Compound titanium-based lubricant and preparation method thereof

A technology of compounding titanium and lubricating grease, applied in the direction of lubricating composition, petroleum industry, etc., can solve the problems of unstable bearing vibration speed, high industrial production cost, no indication of characteristics, etc., to improve the reaction rate and degree of reaction, reproduce High performance, good product quality and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

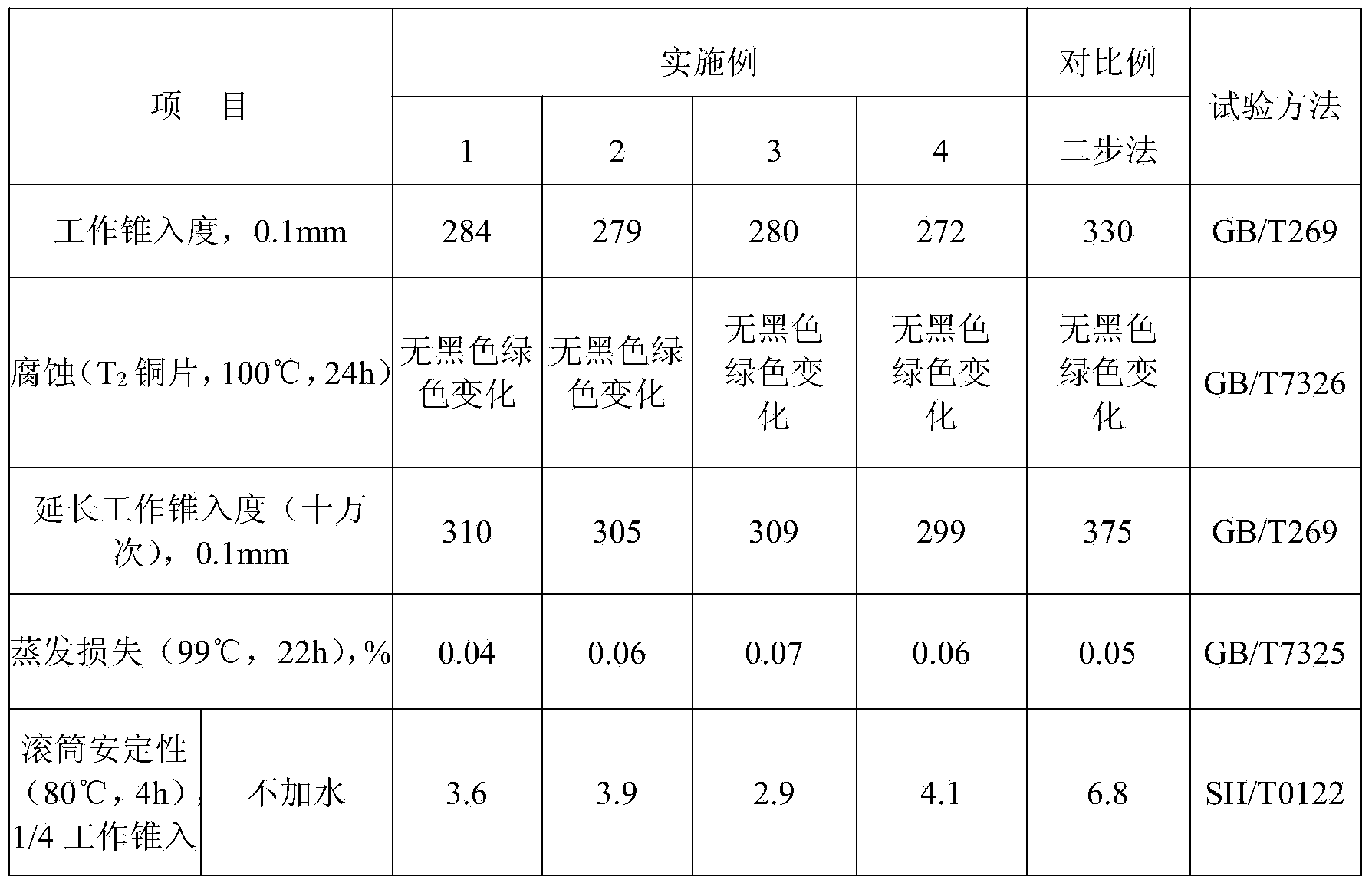

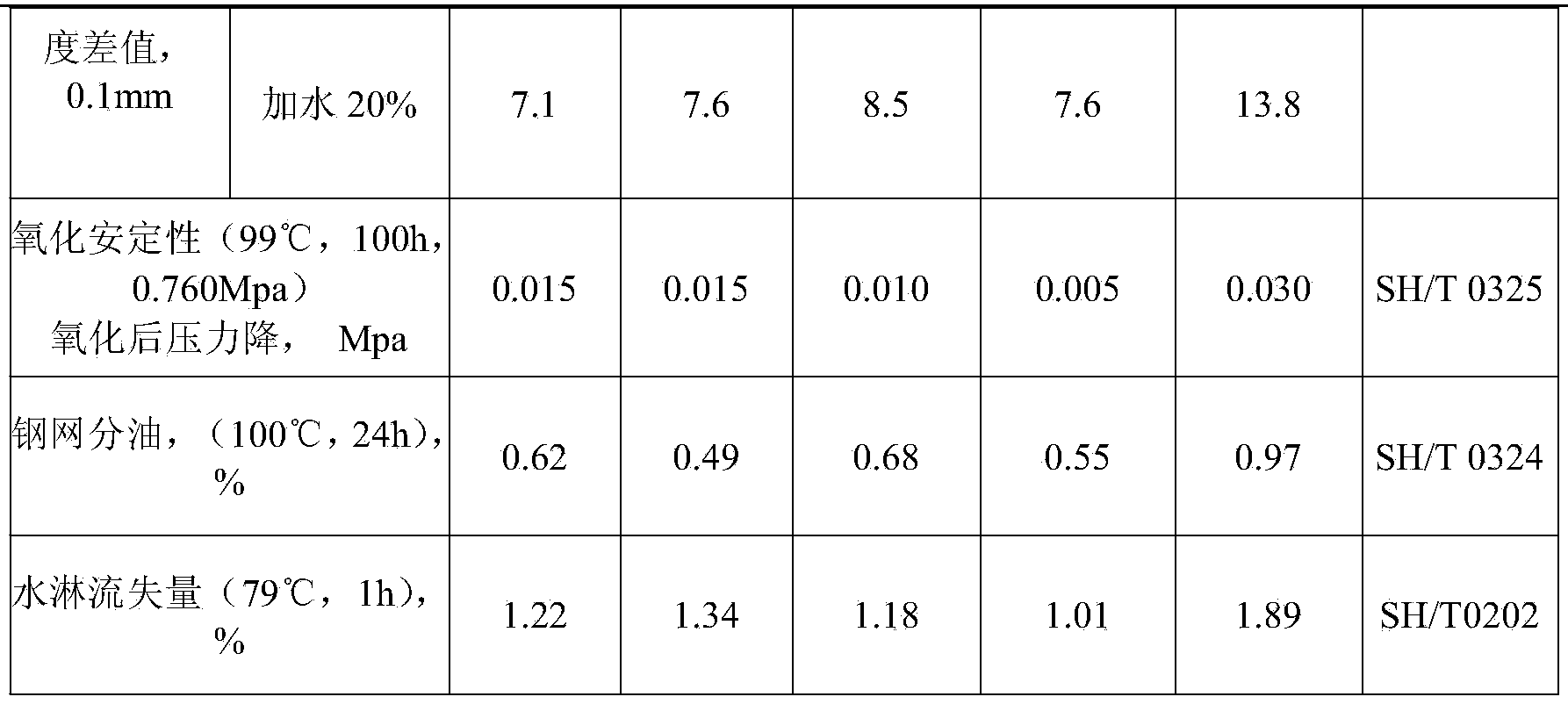

Embodiment 1

[0031] Add 300g150BS oil, 45g trimethylolpropane ester, 10g isopropanol, 40g stearic acid, 11.7g terephthalic acid into the kettle, heat to 65°C, then slowly add 20g tetraisopropyl titanate, keep warm 30min, after the insulation is completed, slowly heat to make the temperature rise to 100°C (in this heating process, isopropanol is volatilized and removed), add 2g distilled water, keep stirring for 20min, then heat to 180°C at a rate of 1°C / min (this temperature rises) During the process, distilled water was volatilized and removed), kept stirring for 30min, then stopped heating, added 80g cold 150BS oil, waited for the temperature to drop to 90°C, added 16g hydrogenated styrene block copolymer and 6g liquid diphenylamine, and then passed through a three-roll mill. After grinding three times, the finished composite titanium-based grease is obtained, and its properties are shown in Table 1.

Embodiment 2

