Ultralight clay foaming equipment

A foaming equipment and clay technology, which is applied in the field of clay foaming, can solve the problems of poor finished products and poor quality of finished products, and achieve the effect of efficient mixing and easy manipulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

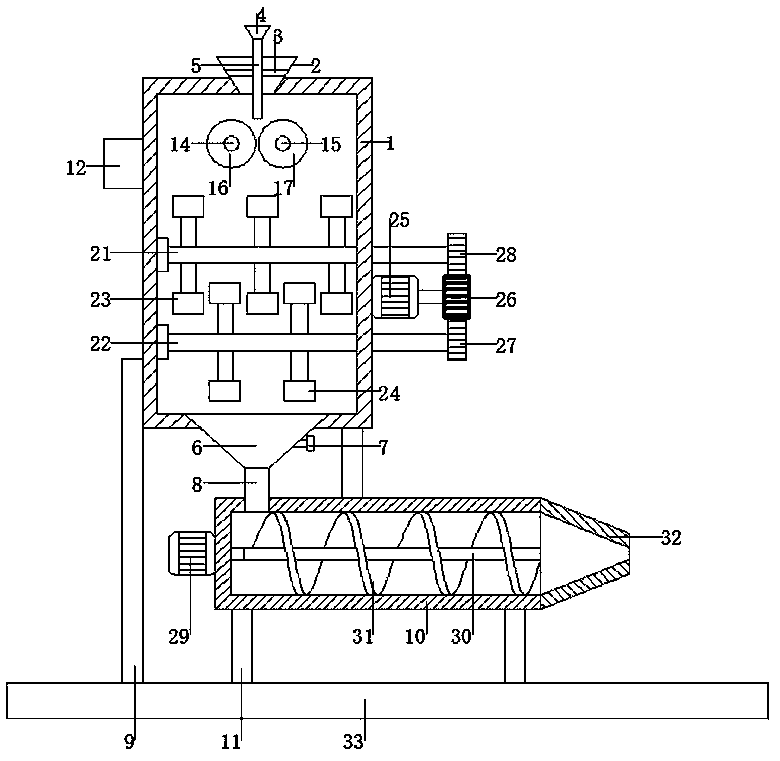

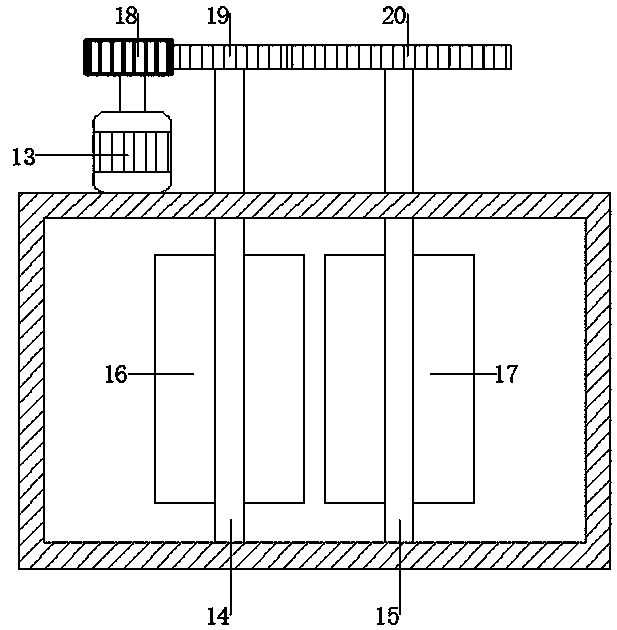

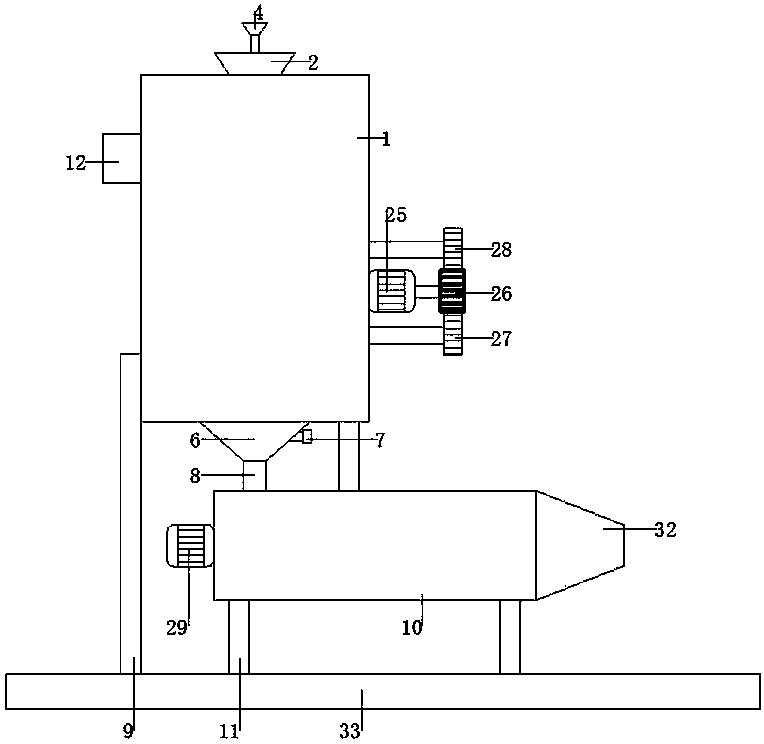

[0033] see Figure 1-3 , a kind of ultra-light clay foaming equipment, comprising a mixing drum 1, the upper end of the mixing drum 1 is fixedly connected with a first feeding funnel 2, and the first feeding funnel 2 communicates with the mixing drum 1, and the first feeding funnel 2 Mainly used for feeding solid materials, the upper side of the first feeding funnel 2 is provided with a second feeding funnel 4, the lower end of the second feeding funnel 4 is fixedly connected with a feeding pipe 5, and the lower end of the feeding pipe 5 Extending into the mixing drum 1, the feed pipe 5 and the second feed funnel 4 are used for feeding liquid materials, and a pair of fixed rods 3 are fixedly connected between the feed pipe 5 and the inner wall of the first feed funnel 2. The fixed rod 3 is mainly used to fix the feed pipe 5, the left end of the mixing drum 1 is fixedly connected with a main controller 12, the main controller 12 plays the role of main control, four switches are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com