Lithium battery electrode slurry stirring-mixing tank convenient to clean

An electrode slurry, stirring and mixing technology, which is applied to mixers, mixers, and mixer accessories with rotary stirring devices, etc., can solve the problems of limited mixing capacity, limited material processing and production efficiency, and more time and energy consumption. , to achieve the effect of preventing residue, fast and efficient cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

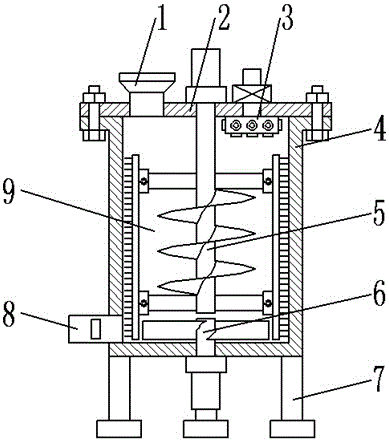

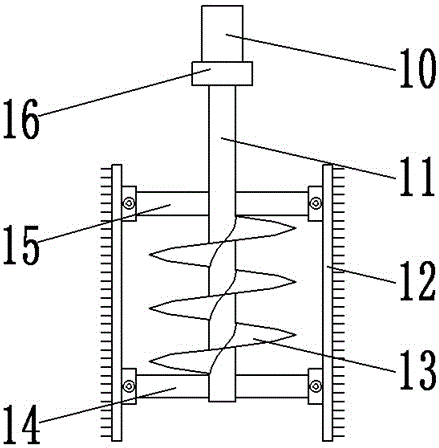

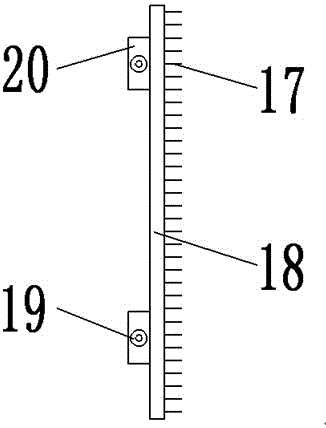

[0019] see Figure 1-5 , a lithium battery electrode slurry stirring and mixing tank that is easy to clean, including a tank body 4 and an upper cover 2; the tank body 4 is set as a hollow cylinder, and the inside is set as a mixing chamber 9, and the top opening is provided with an upper cover 2 The upper cover 2 is fixedly connected with the tank body 4 through the mutual screwing of bolts and nuts, and the upper cover 2 and the tank body 4 are made of stainless steel; the upper cover 2 is provided with a feed pipe 1 and a cleaning device 3; The feed pipe 1 is arranged in a funnel shape, and the top opening is provided with a sealing cover, which is fixed on the left side of the upper cover 2; the cleaning device 3 is composed of a water inlet pipe 21, a water pump 24 and a spray plate 22; the water inlet pipe One end of 21 communicates with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com