloggingMixing methodsTransportation and packagingFixed frameEngineering

The invention discloses a pretreatment kettle for production of a glass edge-wrapping material. The pretreatment kettle comprises a foundation base, vertical fixing frames and a large-dip-angle conveying machine, a pretreatment kettle body is fixedly arranged between the middles of the vertical fixing frames, a material preparing mechanism is arranged between the upper ends of the vertical fixingframes and comprises a solid raw material treatment box, a liquid raw material storage tank, a material collecting bin, a material guiding pipe, a first motor and a material controlling plate, a driving grinding roller and a driven grinding roller are arranged at the upper end of an inner cavity of the solid raw material treatment box, a second motor is arranged on the outer side of the solid rawmaterial treatment box, a cylindrical frame sleeves an output shaft of the second motor, an inclined vibration mesh screen is arranged in the solid raw material treatment box, the first motor is arranged in the middle of the bottom end outside the material collecting bin, the material controlling plate is arranged on the middle side of the bottom end in the material collecting bin, and an inner cavity of the pretreatment kettle body is provided with a horizontal rotating frame, a stirring shaft, a stirring rod and a clearing frame.

Owner:南京汇科高分子材料有限公司

Dyeing raw material blending device for wig production

PendingCN113941264AImprove mixing effect and efficiencyWell mixedFlow mixersRotary stirring mixersProcess engineeringManufacturing engineering

The invention relates to the field of wig production equipment, in particular to a wig production dyeing raw material blending device which comprises a base; a third support fixed to the base, a mixing box fixed to the third support and used for blending and mixing dyeing raw materials, a cover plate fixed to the upper end of the mixing box, and a feeding hopper fixed to and communicated with the upper end of the side wall of the mixing box. The dyeing machine further comprises a stirring and mixing mechanism which is arranged on the bottom face of the cover plate and used for efficiently mixing and stirring the dyeing raw materials in the material mixing box; a circulating mechanism which is arranged on the upper surface of the cover plate, wherein the circulating mechanism is used for enabling the dyeing raw materials in the material mixing box to circularly flow; and a reciprocating type transmission mechanism which is arranged on the upper surface of the cover plate, wherein the reciprocating type transmission mechanism is in transmission connection with the stirring and mixing mechanism and the circulating mechanism. According to the dyeing raw material blending device for wig production, the stirring effect and efficiency of dyeing raw materials are improved, and the dyeing raw materials are mixed more uniformly.

Owner:邵阳市鸿宇发制品有限公司

Powdery material drying equipment with dehumidifying device

InactiveCN106500482AImprove drying qualityDry evenlyDrying solid materials with heatDrying gas arrangementsMicrowaveBiochemical engineering

The invention provides powdery material drying equipment with a dehumidifying device. The powdery material drying equipment comprises a tank body and an upper cover, wherein the inner part of the tank body is provided with a drying cavity; a feeding device is arranged on the upper cover; the feeding device consists of a feeding tank, a pulverizing motor, a pulverizing rotating shaft, a rotating blade and a fixed blade; a stirring device and a circulating lifting device are arranged in the drying cavity; the stirring device consists of a second motor, a stirring shaft and a stirring blade; the circulating lifting device consists of a first motor, a lifting rotating shaft and a spiral lifting blade; a microwave heater is embedded in the tank body; the dehumidifying device is arranged on the side wall of the top of the tank body; and the dehumidifying device consists of a dehumidifying pipe, a filtering tank and a dehumidifier. By carrying out crushing treatment on blocky materials through the feeding device, the improvement of material drying quality is facilitated, and the drying speed is accelerated; heat transferring is facilitated through the stirring device; and the circulating stirring of the materials is realized through the circulating lifting device, and the efficient drying of the materials is facilitated.

