Intelligent reaction system and method for preparing halogenated benzaldehyde by oxidizing halogenated toluene

A halogenated benzaldehyde and a reaction system technology, which is applied in the field of intelligent reaction systems for preparing halogenated benzaldehyde by oxidizing halogenated toluene, can solve the problems of low oxygen utilization rate, high labor cost, difficult waste gas treatment, etc. Effects of temperature distribution, high oxygen utilization rate, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

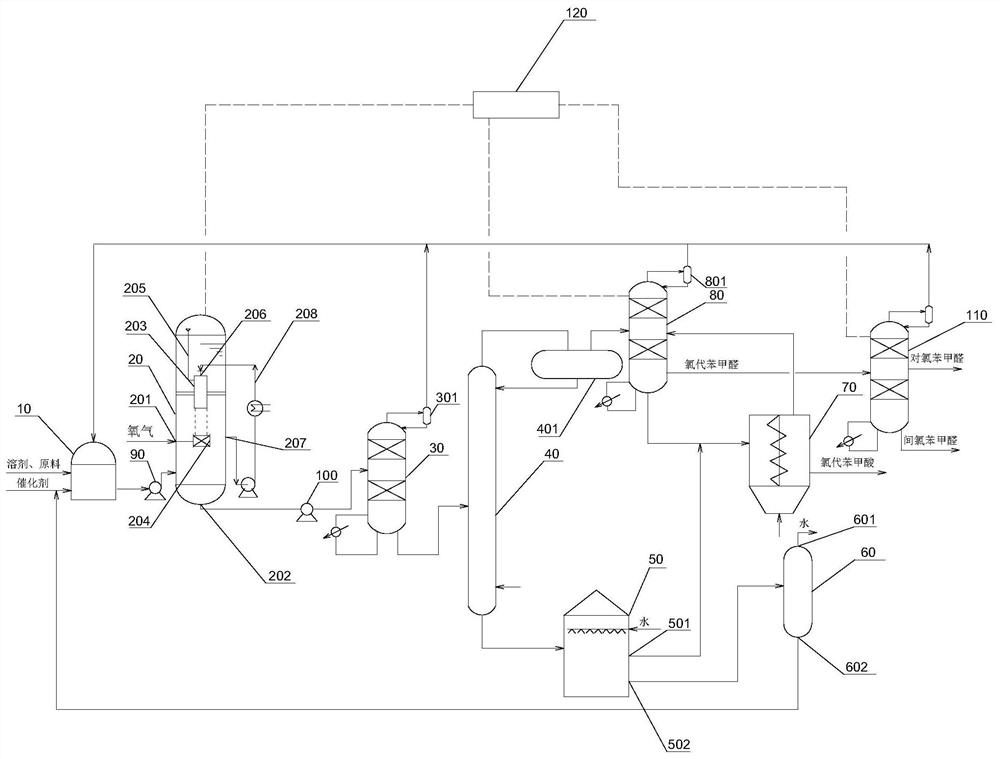

[0073] refer to figure 1 As shown, take the selective oxidation of chlorotoluene to generate chlorobenzaldehyde as an example, specifically including:

[0074]Step 1: Pass chlorinated toluene, solvent (acetic acid), catalyst (Co / Mn / Br composite catalyst), cocatalyst (alkali metal compound) into the batching tank 10 and mix; The pipeline enters the gas-liquid intensified reactor 20; oxygen enters the bottom of the gas-liquid intensified reactor 20 through the oxygen inlet 201; the gas-liquid intensified reactor 20 is a gas-liquid intensified reactor 20 without tail gas discharge, which can improve the oxygen utilization rate and Reduce energy consumption; After the reaction is completed, the mixed material (chlorinated toluene, chlorobenzaldehyde, chlorobenzoic acid, catalyst, solvent) mixed material outlet 202 is sent into the rectifying tower 30 by the mixed material pump 100 through the pipeline, and the subsequent refining process is carried out. distillation separation; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com