Pretreatment kettle for production of glass edge-wrapping material

A glass edging material and pretreatment technology, applied in the directions of transportation and packaging, chemical/physical processes, mixers, etc., can solve the problems of equipment cleanliness decline, low work efficiency, influence of raw material mixing, etc., to reduce raw material loss, Improve mixing efficiency and efficient mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

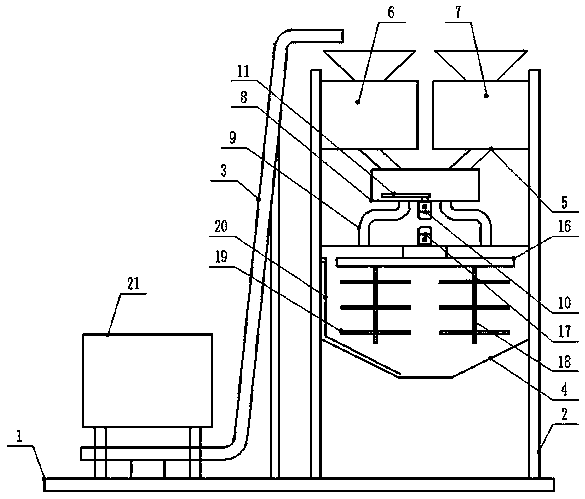

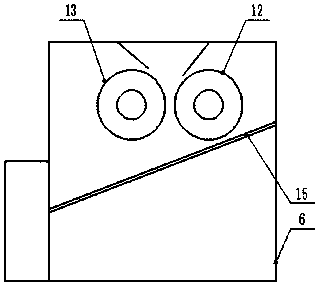

[0016] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6, a pretreatment kettle for the production of glass edging materials provided by the present invention will now be described, including a base base 1, a vertical fixing frame 2 evenly arranged at the upper end of one side of the base base 1 in the length direction, and the other side of the base base 1 in the length direction The upper end is provided with a large inclination conveyor 3, and a pretreatment kettle body 4 is fixed between the middle parts of the vertical fixing frame 2, and a material preparation mechanism 5 is arranged between the upper ends of the vertical fixing frame 2, and the material preparation mechanism 5 It includes a solid raw material processing box 6, a liquid raw material storage box 7, a collection bin 8, a material guide pipe 9, a first motor 10, and a material control plate 11. The upper end of the solid raw material processing box 6 is horizontally s...

Embodiment 2

[0017] Example 2: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , a pretreatment tank for the production of glass edging materials provided by the present invention will now be described. A solid raw material storage box 21 is provided directly above the position of the feeding end of the large-inclination conveyor 3, and the solid raw material storage box 21 is The middle part of the bottom end of the body 21 has a discharge port, and the upper and lower middle parts of the solid raw material processing box body 6 and the liquid raw material storage box body 7 are respectively provided with material guide ports, and the solid raw material processing box body 6 and the liquid raw material storage box body The upper end of the storage box 7 is provided with a feed funnel corresponding to the position of the guide port, and the discharge end of the large-inclination conveyor 3 is located at the upper end of the solid raw material processing box 6. Above, the in...

Embodiment 3

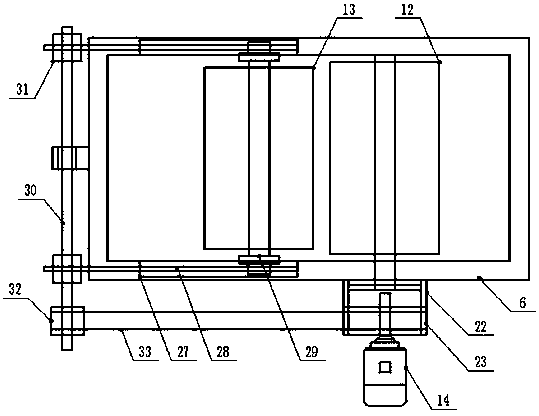

[0018] Embodiment 3: see figure 1 , figure 2 , image 3 Now, a pretreatment kettle for the production of glass edging materials provided by the present invention will be described. The other side end of the screw rod 28 corresponding to the position where the active grinding roller 12 is set respectively moves through the solid raw material processing box 6 The inner end wall protrudes, and a worm 30 is provided above the position of the extending end of the screw mandrel 28, and the extending ends of the screw mandrel 28 are respectively covered with worm gears 31, and the worm screw 30 corresponds to the setting position of the second motor 14. The side end is covered with a first pulley 32, and a first belt 33 is set between the first pulley 32 and the outside of the second cylindrical frame 23, and the outside of the screw rod 28 is connected to the sliding end of the sliding seat 29. There is a connection assembly between them, and the connection assembly includes a mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com