Owner:河南微服网络科技有限公司

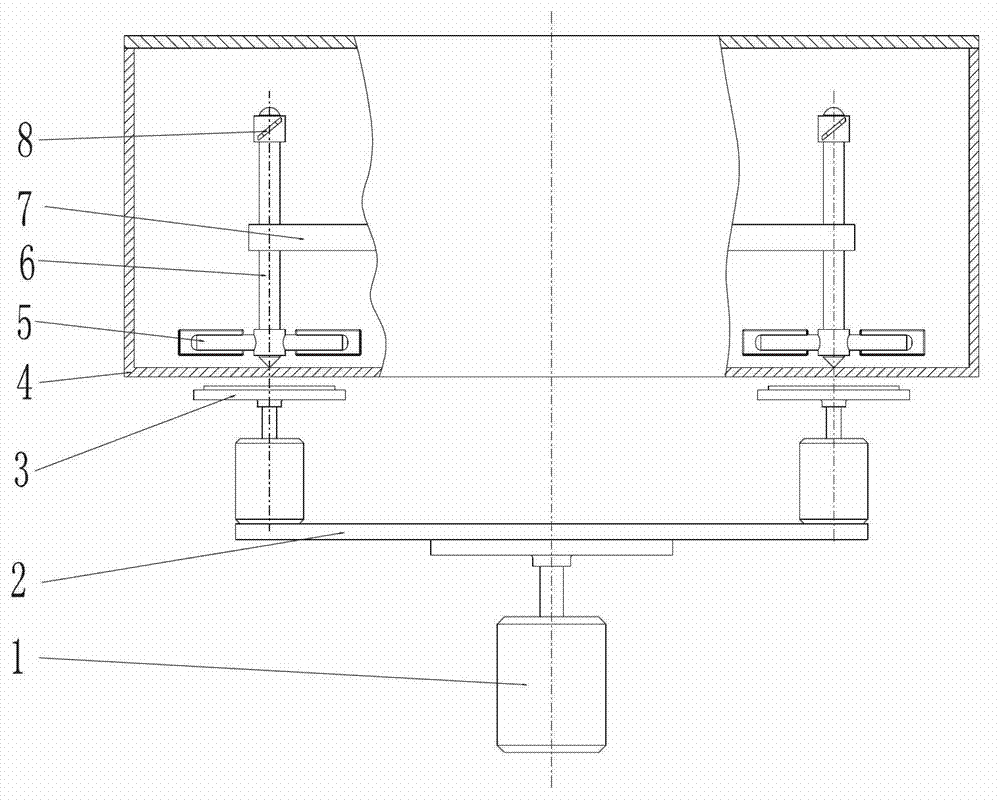

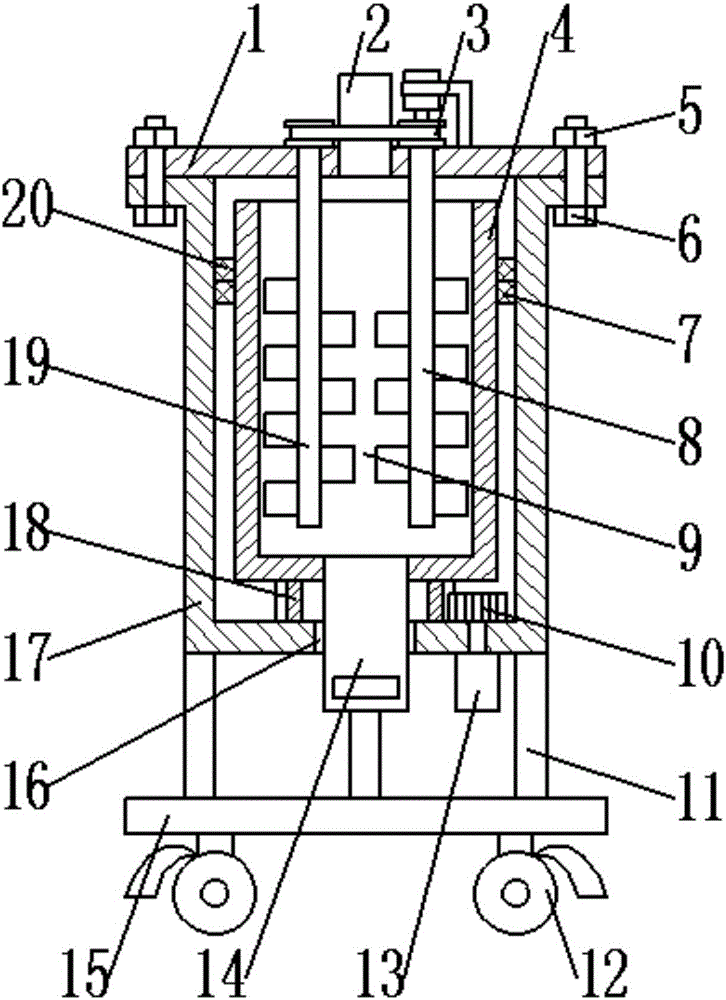

Chemical material reaction device with two stirring devices

InactiveCN106492739AEfficient stirring and mixingFully contactedFeed devicesChemical/physical/physico-chemical moving reactorsMotor driveEngineering

The invention provides a chemical material reaction device with two stirring devices. The chemical material reaction device comprises an outer tank and an inner tank, a discharging pipe mounting hole is formed in the bottom of the outer tank, the inner tank is arranged in the outer tank, an upper cover is arranged at an opening in the top of the outer tank, a feeding pipe and a driving device are arranged on the upper cover, the driving device comprises a first motor, a first driving wheel, a second driving wheel and a driving belt, an upper circular ring is fixed on the outer surface of the inner tank, a lower circular ring is arranged on the lower surface of the upper circular ring, a reaction cavity is formed in the inner tank, a first stirring device and a second stirring device are arranged in the reaction cavity, a discharging device is arranged on the bottom surface of the inner tank, the bottom surface of the outer tank is connected with a bottom plate through a support, and casters are arranged on the bottom surface of the bottom plate. According to the reaction device, a second motor drives the inner tank to rotate, so that materials are conveniently and efficiently stirred and mixed by the first stirring device and the second stirring device, reaction materials more sufficiently contact with each other, and more complete reaction is facilitated.

Owner:河南微服网络科技有限公司

Nutrient solution raw material anti-pollution mixing equipment used for biological medicine

InactiveCN106390841AAvoid pollutionAvoid introducingTransportation and packagingMixersCulture fluidEngineering

The invention provides nutrient solution raw material anti-pollution mixing equipment used for biological medicine. The nutrient solution raw material anti-pollution mixing equipment used for biological medicine comprises a tin body. A stirring cavity is arranged inside the tin body; a feed pipe and an air blowing and driving device are arranged on the top of the tin body; the air bowing and driving device is composed of a transmission box, a first motor and an air inlet pipe; a forward direction stirrer and a backward direction stirrer are arranged in the stirring cavity; the forward direction stirrer is composed of a forward direction stirring shaft, a forward direction stirring blade, a material scratching plate and a gas ejector pipe; the backward direction stirrer is arranged in the bottom of the tin body and is composed of a second motor, a backward direction stirring shaft and a backward direction stirring blade; and a support is arranged in the bottom of the tin body. The arrangement of the air blow and driving device allows air and the nutrient solution raw material to be subjected to contact evenly, which brings convenience to full mixing of the nutrient solution raw material; The backward direction stirrer is used to be subjected to backward direction stir on the nutrient solution raw material and coordinates with the forward direction stirrer to be subjected to efficient stirring and mixing on the nutrient solution raw material, so that the quality of the nutrient solution is improved.

