High-efficiency stirring and mixing equipment for chemical engineering

A stirring mixing and high-efficiency technology, which is applied in the direction of mixers with rotating stirring devices, mixers, chemical instruments and methods, etc., can solve the problems of low efficiency, inconvenient operation, waste of time, etc., and achieve high-efficiency mixing and mixing, convenient and full Mixed, productivity-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

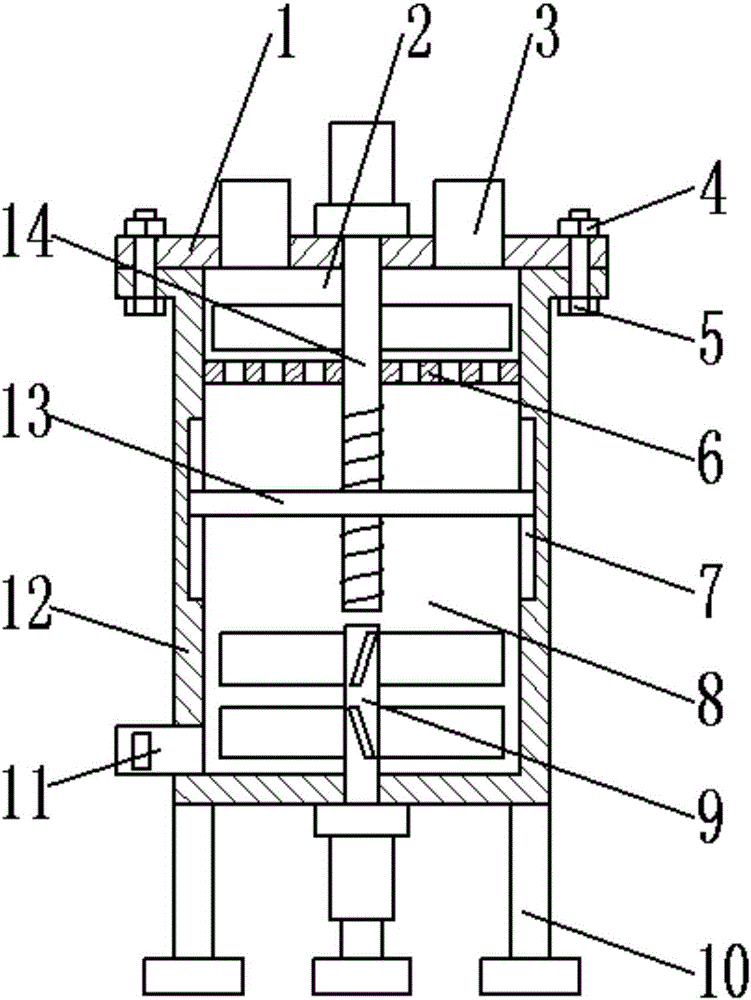

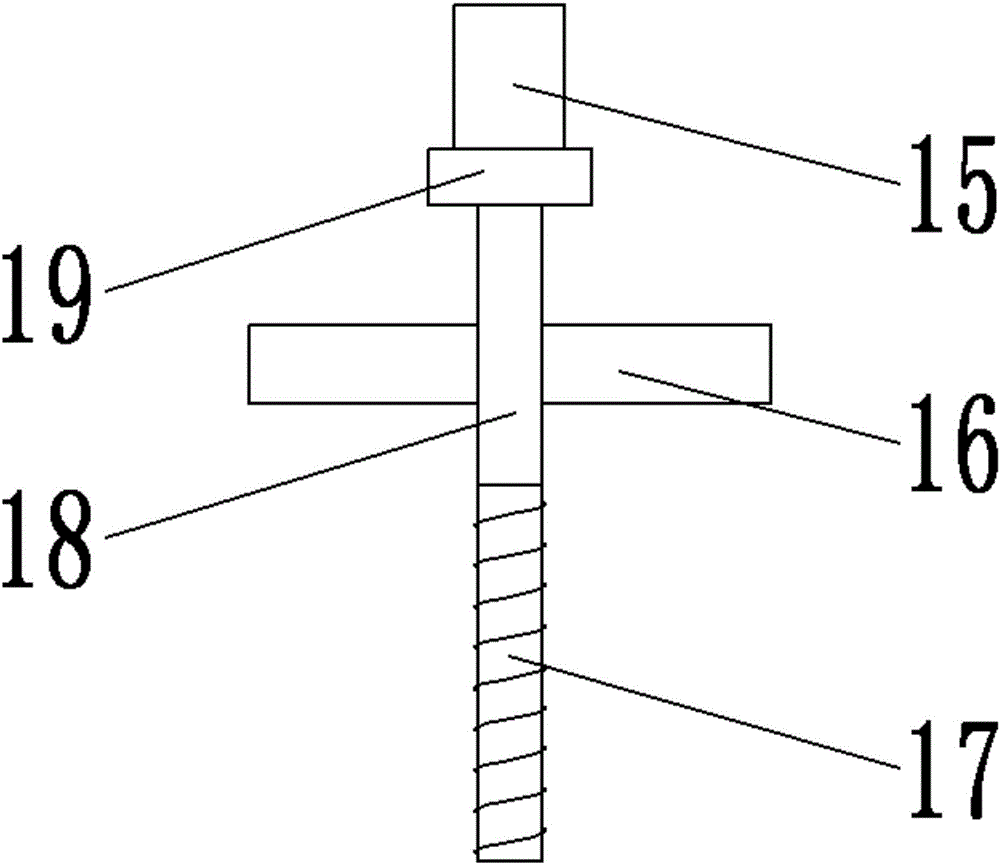

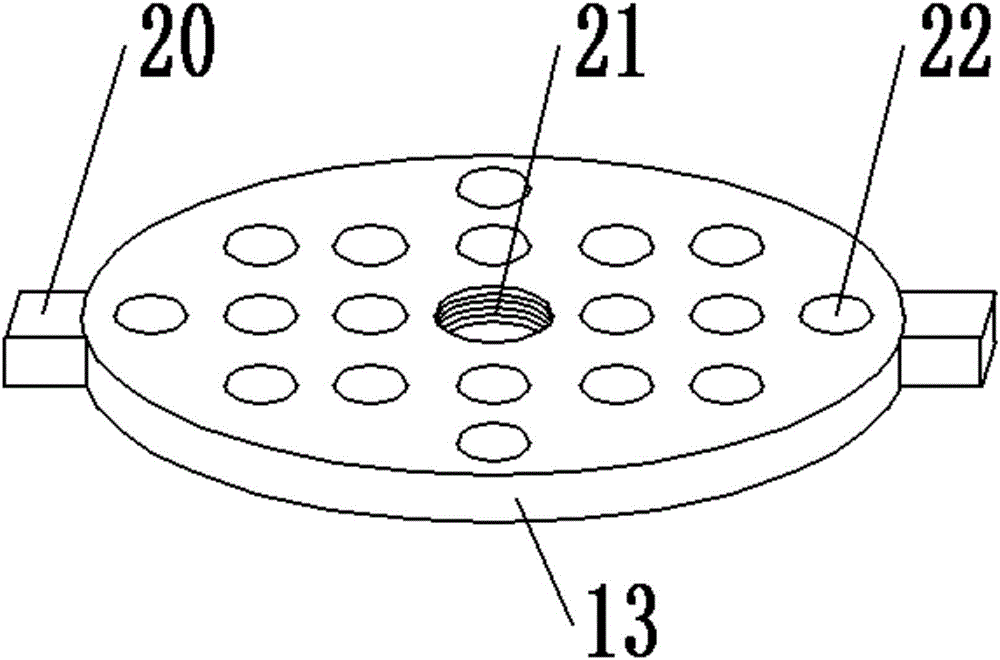

[0021] see Figure 1-4 , a high-efficiency stirring and mixing equipment for chemical industry, including a tank body 12; the tank body 12 is set as a hollow cylinder, made of stainless steel, and the inside is divided into a uniform material chamber 2 and a stirring chamber 8 by a partition 6, and the top opening An upper cover 1 is provided; several blanking holes are evenly distributed on the partition plate 6; the upper cover 1 is connected with the tank body 12 through the mutual screwing of the bolt 5 and the nut 4; the upper cover 1 is provided with a feed pipe 3. The feed pipe 3 is provided with four sets, which are evenly distributed on the upper cover 1, which is convenient for adding various materials at the same time and for thorough mixing; the uniform material chamber 2 is provided with a uniform material device 14; the uniform materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com