Dispersing, mixing and stirring device for getter processing

A stirring device and getter technology, which is applied to mixers with rotating stirring devices, mixers, dissolving, etc., can solve the problems of uneven particle size of materials, mixing and stirring of getters, uneven performance of materials and products, etc. , to achieve the effect of efficient processing getter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

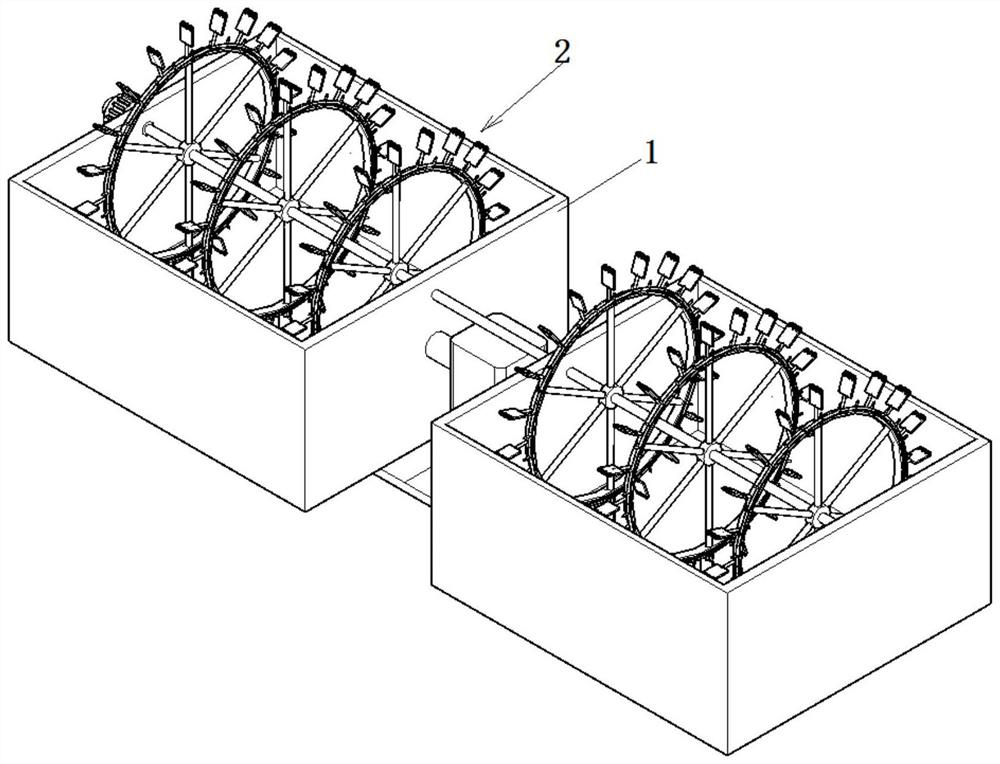

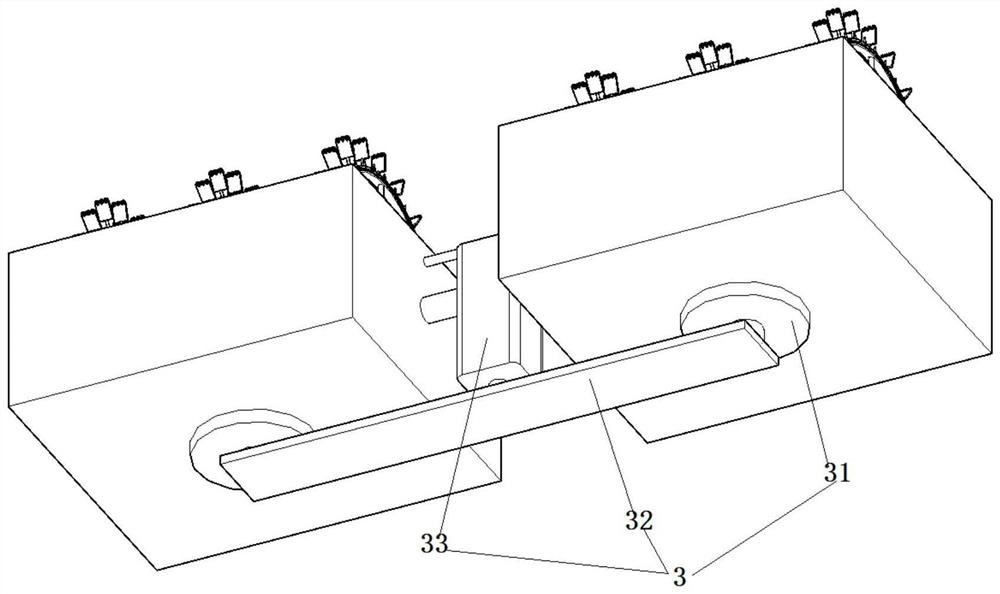

[0034] Such as Figure 1-5 As shown, a getter processing dispersing and mixing agitating device