Fully-disposable integrated injection molding embroidering needle head

A tattoo and needle technology, which is applied in the field of all-thrown integrated injection molding tattoo needles, can solve the problems of blood infectious disease transmission, cosmetic safety hazards, etc., achieve the effect of firm injection molding and avoid the danger of flying needles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

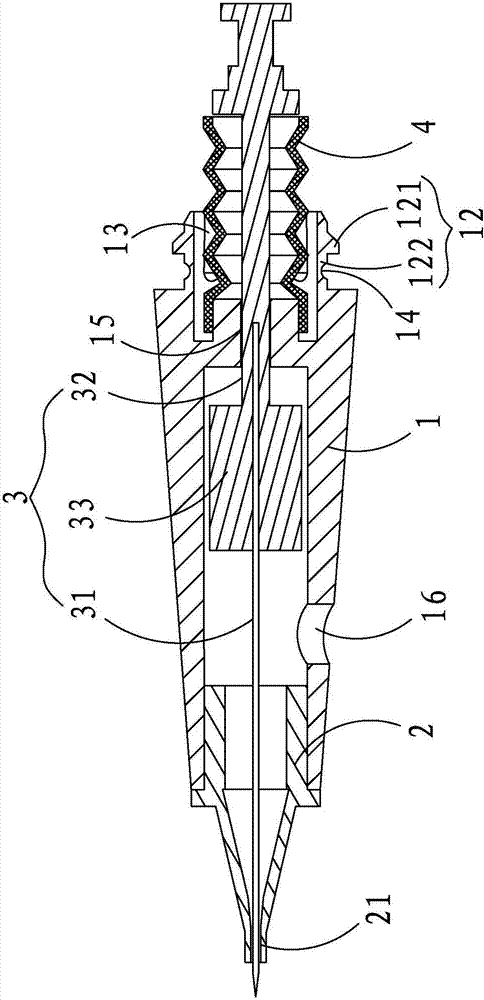

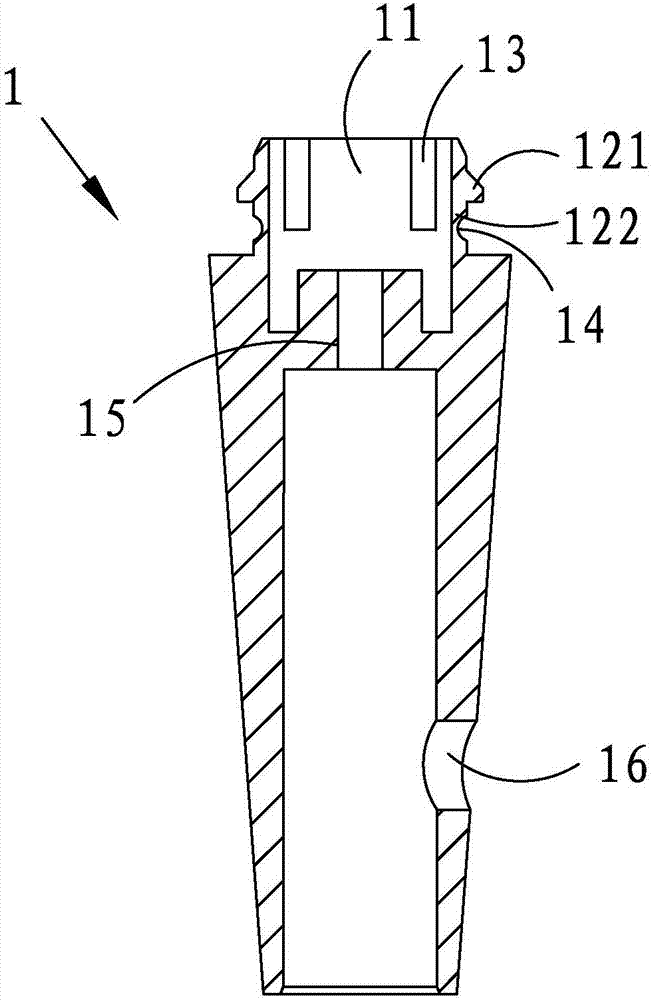

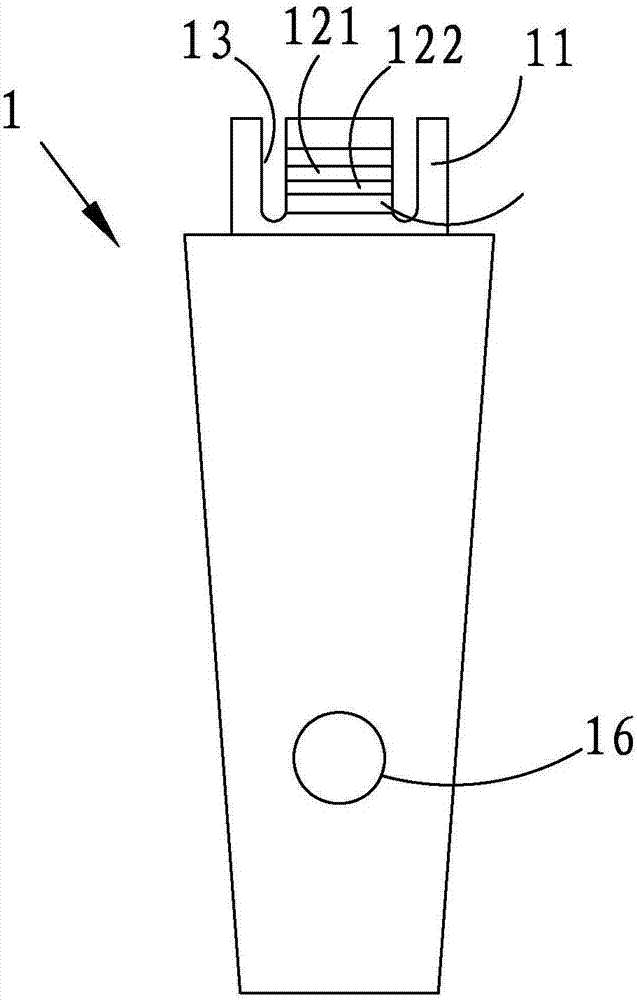

[0026] Embodiment one: see attached figure 1 As shown, a full-throwable integral injection molding tattoo needle is detachably connected to the front end of the tattoo machine, which includes a hollow tubular cylinder 1, a positioning sleeve 2 arranged at the front end of the cylinder 1, and a tattoo needle arranged on the front end of the embroidery machine. The needle body 3 in the needle head and the elastic member 4 which has the tendency to push the needle body 3 to the back of the embroidery needle head. The guide part 11 arranged in the length direction of the embroidery needle and the easy-to-break locking part 12, the locking part 12 cooperates with the front end of the embroidery machine and locks the embroidery needle with the embroidery machine, the gap between the guide part 11 and the locking part 12 There is a gap 13 between them, which is easy to break when the locking part 12 is subjected to a tangential force. Wherein the breaking force of the locking part 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com