High-temperature-resistant and high-pressure-resistant viscosity reducer for oil-based drilling fluid and preparation method of viscosity reducer

A technology of oil-based drilling fluid and viscosity reducer, which is applied in the field of oil drilling, can solve problems such as unsuitable operation, viscosity reducer cannot withstand high temperature and high pressure, etc., and achieve large steric hindrance, good dilution and viscosity reduction effect, and reduce viscosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

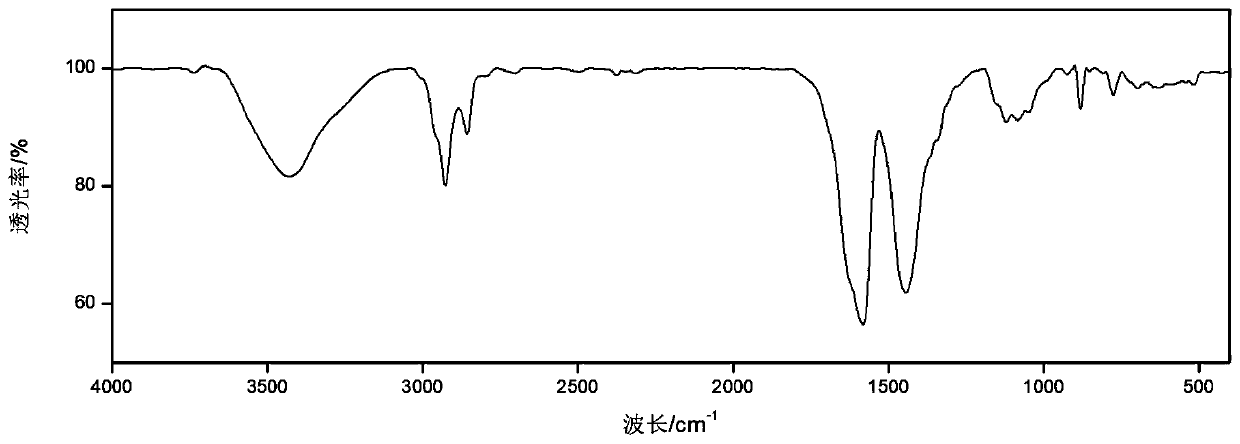

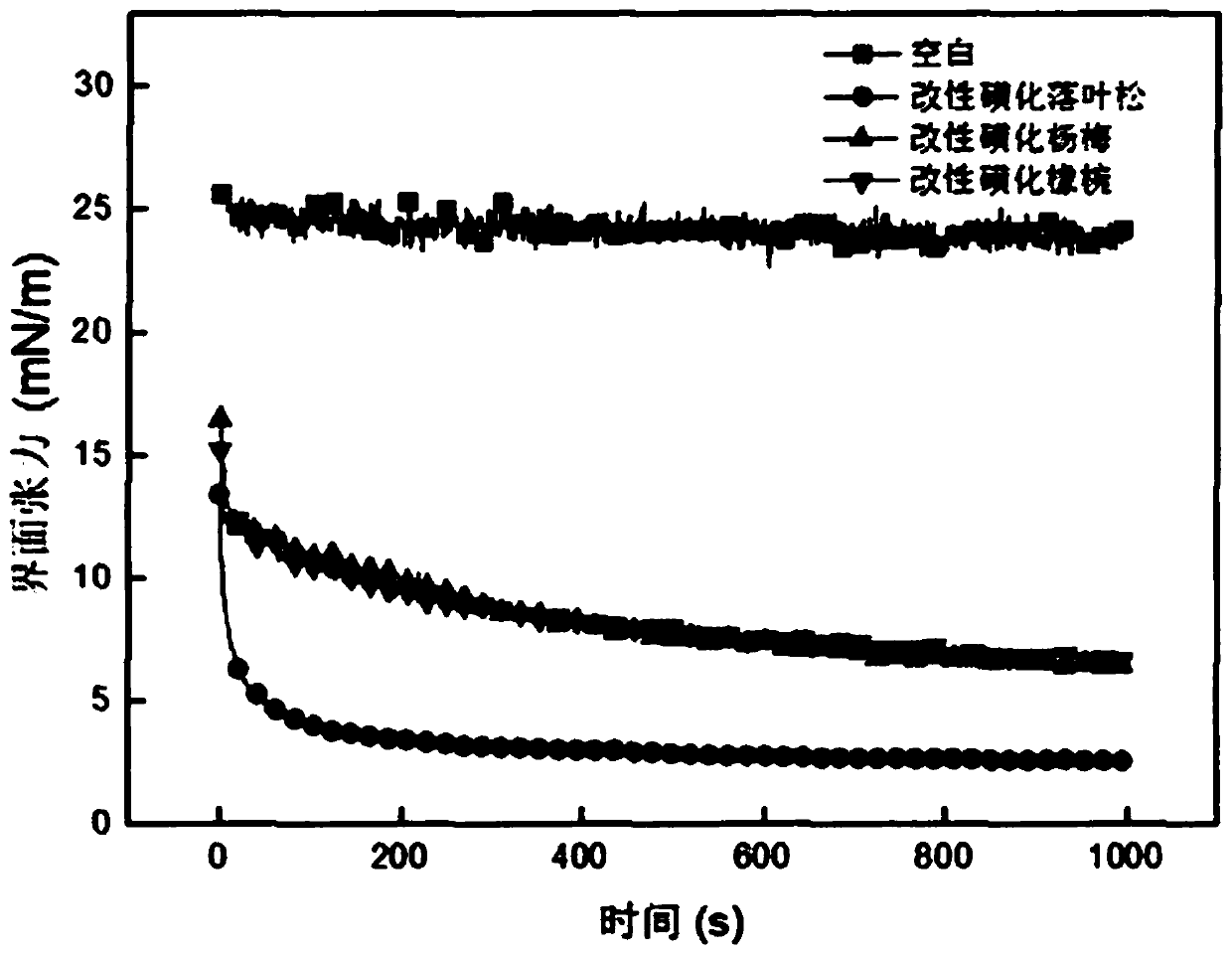

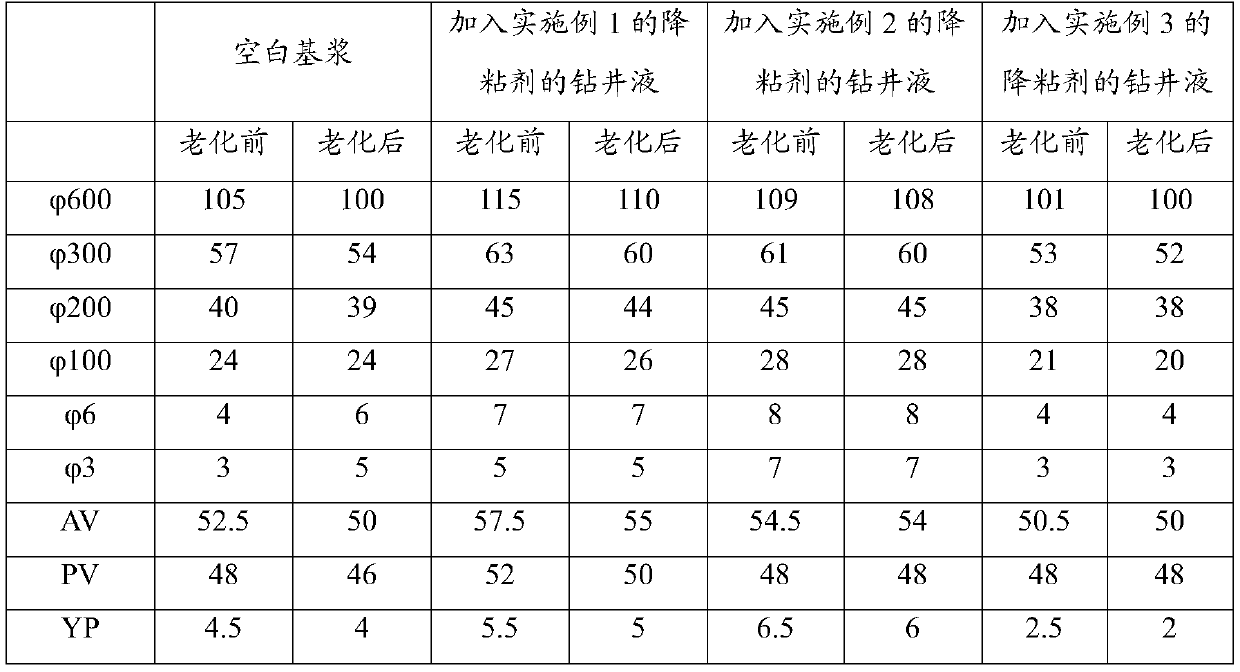

[0031] Add 5.16g of diethylenetriamine and 10.02g of lauric acid to the three-necked flask, control the molar ratio of the reactants to 1:1, then add 50g of xylene as the reaction medium and water-carrying agent, and put the magnet into the three-necked flask ;Put the three-necked flask in the oil bath, connect the water separator above the middle bottle mouth of the three-necked flask, connect the condensing reflux device above the water separator, and connect the thermometer on one side of the three-necked flask; open the condensing reflux device, and the oil bath starts Heating, the target temperature is 180°C, initially set the temperature of the oil bath to 150°C, when the temperature is close to the target temperature, adjust the preset temperature of the oil bath again, pay attention to the water in the water separator and the carrying water at all times during the heating process The amount of the agent is adjusted accordingly, and the heating rate is adjusted according...

Embodiment 2

