Ni-Rh-based diesel reforming catalyst and preparation method and application thereof

A technology for reforming catalysts and diesel oil, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., and can solve problems such as unsuitable for mass production and low dispersion of active metals in Ni-Rh-based catalysts , achieve important market value and promotion value, improve micro-mixing efficiency, and improve mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

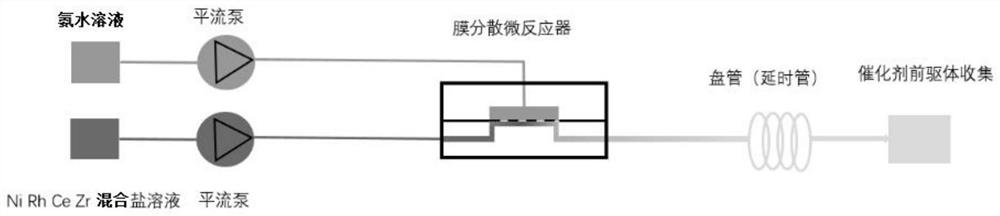

[0027] The invention provides a kind of preparation method of Ni-Rh base diesel oil reforming catalyst, comprises the following steps:

[0028] In the membrane dispersion microreactor, the mixed salt solution of nickel salt, rhodium salt, cerium salt and zirconium salt enters the main channel of the membrane dispersion microreactor as the continuous phase, and the ammonia solution enters the membrane dispersion microreactor as the dispersed phase. After the microfiltration membrane of the microreactor is sheared, it is mixed with the continuous phase for co-precipitation reaction to obtain a slurry;

[0029] Aging and separating the slurry in sequence to obtain a catalyst precursor;

[0030] The catalyst precursor is sequentially dried, calcined and reduced to obtain a Ni-based diesel reforming catalyst;

[0031] In the nickel salt, rhodium salt, cerium salt and zirconium salt, the molar ratio of Ce to Zr is (1~9):1, the molar ratio of Ce to Ni is (1~10):1, and the molar rati...

