Patents

Literature

41results about How to "Seawater corrosion resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for performing anticorrosive hydrophobic modification on surface of aluminum alloy

InactiveCN101885934ACoating thickness is thinImprove adhesionAnti-corrosive paintsMetallic material coating processesSpray coatingLayer thickness

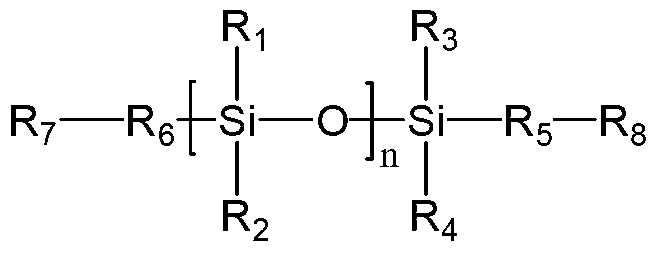

The invention discloses a method for performing anticorrosive hydrophobic modification on the surface of an aluminum alloy, which belongs to the technical field of corrosion prevention. The method specifically comprises the following steps of: (1) performing surface degreasing and oil removing on an aluminum alloy material by using conventional alkaline degreasing solution first, performing surface activation treatment by using reductive acidic cleaning solution, and then performing inactivation and sealing treatments on the activated surface; (2) preparing a composition with a hydrophobic effect, wherein the composition consists of a first component and a second component in a weight ratio of 9-16:1, the first component is prepared from the following materials in percentage by weight: 35 to 60 percent of fluorocarbon resin, 10 to 40 percent of anticorrosive pigment, 1 to 8 percent of organosilicon compound, 0.5 to 5 percent of dispersing agent, 0.5 to 3 percent of anti-settle agent and 10 to 40 percent of organic solvent, and the second component is a fatty series / aromatic series curing agent; and (3) performing anticorrosive hydrophobic modification on the surface of the aluminum alloy, namely coating the composition with the hydrophobic effect in the step (2) on the surface of the aluminum alloy after treatment in a brush coating, spray coating or dip coating mode, and curing the surface for about 12 hours. The anticorrosive hydrophobic coating layer obtained on the surface of the aluminum alloy by using the technique of the invention has the advantages of thin coating layer thickness, high adhesive force, sea water corrosion resistance, surface super-hydrophobic property and the like.

Owner:BEIJING UNIV OF CHEM TECH

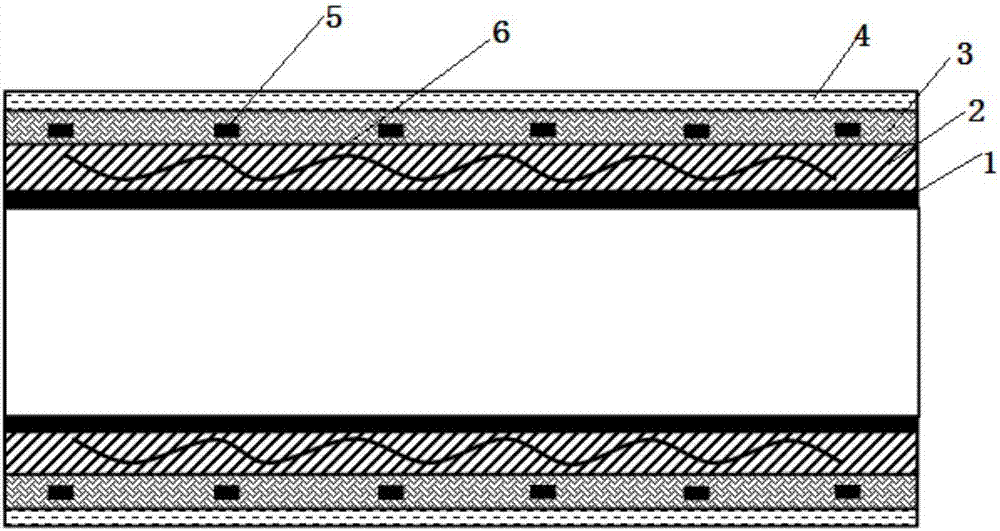

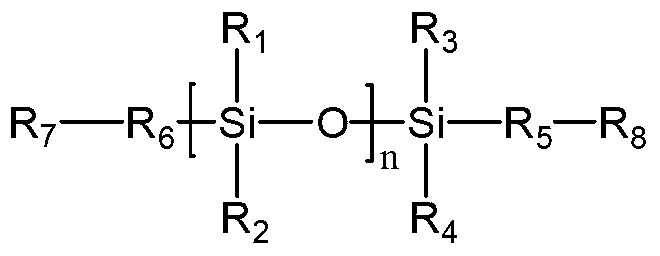

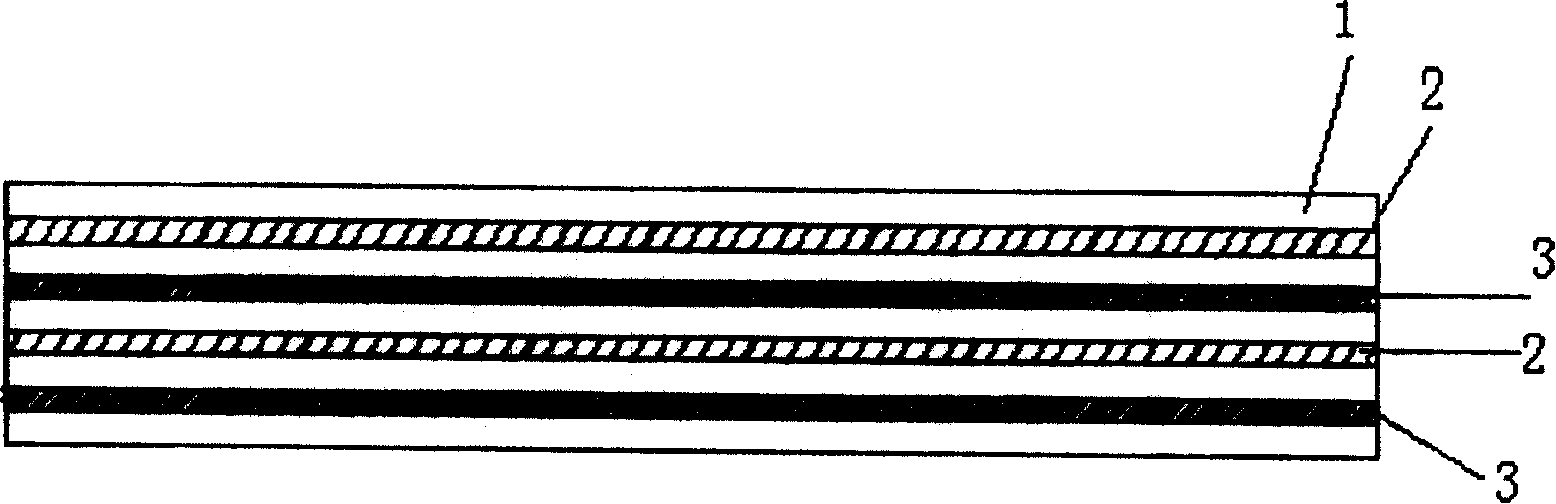

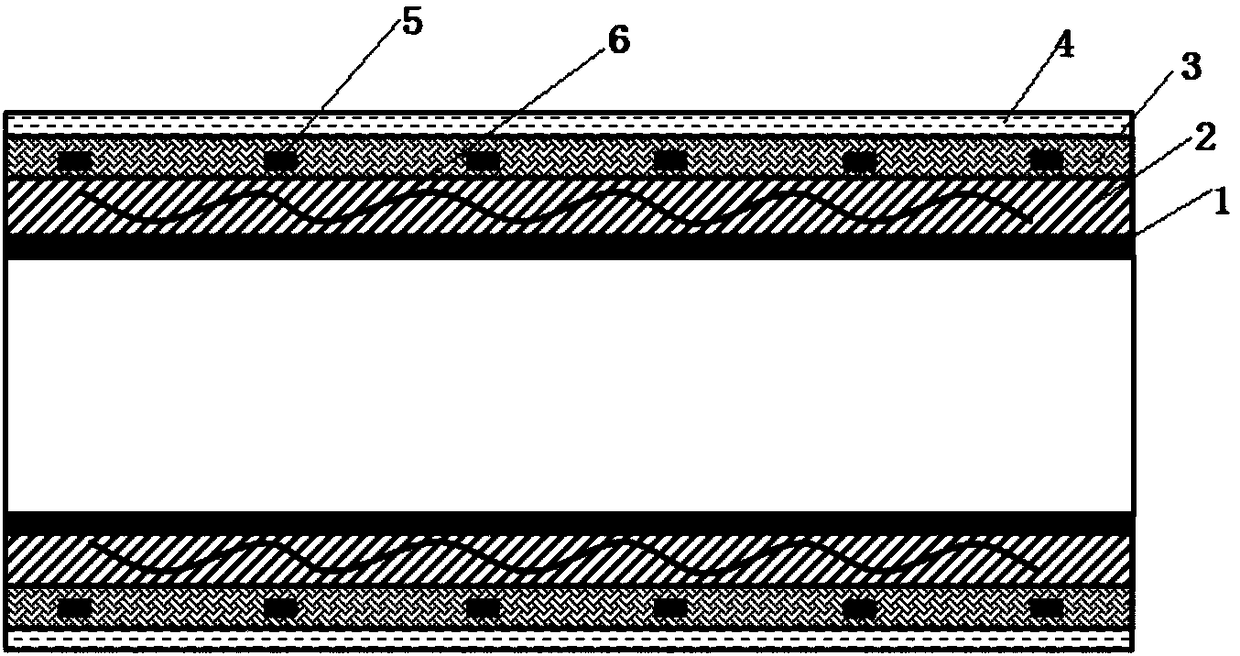

Intelligent monitoring three-dimensional composite underwater vehicle shell body and preparation method thereof

ActiveCN106926532ALight weightImprove mechanical stabilityWaterborne vesselsSynthetic resin layered productsCorrosion resistantStrain sensor

The invention discloses an intelligent monitoring three-dimensional composite underwater vehicle shell body and a preparation method of the intelligent monitoring three-dimensional composite underwater vehicle shell body. The underwater vehicle shell body comprises a plurality of layers of structures from exterior to interior and comprises four parts of a corrosion resistance layer, an impact resistance layer, a rigidity layer and a metal sealing layer, one or more strain sensors is / are adopted in the impact resistance layer and the rigidity layer of a three-dimensional composite structure at the same time and introduced into the three-dimensional composite structure, and the stress state of the structure of the shell body is monitored through sensing of the micro-strain of the shell body in the working process. The three-dimensional prefabricated part structure guarantees the mechanical stability of the whole shell body, meanwhile, due to the arrangement of the impact resistance layer and the rigidity layer, the composite underwater vehicle shell body can adapt to different complex underwater environments.