[0034] Add 5.16g of diethylenetriamine and 10.02g of lauric acid to the three-necked flask, control the molar ratio of the reactants to 1:1, then add 50g of xylene as the reaction medium and water-carrying agent, and put the magnet into the three-necked flask Flask; put the three-necked flask in the oil bath, connect the water separator above the middle bottle mouth of the three-necked bottle, connect the condensing reflux device above the water separator, and connect the thermometer on one side of the three-necked flask; open the condensing reflux device, oil bath Start to heat up, the target temperature is 180°C, initially set the temperature of the oil bath to 150°C, when the temperature is close to the target temperature, adjust the preset temperature of the oil bath again, pay attention to the water in the water separator and the portable The amount of water agent, and adjust the heating rate accordingly, to avoid too fast temperature rise and cause a large amount of water...

Embodiment 3

[0037]Add 5.16g of diethylenetriamine and 10.02g of lauric acid to the three-necked flask, control the molar ratio of the reactants to 1:1, then add 50g of xylene as the reaction medium and water-carrying agent, and put the magnet into the three-necked flask Flask; put the three-necked flask in the oil bath, connect the water separator above the middle bottle mouth of the three-necked bottle, connect the condensing reflux device above the water separator, and connect the thermometer on one side of the three-necked flask; open the condensing reflux device, oil bath Start to heat up, the target temperature is 180°C, initially set the temperature of the oil bath to 150°C, when the temperature is close to the target temperature, adjust the preset temperature of the oil bath again, pay attention to the water in the water separator and the portable The amount of water agent, and adjust the heating rate accordingly, to avoid too fast temperature rise and cause a large amount of water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com