Processing method for TC4 titanium alloy large-sized bar

A processing method and titanium alloy technology, which is applied in the field of titanium alloy bar preparation, can solve the problems of difficulty in increasing the length or unit weight of the bar, low level of ultrasonic flaw detection, poor product quality consistency, etc., and achieve high level of flaw detection and stable product quality Good performance and less internal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

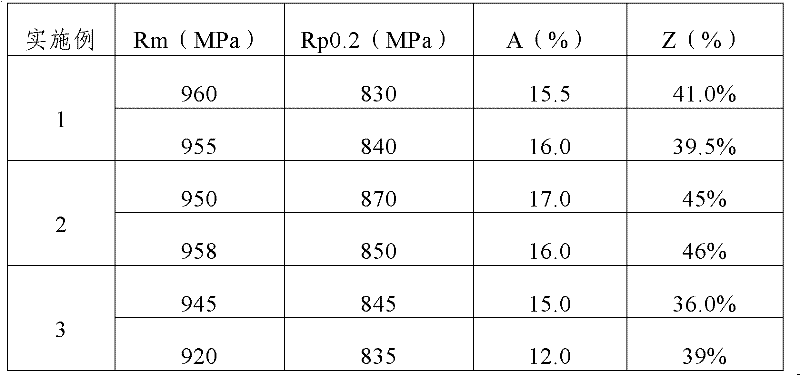

Embodiment 1

[0023] In this embodiment, a TC4 titanium alloy ingot with a diameter of Φ700mm is used as a raw material to process a TC4 titanium alloy rod with a diameter of Φ250mm. The processing method is as follows:

[0024] Step 1. Use a 2500T hydraulic press to forge a TC4 titanium alloy ingot with a diameter of 700mm at a temperature of 1150°C for 2 fires. The forging ratio of each fire is controlled to be 1.5, and the final forging temperature is not lower than 900°C. Obtain a forging billet of 400mm×400mm×850mm; before each forging, the ingot is heated to 1150°C with a gas furnace and kept for 390min;

[0025] Step 2. Use a 2500T hydraulic press to repeatedly upsetting and elongating the forged billet of 400mm×400mm×850mm described in step 1 under the condition that the temperature is 20°C above the β transformation point of the ingot. The forging ratio is all 1.5, and the final forging temperature is not lower than 820°C; before each forging, the forging billet is heated to 20°C a...

Embodiment 2

[0029] In this embodiment, a TC4 titanium alloy ingot with a diameter of Φ700mm is used as a raw material to process a TC4 titanium alloy bar with a diameter of Φ200mm. The processing method is as follows:

[0030] Step 1. Use a 2500T hydraulic press to open and forge the TC4 titanium alloy ingot with a diameter of Φ700mm at a temperature of 1200°C for 2 fires. The forging ratio of each fire is controlled to be 1.5, and the final forging temperature is not lower than 900. °C to obtain a 380mm × 380mm × 760mm forging billet; the ingot was heated to 1200 °C in sections with a gas furnace before each fire forging and kept for 370min;

[0031] Step 2. Use a 2500T hydraulic press to forge the 380mm×380mm×760mm forging billet described in step 1 repeatedly for 3 fires under the condition that the temperature is 30°C above the β transformation point of the ingot. The ratios are 1.8, 1.7 and 1.5 in turn, and the final forging temperature is not lower than 820°C; before each forging, h...

Embodiment 3

[0035] In this embodiment, a TC4 titanium alloy ingot with a diameter of Φ800mm is used as a raw material to process a TC4 titanium alloy bar with a diameter of Φ400mm. The processing method is as follows:

[0036]Step 1. Use a 3150T hydraulic press to open and forge a Φ800mm TC4 titanium alloy ingot at a temperature of 1180°C for 3 fires. The forging ratios of each fire are 2.6, 2.4 and 1.5 in sequence, and the final forging temperature is not lower than 900°C to obtain a forging billet of 580mm×580mm×1200mm; before each forging, the ingot was heated to 1180°C with a gas furnace and kept for 430min;

[0037] Step 2. Using a 3150T hydraulic press, repeatedly upsetting and elongating the 580mm×580mm×1200mm forging billet described in step 1 under the condition that the temperature is 50°C above the β transformation point of the ingot and forging for 3 times. The ratios are 1.8, 1.7 and 1.5 in turn, and the final forging temperature is not lower than 820°C; before each forging, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com