Preparation method for common casting iron-based ceramic composite vertical grinding roller

A ceramic composite material, iron-based technology, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as high requirements for casting equipment, insufficient grinding roller strength, and complex process implementation, avoiding pores and clamping. The effect of slag, easy casting process and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention comprises the steps:

[0033] 1) Select fused zirconia corundum particles with a particle size of 2-4mm, the mass percentage of the particles is 21-28wt%Al, 29-33wt%Zr, the rest is O, and the hardness of the particles is HRC70-75;

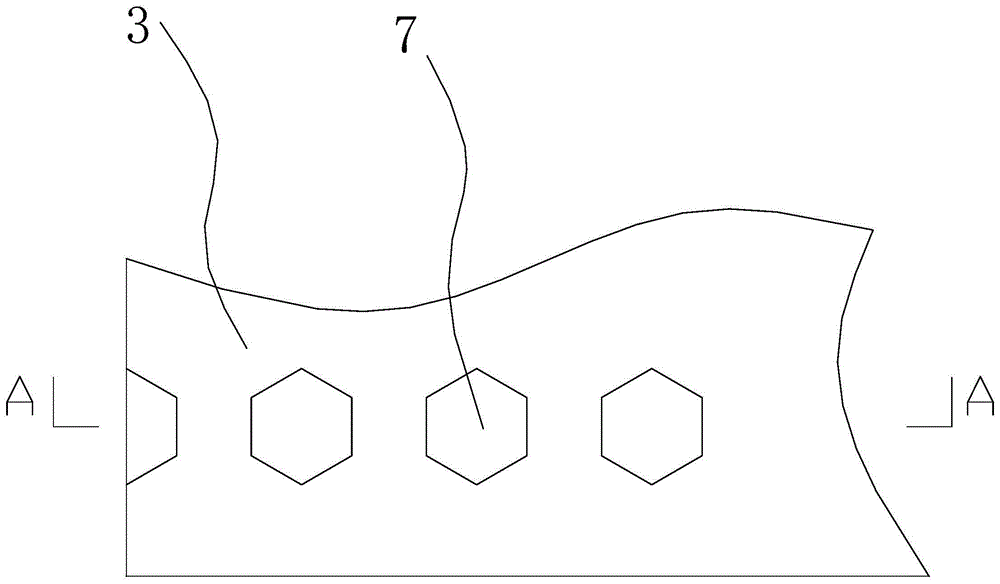

[0034] 2) Mix the above fused zirconia corundum particles with 2-4wt% binder, and add 1-3wt% of the mixed powder of aluminum powder and rare earth powder while mixing; mix evenly and spread it in the mold, and put it in the oven Keep warm at 150-300°C for 20-30 minutes, and after demoulding, the arc-shaped honeycomb-shaped zirconium corundum ceramic particle preform is cooled for use; the size and shape of the preform are 1 / 15-1 of the arc outer surface of the vertical grinding roller / 20, the thickness is 10-50mm;

