Mixing equipment for polycarbonate modified material

A modified material, polycarbonate technology, applied in mixers, mixers with rotating containers, dissolution, etc., can solve problems such as inability to achieve mixing, reduced cleanliness of mixing tanks, and single mixing methods for raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

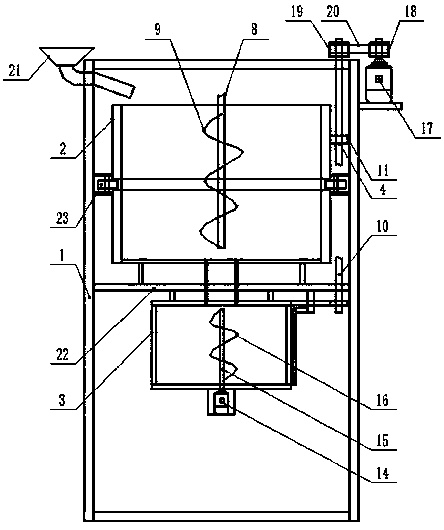

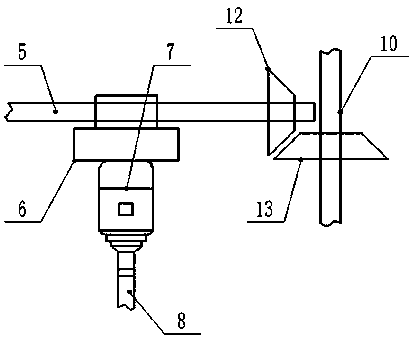

[0013] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , a kind of mixing equipment for polycarbonate modified materials provided by the present invention is now described, including a mixing box 1, and a primary mixing tank 2 is provided on the middle side of the upper end of the inner cavity of the mixing box 1, and the A secondary mixing tank 3 is provided in the mixing box 1 and located on the middle side below the position of the primary mixing tank 2, and a mixing assembly 4 is provided at the upper end of the inner cavity of the mixing box 1, and the mixing assembly 4 is the screw mandrel 5 that is provided on the middle side of the top end of the mixing box 1, the sliding seat 6 provided at the lower end of the screw mandrel 5, the first motor 7 provided at the lower end of the sliding seat 6, and the first motor 7 vertically The downward output shaft is connected to the first agitating shaft 8 by a coupling, the first agitating blade 9 provided on the...

Embodiment 2

[0014] Example 2: see figure 1 , figure 2 , Figure 4Now, a kind of mixing equipment for polycarbonate modified materials provided by the present invention will be described. A third motor 17 is provided on the outer wall of the top end of the mixing box 1, and the output of the third motor 17 is vertically upward. A driving pulley 18 is sleeved on the shaft, and the top end of the transmission shaft 10 moves through the inner top wall of the mixing box 1 to protrude and its protruding end is covered with a driven pulley 19. The driving pulley 18 A belt 20 is set between the outside of the driven pulley 19, the mixing box 1 is a hollow cylinder, and the top side wall of the mixing box 1 has a feed port, and the mixing box 1 A feed funnel 21 is arranged on the outer side of the top of the casing 1, and the discharge end at the bottom of the feed funnel 21 is communicated with the feed inlet through a pipeline. The feed end of the guide pipe is connected to the feed port, th...

Embodiment 3

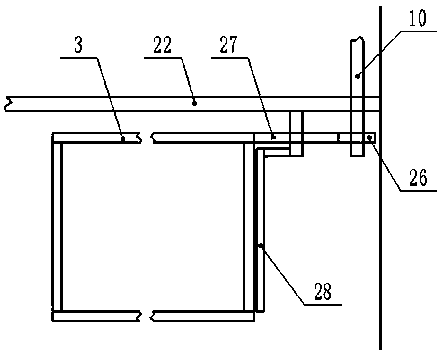

[0015] Embodiment 3: see figure 1 , image 3 , the mixing equipment for a polycarbonate modified material provided by the present invention is now described, the secondary mixing tank 3 includes an upper disc-shaped frame, a lower disc-shaped frame and an upper disc-shaped frame It is composed of a cylindrical filter frame provided between the lower disc-shaped frame body. The cylindrical filter frame is uniformly and densely opened with filter holes, and the upper end of the upper disc-shaped frame body is provided with an annular chute and the annular An annular slider is movable in the chute, and a vertical frame is evenly arranged between the upper end of the annular slider and the lower end of the fixed frame 22, and a circular discharge opening is opened in the middle of the bottom of the primary mixing tank 2 And the circular material discharge port is vertically connected downward with a material guide tube, the middle part of the top of the secondary mixing tank 3 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com