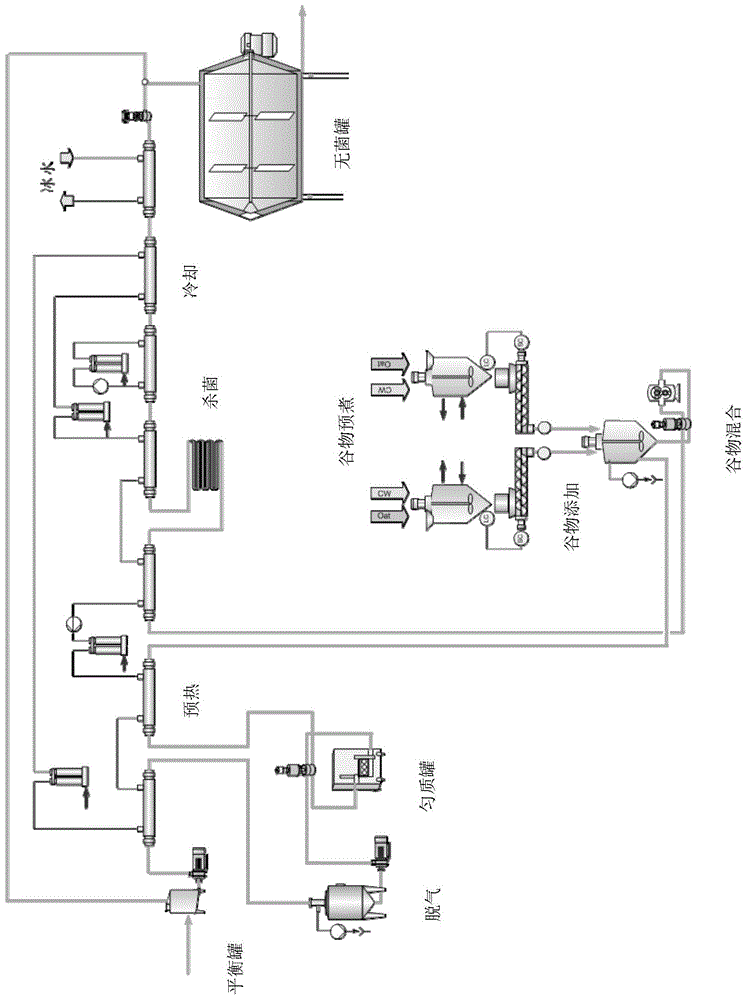

Continuous production process and devices of milk drink containing cereal grains

A technology for grain granules and production equipment, applied in dairy products, food science, milk preparations, etc., can solve problems such as affecting product consistency and stability, high coordination control requirements, increasing production costs, etc., and achieve extended continuous operation. Time, reduce production cost, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