Owner:ZHENGZHOU TIANSHUN ELECTRONICS TECH CO LTD

Efficient stirring mechanism, and environment-friendly pedestal pan using same

PendingCN111603969AExtend the mixing timeImprove mixing effectWater closetsTransportation and packagingElectric energyPower grid

Owner:四川升腾元创机电技术研究有限公司

Light pressure rotator and light pressure rotating device

InactiveUS7963691B2Efficient stirring and mixingPressure be relatively less heavyFrom solar energyRotary stirring mixersEngineeringIrradiation

The light pressure rotator (1) is the light pressure rotator being light pressure trapped by irradiation with light and light pressure rotating about the central axis O of rotation, characterized in that a reverse torque generating section generating a torque for rotating the rotator in the direction reverse to the predetermined direction is removed from a section arranged with three blades (2) each having a first side face (3) extending in the radial direction from the central axis O of rotation, a second side face (4) facing the central axis O of rotation, a third side face (5) facing the first side face (3), a lower surface (6) intersecting the central axis O of the rotation, and an upper surface (7) facing the lower surface (6). The light pressure rotating device comprises the light pressure rotator (1), a light source (C), and an objective (condenser) lens D.

Owner:THE RITSUMEIKAN TRUST

Plant total nutrition special granular fertilizer and preparation method thereof

PendingCN110683887AAchieve integrationGood effectPotassium fertilisersFertilizer mixturesAgricultural scienceNutrition

The invention discloses a plant total nutrition special granular fertilizer and a preparation method thereof, and belongs to the technical field of fertilizers. The fertilizer comprises the followingraw materials in parts by weight: 100-150 parts of crushed and fermented garden waste, 30-50 parts of a humectant, 10-15 parts of a pH regulator, 15-20 parts of a insecticide, 15-20 parts of a bactericide, and 5-10 parts of mineral nutrition elements, wherein the mineral nutrition elements are composed of hydrogen, carbon, oxygen, nitrogen, potassium, and calcium. Through the development of the plant total nutrition special granular fertilizer, the crushed and fermented garden waste can be effectively used, integration of an organic fertilizer and a chemical fertilizer is realized, and an appropriate amount of the additives is added to realize water and fertilizer conservation. According to different plants and different growing periods, different special granular fertilizers are prepared,there is no such special granular fertilizer on the market, and the special granular fertilizer is not easy to prepare.

Owner:东营市园林绿化中心

Ultralight clay foaming equipment

InactiveCN110303574AEasy to rollEfficient stirring and mixingMixing operation control apparatusPretreatment controlSolenoid valveDrive shaft

The invention discloses ultralight clay foaming equipment, and belongs to the technical field of clay foaming. The ultralight clay foaming equipment comprises a stirring cylinder, the upper end of thestirring cylinder is fixedly connected with a first feeding funnel, the first feeding funnel communicates with the stirring cylinder, a main controller is fixedly connected to the left end of the stirring cylinder, a discharging port is fixedly connected to the lower end of the stirring cylinder, the discharging port communicates with the stirring cylinder, an electromagnetic valve is installed on the discharging port, the electromagnetic valve is electrically connected with the main controller, the front inner wall of the stirring cylinder is sequentially and rotationally connected with a first driving shaft and a first driven shaft from left to right, the rear end of the first driving shaft and the rear end of the first driven shaft penetrate through the stirring cylinder, the circumferential surface of the first driving shaft and the circumferential surface of the first driven shaft are fixedly connected with a driving grinding roller and a driven grinding roller respectively, a first motor is fixedly connected to the rear end of the stirring cylinder, and the first motor is positioned on the left side of the first driving shaft. According to the ultralight clay foaming equipment, uniform mixing is achieved, and the quality of finished products is effectively improved by adopting the extruding mode after full stirring.

Owner:山东博士爱文具有限公司

Fosaprepitant supercritical reaction preparation method

InactiveCN109608498AEfficient stirring and mixingImprove production efficiencyGroup 5/15 element organic compoundsPressure vessel componentsHydrogenFiltration

The invention discloses a fosaprepitant supercritical reaction preparation method, and solves the problems of low stirring efficiency, separate reaction and filtration on different equipment, and longoperation period in existing fosaprepitant supercritical reaction preparation. The method includes the steps of: feeding, air replacement, filling of hydrogen and carbon dioxide, heating and stirringfor supercritical reaction, dissolution of the reaction product by a solvent and filtration. The method provided by the invention has the advantages of high stirring efficiency, short preparation period, etc.