Owner:山东宽原新材料科技有限公司

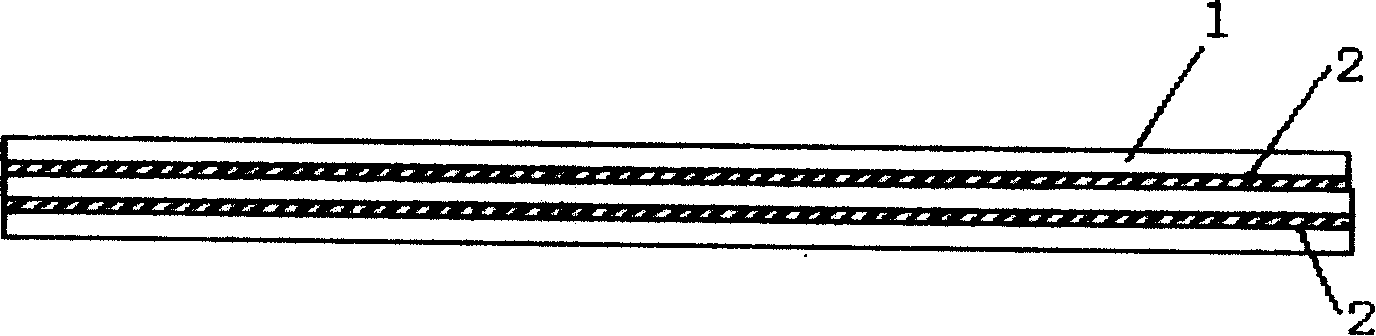

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts thefollowing steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

