Transfer device for foundry molds

A transfer device and casting mold technology, which is applied in the direction of manufacturing tools, casting equipment, and mold handling equipment, can solve the problems of large labor consumption, reduced service life of casting molds, and large losses, so as to ensure product quality and ensure castings quality and life-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

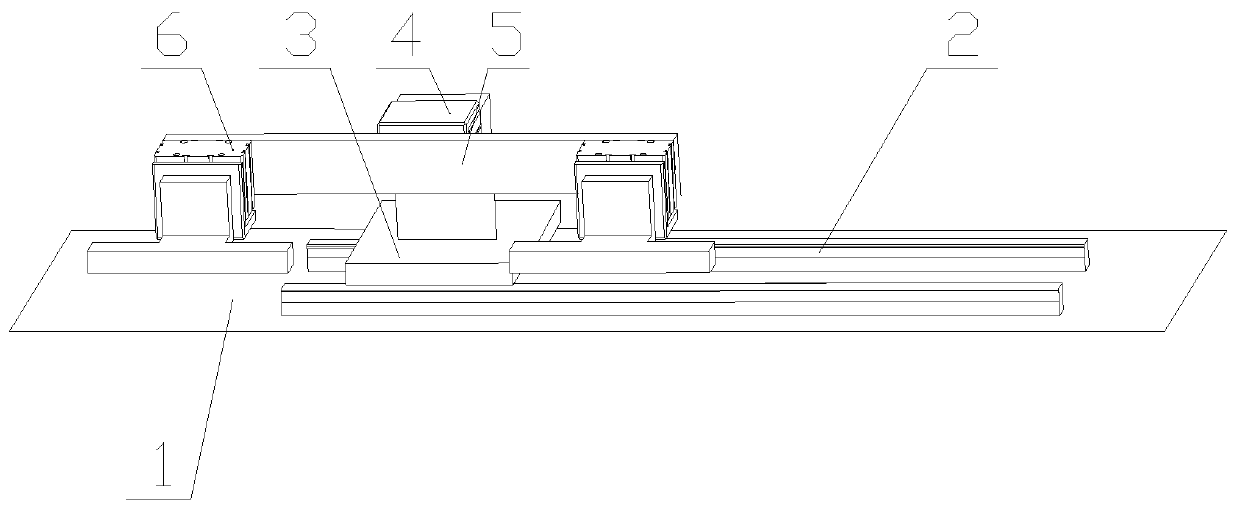

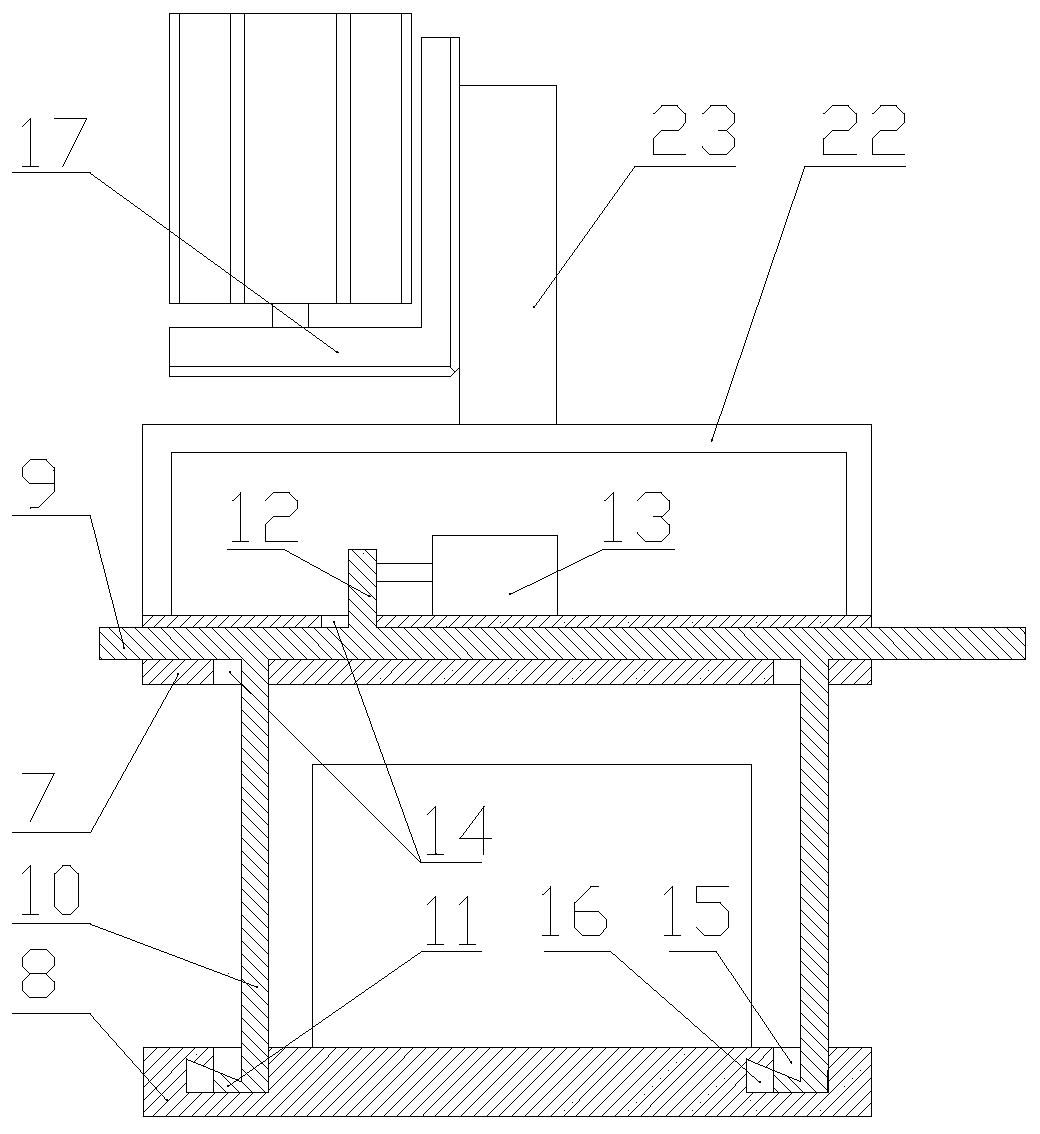

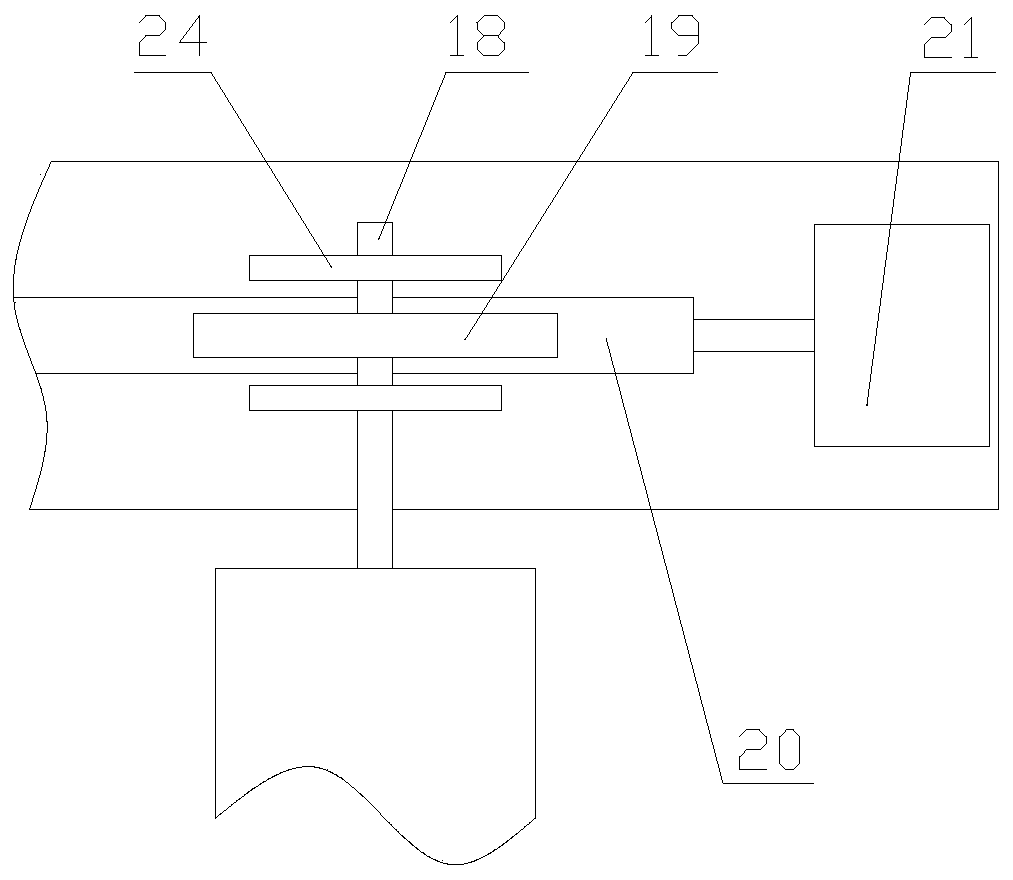

[0027] see Figure 1 to Figure 4 , is a transfer device for casting molds, including a working platform, two guide rails parallel to each other are arranged on the working platform, a movable supporting seat is arranged on the two guiding rails, a driving device is connected with the moving supporting seat, and is used to drive the moving supporting seat Translate along the two guide rails, a translation cylinder is provided on the mobile support seat, the piston rod of the translation cylinder extends to one side of the two parallel guide rails in the horizontal direction and is perpendicular to the two guide rails, and a piston rod parallel to the two guide rails is fixed on the translation cylinder. The mounting arms of the two guide rails are respectively provided with mold loading devices at both ends of the mounting arms.

[0028] The mobile support seat includes a base and a turntable, the turntable is rotatably supported on the base through a thrust bearing, the base i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com