includes two mixing boxes 1 arranged at intervals on the left and right; mixing components are assembled and connected in the mixing boxes 1; the material is carried out through the mixing components mix.

[0035] The above mixing components are assembled and connected by rotating drive shafts.

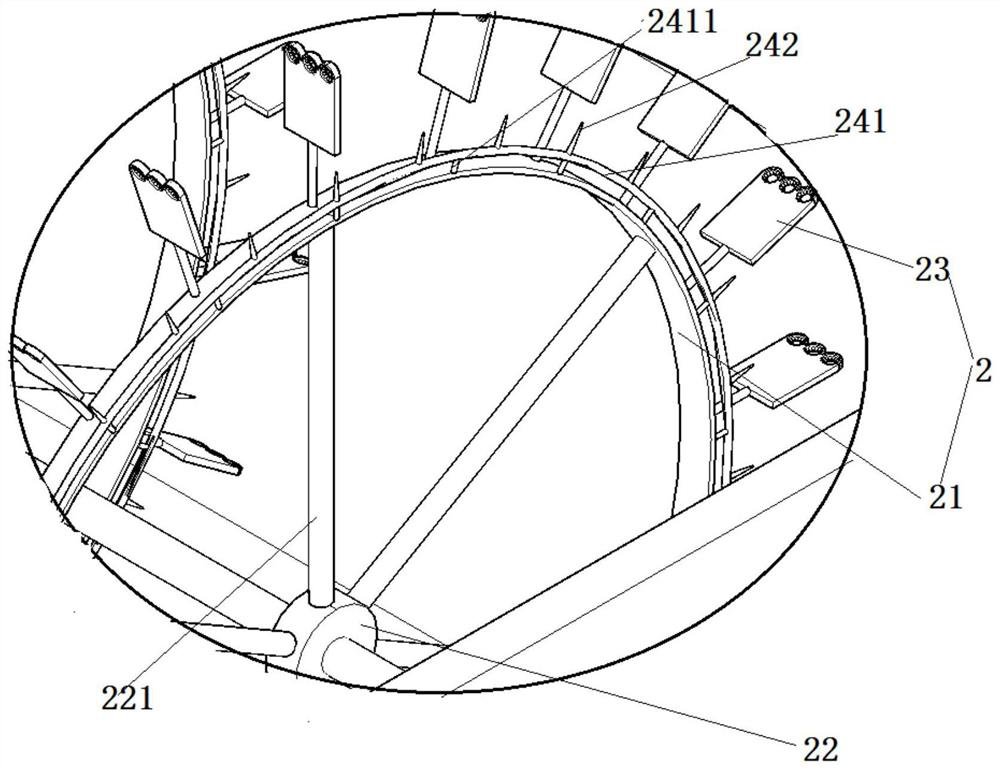

[0036] The specific structure of the mixing component is as follows:

[0037] The mixing components all include several mixing parts 2 arranged at intervals left and right, and the mixing parts 2 all include a rotating ring b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com