Owner:SICHUAN PHARMA

Asphalt stirring equipment

The invention discloses asphalt stirring equipment. A box body is included. An open middle inner cavity is formed in the box body; a bottom opening is formed in a lower end wall of the middle inner cavity in a connection manner; a power transmission inner cavity located in the box body is formed in one side of the middle inner cavity; a plurality of electric heating stirring devices which are usedfor stirring in a crossed manner and can adopt electric heating to raise a temperature are rotatably arranged between the end walls of the two sides of the middle inner cavity; an electric heating stirring device is arranged on one side; the plurality of electric heating stirring devices are arranged on the other side; and a single-body driving device and a multi-body driving device for driving the electric heating stirring devices on the two sides to rotate are arranged in the box body. The asphalt stirring equipment is simple in structure, a design of multiple sets of stirring cylinders isadopted, electric heating wires are arranged in the stirring cylinders, and asphalt is fully stirred through the electric heating wires on the premise that the distance between the multiple sets of stirring cylinders can be adjusted.

Owner:福建省华实建工集团有限公司 +1

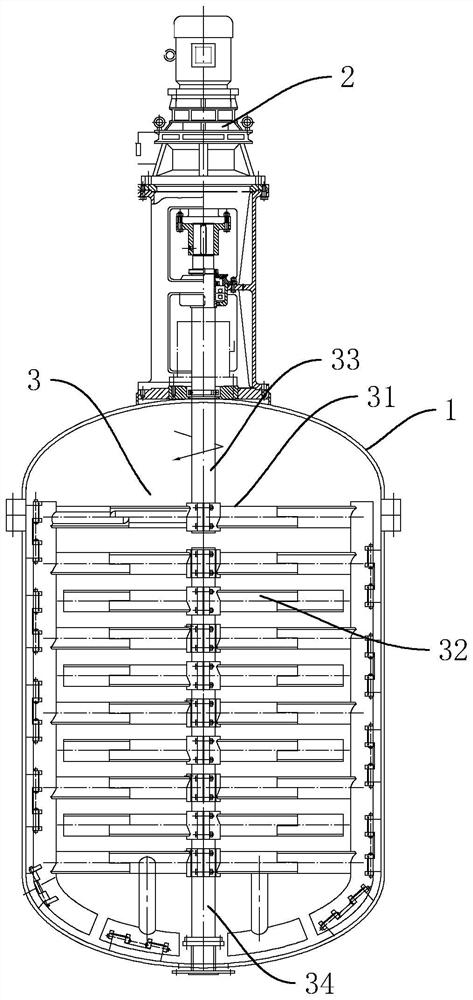

Stirring equipment with positive and negative cross flow mixing function

PendingCN114452857AEfficient stirring and mixingEnergy efficientRotary stirring mixersTransportation and packagingEngineeringAgitator

The stirring equipment comprises a kettle body, a driving assembly arranged on the kettle body and a stirring assembly arranged in the kettle body, the driving assembly is used for driving the stirring assembly to execute stirring action, the stirring assembly comprises a movable stirrer and a fixed stirrer, the movable stirrer is in linkage with the driving assembly, and the fixed stirrer is in linkage with the movable stirrer. The driving assembly is used for driving to rotate and stir; the fixed stirrer is fixed in the kettle body; materials are stirred in the kettle body through the movable stirrer and the fixed stirrer, and blades of the fixed stirrer and the movable stirrer face opposite directions. According to the invention, positive and negative cross flow mixing can be realized only by using one driving device, so that a good stirring effect can be achieved, and energy consumption can be reduced.

