Automatic assembly machine of gas stove ignition device, and control method thereof

A technology of ignition device and gas stove, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of poor product quality stability and low efficiency, and achieve the effect of good product quality stability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

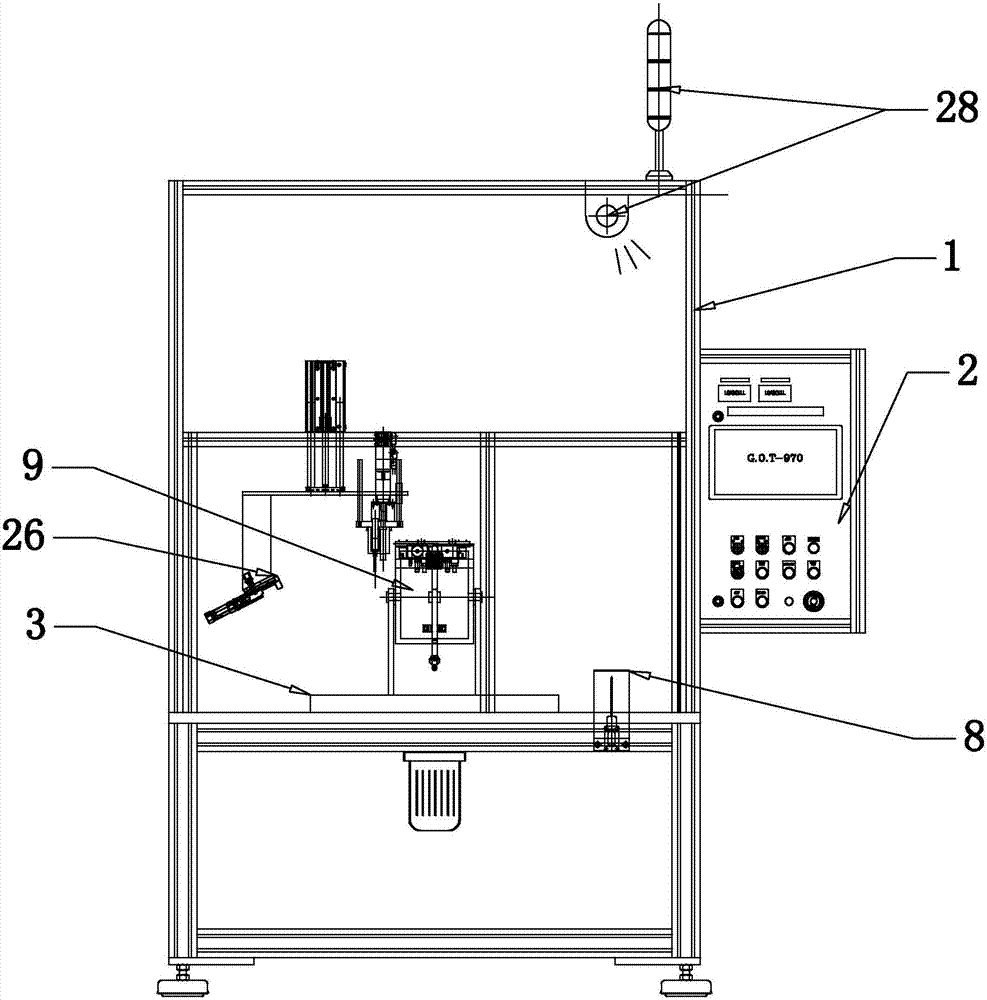

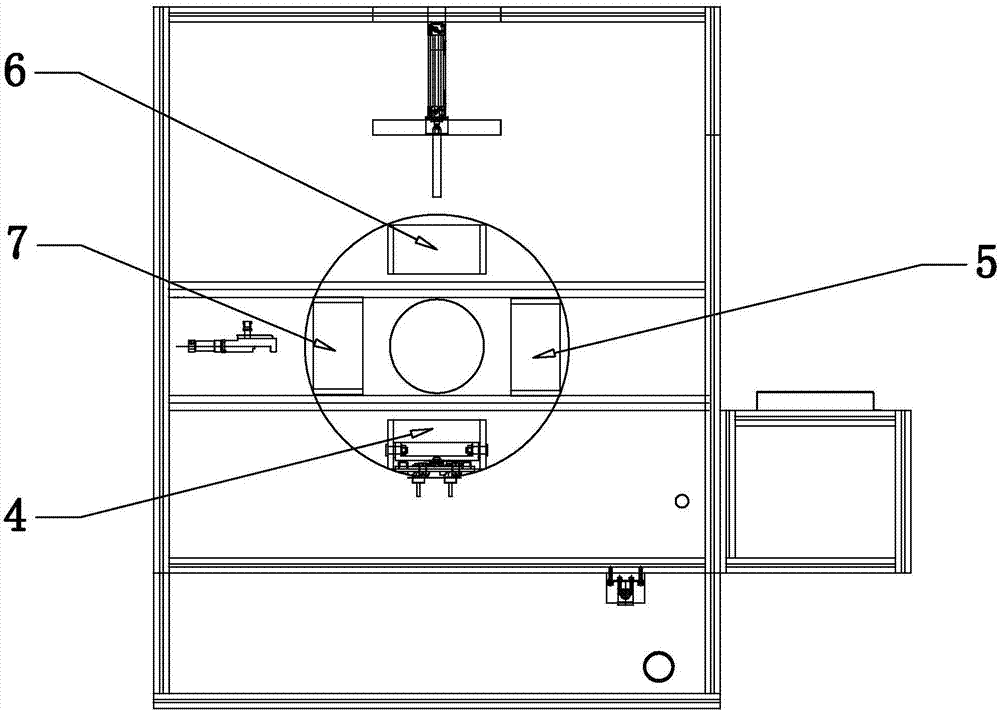

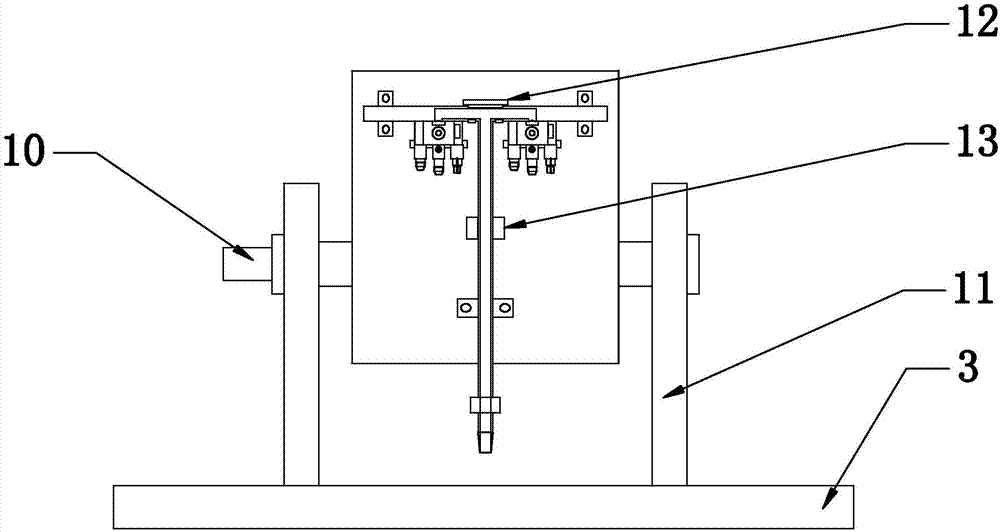

[0031] Embodiment one: if Figure 1-8 As shown, the present invention is an automatic assembly machine for a gas stove ignition device, comprising a frame 1 and a control unit 2, the frame 1 is provided with a working platform, and the center of the working platform is provided with a rotating device 3, and the rotating device 3 The four sides are respectively provided with a loading and unloading station 4, a tightening station 5, a flow regulating station 6 and an air tightness testing station 7 in sequence, and the frame 1 is provided with a start switch 8, a control unit 2 and a power system , the start switch 8 is a start button, the rotating device 3, the loading and unloading station 4, the tightening station 5, the flow regulating station 6 and the air tightness detection station 7 are all connected to the power system and the control unit 2, the The start switch 8 is connected to the control unit 2 . The control unit is connected with a paint spotting and scanning wo...

Embodiment 2

[0045] Embodiment two: if Figure 1-8 As shown, the present invention is an automatic assembly machine for a gas stove ignition device, such as Figure 1-8 As shown, the present invention is an automatic assembly machine for a gas stove ignition device, comprising a frame 1 and a control unit 2, the frame 1 is provided with a working platform, and the center of the working platform is provided with a rotating device 3, and the rotating device 3 The four sides are respectively provided with a loading and unloading station 4, a tightening station 5, a flow regulating station 6 and an air tightness testing station 7 in sequence, and the frame 1 is provided with a start switch 8, a control unit 2 and a power system , the rotating device 3, the loading and unloading station 4, the tightening station 5, the flow regulating station 6 and the air tightness detection station 7 are all connected to the power system and the control unit 2, and the start switch 8 is connected to the contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com