[0033] Add 295g 600SN oil, 40g pentaerythritol ester, 20g butyl acetate, 36g stearic acid, 4g dodecyl stearic acid, 9.7g salicylic acid into the kettle, heat to 80°C, slowly heat 20g tetraisopropyl titanate , heat preservation reaction for 20min, after the heat preservation is finished, slowly heat to make the temperature rise to 105 ℃ (during this heating process, butyl acetate is volatilized and removed), add 2g distilled water, keep stirring for 20min, then heat to 190 ℃ at the rate of 1.5 ℃ / min (During this heating process, distilled water was volatilized and removed), keep stirring for 30min, then stop heating, add 80g cold 600SN oil, wait for the temperature to drop to 90°C, add 10g ethylene-propylene copolymer and 5g liquid diphenylamine, then pass through a three-roll mill After grinding three times, the finished composite titanium-based grease is obtained, and its properties are shown in Table 1.

Embodiment 3

[0035] 360g 600SN oil, 80g pentaerythritol ester, 20g butyl acetate, 40g stearic acid, 9.7g salicylic acid were added to the kettle, heated to 75°C, 35g tetraisopropyl titanate was slowly added, and the reaction was incubated for 30min. , slowly heated to make the temperature rise to 105 ℃ (during this heating process, butyl acetate was volatilized and removed), added 5g distilled water, after thermal insulation and stirring for 30min, then heated to 190 ℃ at a rate of 1.5 ℃ / min (in this heating process, distilled water volatilization and removal), keep stirring for 30min, then stop heating, add 80g cold 600SN oil, wait for the temperature to drop to 90℃, add 15g polymethyl methacrylate, 4g liquid diphenylamine and 2.5g polymer liquid phenol, and then pass through three rolls The composite titanium-based lubricating grease was obtained by grinding three times by the grinding machine, and its properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com