Stirring equipment with positive and negative cross flow mixing function

A kind of mixing equipment, forward and reverse technology, applied in the direction of mixer with rotating stirring device, mixing machine, dissolving, etc., can solve the problems of high energy consumption, insufficient mixing effect, etc., achieve energy saving effect, efficient mixing effect, good The effect of the mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the embodiments given in the accompanying drawings.

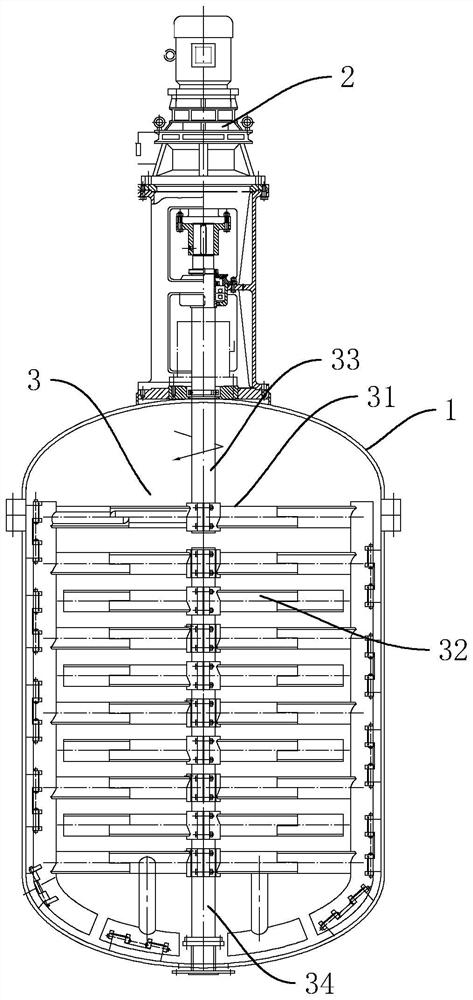

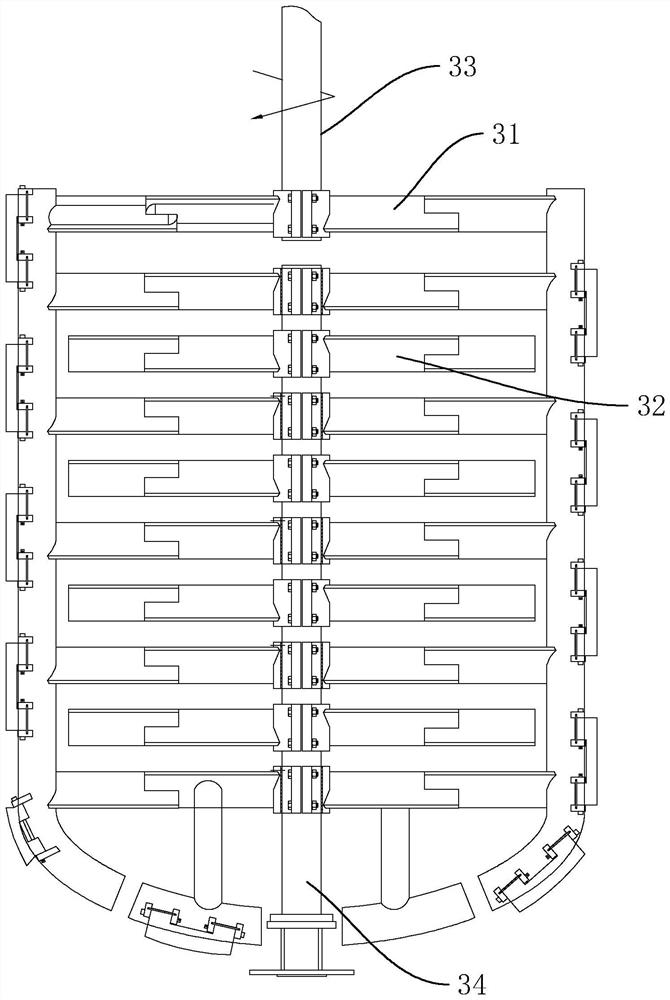

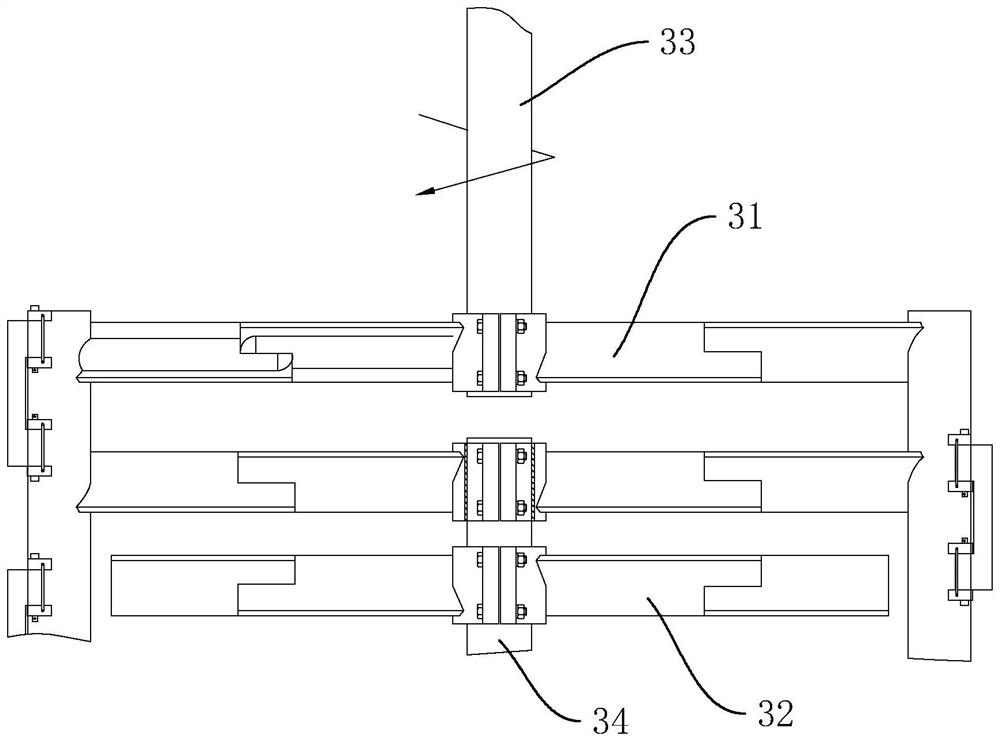

[0023] refer to Figure 1-4 as shown,

[0024] A stirring device with positive and negative cross flow, including a kettle body 1, a driving assembly 2 arranged on the kettle body 1, and a stirring assembly 3 arranged in the kettle body 1, and the driving assembly 2 is used to drive the stirring assembly 3 to perform stirring action , it is characterized in that the stirring assembly 3 includes a movable agitator 31 and a fixed agitator 32, the movable agitator 31 is linked with the drive assembly 2, and is driven by the drive assembly 2 to rotate and stir; the fixed agitator 32 is fixed in the kettle body 1; Inside the kettle body 1, the materials are stirred by the movable agitator 31 and the fixed agitator 32, and the blades of the fixed agitator 32 and the movable agitator 31 face opposite directions.

[0025] Wherein the drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com