Combined helical fan flow mixing water distributor

A technology of stirring water distributor and fan flow, which is applied in the field of high-efficiency anaerobic treatment equipment, can solve the problems of not being given, narrow application range, etc., and achieve the effect of simple structure, low cost and operation cost, and favorable effects for survival

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

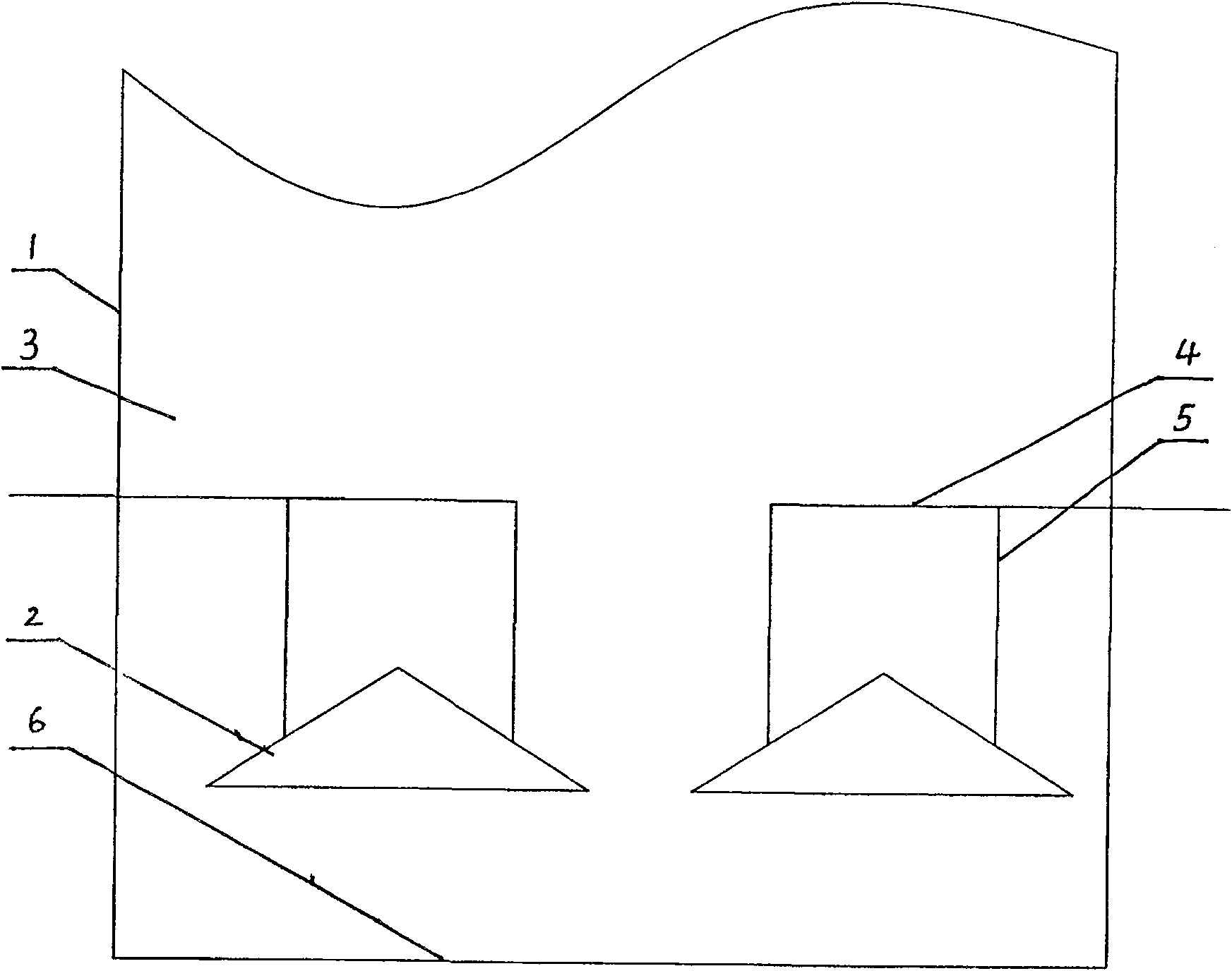

[0033] Example 1: A cylindrical high-efficiency anaerobic reactor with a diameter of 6m≤D≤16m

