Square cell clamp and ejection mechanism

A square cell and fixture technology, applied in circuits, electrical components, primary batteries, etc., can solve the problems of high positioning accuracy, scratches on the surface of the cell, and unevenness on the surface of the cell, reducing positioning accuracy requirements and changing models. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific drawings.

[0031] In the description of the following specific embodiments, the coordinates are referred to: figure 1 The up and down directions in the middle are up and down, the left and right directions are left and right, the direction perpendicular to the paper surface is back, and vice versa. In the specific embodiment of the present invention, the front-rear direction is the longitudinal direction, and the left-right direction is the horizontal direction.

[0032] In order to solve many problems in the prior art, the present invention discloses a square cell clamp and ejection mechanism, wherein the square cell clamp mainly includes two parts, a bushing part and a clamping part.

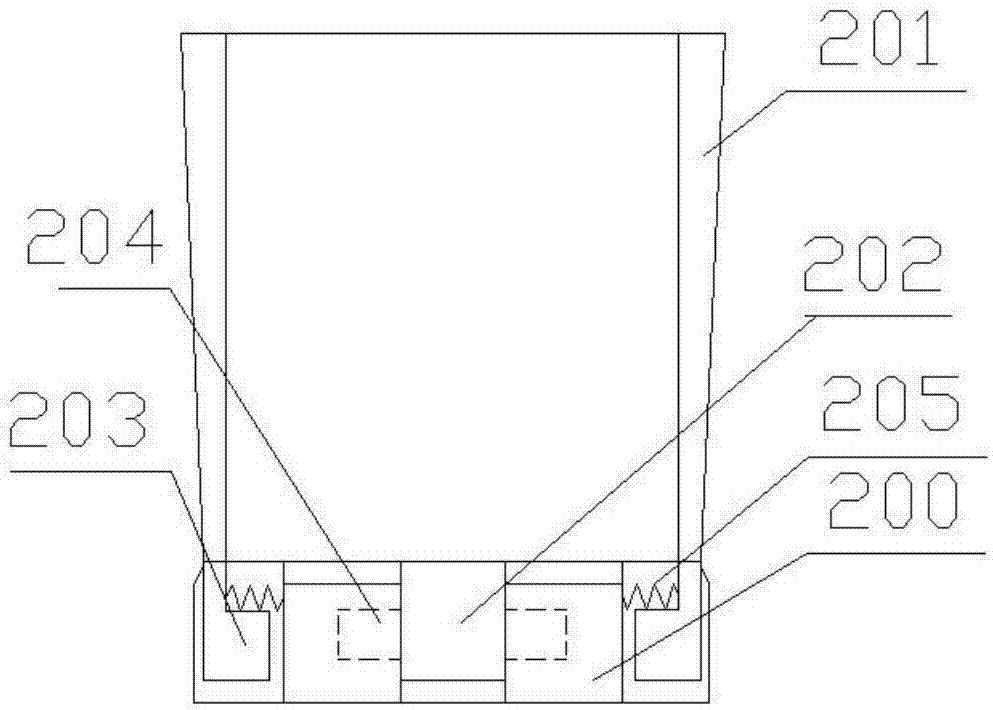

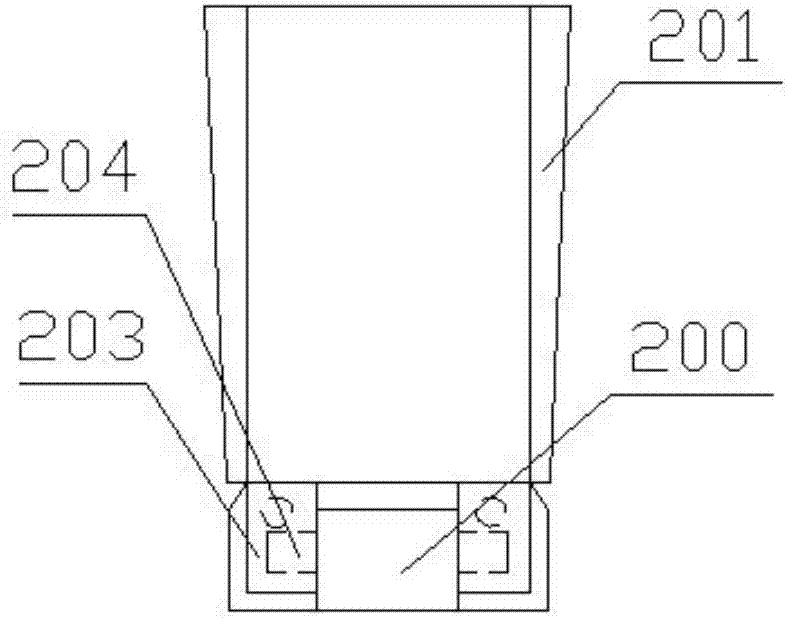

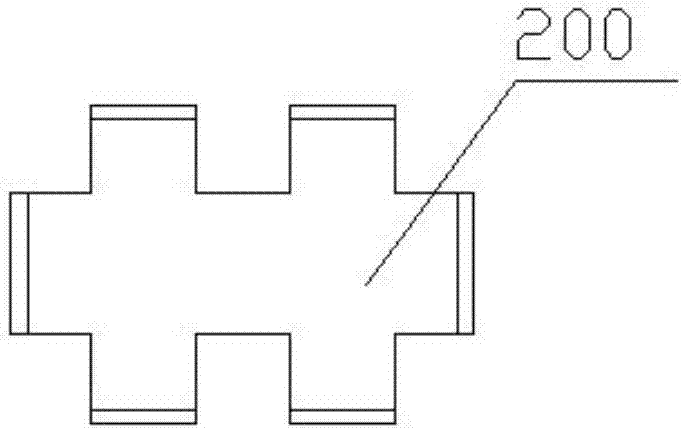

[0033] Among them, the bushing part such as figure 1 , figure 2 As shown, it mainly includes a bottom plate 200 and four side plates 201, and the four side plates 201 are rotatably arranged on the front, rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com