Automatic assembly, detection and marking method and system for electronic detonator

An electronic detonator and automatic assembly technology, applied in detonators, offensive equipment, etc., can solve the problems of employees not being able to operate remotely, low production efficiency, etc., and achieve the effects of high safety, high production efficiency, and improved automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

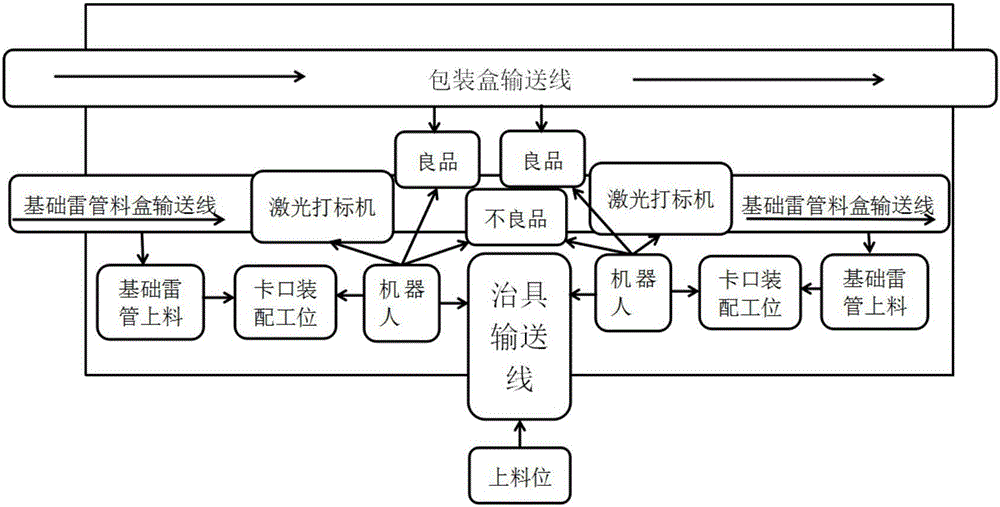

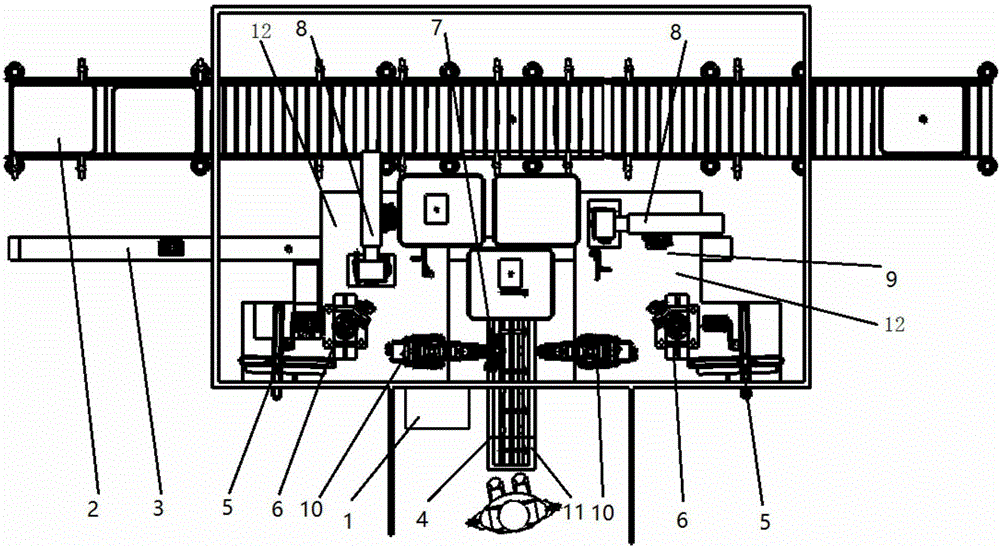

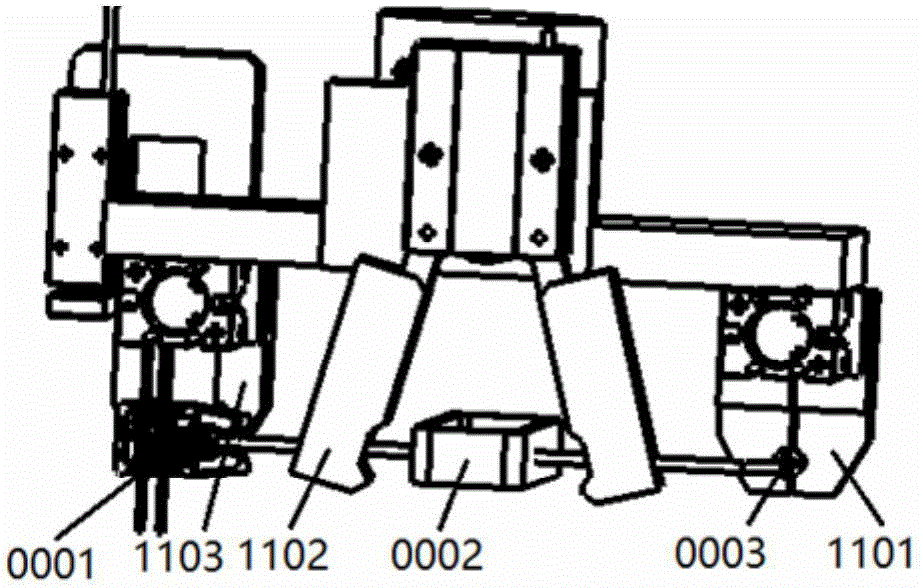

[0033] Embodiment 1 of the present invention: electronic detonator automatic assembly, detection, and marking method. First, the module assembly is installed on the foot wire fixing fixture. The module assembly is connected to the electronic detonator control module through the foot wire with a sealing plug by the quick wire clamp. Composed together, the foot line fixing jig is fixed on the jig conveying line, and the module components are sent into the explosion-proof room through the jig conveying line; at the same time, the basic detonator feeding mechanism automatically transfers a single foundation The detonator is extracted from the material box and sent to the tight mouth mechanism; then the robot automatically clamps the module assembly out of the foot line fixing jig, and automatically assembles the electronic control module and sealing plug part of the module assembly into the tight mouth The mechanism is assembled with the basic detonator; then the robot takes out th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com