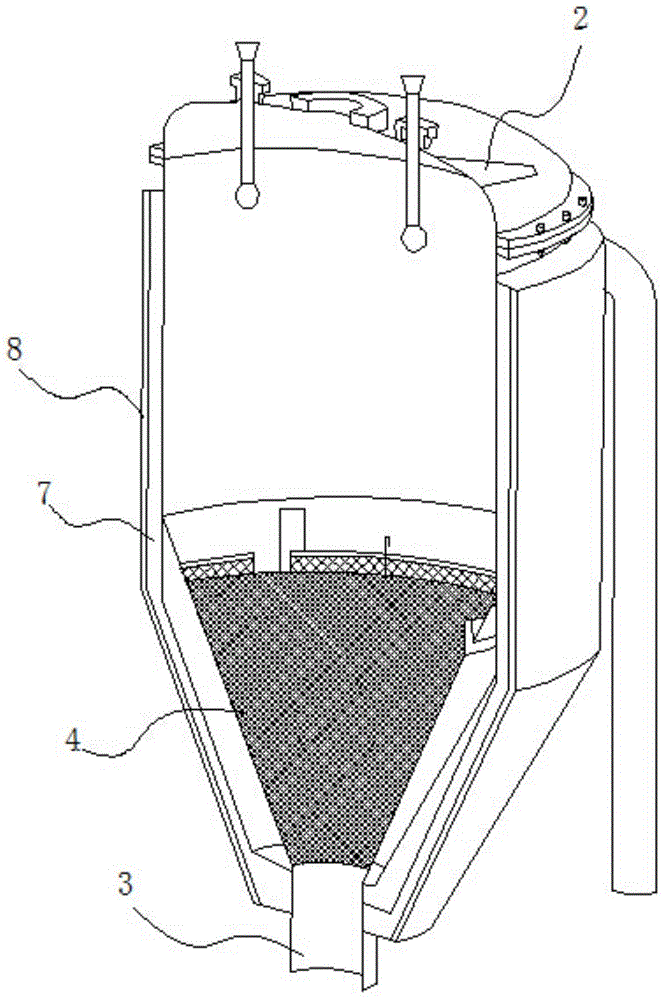

[0034] Embodiment one: see Figure 1~4 Shown, a kind of continuous addition production equipment that contains grain particle milk beverage, comprises aseptic tank, heat exchange sterilization conveying pipeline and particle addition equipment, and described particle addition equipment includes several precooking tanks (for several kinds of cereals) Mixing and adding), mixing tank and quantitative delivery mechanism:

[0035] The top of the precooking tank 1 is provided with a grain feeding port 2 and a water injection port, the bottom is provided with a product outlet 3, a heating mechanism is provided on the inner side of the tank wall, the tank body is close to the product outlet, and a screen is provided along the inner wall of the tank wall. 4. A cavity is provided between the screen 4 and the tank wall, and a drain is provided on the tank wall corresponding to the cavity, and an agitator is provided in the tank;

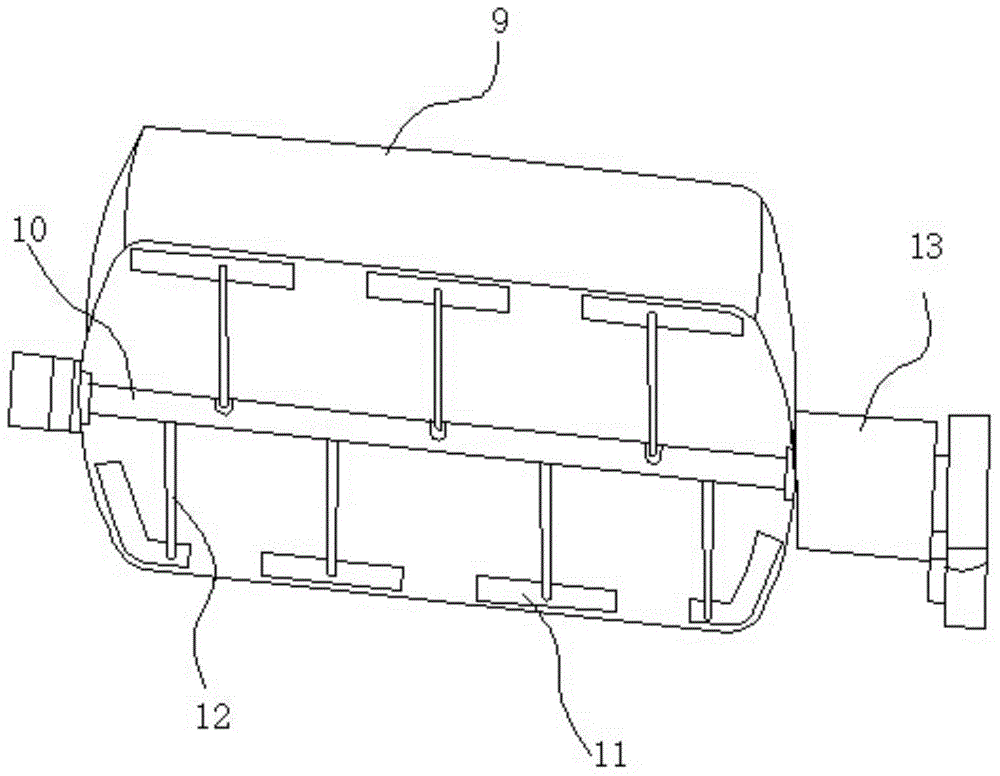

[0036] The top of the mixing tank 5 is provided with a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com