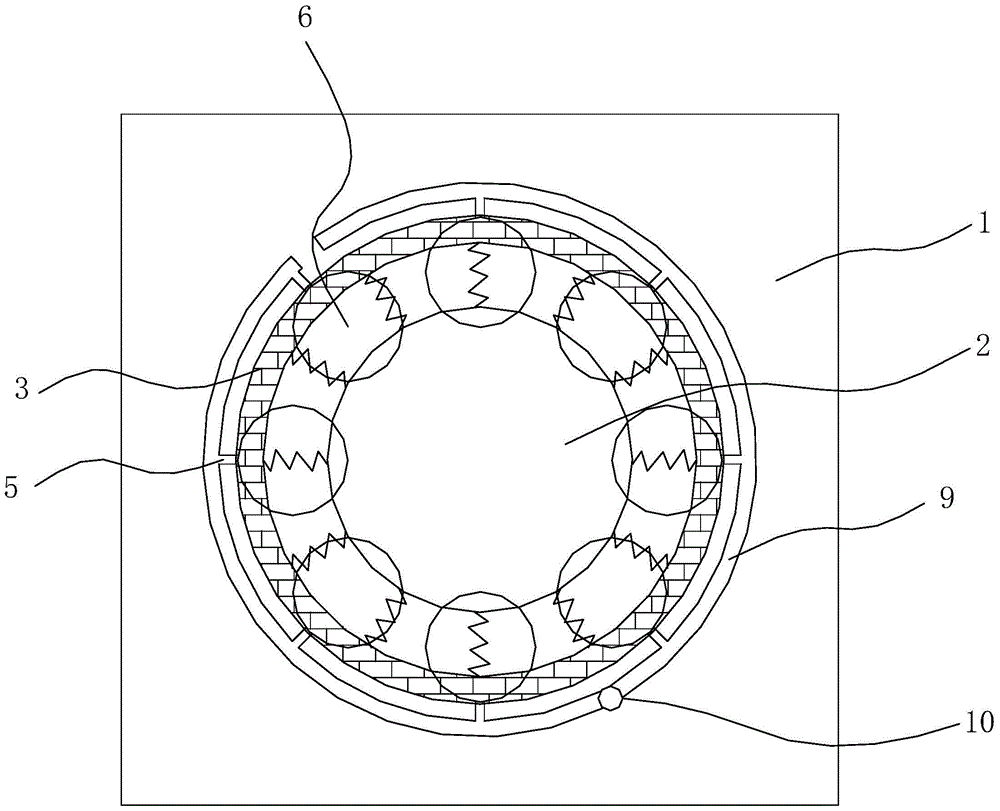

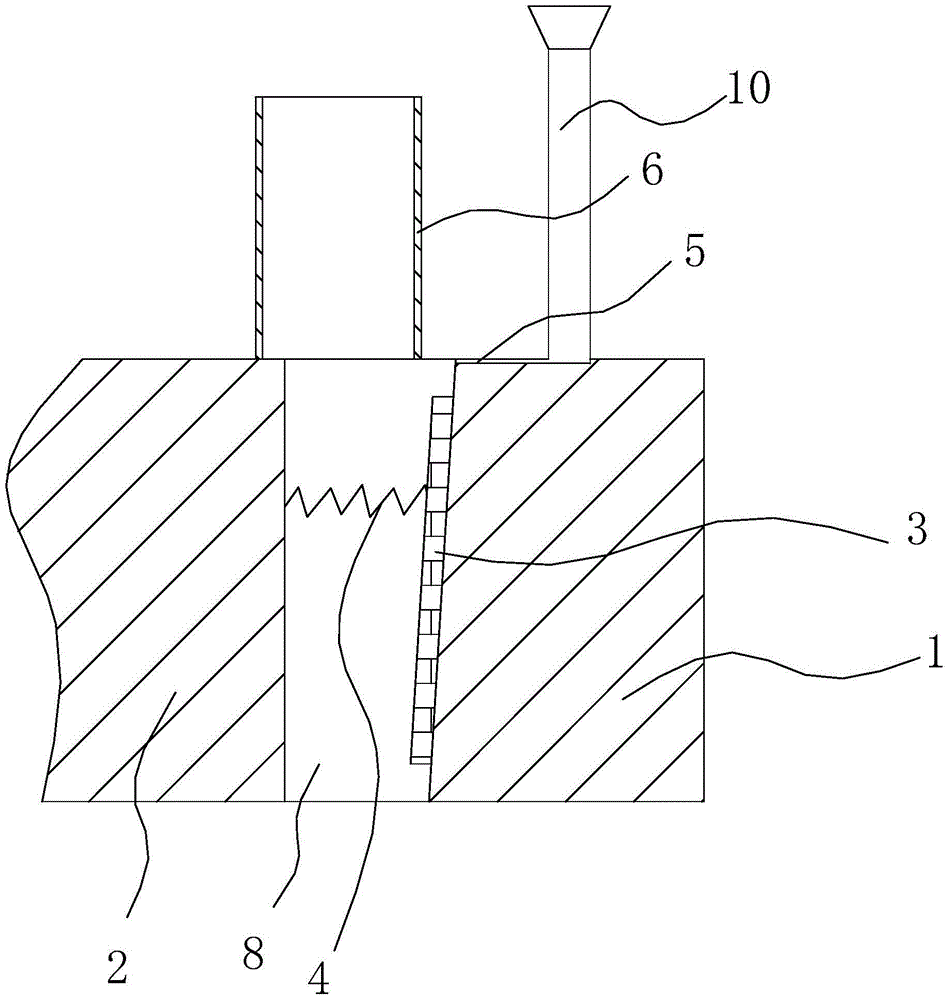

[0035] Such as Figure 1-2 As shown, 3) Put the zirconium corundum ceramic particle preform 3 obtained above into the cavity 8 of the vertical mill roller sand mold 1, place them side by side along the ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com