Chemical material reaction device with two stirring devices

A stirring device and reaction equipment technology, which is applied in chemical/physical/physical-chemical mobile reactors, chemical/physical processes, chemical/physical/physical-chemical processes, etc., can solve the problems of insufficient stirring, increased product production costs, and reaction Waste of raw materials and other issues, to achieve the effect of convenient movement and fixation, extended service life, and full contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

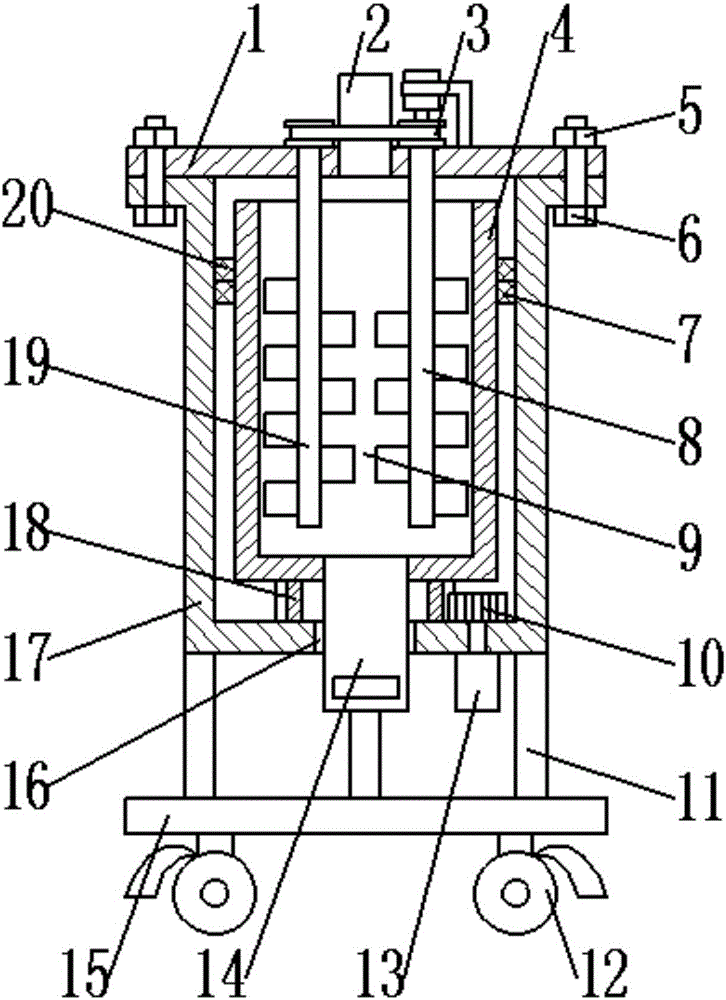

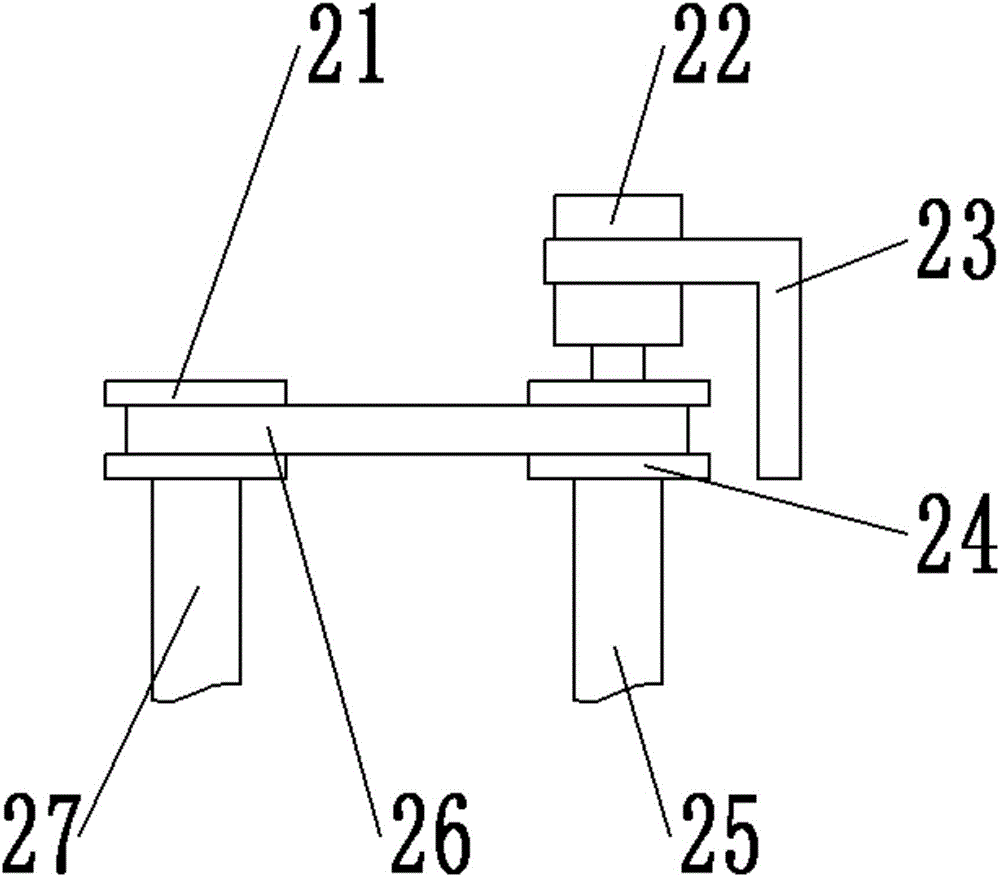

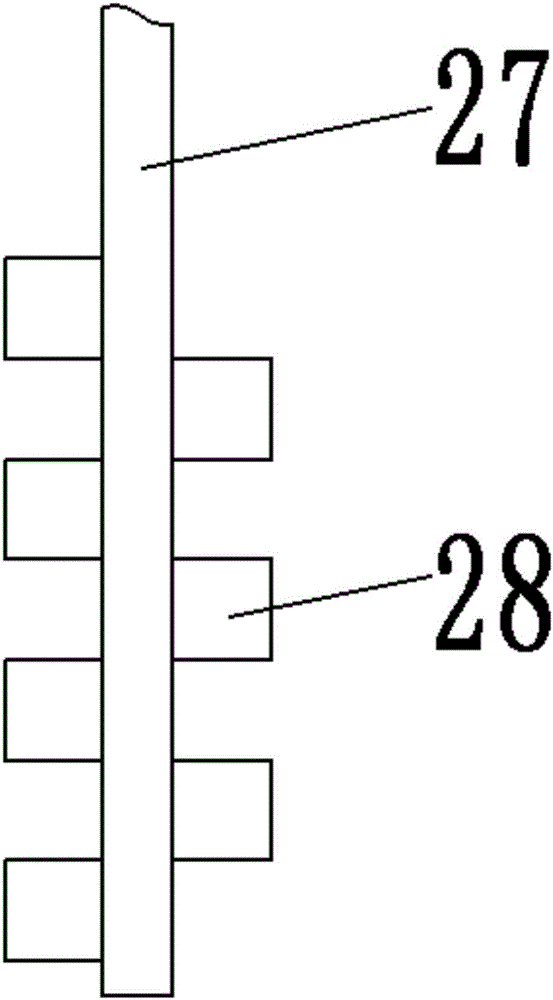

[0018] see Figure 1-5 , a chemical material reaction equipment with two sets of stirring devices, including an outer tank 17 and an inner tank 4; the outer tank 17 is set as a hollow cylinder, the bottom is provided with a discharge pipe installation hole 16, and the inside is provided with an inner tank 4. An upper cover 1 is provided at the top opening; the upper cover 1 is fixedly connected with the outer tank 17 through the mutual screwing of the bolt 6 and the nut 5; the upper cover 1 is provided with a feeding pipe 2 and a driving device 3; The feeding pipe 2 is arranged in the middle part of the upper cover 1; the driving device 3 is composed of a first motor 22, a first transmission wheel 21, a second transmission wheel 24 and a transmission belt 26; The upper surface of the cover 1 is fixedly connected, and the first motor 22 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com