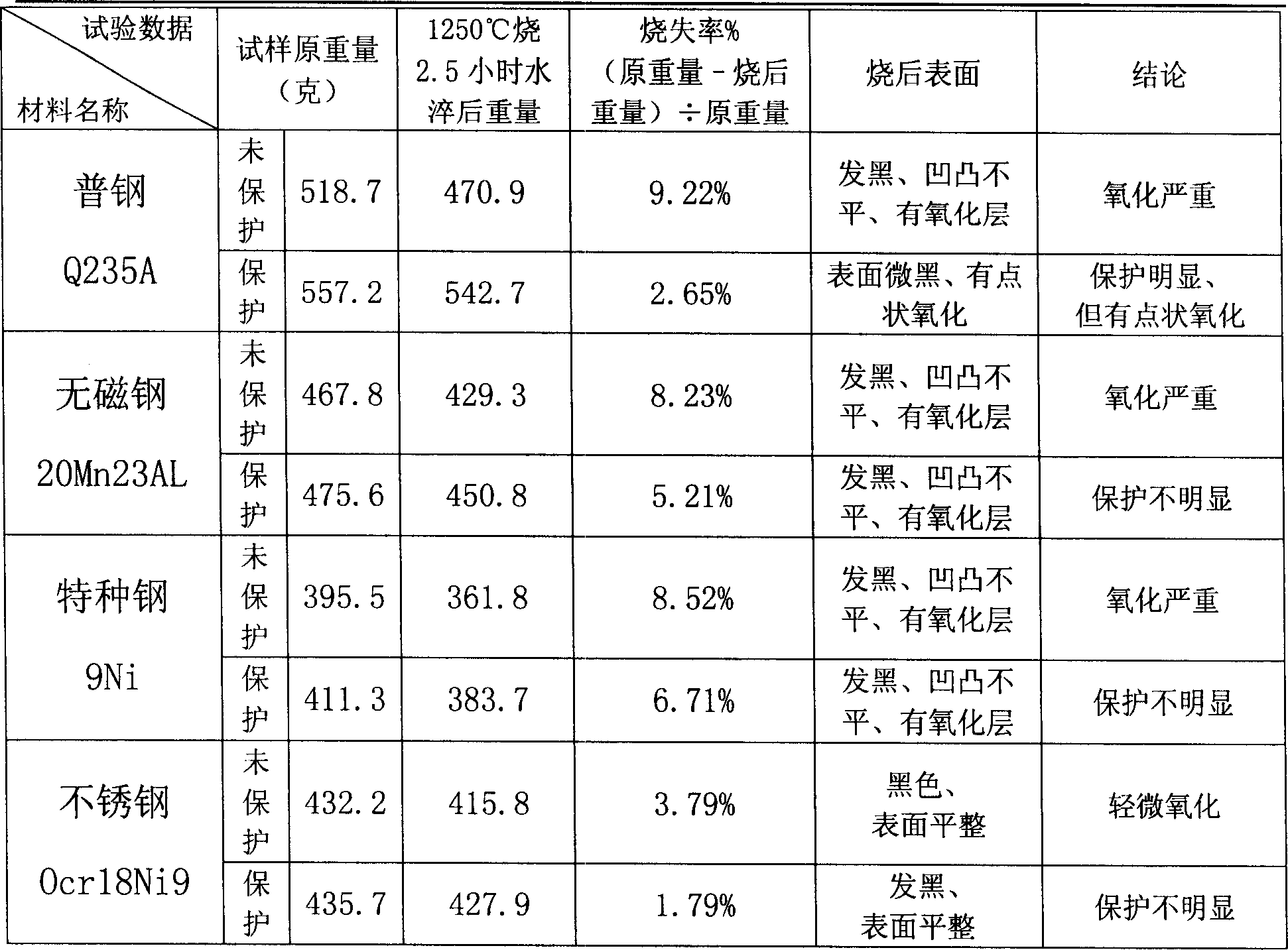

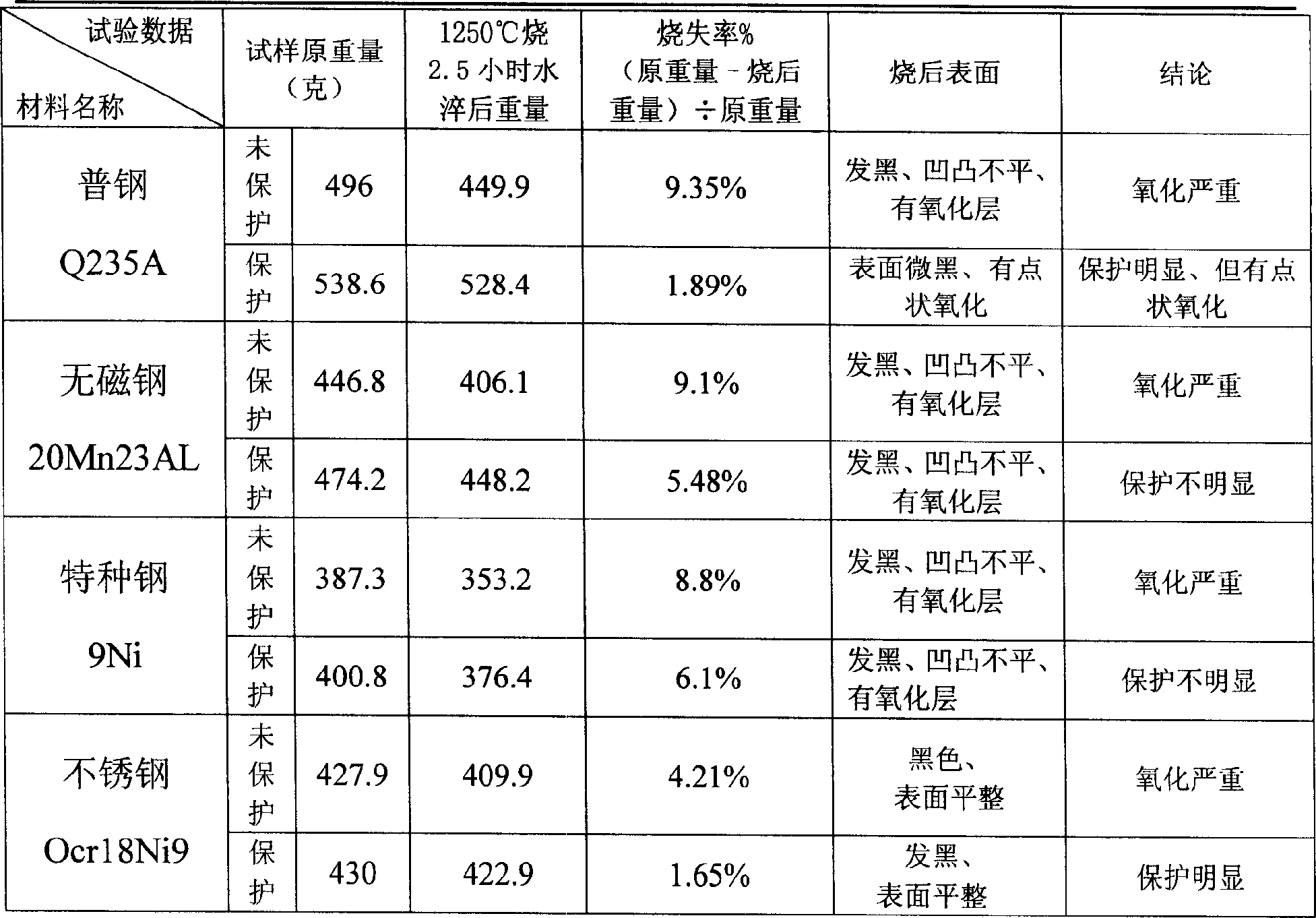

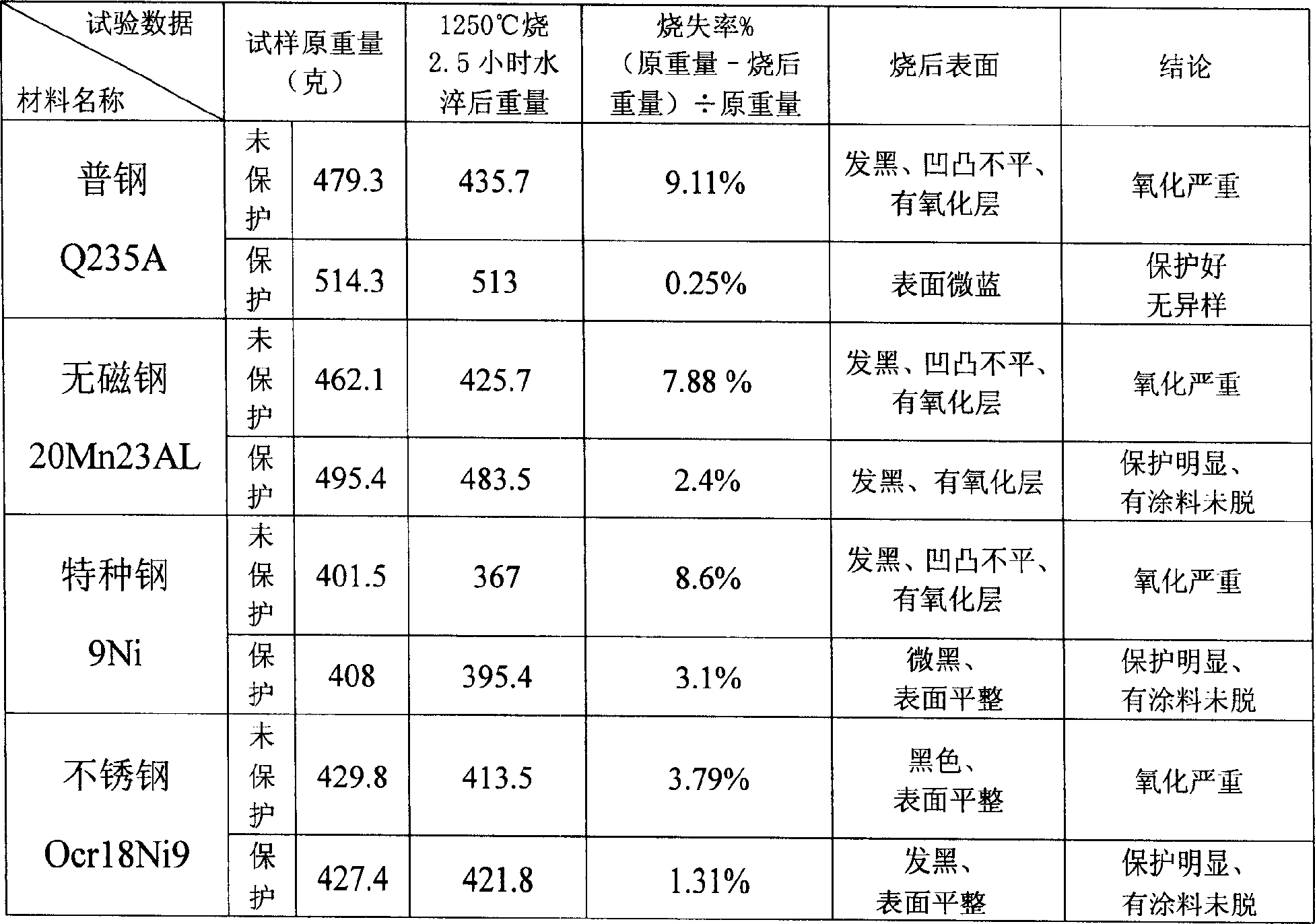

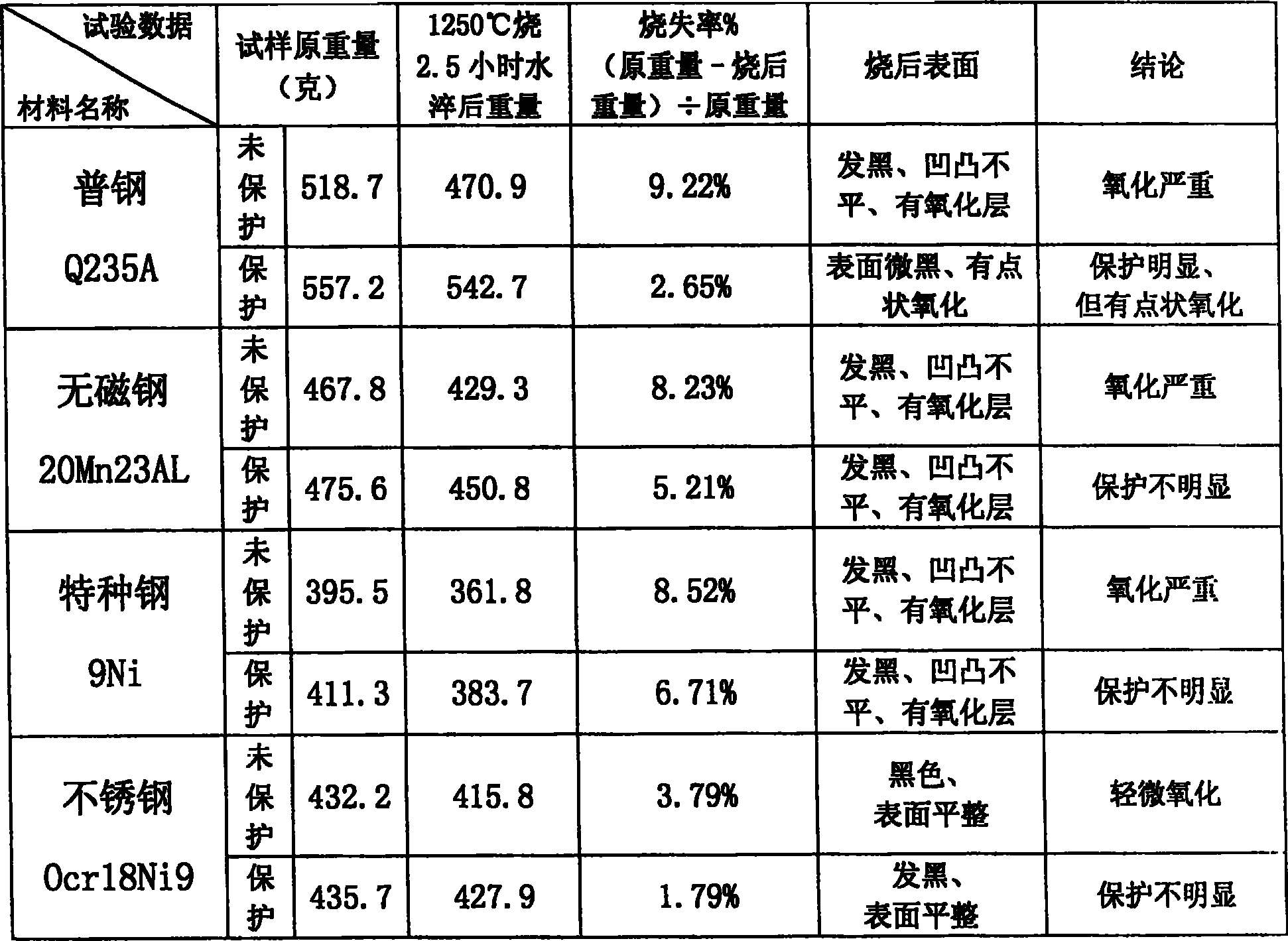

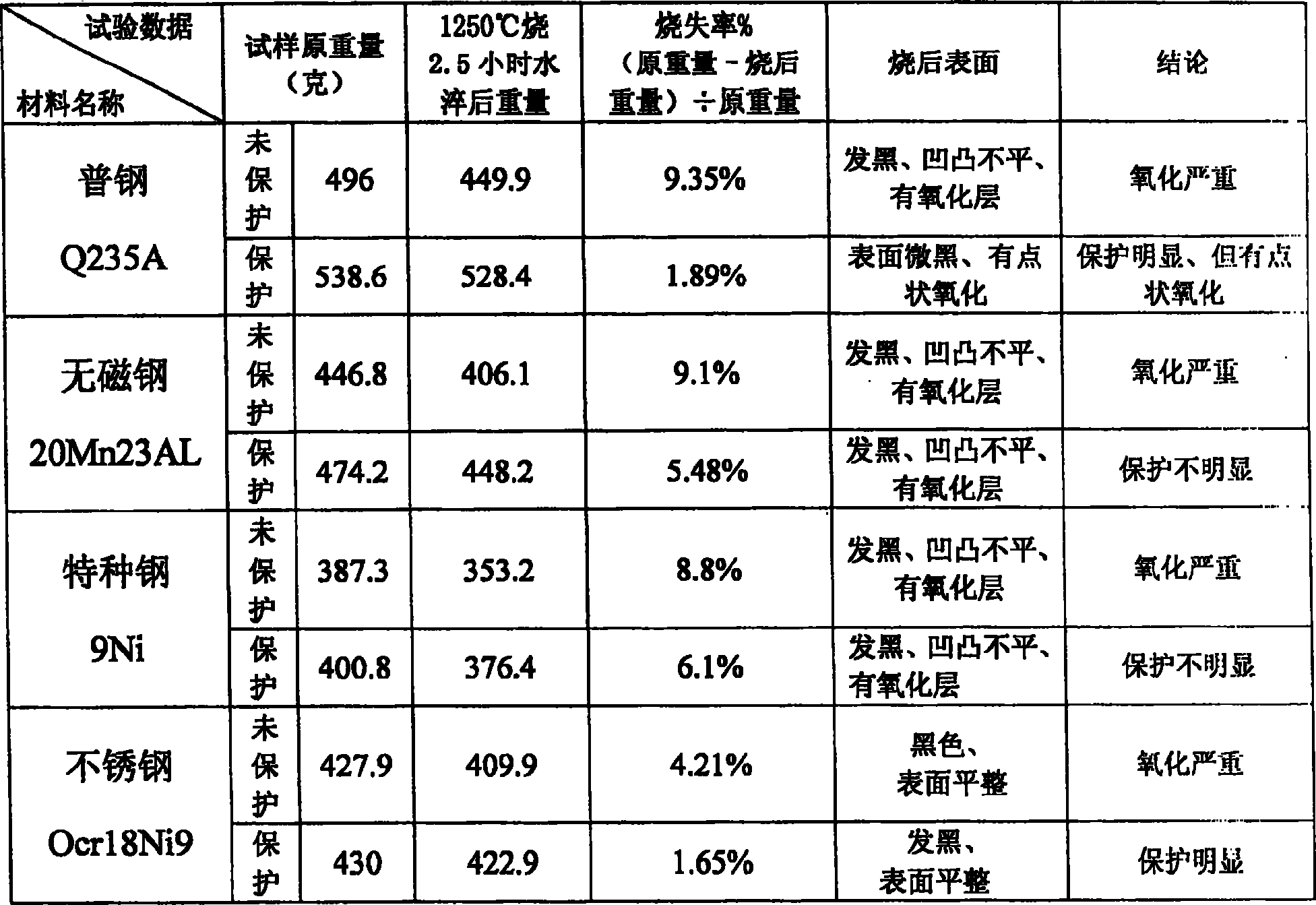

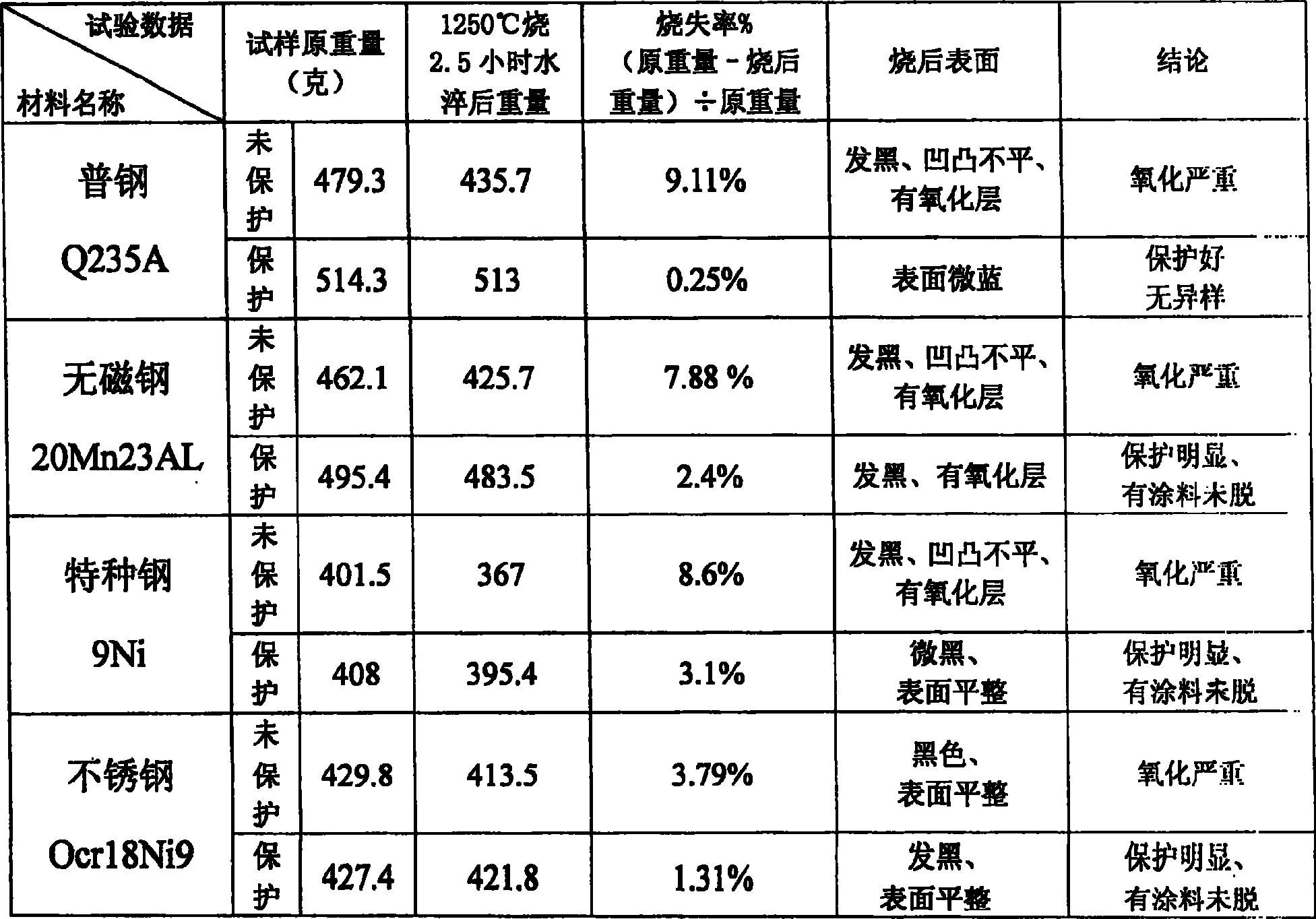

Antioxidation coating material of Nano silicate in use for annealing billet in series

