Manufacturing process of porous component and porous component

A technology for porous components and components, which is used in the field of manufacturing porous components and components, and can solve problems such as distortion and part size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

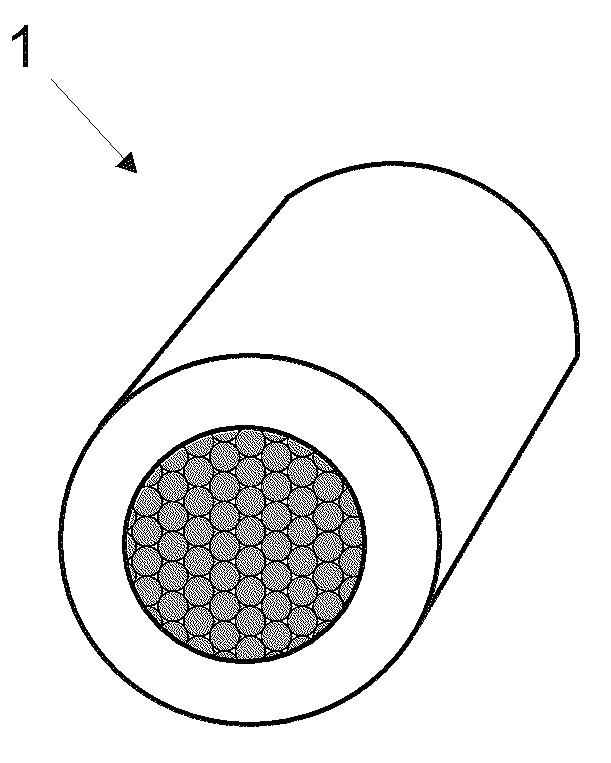

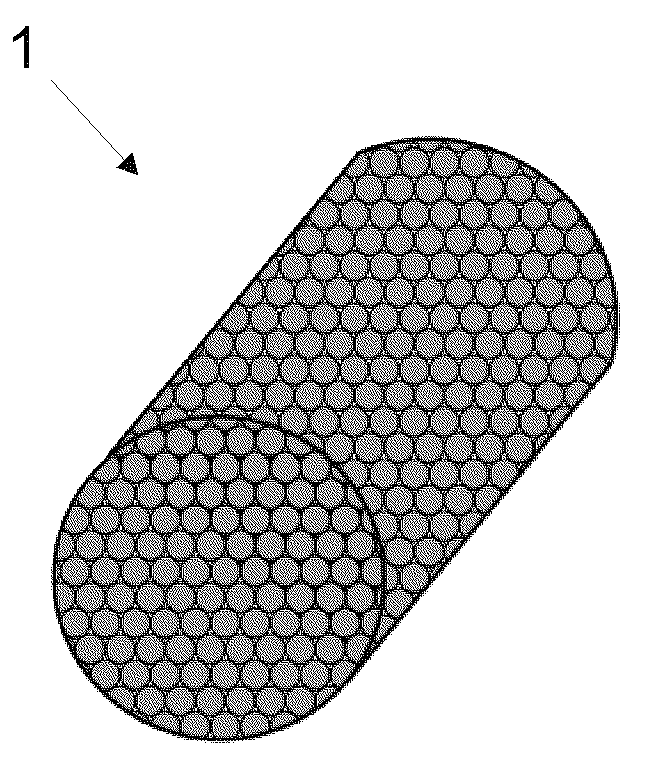

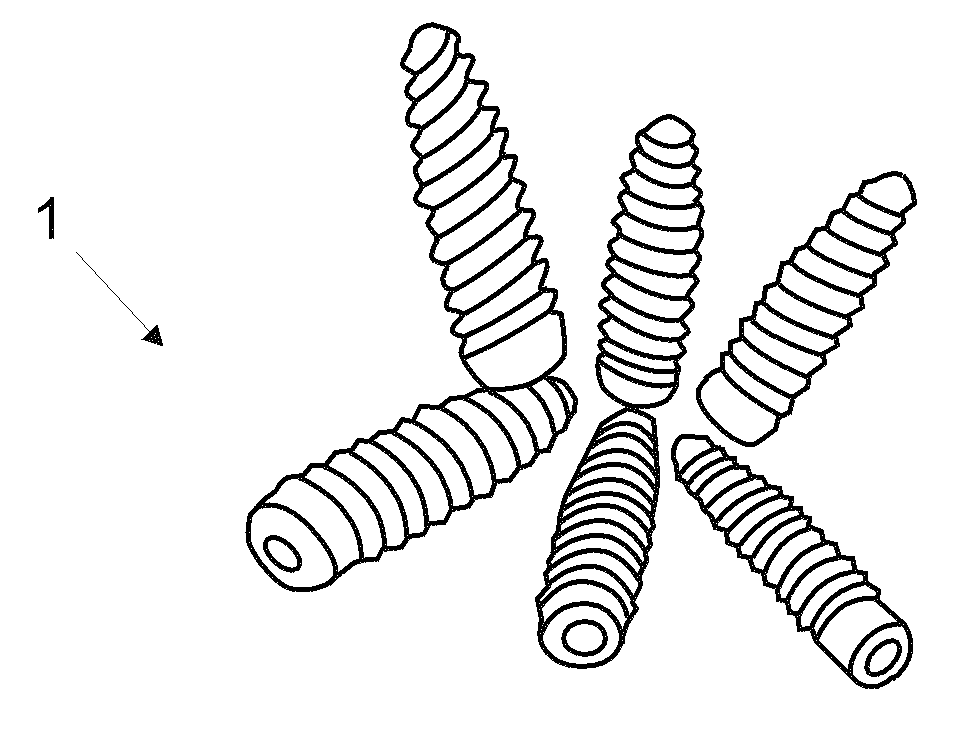

[0026] In the present invention, the method used to manufacture the porous material is Powder Injection Molding (PIM), which is a deformation technique of powder metallurgy, and is modified in the invention herein so that It is possible to obtain a porous structure with the characteristics necessary for the specific intended application; in other words, for seeking a homogeneously distributed porous part of the gaseous fluid (flow restrictor) of the aerostatic bearing.

[0027] One such application concerns the aerostatic bearings of compressors, where the bearings of the compressors are realized by a layer of gas that balances the linear motion of the piston inside the cylinder. In order to do this, the amount of gas used to support the piston needs to be constant, so as to control the fluid flow, it is necessary to use a porous part 1 with a homogeneous porous structure that not only allows regulation of the flow but is evenly distributed in the system to be undertaken. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com