Unartificial process for processing tooth socket

A non-artificial, braces technology, applied in dentistry, orthodontics, dental restorations, etc., can solve the problems of labor cost, processing quality accuracy varies from person to person, and poor quality stability, so as to reduce production and processing costs and improve Good processing efficiency and product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The present invention is achieved through the following technical solutions:

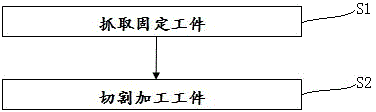

[0021] The process of non-artificially processing the braces includes the following steps in sequence:

[0022] S1: Grab a fixed workpiece

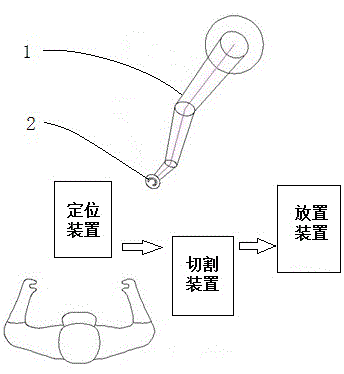

[0023] The workpiece is clamped by a mechanical device, and the workpiece is firmly adsorbed and clamped by negative pressure, and at the same time, the clamping position of the brace is accurately positioned by a positioning device; preferably, the mechanical device is a robot or a mechanical arm. When the processing workpiece, that is, the dental crown after lamination treatment, appears in the operation table or working area of the robot or the mechanical arm 1, the robot or the mechanical arm 1 executes the action of grabbing the dental crown 2 according to the instructions issued by the control terminal, and adjusts and determines The clamping orientation of the mouthpiece 2 is convenient for subsequent processing operations.

[0024] S2: cuttin...

Embodiment 2

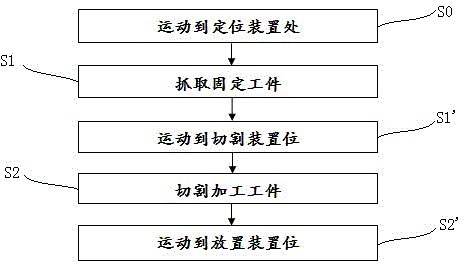

[0030] As an improvement of the process of non-manually processing dental braces in the present invention, before the step S1, the mechanical equipment is also moved to the positioning device, and after the step S1, the mechanical equipment is also moved to the cutting device position. After S2, the movement of the mechanical equipment to the placement device position is also included. Include the following steps in turn:

[0031] S0: The mechanical equipment moves to the positioning device

[0032] The mechanical equipment is movable, including but not limited to a movable robot or mechanical arm 1 . Through this step, the control end issues instructions to the working robot or the mechanical arm 1, requiring it to move to the positioning device where the workpiece is located.

[0033] S1: Grab a fixed workpiece

[0034] The workpiece is clamped by a mechanical device, and the workpiece is firmly adsorbed and clamped by negative pressure, and at the same time, the clamping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com