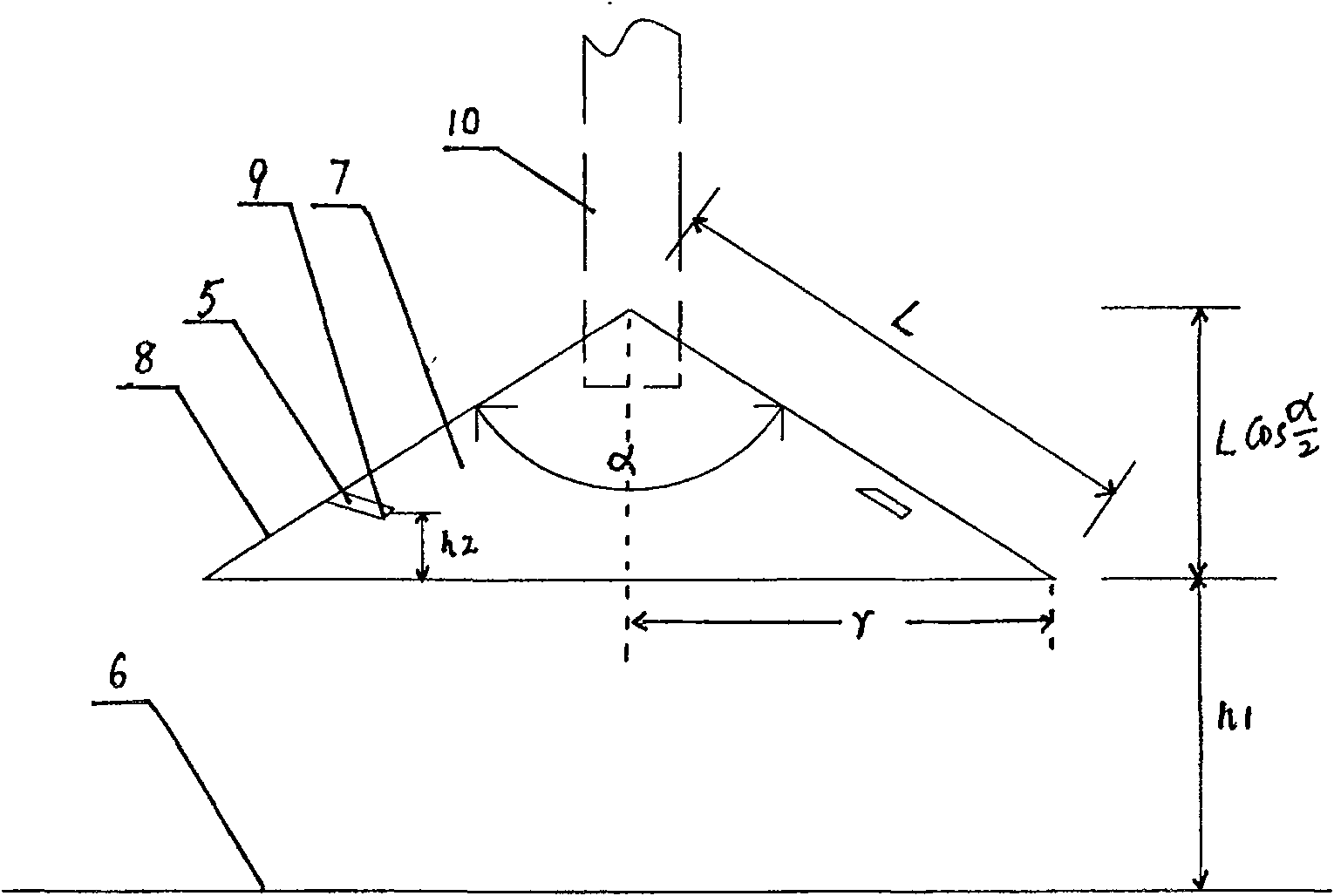

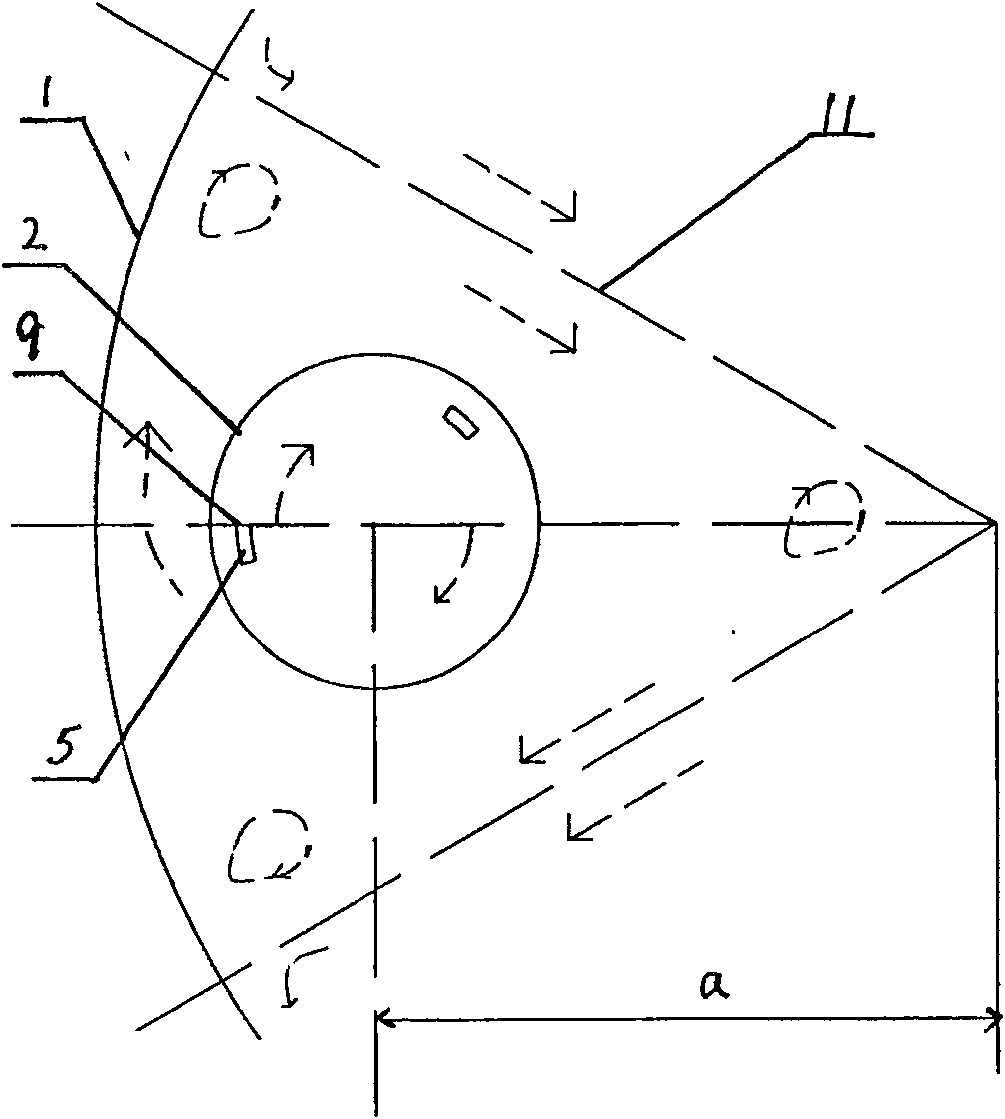

[0034] The present invention comprises the swirl hood 2 installed at the lower part of the lower reaction chamber 3 in the reactor housing 1, one end of the waste water input pipe 4 above the swirl hood 2 is connected to the waste water main pipe, and the other end passes through the reactor housing 1. The side wall enters the lower reaction chamber 3 and connects to the waste water input branch pipe 5, and there are 4 uniformly distributed at a distance from the center of the reactor, the apex angle of the axis plane is α, the side length is L, and the bottom radius is r ( r = Lsim α 2 ) , The height from the bottom to the bottom of the anaerobic reactor shell is h 1 The swirl hood 2.

[0035] Each swirl hood 2 has 2-4 waste ...

Embodiment 2

[0065] Example 2: A cylindrical high-efficiency anaerobic reactor with a diameter of 12m≤D≤28m

[0066] The structure of embodiment 2 is basically the same as embodiment 1, the difference is:

[0067] There are 6 evenly distributed at a distance from the center of the reactor, the axis plane vertex angle is α, the side length is L, and the bottom radius is r ( r = Lsim α 2 ) , The height from the bottom to the bottom of the anaerobic reactor shell is h 1 The swirl hood 2.

[0068] Each swirl hood 2 has 3-5 waste water input branch pipes 5, the upper ends of the 3-5 waste water input branch pipes 5 are all connected to the waste water input pipe 4, and the lower ends of the 3-5 waste water input branch pipes 5 pass through the swirl hood vertically respectively 2. The height from the bottom of the swirl hood 2 is h 2The outlet 9 of the wast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com