Owner:浙江长城搅拌设备股份有限公司

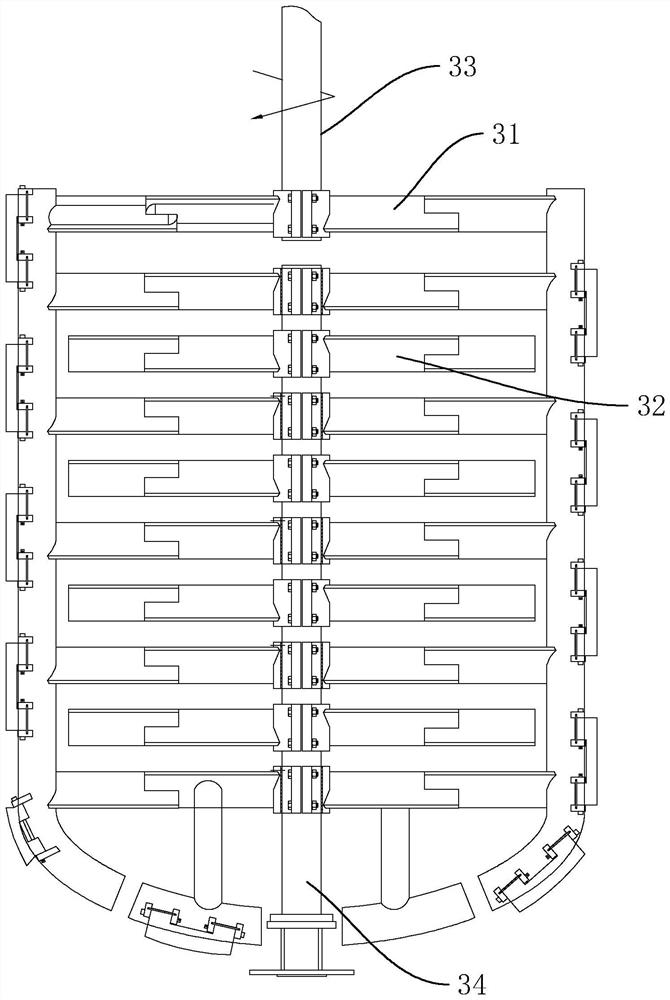

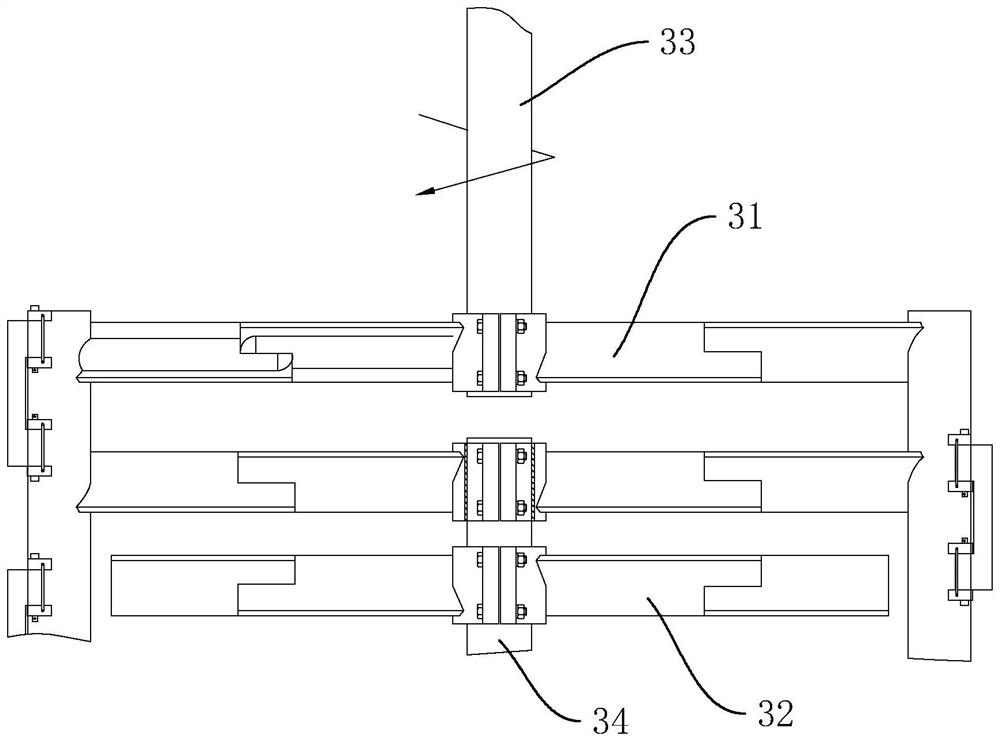

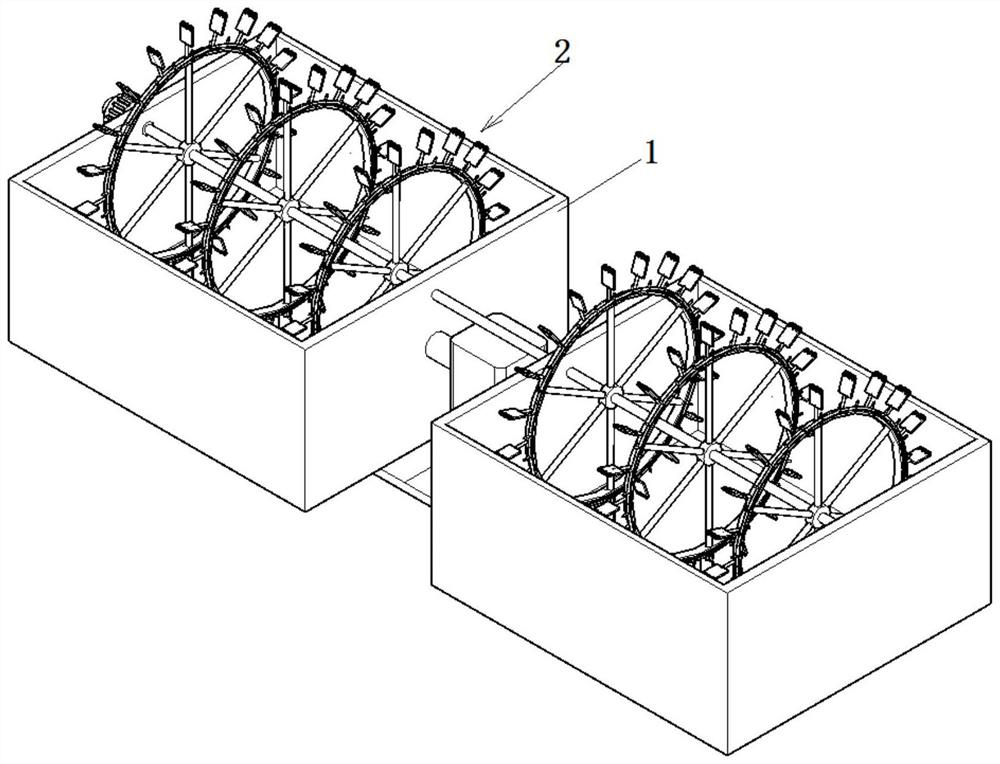

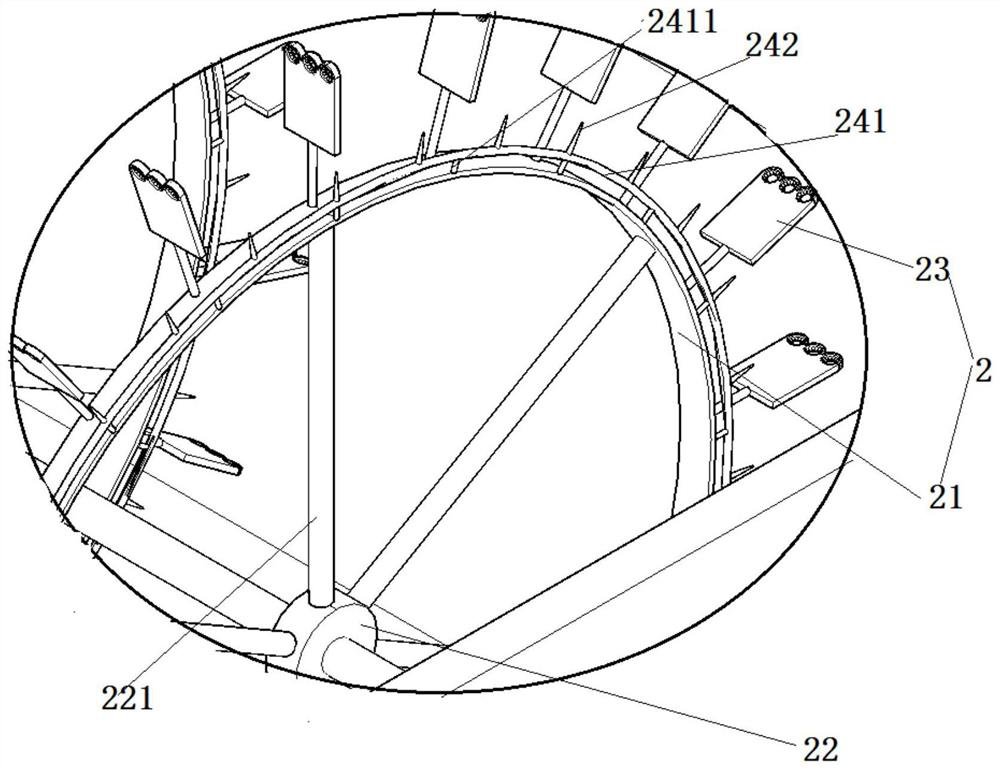

Dispersing, mixing and stirring device for getter processing

PendingCN113457553AImprove processing productivityEfficient stirring and mixingRotary stirring mixersDrive shaftElectric machinery

The invention discloses a dispersing, mixing and stirring device for getter processing. The dispersing, mixing and stirring device comprises a plurality of mixing box bodies which are arranged left and right at intervals; mixing assemblies are assembled and connected in the mixing box bodies; the mixing assemblies are assembled and connected through a rotary driving shaft; each mixing assembly comprises a plurality of mixing parts which are arranged at intervals left and right, each mixing part comprises a rotating ring body, each rotating ring body is fixedly connected with a plurality of stirring parts, each stirring part comprises a material plate body, each material plate body is provided with a plurality of curved-surface bulges, each curved-surface bulge is provided with a through hole, and the hole wall of each through hole is fixedly connected with a plurality of material crushing conical rods; a central seat is concentrically arranged on the rotating ring body, and a plurality of connecting rods are fixedly connected between the inner side wall of the rotating ring body and the central seat; the rotary driving shaft penetrates through the central seat and the side wall of the mixing box body; a driving motor is assembled and connected to the end part of the rotary driving shaft; and according to the design of the parts of the device, the machining production efficiency of the getter is effectively improved in the getter machining process.

