Durable and environment-friendly sisal hemp shoe sole

A kind of environmental protection and sisal technology, applied in the direction of shoe soles, applications, footwear, etc., can solve the problems of insufficient hardness of the soles, wearing discomfort, accidental drafting, etc., to improve rough wearing discomfort, improve deformation resistance, and improve non-curling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

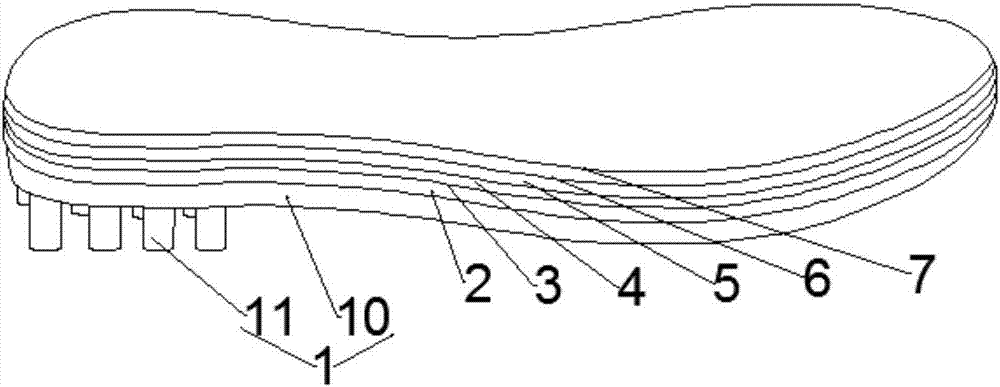

[0028] A durable and environmentally friendly sisal sole, comprising: a bottom layer 1, a first cloth layer 2, a first aluminum foil layer 3, a sisal leaf layer 4, a loofah layer 5, a second aluminum foil layer 6, The second cloth layer 7 and the third cloth layer 8, the first cloth layer 2, the second cloth layer 7, and the third cloth layer 8 are all made of 2-4 layers of cloth stacked from bottom to top and then sewn. The distance between any two stitches of the first fabric layer 2, the second fabric layer 7, and the third fabric layer 8 is controlled to be between 0.5-1cm;

[0029] Wherein, the cloths of the first cloth layer 2 and the second cloth layer 7 are all woven from modified sisal fibers, and the modification of sisal fibers is as follows: adding no After soaking in water and ethanol for 5 minutes, add NaOH aqueous solution with a mass fraction of 2%, stir to make it evenly mixed, heat up to 35°C and soak for 20 minutes in a closed manner, filter to obtain the fi...

Embodiment 2

[0042] A durable and environmentally friendly sisal sole, comprising: a bottom layer 1, a first cloth layer 2, a first aluminum foil layer 3, a sisal leaf layer 4, a loofah layer 5, a second aluminum foil layer 6, The second cloth layer 7 and the third cloth layer 8, the first cloth layer 2, the second cloth layer 7, and the third cloth layer 8 are all made of 2-4 layers of cloth stacked from bottom to top and then sewn. The sewing control of the first fabric layer 2, the second fabric layer 7, and the third fabric layer 8 is between 0.5-1cm between any two needles;

[0043] Wherein, the cloths of the first cloth layer 2 and the second cloth layer 7 are all woven from modified sisal fibers, and the modification of sisal fibers is as follows: adding no After soaking in water and ethanol for 10 minutes, add NaOH aqueous solution with a mass fraction of 2%, stir to mix evenly, heat up to 40°C and soak for 25 minutes in a closed manner, filter to obtain the first filtrate and the ...

Embodiment 3

[0056] A durable and environmentally friendly sisal sole, comprising: a bottom layer 1, a first cloth layer 2, a first aluminum foil layer 3, a sisal leaf layer 4, a loofah layer 5, a second aluminum foil layer 6, The second cloth layer 7 and the third cloth layer 8, the first cloth layer 2, the second cloth layer 7, and the third cloth layer 8 are all made of 2-4 layers of cloth stacked from bottom to top and then sewn. The sewing control of the first fabric layer 2, the second fabric layer 7, and the third fabric layer 8 is between 0.5-1cm between any two needles;

[0057] Wherein, the cloths of the first cloth layer 2 and the second cloth layer 7 are all woven from modified sisal fibers, and the modification of sisal fibers is as follows: adding no After soaking in water and ethanol for 8 minutes, add NaOH aqueous solution with a mass fraction of 2%, stir to mix evenly, heat up to 37°C and soak for 23 minutes in a closed manner, filter to obtain the first filtrate and the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com