Forming method of composite material part with variable cross-section closed cavity

A composite material and molding method technology, applied in the field of composite material molding, can solve problems such as the inability to guarantee the pressure of the inner and outer cavity and affect the quality of the product, and achieve the effects of good product quality stability and strong manufacturability and practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Due to the variable cross-section closed cavity structure area, pipe beam structure area, and wall plate structure area in the product structure, silicon capsule pressurization, mold pressurization, foam pressurization and vacuum bag pressurization are used for molding for different areas, so that the product Different structural parts realize co-curing molding.

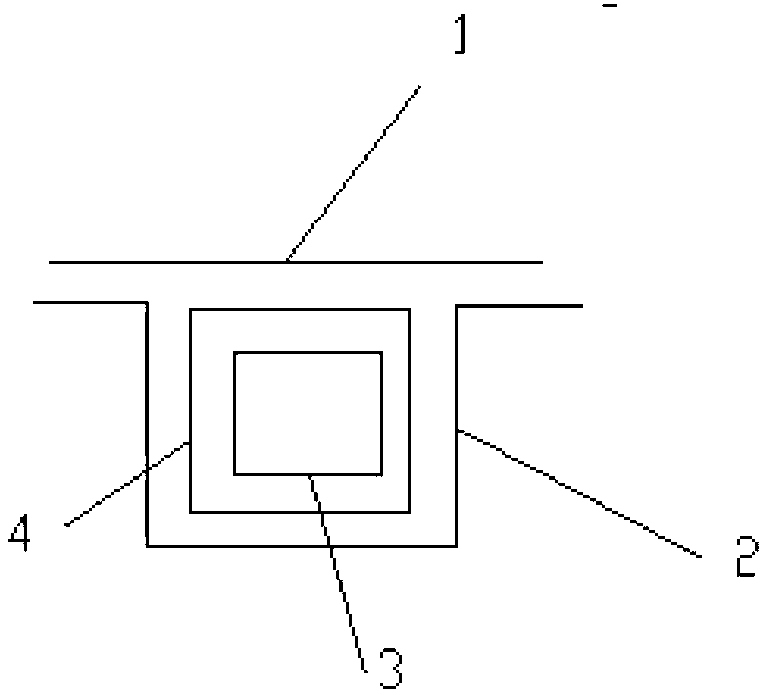

[0019] see figure 1 , figure 1 Explanation of the principle of using silicone rubber pressurization and mold pressurization for the pipe beam: tooling cover plate 1 tooling layer 2 silicone rubber 3 pipe beam structure products 4

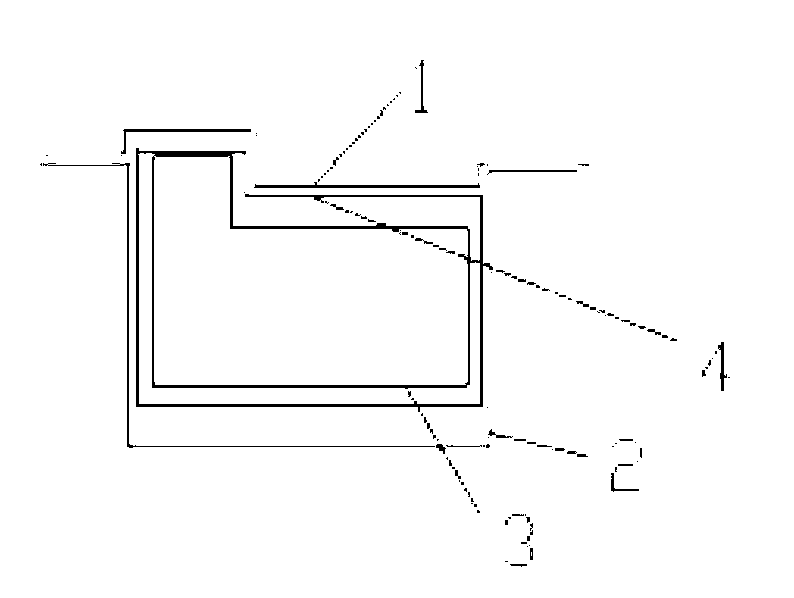

[0020] join figure 2 , figure 2 Explanation of the principle of using foam pressurization and mold pressurization for the variable cross-section closed cavity area, tooling cover plate 1 tooling pavement layer 2 foam 3 variable cross-section closed cavity structure product 4

[0021] The molding method is,

[0022] 1) Mold design and manufacture:

[0023] ●Design: The moldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com