Owner:安徽有研吸气材料有限公司

Workpiece surface spraying and curing production line

InactiveCN113649215AHigh degree of automationImprove production and processing efficiencyLiquid spraying apparatusSpray boothsProduction linePowder Spray

The invention relates to the field of workpiece surface spraying equipment, in particular to a workpiece surface spraying and curing production line which comprises a curing oven, a powder spraying room, a feeding room and a conveying line used for conveying workpieces. The curing oven is in a circular arc shape, an automatic up-down type powder spraying mechanism and a material pumping mechanism are arranged in the powder spraying room, and the automatic up-down type powder spraying mechanism is in transmission connection with the conveying line. The material pumping mechanism is used for conveying paint to the automatic up-down type powder spraying mechanism, the automatic up-down type powder spraying mechanism is in transmission connection with the material pumping mechanism, a material mixing mechanism used for mixing paint is arranged on the outer side of the powder spraying room, and the material pumping mechanism drives the material mixing mechanism to work in the flowing process of the paint by sucking the paint; and a feeding assembly used for hanging workpieces on the conveying line is arranged in the feeding room. According to the workpiece surface spraying and curing production line, automatic machining of conveying, spraying and feeding of the workpieces is achieved, the automation degree is greatly improved, the labor intensity is reduced, the production efficiency is improved, and the spraying quality of the workpieces is improved.