This invention relates to nanoscale silicate anti-oxidation coating for steel billet annealing. The coating is composed of: composite binder 20-30 wt.%, composite phosphate curing agent 8-12 wt.%, and composite aluminosilicate filler 58-72 wt.%. The coating can resist 1500 deg.C high temperature. The coating does not need any surface treatment, and can be directly sprayed onto the surface of steel billet, and cured at normal temperature for 10 min. Before annealed and hot-rolled, the coated steel billet is water-quenched for several seconds so that the coating layer is removed without any trace, and the surface quality is improved. The coating can reduce the loss-on-ignition of various steels, thus can be used for surface protection of refractory materials used as furnace kiln lining. Besides, the coating can also be used as inner and outer wall coating, and metal surface (bridge, bridge pier and dam) coating with water, corrosion and oxidation resistance.

Owner:沁阳市皇甫喷射防腐技术有限公司

Brake gasket and its preparng metod

The preparation process of brake gasket includes the following steps: preparing sisal fiber via cutting sisal into 10-20 mm long segment, soaking in anhydrous alcohol plus benzene solution, washing with anhydrous alcohol and deionized water, boiling in NaOH solution, cooling to room temperature, washing with deionized water to neutrality and stoving in stove; mixing sisal fiber, phonetic resin, copper powder, graphite powder, MoS2, pre-polymer, metal oxide, butadiene-acrylonitrile rubber, non-metal compound and barium sulfate in a high speed mixer to form mixture material; making blank with the mixture material; hot pressing the blank to form; and heat treatment at 190-200 deg.c. The present invention makes asbestos-free brake gasket with sisal fiber as reinforcing material, and the brake gasket has stable friction coefficient, less heat degradation, low wear, no couple wear, smooth braking, low noise and no environmental pollution.

Owner:XI AN JIAOTONG UNIV +1

Wet type polyurethane joint material for thermal insulation for seabed oil and gas pipeline interface and preparation method of wet type polyurethane joint material

The invention discloses a wet type polyurethane joint material for thermal insulation for a seabed oil and gas pipeline interface. The polyurethane joint material comprises a component A and a component B, wherein the component A comprises polyether polyol, polysiloxane polyhydric alcohol, a chain extender and a catalyst; the component B is modified isocyanate or a derivate of the modified isocyanate; the component B comprises 10 to 30% of NCO (Isocyanate Group) based on mass percent; and the mass ratio of the component A to the component B is 0.25 to 4:1. The wet type polyurethane joint material has the beneficial effects as shown in follows: 1, the adopted catalyst is mercury-free, environment-friendly, long in flowing period and fast to cure in later period; 2, the production cycle is short, a die is at low temperature, and the offshore in-situ casting work can be conveniently carried out; and 3, a product is a silicon-containing material and has relatively low water absorption and is resistant to seawater corrosion.

Owner:CHINA NAT OFFSHORE OIL CORP +1

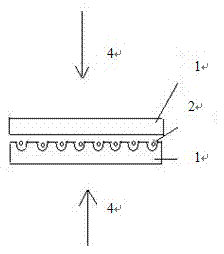

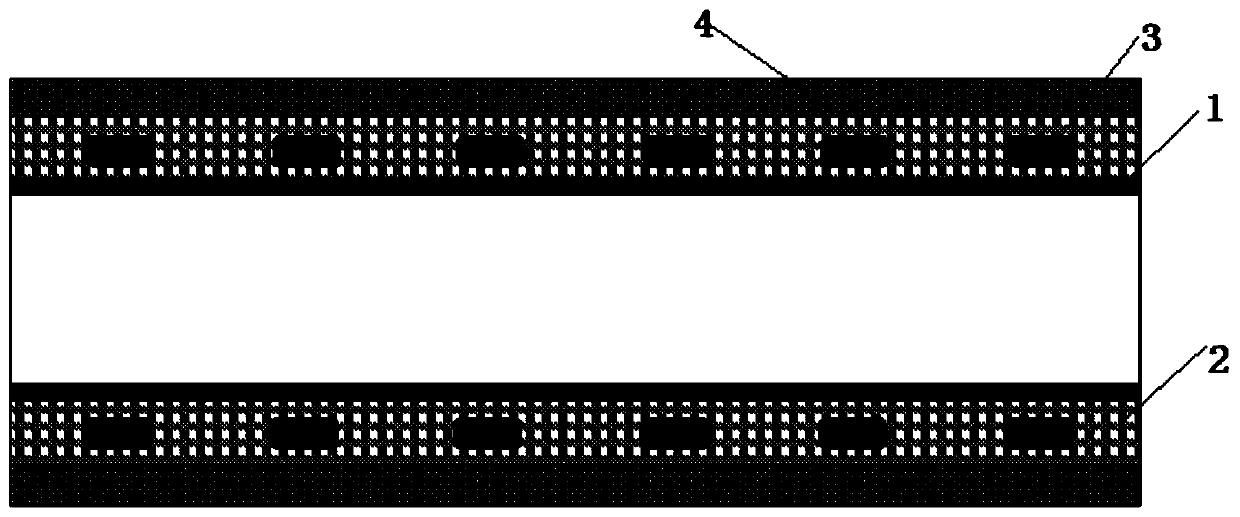

Strain monitoring two-dimensional winding composite material underwater vehicle shell and preparation method thereof

ActiveCN106903948ALight weightImprove mechanical stabilityWaterborne vesselsSynthetic resin layered productsCarbon fibersResin matrix

The invention discloses a strain monitoring two-dimensional winding composite material underwater vehicle shell and a preparation method thereof. The underwater vehicle shell comprises three parts from inside to outside: a metal sealing layer, a rigid strength layer and a corrosion-resistant layer, wherein the rigid strength layer is prepared by adopting a plurality of carbon fiber mixing and combination modes on the surface of the metal sealing layer, so that the underwater vehicle shell can adapt to different complicated underwater environments; the corrosion-resistant layer is prepared from chopped fiber reinforced resin matrix composite materials, so that the surface not only has the characteristic of resisting seawater corrosion, but also achieves the purpose of promoting the binding strength through the reinforcement action of the chopped fibers so as to effectively guarantee the service life. Through the embedding use of optical fibers or strain gauges or other different forms of strain inductors in the structure of the two-dimensional winding composite material rigid strength layer, the small strain of the whole shell structure or structure inner layer under high external pressure condition can be effectively perceived, and the real-time monitoring on the service status change of the underwater vehicle shell can be achieved.

