Fosaprepitant supercritical reaction preparation method

A fosaprepitant and supercritical technology, applied in the field of supercritical reaction preparation of fosaprepitant, can solve the problems of low efficiency and long operation period, and achieve the effects of accelerating diffusion, accelerating temperature increase and improving preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

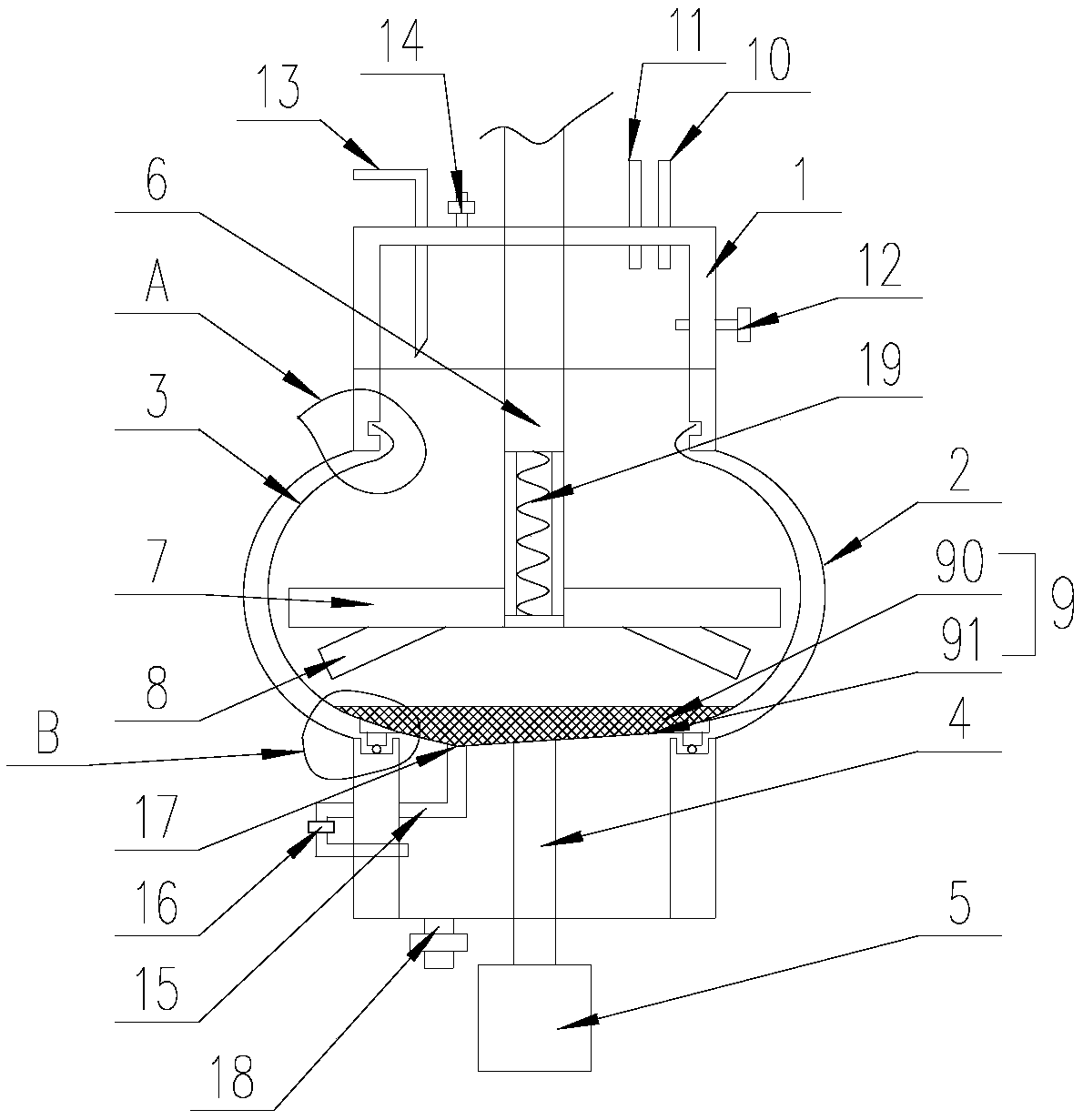

[0054] A kind of fosaprepitant supercritical reaction preparation method, comprises the steps:

