Vegetable gelatin fracturing fluid and preparation method thereof

A fracturing fluid and plant glue technology, applied in the field of fracturing fluid, can solve the problems of large price fluctuations and inability to produce on a large scale, and achieve the effects of excellent gel performance, large molecular weight, and strong thickening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Add 100 parts by weight of water into the reaction kettle, heat to 80°C, then add 90 parts by weight of glycerin, slowly add 90 parts by weight of borax under stirring conditions, and react at this temperature for 100 minutes. Obtain organoboron crosslinking agent after complete reaction;

[0026] Step 2: Add 90 parts by weight of butyl titanate into the reaction kettle, heat to 60°C, add 70 parts by weight of triethanolamine under stirring conditions, and add 70 parts by weight of glycerin after 30 minutes, at this temperature React for 160 minutes to get organic titanium high temperature stabilizer;

[0027] Step 3: Measure 80 parts by weight of water, pour it into a blender, slowly add 0.2 parts by weight of konjac gum, prevent the formation of fish eyes during the addition process, and adjust the speed at all times to ensure the vortex state; then continue to stir to fully dissolve it Form a uniform solution to obtain the required base liquid; in the prepar...

Embodiment 2

[0029] Step 1: Add 120 parts by weight of water into the reaction kettle, heat to 85°C, then add 100 parts by weight of glycerin, slowly add 100 parts by weight of borax under stirring conditions, and react at this temperature for 125 minutes. Obtain organoboron crosslinking agent after complete reaction;

[0030] Step 2: Add 100 parts by weight of butyl titanate into the reaction kettle, heat to 75°C, add 80 parts by weight of triethanolamine under stirring conditions, and add 80 parts by weight of glycerin after 45 minutes, at this temperature React for 180 minutes to get organic titanium high temperature stabilizer;

[0031] Step 3: Measure 90 parts by weight of water, pour it into a blender, slowly add 0.3 parts by weight of konjac gum, prevent the formation of fish eyes during the addition process, and adjust the speed at all times to ensure the vortex state; then continue to stir to fully dissolve it Form a uniform solution to obtain the required base liquid; in the pre...

Embodiment 3

[0033] Step 1: Add 140 parts by weight of water into the reaction kettle, heat to 90°C, then add 110 parts by weight of glycerin, slowly add 110 parts by weight of borax under stirring conditions, and react at this temperature for 150 minutes. Obtain organoboron crosslinking agent after complete reaction;

[0034] Step 2: Add 110 parts by weight of butyl titanate into the reaction kettle, heat it to 90°C, add 90 parts by weight of triethanolamine under stirring conditions, and add 90 parts by weight of glycerin after 60 minutes. React for 200 minutes to get organic titanium high temperature stabilizer;

[0035] Step 3: Measure 100 parts by weight of water, pour it into a blender, slowly add 0.4 parts by weight of konjac gum, prevent the formation of fish eyes during the addition process, and adjust the speed at all times to ensure the vortex state; then continue to stir to fully dissolve it Form a uniform solution to obtain the required base liquid; in the prepared base liqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

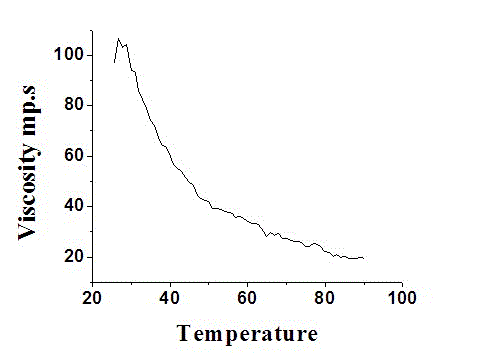

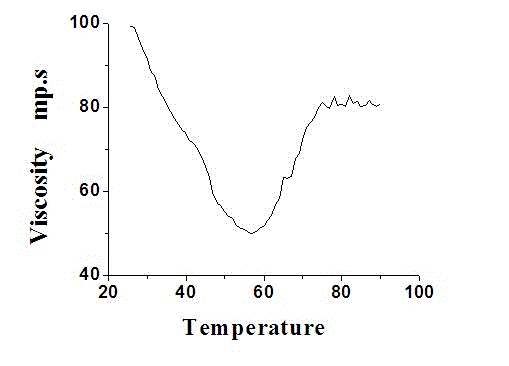

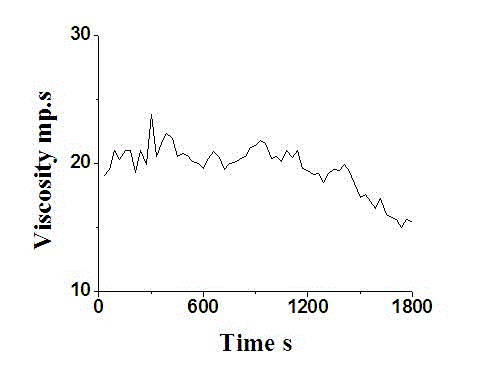

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com