Owner:山东宽原新材料科技有限公司

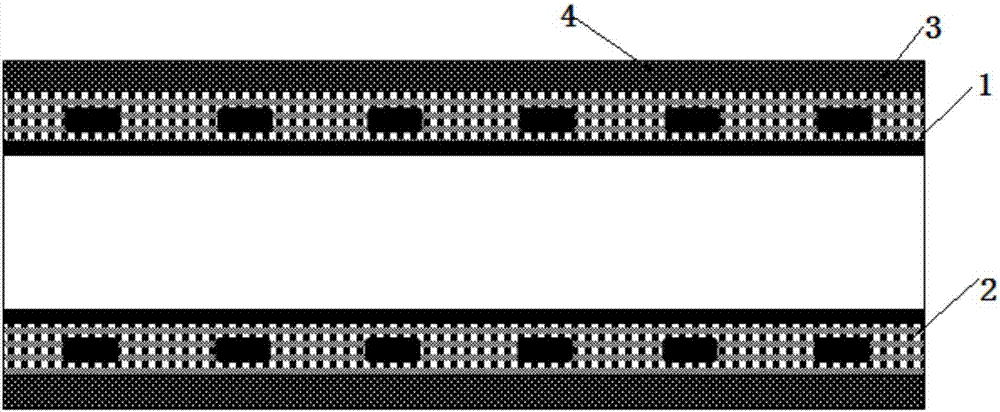

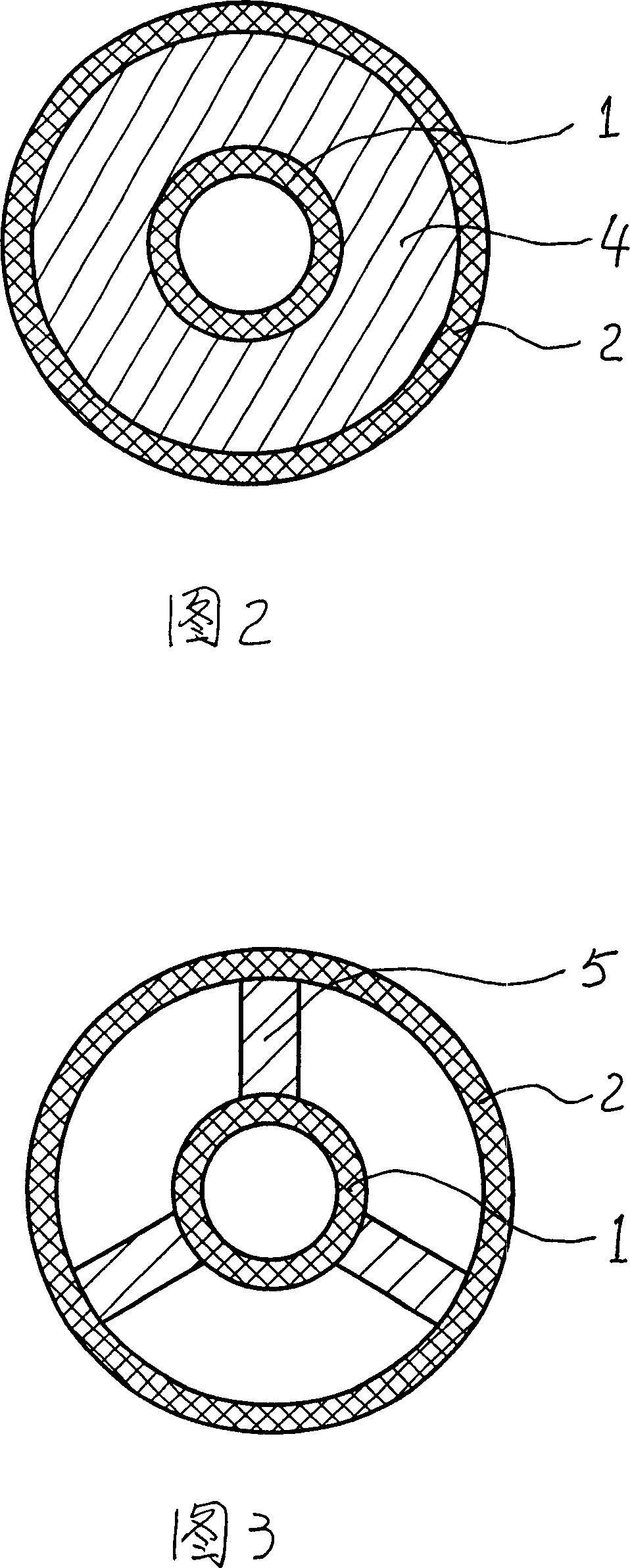

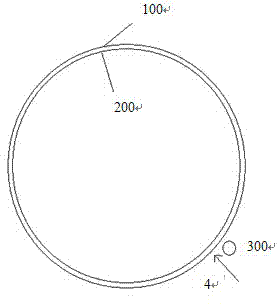

Hydrophone and manufacturing method thereof

PendingCN109474871ABandwidthHigh sensitivityPiezoelectric/electrostrictive transducersTransducers for subaqueous useBroadbandCorrosion

The invention relates to a high-sensitivity, broadband and low-cost hydrophone capable of working for a long term under a condition of high hydrostatic pressure. The hydrophone is used in a deep oceansurvey and communication sonar system, and is used for solving problems of the existing underwater acoustic transducer, such as low hydrostatic pressure resistance, incompatibility between high performance and high pressure resistance, poor corrosion resistance in working for a long term and relatively narrow bandwidth.

Owner:中国科学院声学研究所北海研究站

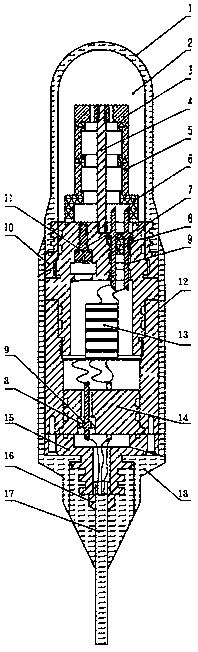

Deep-sea triggered active type creature trap and control method

ActiveCN109122611AAvoiding the Effects of Triggered StartupsIncreased likelihood of entering trapping areasFishing netsPisciculture and aquariaDeep sea creatureTrapping

