Plant total nutrition special granular fertilizer and preparation method thereof

A full-nutrient, granular fertilizer technology, applied in potash fertilizer, application, inorganic fertilizer and other directions, can solve problems such as difficult preparation, and achieve the effect of good effect and scientific and reasonable preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A special granular fertilizer for plant full nutrition, comprising the following raw materials in parts by weight: 100 parts of crushed and fermented garden waste, 30 parts of humectant, 10 parts of pH regulator, 15 parts of insecticide, 15 parts of bactericide, and mineral nutrients 5 parts, mineral nutrients are composed of hydrogen, carbon, oxygen, nitrogen, potassium and calcium.

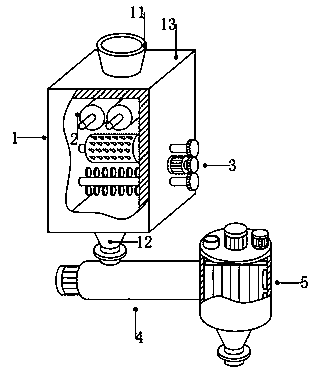

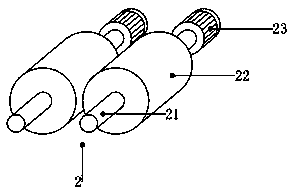

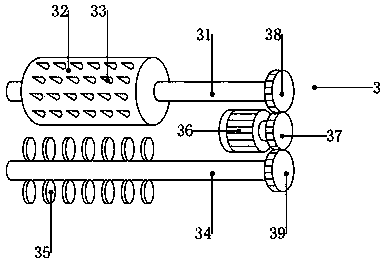

[0039] to combine Figure 8Shown, a kind of preparation method of plant full nutrition special granular fertilizer, its preparation method is as follows:

[0040] S1. Garden waste crushing and fermentation: crush the garden waste for 30-45 minutes, ferment the crushed garden waste for 10-15 days, and wait for use;

[0041] S2. Stirring and mixing: add humectants, pH regulators, insecticides, bactericides and mineral nutrients to the crushed and fermented garden waste, stir and mix, stir evenly, and set aside;

[0042] S3. Particle forming: Finally, use a particle forming machine to perf...

Embodiment 2

[0051] A special granular fertilizer for plant full nutrition, comprising the following raw materials in parts by weight: 125 parts of crushed and fermented garden waste, 40 parts of humectant, 12 parts of pH regulator, 17 parts of insecticide, 18 parts of bactericide, and mineral nutrients 7 parts, mineral nutrients are composed of hydrogen, carbon, oxygen, nitrogen, potassium and calcium.

Embodiment 3

[0053] A special granular fertilizer for plant full nutrition, comprising the following raw materials in parts by weight: 150 parts of crushed and fermented garden waste, 50 parts of humectant, 15 parts of pH regulator, 20 parts of insecticide, 20 parts of bactericide, and mineral nutrients 10 parts, mineral nutrients are composed of hydrogen, carbon, oxygen, nitrogen, potassium and calcium.

[0054] The fertilizer prepared in Example 1 is suitable for the late stage of plant growth, the fertilizer prepared in Example 2 and Example 1 is suitable for the middle stage of plant growth, and the fertilizer prepared in Example 3 is suitable for the early stage of plant growth.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com