Self-washed type feed stirring, mixing and drying integral equipment

A feed mixing and self-washing technology, which is applied to feed, chemical instruments and methods, and cleaning methods using liquids, etc., can solve the problems of easy adhesion to the inner wall of the machine, unfavorable full mixing of fertilizers, and no drying equipment. Conducive to uniform heating, preventing direct discharge to pollute the environment, and speeding up drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

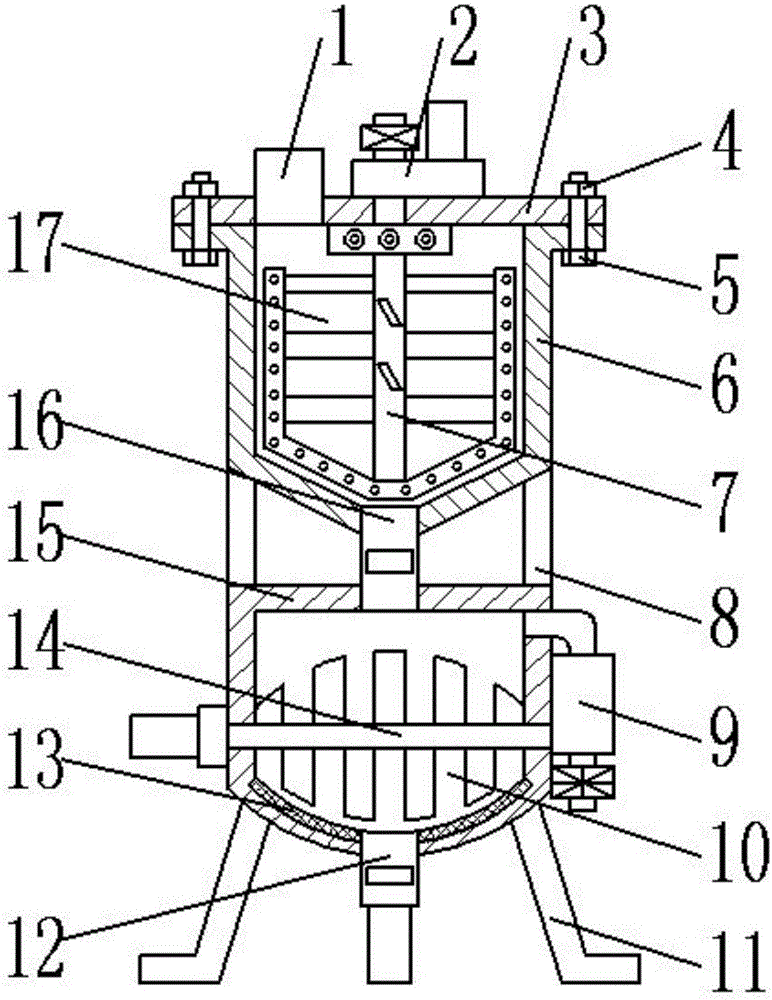

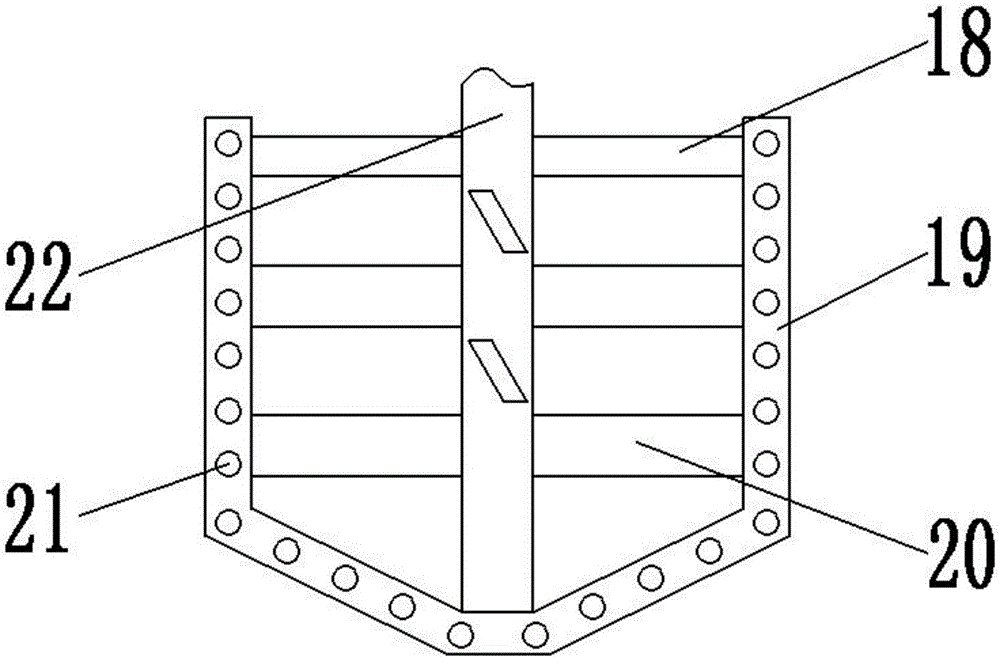

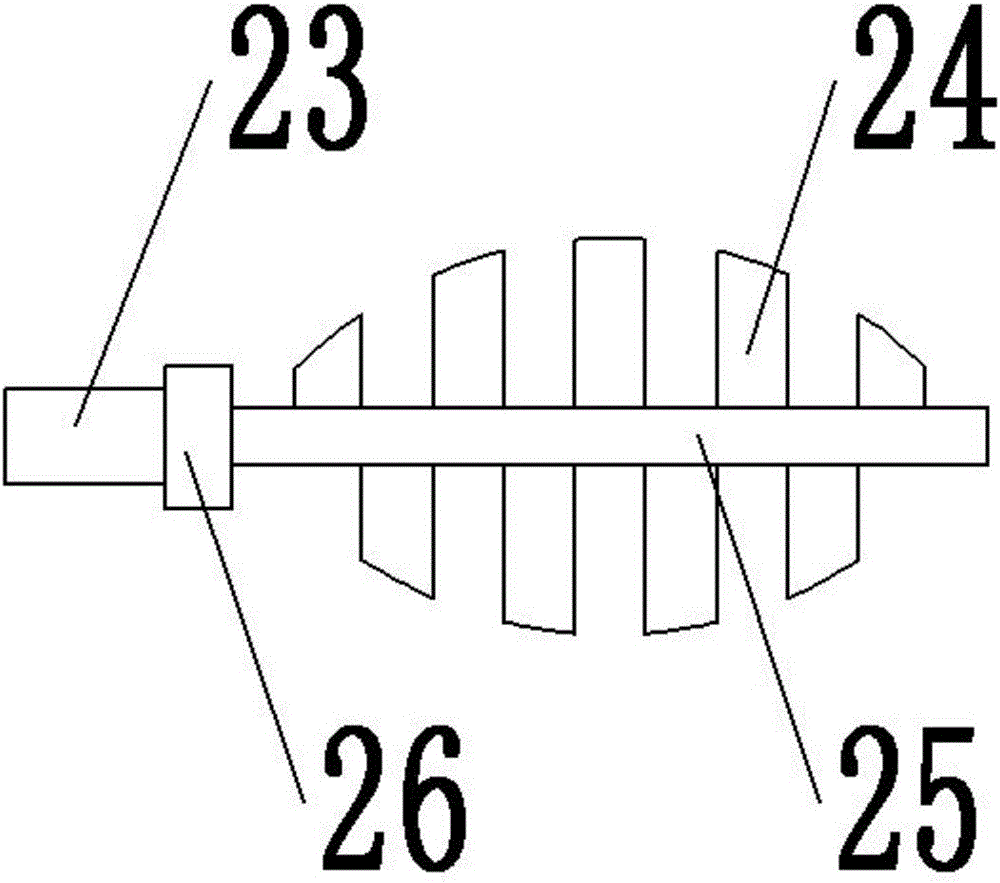

[0020] see Figure 1-5, a self-washing type feed mixing and drying integrated equipment, including a mixing tank 6 and a drying tank 15; the mixing tank 6 and the drying tank 15 are made of stainless steel, the mixing tank 6 is set as a hollow cylinder, and the bottom is set In the shape of a funnel, the inside is set as a stirring chamber 17, and the top opening is provided with a loam cake 3; the drying tank 15 is set as a hollow cylinder, the bottom is set as a hemisphere, and the inside is set as a drying chamber 10; the loam cake 3 passes through The mutual screwing of the bolt 5 and the nut 4 is fixedly connected with the stirring tank 6; the upper cover 3 is provided with a feed pipe 1 and a cleaning and driving device 2; the feed pipe 1 is arranged on the left side of the upper cover 3; the cleaning The cleaning and driving device 2 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com