Owner:SHANGHAI OCEAN UNIV

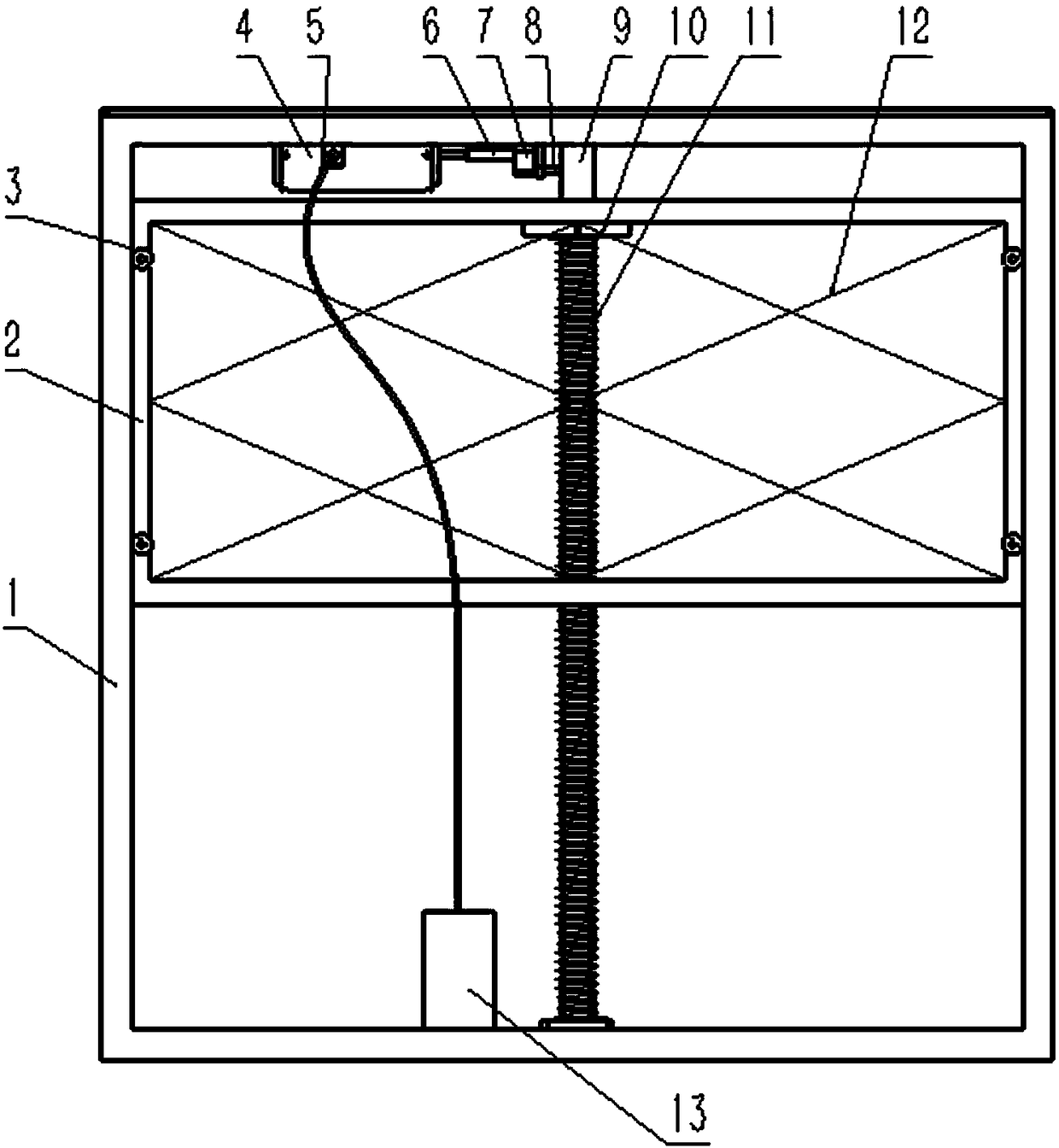

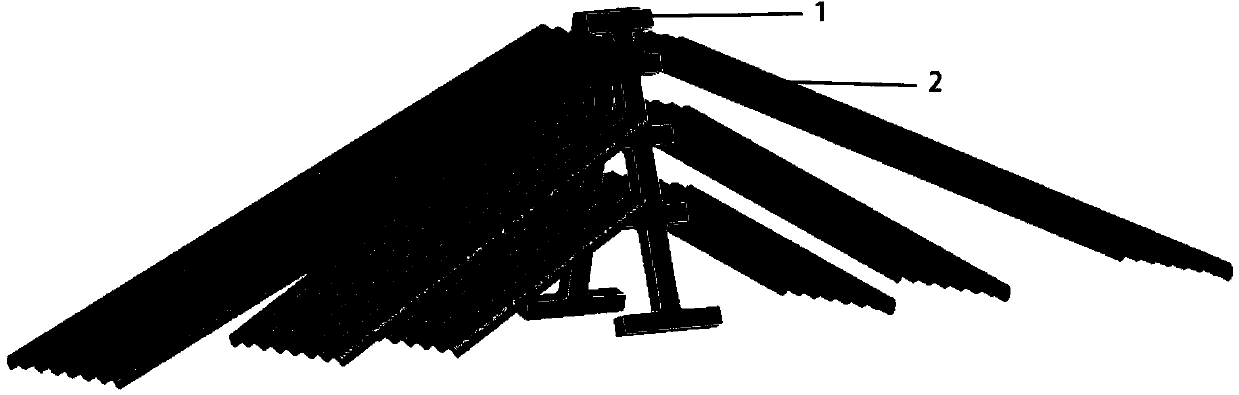

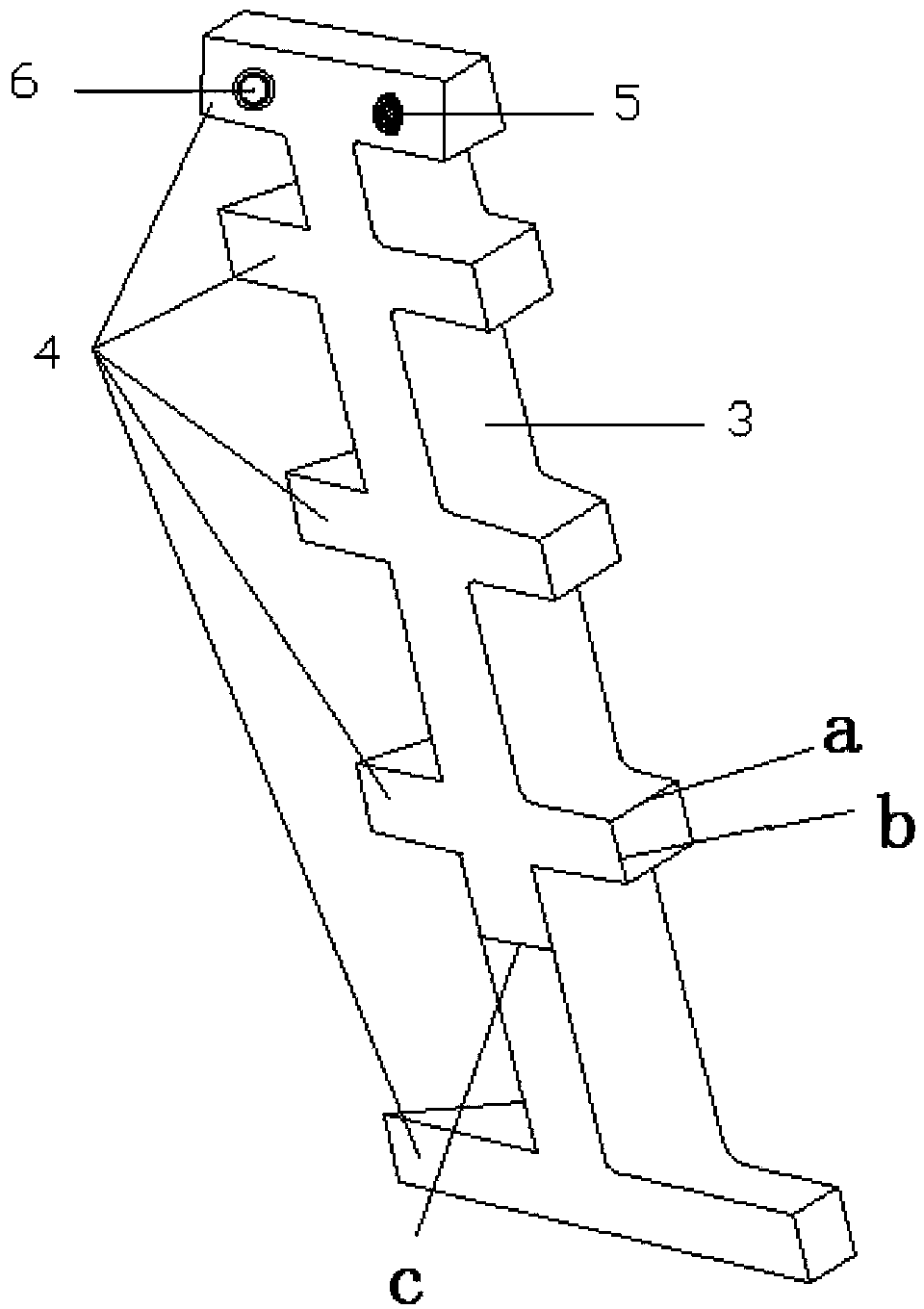

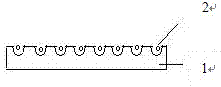

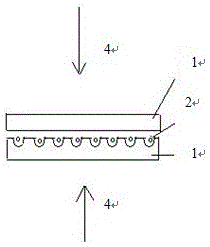

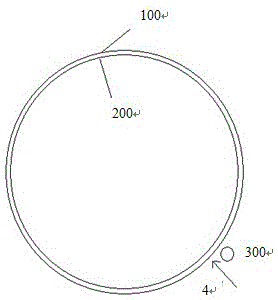

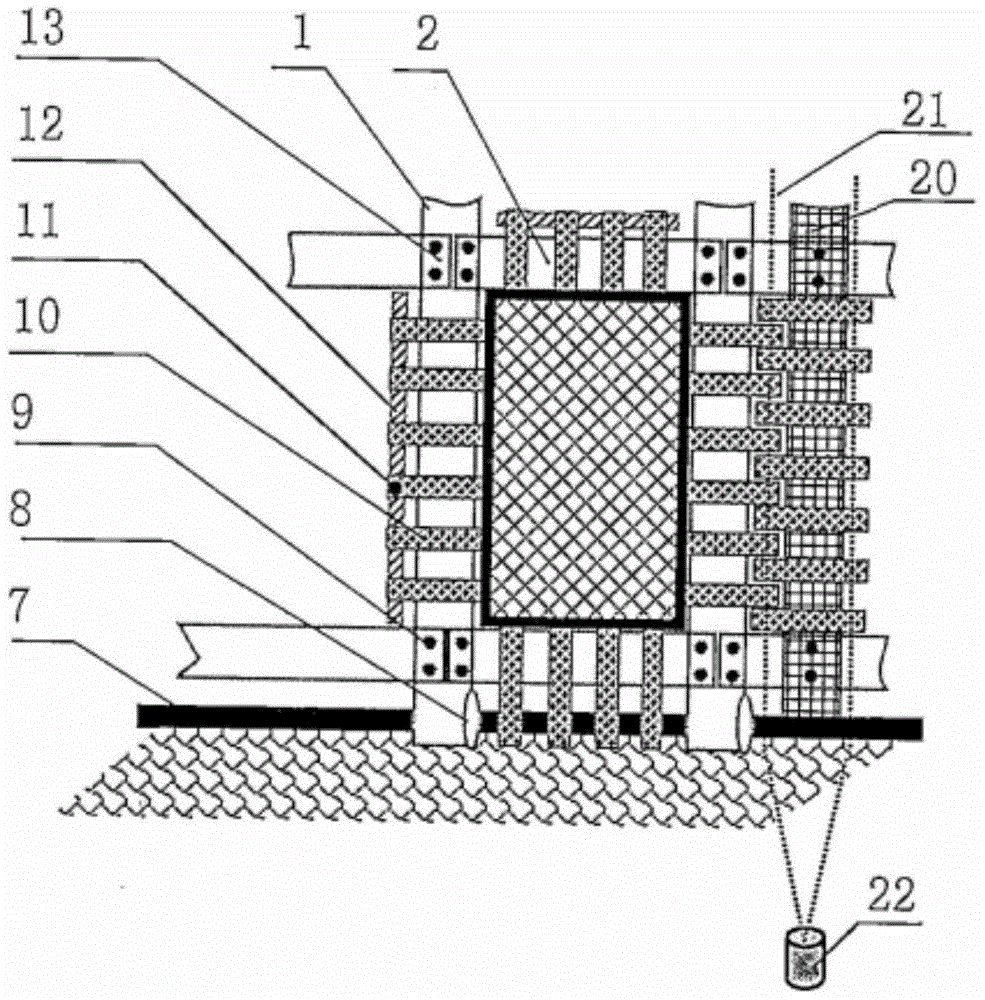

Multi-layer combined type stereoscopic holothurian culture adhesion substrate and combination method thereof

ActiveCN103430885ASeawater corrosion resistantRepeatable and sustainable useClimate change adaptationPisciculture and aquariaDiseaseSewage

The invention relates to a multi-layer combined type stereoscopic holothurian culture adhesion substrate and a combination method of the multi-layer combined type stereoscopic holothurian culture adhesion substrate, and belongs to the field of aquaculture devices. The multi-layer combined type stereoscopic holothurian culture adhesion substrate is composed of two rib frame structures with multi-layer crossarms and corrugated plates, each rib frame structure is a left and right symmetric structure composed of a main frame in the vertical direction and the crossarms perpendicular to the main frame, and the junction positions of the main frame and the crossarms are melted to be integrated structures. The two rib frame structures are embedded to form a reverse V-shaped structure, and the corrugated plates are hasped on the crossarms of the rib frame structures. The multi-layer combined type stereoscopic holothurian culture adhesion substrate can be combined quickly according to needs, after the combination, culture inhabiting faces are formed between all the corrugated plates, holothurian inhabiting is facilitated, and living space of holothurian is increased. The multi-layer combined type stereoscopic holothurian culture adhesion substrate and the combination method have the advantages of being easy and convenient to operate, seawater corrosion resistant, good in water permeability, large in surface area, good in shielding and capable of being used continuously, sewage is not prone to deposit, many shelter spaces are arranged, organic matter deposition is easy, mature holothurian recapture is facilitated, meanwhile, the culture density can be increased, and diseases are prevented from happening.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Preparation of high-protection composite material based on TPV base material and application of high-protection composite material in high-flexibility flexible cable products

InactiveCN109337217AImprove the protective effectOvercome the disadvantage of poor blending compatibilityRubber insulatorsPolymer scienceAntioxidant

The invention relates to the technical field of cables, and discloses preparation of a high-protection composite material based on a TPV base material. The preparation comprises the following steps: taking a plurality of maleic anhydride at the first; and adding the maleic anhydride into EPDM for grafting reaction to obtain EPDM-g-MA with a grafting rate of 1-3%, wherein the grafting reaction comprise steps of premixing EPDM, a free radical initiator and additives and then adding the mixture to an internal mixer. The preparation of the high-protection composite material based on the TPV base material and the application of the high-protection composite material in high-flexibility flexible cable products overcome a shortcoming of poor blending compatibility between the EPDM as a non-polarmaterial and strong polar nylon by grafting non-polar EPDM with maleic anhydride and then reacting with nylon to obtain modified EPDM, and improve blending processability and high strength of the TPVmaterial; and antioxidants, light stabilizers and internal lubricants are added to make the prepared TPV material have relatively long service life and processing stability.

Owner:YANGZHOU YAGUANG CABLE

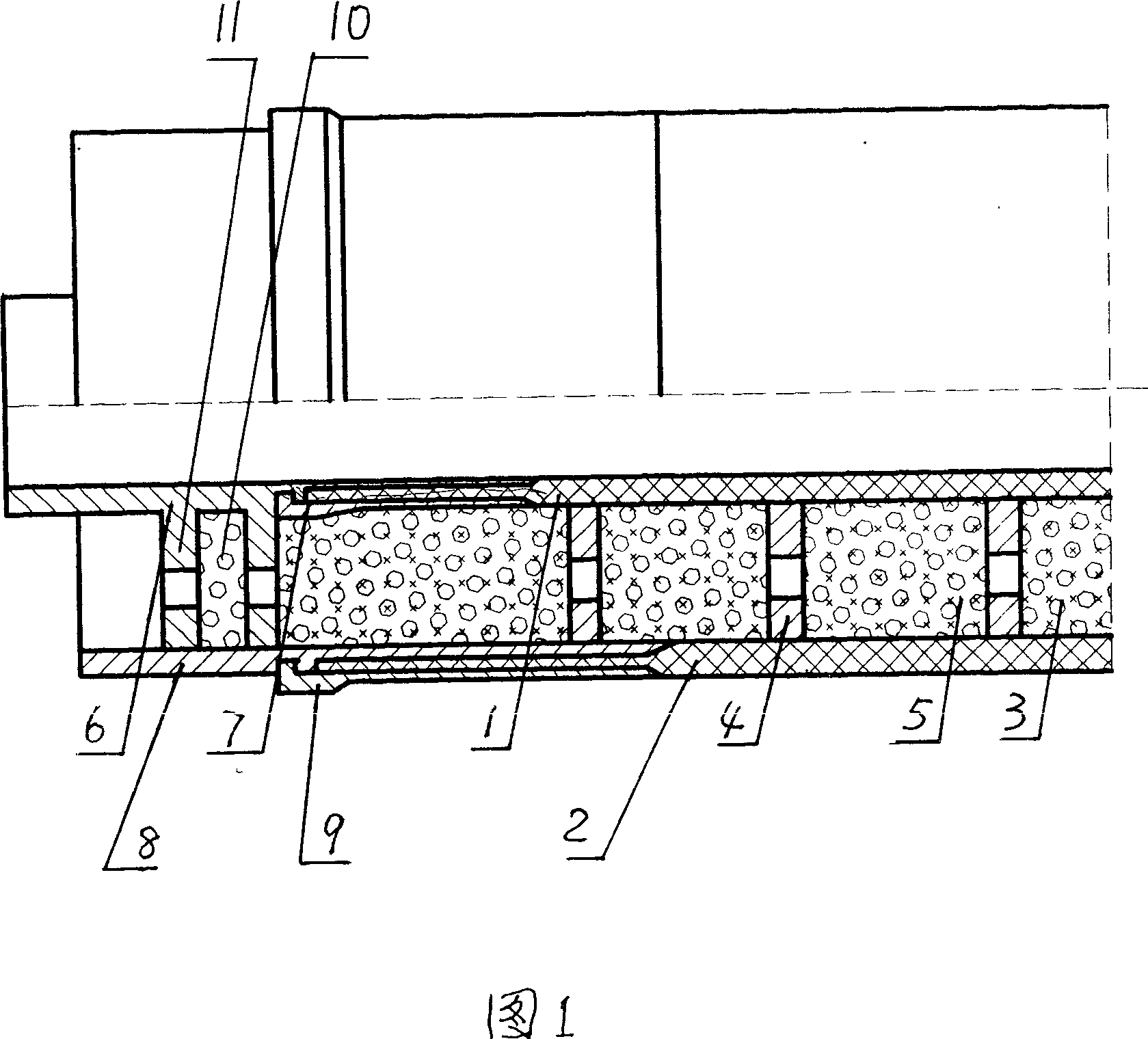

Submarine oil pipeline and dedicated connector therefor

InactiveCN1971117AExtend your lifeAvoid aerial breakageRigid pipesPipe connection arrangementsWaxSeawater

The invention relates to a submarine oil pipe line and the special connecting rod, belonging to oil transmission pipe technology area. The technology scheme constituting the submarine oil pipe line and the special connecting rod is that the submarine oil pipe line comprises inner and outer rubber hose made of rubber and with certain distance, there is certain space among rubber hoses and several supports divides the space to several material rooms, in which balance weight or heat insulation material is filled; the special connecting rod comprises core of inner pipe, sleeve of inner pipe clipped on the core of inner pipe, core of outer pipe and sleeve of outer pipe clipped on the core of outer pipe. Above mentioned submarine oil pipe line and the special connecting rod solve the problem of pipe blockage which is generated by seawater corrosion, easy overhead and breakage by bad bending performance and easily suspending wax by variable diameter at the connecting rod position. It can be applied in submarine oil transmission.

