Regenerated plastic base sisal hemp fiber reinforced construction mould plate and its processing method

A technology of building formwork and sisal fiber, applied in the field of building formwork and its processing, can solve the problems of rapid destruction of the formwork surface, lack of affinity, filling and other problems, so as to achieve lower production and construction costs, more repeated use, and expanded applications. field effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

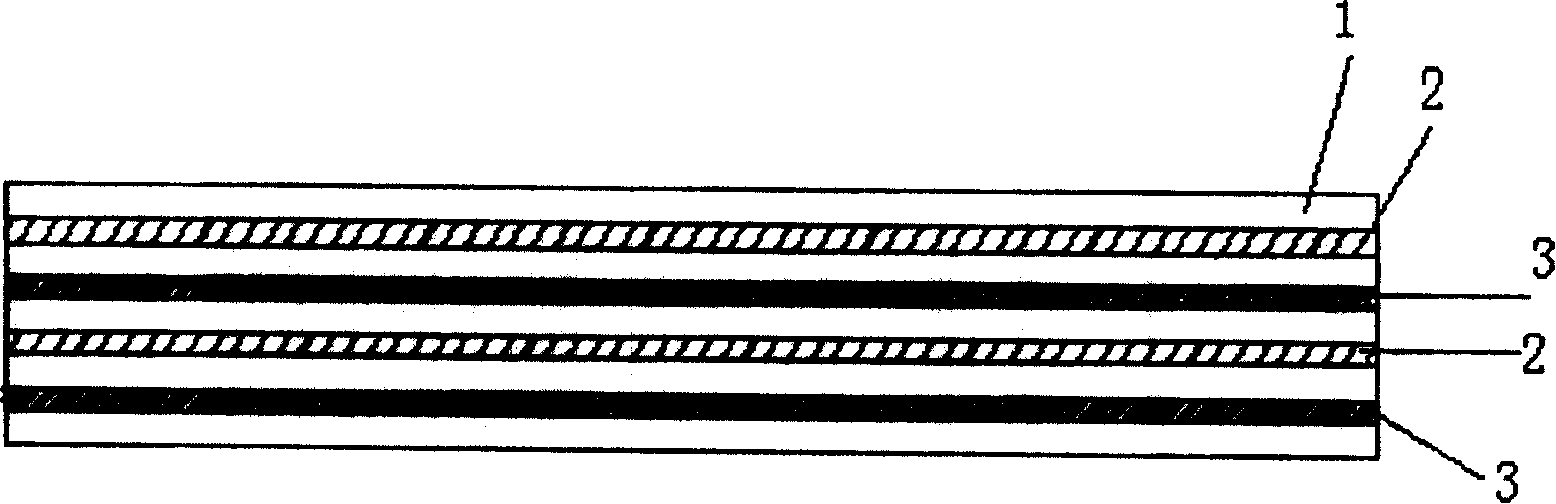

[0051] Embodiment 1, waste and old PVC-based sisal fabric and sisal blade reinforced building formwork (using two layers of sisal fabric 2 and two layers of dry sisal blade 3 as reinforcing materials, two layers of sisal blade are vertically arranged, and waste and old PVC As base material 1, building formwork made of wood powder as filler, such as figure 1 shown)

[0052] (1) The sisal fiber fine-dried hemp is made into sisal yarn with a fineness of 0.2 kg / km and a twist of 80 twists / m by traditional processing technology, and then weaves it into a warp density of 10 strands / 10 cm and a weft density of 10 strands / 10 cm. It is a plain weave fabric with 10 threads / 10 cm, and the fabric width is 1.5 meters. The woven sisal fabric 2 is boiled and bleached in a 10% sodium hydroxide aqueous solution at a temperature of 100°C for 30 minutes, dried, then soaked in a 5% KH550 coupling agent solution for 30 minutes, and dried Finally, it is dried at 120°C, and the moisture content of...

