Modified ardealite roadbed material

A roadbed material, phosphogypsum technology, applied in the field of road engineering, can solve the problems of water stability not meeting the required requirements, phosphogypsum can not be compacted, ecological environment impact, etc., to meet the strength and elastic modulus requirements, The effect of high compaction and reduced environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

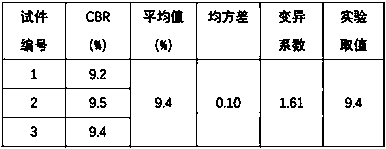

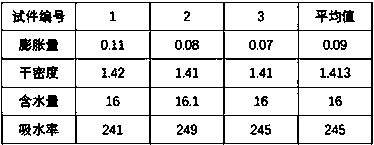

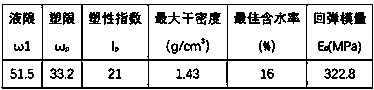

Embodiment 1

[0016] Take 15t of phosphogypsum, 15t of sand / clay, 5t of fly ash, 2t of quicklime as raw materials, and thoroughly mix and stir to obtain the base material; before construction, add curing agent to the base material, mix evenly, and add amount of curing agent Add 300g for every 1 cubic meter of base material. The curing agent is a potassium hydroxide aqueous solution with a mass concentration of 0.4-0.6%.

[0017] Use the base material with curing agent as the roadbed raw material for direct construction and use.

Embodiment 2

[0019] Take 40t phosphogypsum, 40t clay, 8t fly ash, and 3t calcium carbide slag as raw materials. After fully mixing and stirring, the base material is obtained; before construction, add curing agent to the base material and mix evenly. The amount of curing agent added is Add 500g to 1 cubic meter of base material. The curing agent is a mixture of a 4-6% calcium dodecyl sulfonate aqueous solution and a 4-6% calcium lignosulfonate aqueous solution with a mass concentration.

[0020] Use the base material with curing agent as the roadbed raw material for direct construction and use.

Embodiment 3

[0022] Use 30t phosphogypsum, 30t sand, 6t fly ash, 2.5t calcium carbide slag as raw materials, and fully mix and stir to obtain the base material; before construction, add curing agent to the base material, mix evenly, and add amount of curing agent Add 400g per cubic meter of base material. The curing agent is an aqueous solution of calcium dodecyl sulfonate with a mass concentration of 4-6%.

[0023] Use the base material with curing agent as the roadbed raw material for direct construction and use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com