Owner:欧亚管业股份有限公司

Strapping tape for deep sea buoyancy material and preparation method thereof

The invention discloses a strapping tape for a deep sea buoyancy material and a preparation method thereof. The strapping tape material takes ethylene propylene diene monomer rubber as a matrix resin, graphite powder as a reinforcing agent, gamma-chlorine propyl triethoxy silane as a surfactant, multi-alkenyl irradiation sensitizing agent as a cross-linking auxiliary, quad[beta-(3,5-ditertiary butyl-4-hydroxide phenyl) propionic acid] pentaerythritol ester-1010 as an antioxidant, diisodecyl adipate-DDA as a plasticizing agent, zinc stearate-ZnSt2 as a stabilizing agent. A final annular strapping tape product can be obtained by proportioning the components according to a certain ratio, extruding to form an ethylene propylene diene monomer rubber strip and a smooth rubber strip of groove structures by using a double-screw rod extruder, annually winding high-performance fibers on a large rolling shaft with the ethylene propylene diene monomer rubber strip of the groove structure, subsequently attaching the smooth rubber strip, and subsequently forming in a mutual extrusion manner by using the large rolling shaft and the small rolling shaft which can be heated, after extrusion forming, taking down the extruded strapping tape from the large rolling shaft, and subsequently performing normal temperature irradiation cross-linking aftertreatment in a high-energy electronic accelerator.

Owner:北京大敖海洋科技有限公司

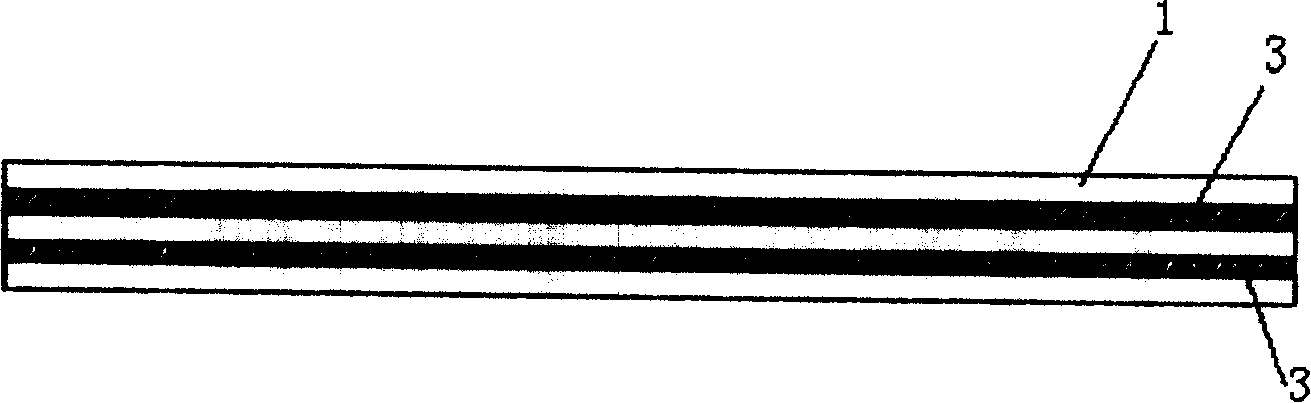

Regenerated plastic base sisal hemp fiber reinforced construction mould plate and its processing method

InactiveCN100383080CImprove waterproof performanceImprove corrosion resistanceSolid waste managementSisal fiberCorrosion

The present invention relates to sisal fiber reinforced regenerated plastic building shuttering and its making process. The sisal fiber reinforced regenerated plastic building shuttering consists of laminated plastic base and sisal fabric-dry sisal leaf layer, and through hot pressing to form integral. The building shuttering is made through sorting, cleaning and pelletizing waste plastic; banburing together with stuffing to form sheet in certain size; laminating the plastic sheets and sisal fabric-dry sisal leaf layers and hot pressing. The building shuttering has high strength, high corrosion resistance, high rain water resistance, smooth surface, convenient construction and environment friendship.

Owner:WUHAN TEXTILE UNIV

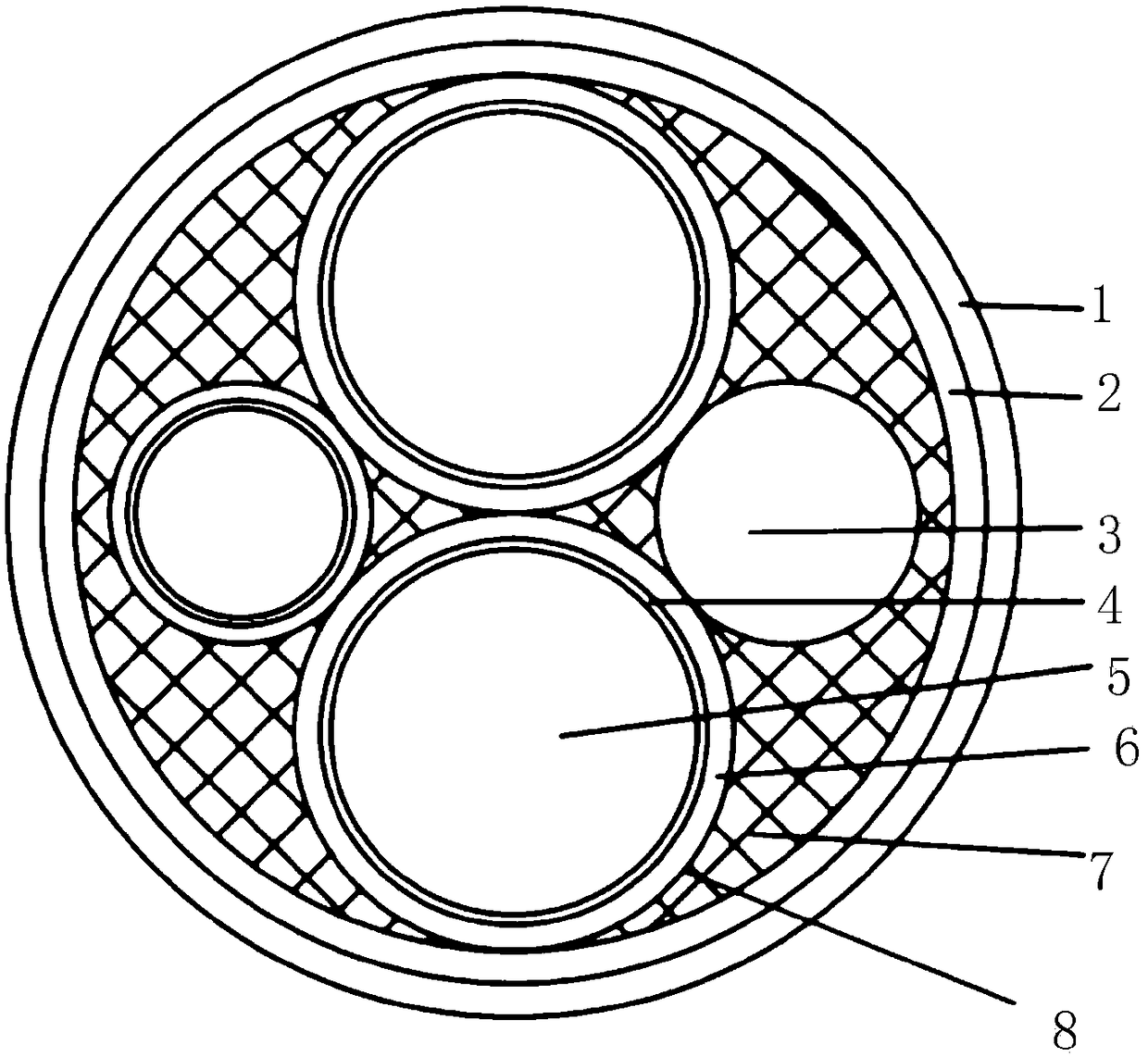

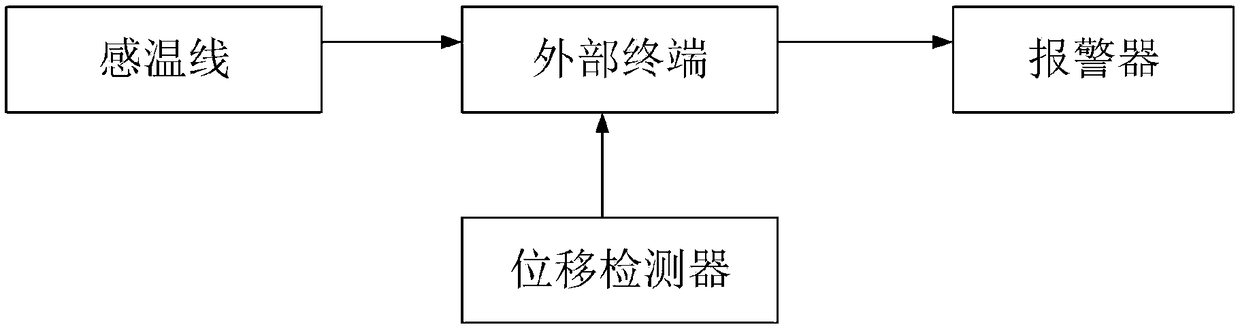

Anti-corrosion seawater cable, production method and detection method thereof

InactiveCN109344359AAvoid wear and tearImprove seawater corrosion resistanceMeasurement devicesCommunication cablesElectrical conductorMicrobial corrosion

The invention belongs to the field of cable production and discloses an anti-corrosion seawater cable, a production method and a detection method thereof. The detection method includes such step as setting an anticorrosion layer inside that anticorrosion layer, tightly sleeve a waterproof corrosion layer inside the anticorrosion layer, sleeving a temperature sensing wire and a metal conductor inside the waterproof corrosion layer, and setting the temperature sensing wire and the metal conductor inside the anticorrosion layer to obtain anticorrosion cable. The inside of the metal conductor is ametal conductor, and the outside of the metal conductor is tightly wrapped with an insulating layer. The anti-seawater corrosion cable provided by the invention has high tear resistance and fatigue resistance, and can prevent abrasion of the cable and corrosion by microorganisms. The utility model has the seawater corrosion resistance, greatly improves the seawater corrosion resistance of the cable, prolongs the effective period of the seawater corrosion protection, and avoids the loss caused by the failure of timely maintenance by utilizing the principle of Seebeck effect and real-time monitoring the temperature change correspondence of the cable through the set temperature sensing line.