Embodiment 2

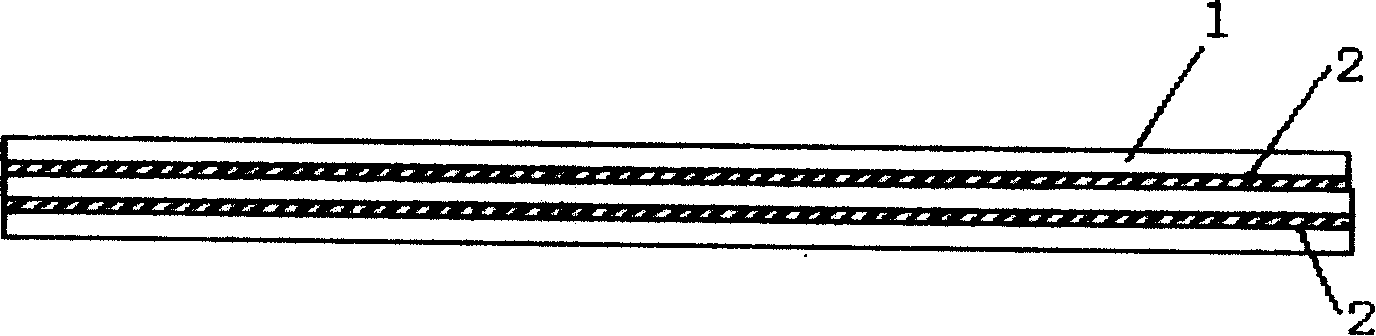

[0057] Embodiment 2, waste and old PE-based sisal fabric reinforced building formwork (adopting two layers of sisal fabric 2 as the reinforcement layer, using waste and old PE as the base layer 1, using chaff powder as the building formwork made by the filler, such as figure 2 shown)

[0058] (1) The sisal fiber fine-dried hemp is made into sisal yarn with a fineness of 0.5 kg / km and a twist of 60 twists / m by traditional processing technology, and then weaves it into a warp density of 20 strands / 10 cm and a weft density of It is 20 threads / 10cm plain weave fabric, and the fabric width is 1.5 meters. The woven sisal fabric 2 is boiled and bleached in a 10% sodium hydroxide aqueous solution at a temperature of 100°C for 30 minutes, dried, then soaked in a 15% KH550 coupling agent solution for 30 minutes, and dried Finally, it is dried at 120°C, and the moisture content of the fabric is controlled below 1%.

[0059] (2) Remove sundries from the waste PVC material recovered fro...

Embodiment 3

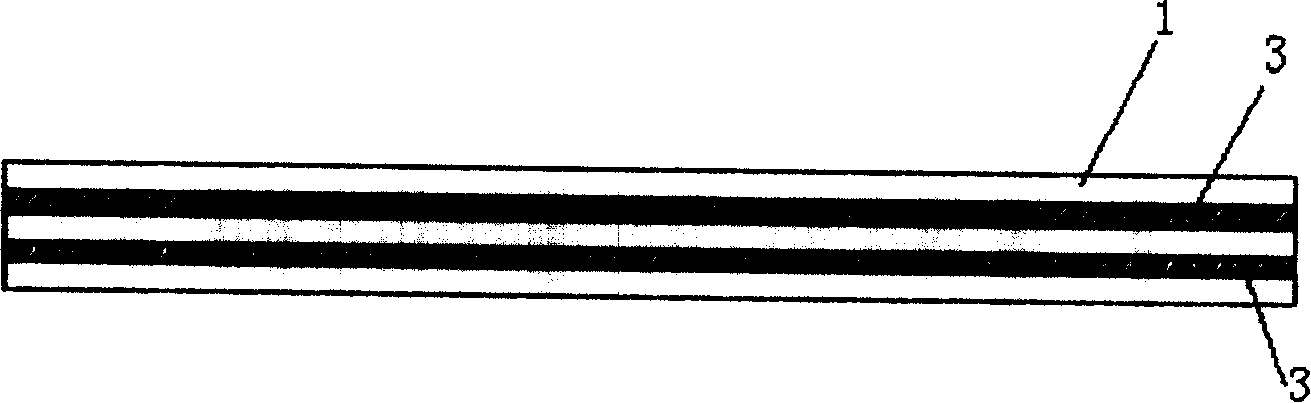

[0062] Embodiment 3, waste and old PVC-based sisal leaves reinforced building formwork (using two layers of sisal leaves 3 as the reinforcement layer, the two layers of sisal leaves are arranged vertically, using waste and old PVC as the base layer 1, and using calcium carbonate powder as fillers) building templates such as image 3 shown)

[0063] (1) Boil the picked sisal leaves in boiling water for 10 minutes, then heat-press and dry them on a hot press at 120°C and 1.5MPa to make dry leaves, then cut the leaves to a length of 50 cm, and then put them on 0.5*0.5 cm holes, the distance between holes is 1 cm. Then put the leaves into the 20% KH560 coupling agent solution and soak for 60 minutes, then dry them at 120° C., and control the water content below 1%.

[0064] (2) Remove impurities from the waste PVC material recovered from the waste purchase station, then use mechanical washing and purification, and then cut and crush it with a crusher to make granules; feed calci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com