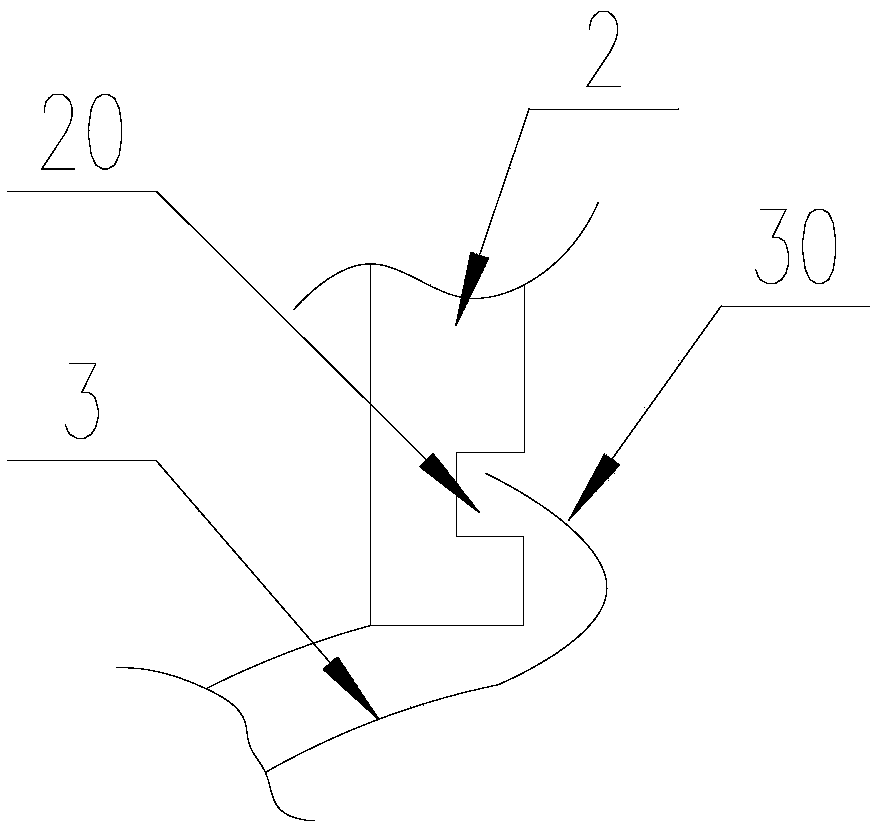

[0055] Step 1: Turn on the drive motor 5, adjust the rotating speed to 120-150rpm, and the inner tank 3 rotates slowly relative to the outer tank 2;

[0056] Step 2: add aprepitant dibenzyl phosphate and palladium carbon with a mass fraction of 5% in the inner tank 3 through the raw material and catalyst inlet 13 respectively, and the amount of palladium carbon added is aprepitant dibenzyl phosphate 0.5% by weight;

[0057] Step 3: Pass carbon dioxide through the carbon dioxide inlet 10 to replace the air in the tank;

[0058] Step 4: Passing hydrogen gas from the hydrogen gas inlet 11 to form a hydrogen partial pressure of 0.6-0.7 MPa;

[0059] Step five: feed carbon dioxide from the carbon dioxide inlet 10 so that the air pressure in the tank is 13-14MPa;

[0060] Step 6: Turn on the heating element 19 so that the temperature in the tank is 35-36°C;

[0061] Step 7: Adjust th...

Embodiment 2

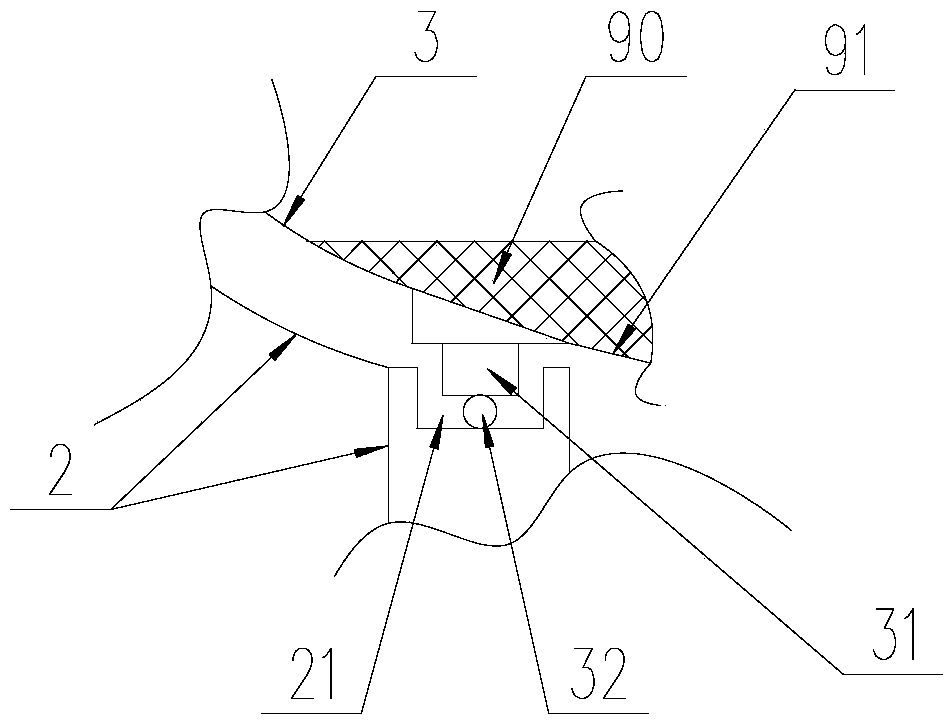

[0081] The difference between this embodiment and Embodiment 1 is that there are two stirring paddles 7 and the sub-blades 8 facing the inner recess of the arc-shaped structure are respectively arranged at the bottom thereof, and the sub-blades 8 can assist in stirring the raw material at the lower end of the inner recess, so that The raw materials at the upper end of the inner concave part can fall and be turned to achieve more uniform and efficient mixing.

[0082] The stirring shaft 6 is located inside a section of the inner tank 3 and a heating element 19 is provided.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com