Owner:邵阳市君伟建材有限公司

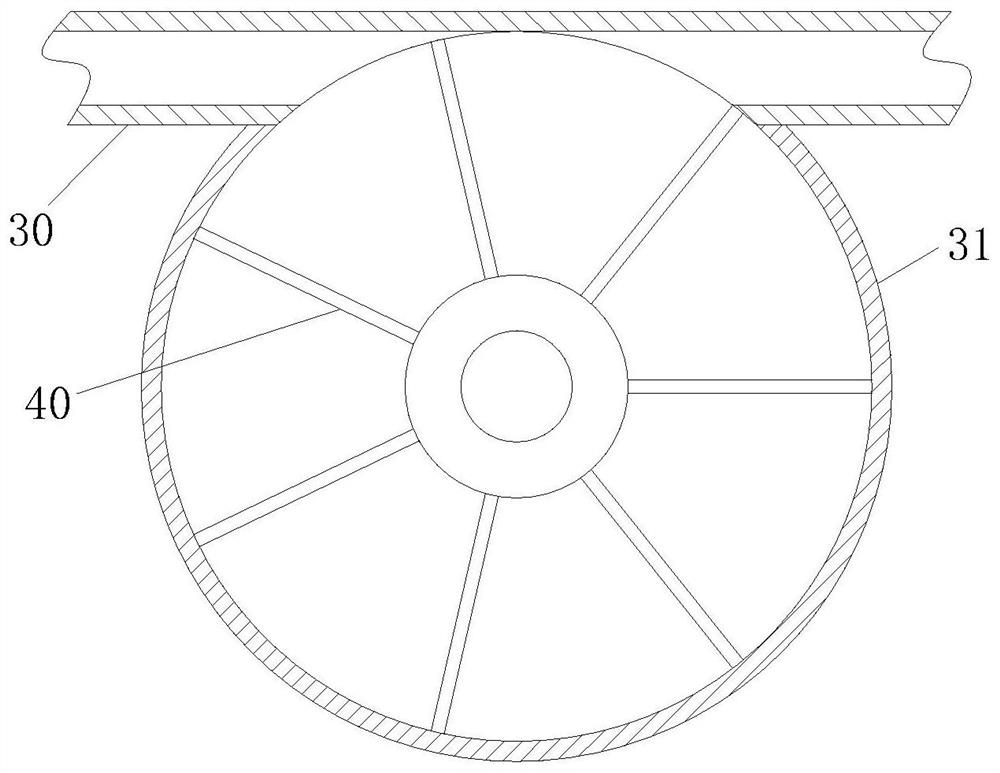

Combined helical fan flow mixing water distributor

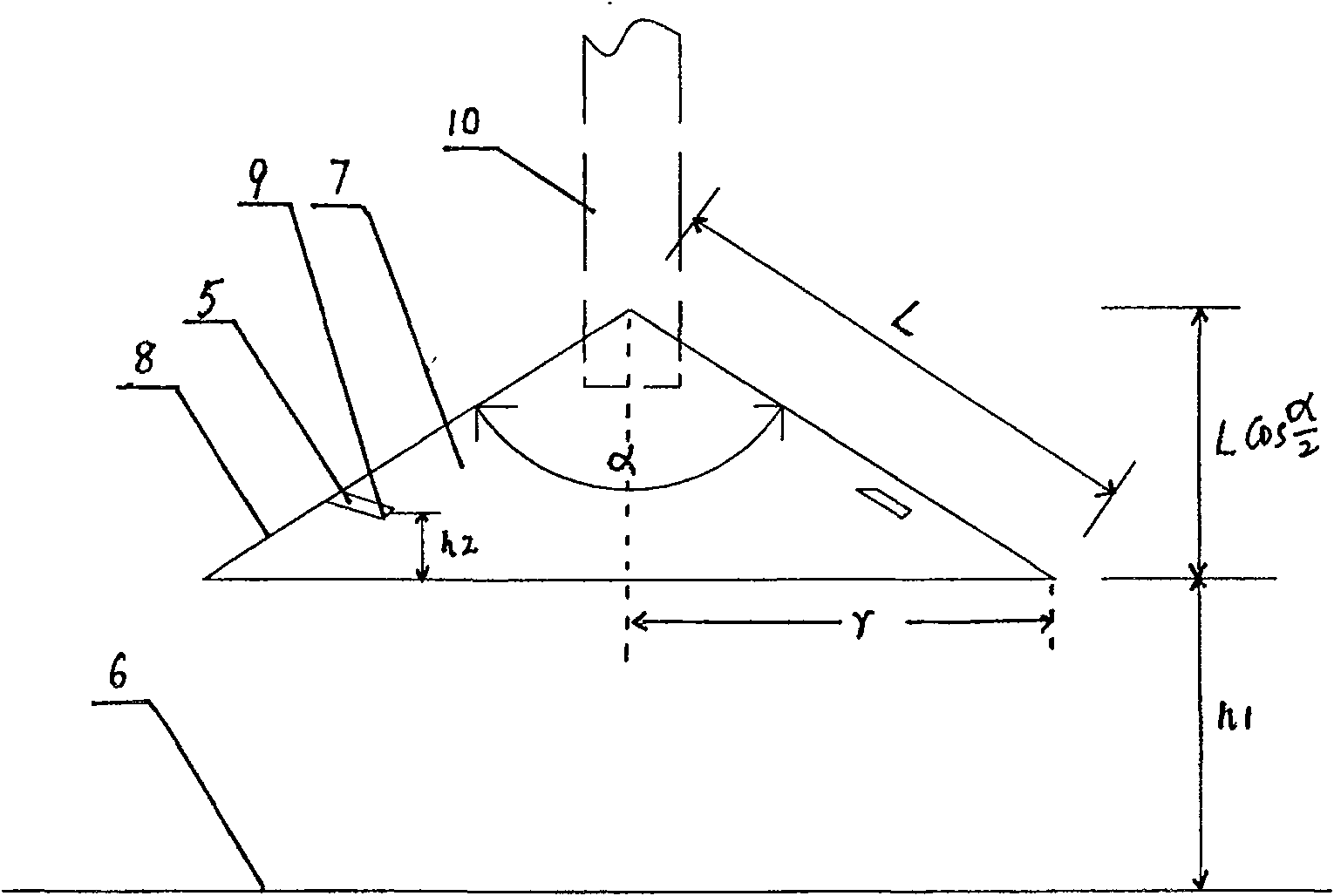

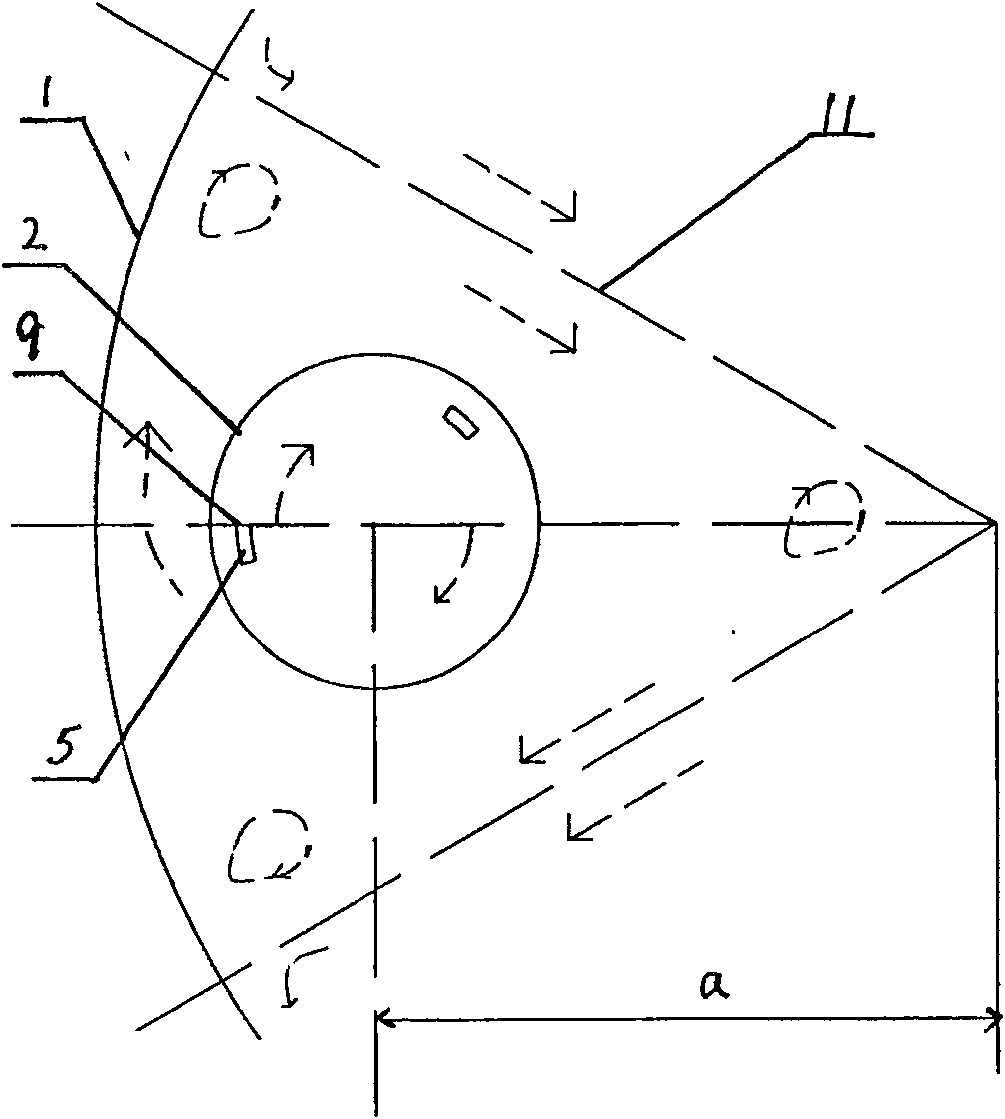

InactiveCN100540484CGood for enhancing mass transferConducive to survivalTreatment with anaerobic digestion processesReaction zoneEngineering

The invention discloses a water distributor for combined spiral fan-current stirring, comprising a swirl mask and an intake pipe for sewage. The invention is characterized in that: 1. four swirl masks (the diameter thereof is more than or equal to 6 m and less than or equal to 16 m), or six swirl masks (the diameter thereof is more than or equal to 12 m and less than equal to 28 m) are evenly distributed at the places with a distance of a to the center of the reactor; the apex angle of the shaft plane thereof is alpha; the side length is L, the radius of the bottom is r and the height from the bottom to the bottom part of the enclosure of an anaerobic reactor is h1. 2. the lower parts of two to four wastewater intake branches (the diameter thereof ranges from 6m to 16m) or three to five wastewater intake branches (the diameter thereof ranges from 12m to 28m) vertically go through the swirl masks respectively. The outlets of the wastewater intake branches with same diameter, same swirl-flow direction and forming an angle beta downwards with the level in the shearing direction are arranged evenly on the place of the internal wall and keeping a distance of h2 from the mask bottom to enable the swirl generated by wastewater to keep in the same direction. 3. the swirl flow direction formed by a plurality of swirl masks enables the intersection of any two swirls to keep the same flow direction. The invention has the advantages of high effective stirring and mixing, being beneficial to enhancing mass transfer in reaction zones and the existence of granular sludge, simple structure, low manufacturing and operation cost.

Owner:陈协

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com