High-definition screen

A technology for clearing screens and screens, applied in optics, instruments, projection devices, etc., can solve the problems of insufficient high-definition screen images and short service life, and achieve the effects of improving color reproduction, good dimensional stability, and excellent physical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, this technical scheme will be further described:

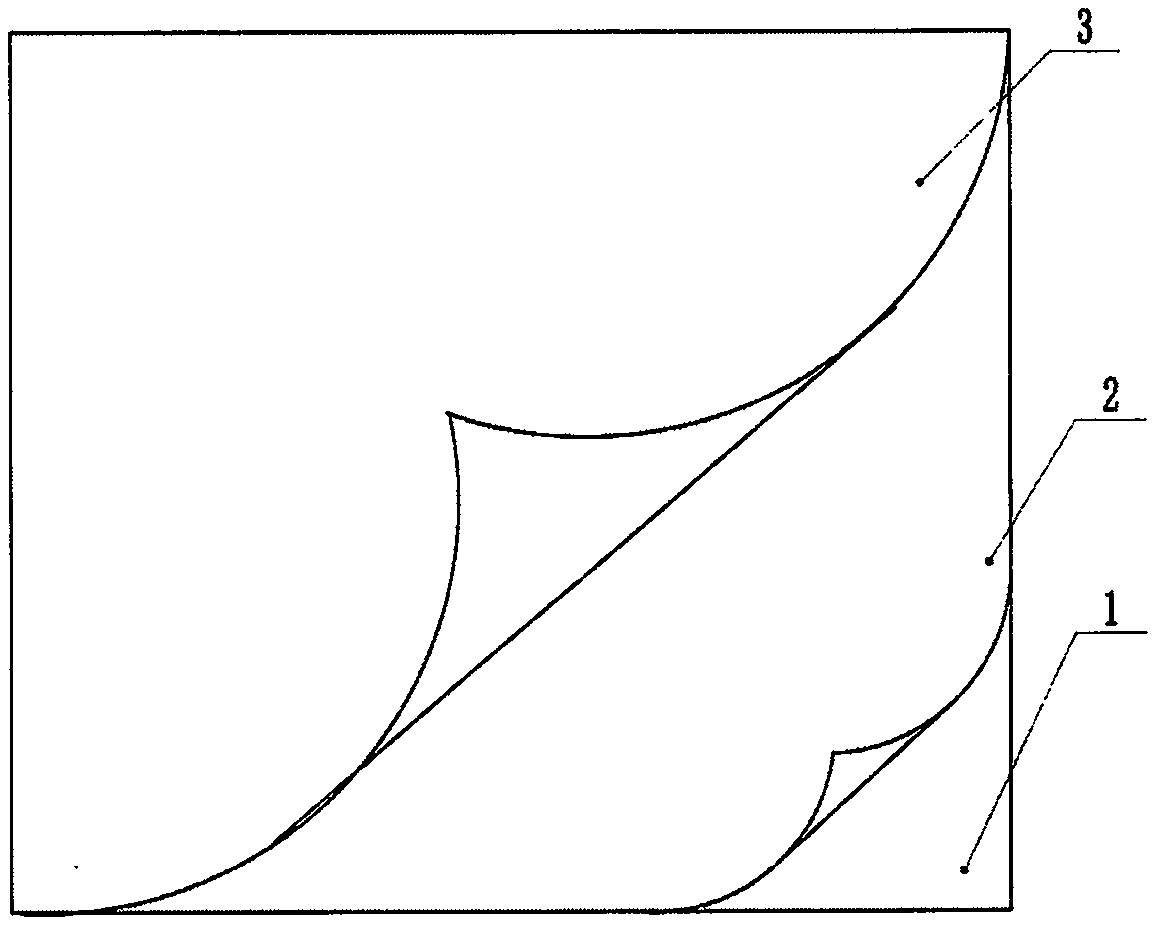

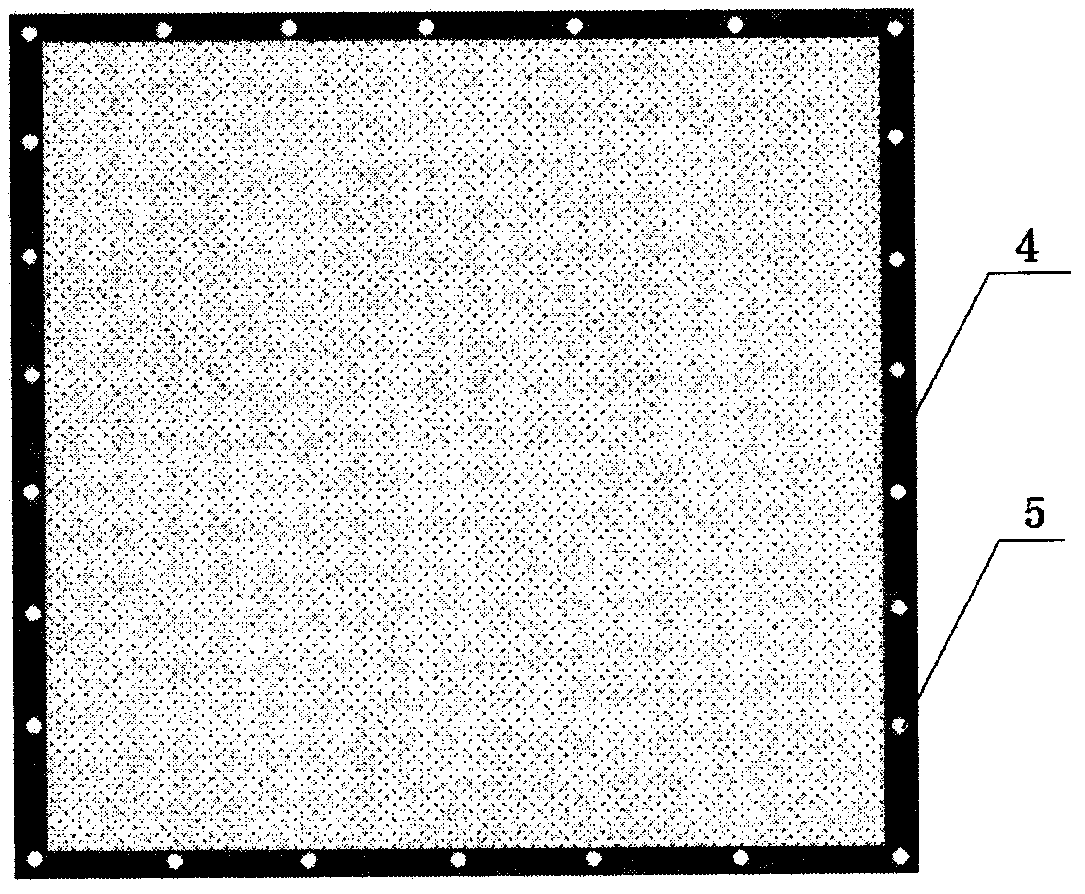

[0033] Such as figure 1 As shown, a high-definition screen includes a flexible film 1, a metal film 2, a scattering and diffusion composite film 3, and sound-permeable holes.

[0034] First, the flexible film 1 with a thickness of 45-55 filaments is used as a substrate and placed on the bottom layer. The flexible film 1 is generally a tough polymer sheet with a certain thickness. Its good water impermeability allows the flexible film 1 to Used as a substrate.

[0035] Furthermore, the flexible film 1 can be a flexible film 1 of various materials such as PET and PC, but PET film and PC film are the first choice, firstly because PET film has excellent physical properties, chemical properties and dimensional stability , transparency, and recyclability. Secondly, PC film also has excellent physical properties, especially excellent impact resistance, high tensile strength, be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com