Embodiment 1

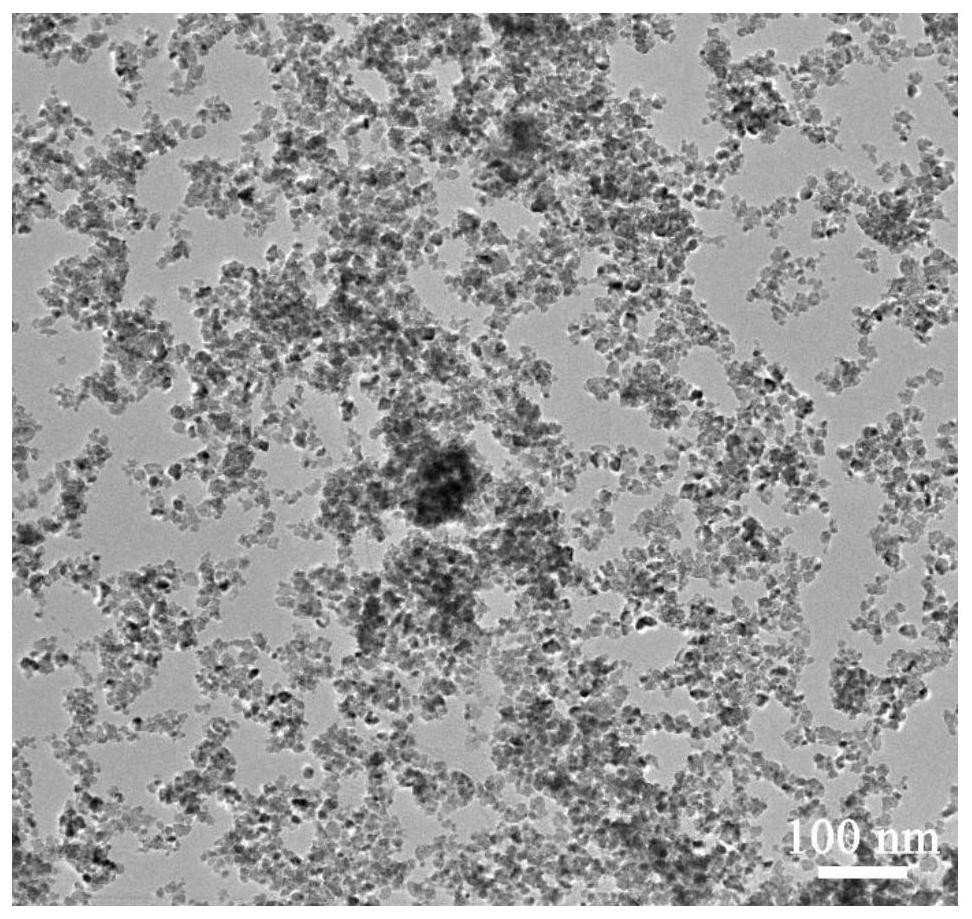

[0055] Dissolve zirconium nitrate and cerium nitrate in water, stir and mix at normal temperature for 6h, add nickel nitrate and rhodium nitrate successively, continue stirring at normal temperature for 6h, obtain mixed salt solution (total ion concentration is 0.2mol / L, Ce:Zr:Ni: The Rh molar ratio is 42:14:15:1) and ammonia solution (0.2mol / L) were loaded into two Erlenmeyer flasks respectively, and the membrane dispersion microreactor was placed in a water bath at 40°C, and the mixed salt solution was used as The continuous phase enters the main channel (length 40mm, width, height 1mm), and the ammonia solution passes through the microfiltration membrane of the membrane dispersion microreactor as the dispersed phase (pore diameter 5 μm, open porosity ≤ 60%, size 3mm (length) × 1mm (width)) after shearing, and then mixed with the continuous phase in the main channel to carry out co-precipitation reaction; wherein, the flow rate of the continuous phase is within the range of 1...

Embodiment 2

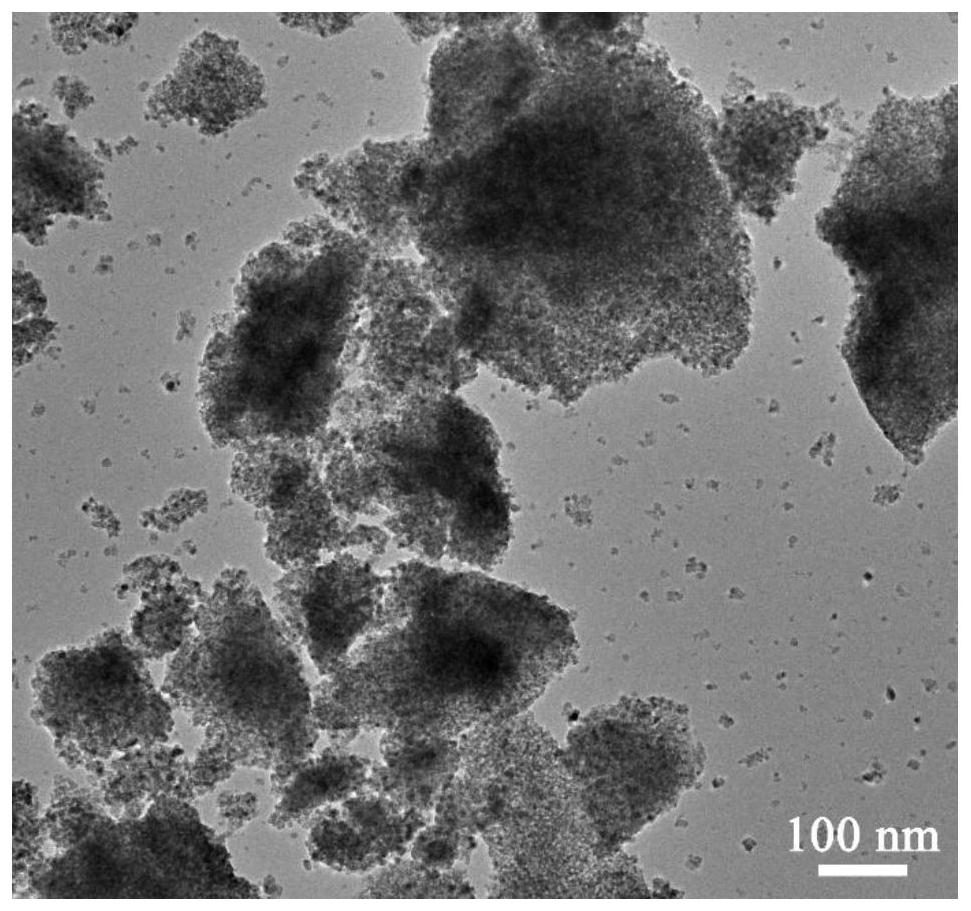

[0059] Dissolve zirconium nitrate and cerium nitrate in water, stir and mix at normal temperature for 6h, add nickel nitrate and rhodium nitrate successively, continue stirring at normal temperature for 6h, obtain mixed salt solution (total ion concentration is 0.4mol / L, Ce:Zr:Ni: The Rh molar ratio is 42:14:15:1) and ammonia solution (0.4mol / L) were loaded into two Erlenmeyer flasks respectively, and the membrane dispersion microreactor was placed in a water bath at 40°C, and the mixed salt solution was used as The continuous phase enters the main channel (length 40mm, width, height 1mm), and the ammonia solution passes through the microfiltration membrane of the membrane dispersion microreactor as the dispersed phase (pore diameter 5 μm, open porosity ≤ 60%, size 3mm (length) × 1mm (width)) after shearing, then mixed with the continuous phase in the main channel, and carried out co-precipitation reaction for 20min; wherein, the flow rate of the continuous phase is 10mL / min, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com