Owner:HAINAN UNIVERSITY

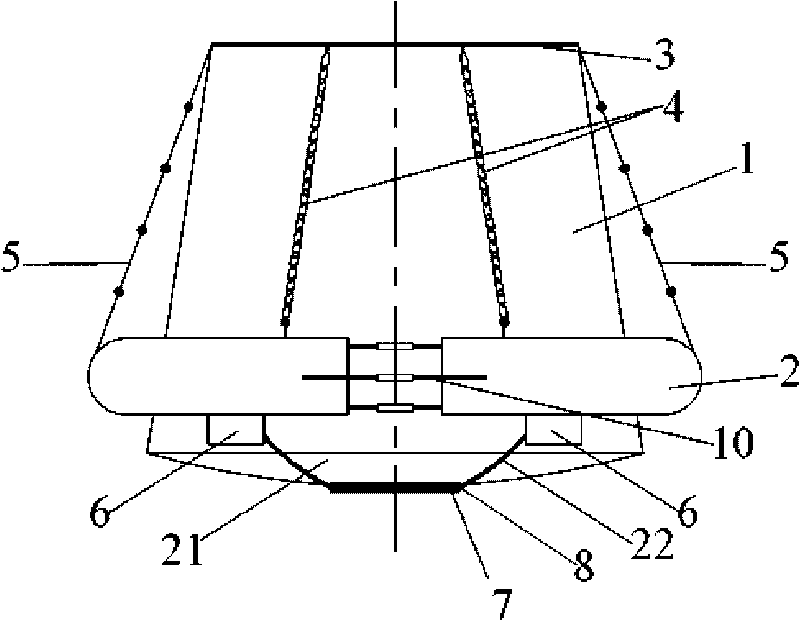

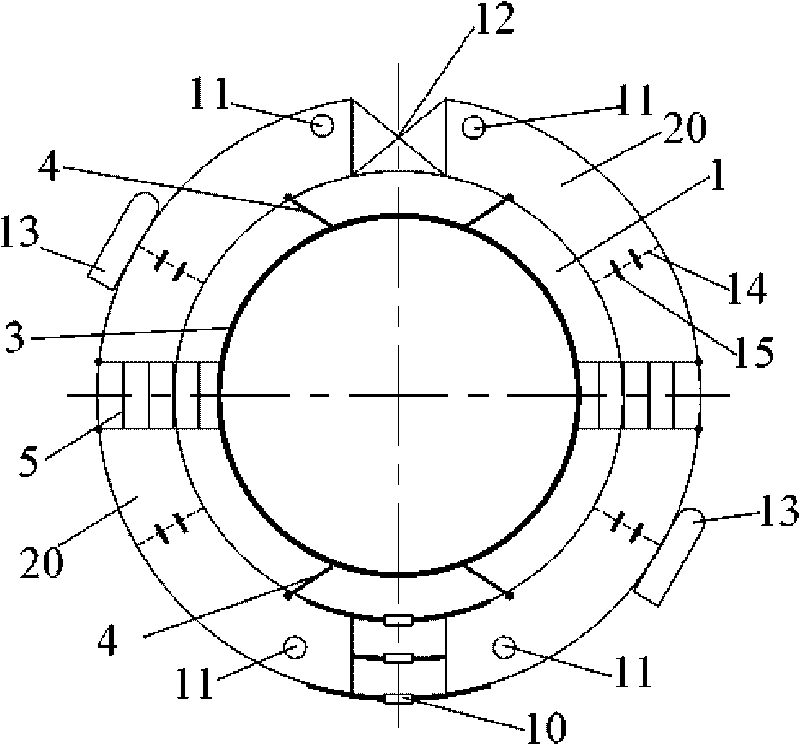

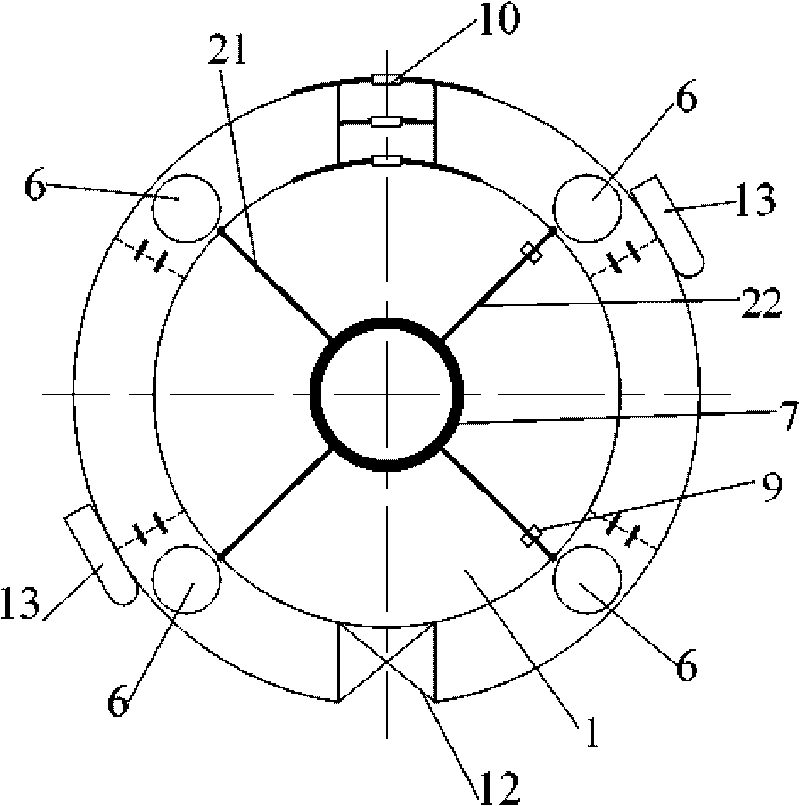

Maritime emergent floating bag life-saving system for re-entry capsule

The invention provides a maritime emergent life-saving system for a re-entry capsule, relating to a maritime emergent life-saving system for the re-entry capsule. The invention solves problems that the underwater re-entry capsule is in inclined posture in water. Two semicircular air bags of the life-saving system are arranged oppositely to form a circular ring, wherein one aerating air bottle is arranged on each semicircular air bag, an adapter ring is connected with a hatch of the re-entry capsule, a plurality of positioning chains are symmetrically arranged between the floating bag and the adapter ring, both sides of the re-entry capsule are respectively provided with one rope ladder for boarding, and an iron ring is arranged under the floating bag; and a plurality of nylon ropes with fixed length and a plurality of nylon ropes with adjustable length are symmetrically arranged between the iron ring and the floating bag along the axial line of the re-entry capsule, one end of each nylon rope with fixed length is connected with the iron ring, the other end thereof is connected with the inner rim of the floating bag, one end of each nylon rope with adjustable length is connected with the iron ring, and the other end thereof is connected with the inner rim of the floating bag by a unidirectional tensioner. The floating bag life-saving system realizes the alignment of the maritime inclined re-entry capsule and provides a working platform for rescuers.

Owner:HARBIN INST OF TECH

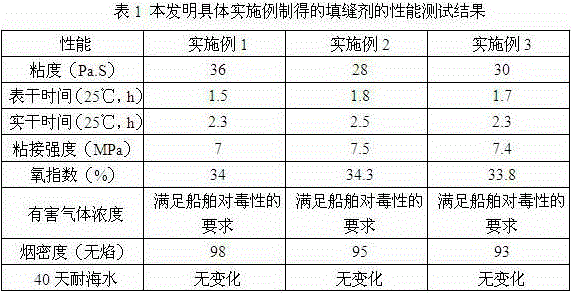

Two-component low-toxicity flame-retardant epoxy-based joint mixture and preparation method thereof

ActiveCN106349873AConsider performanceImprove flame retardant performanceFireproof paintsAnti-corrosive paintsZinc compoundsWear resistant

The invention relates to a two-component low-toxicity flame-retardant epoxy-based joint mixture and relates to coatings for ship gutterways. The two-component low-toxicity flame-retardant epoxy-based joint mixture comprises a component A and a component B which are mixed in a weight ratio of 2 to 1, wherein the component A comprises, by weight, 100 parts of phosphorized epoxy resin, 40-60 parts of hydroxide, 40-60 parts of acid zinc compound, 3-5 parts of organosilicon coupling agent, 1-2 parts of highly-wear-resistant carbon black and 10-20 parts of precipitated white carbon; the component B comprises, by weight, 40-50 parts of epoxy-amine curing agent and 8-10 parts of DMP-30; the hydroxide is selected from one of aluminum hydroxide and magnesium hydroxide, and the acid zinc compound is one of zinc borate and zinc stannate. The two-component low-toxicity flame-retardant epoxy-based joint mixture is capable of meeting the performance requirements on joint mixtures for the ship gutterways and has the comprehensive advantages of low toxicity, flame retardance, resistance to seawater corrosion and self-leveling.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Duplex stainless steel pipe used under marine environment and machining method of duplex stainless steel pipe

InactiveCN111230406AStrong toughnessImprove rigidityCorrosion preventionPipe protection against corrosion/incrustationSS - Stainless steelPipe

The invention discloses a duplex stainless steel pipe used under a marine environment and a machining method of the duplex stainless steel pipe. The special process of a composite pipe is adopted, a pipeline material of the composite pipe is divided into two layers, the outer layer is made of a material specially prepared for seawater corrosion resistance, the inner layer is made of a material specially prepared for resistance to corrosion of hydrogen sulfide, hydrogen and other oil gas substances, the outer layer and the inner layer are subjected to machining, heat treatment and extrusion into a whole, the structure strength, machinability and weldability of the composite pipe are further emphasized in the material formula, and the composite pipe with a certain difference formed between the materials of the inner layer and the outer layer is formed. The toughness of the inner duplex stainless steel layer is higher than that of the outer duplex stainless steel layer, the rigidity of the outer duplex stainless steel layer is higher than that of the inner duplex stainless steel layer, by controlling the alloy ratio of the inner duplex stainless steel layer to the outer duplex stainless steel layer, the inner duplex stainless steel layer is more resistant to hydrogen sulfide corrosion and has higher hydrogen brittleness resistance, and the outer duplex stainless steel layer has higher seawater corrosion resistance and better impact resistance.

Owner:WUXI XINFENG TUBE IND

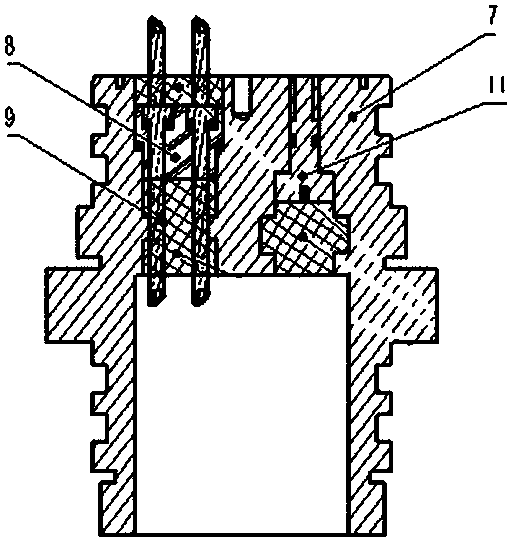

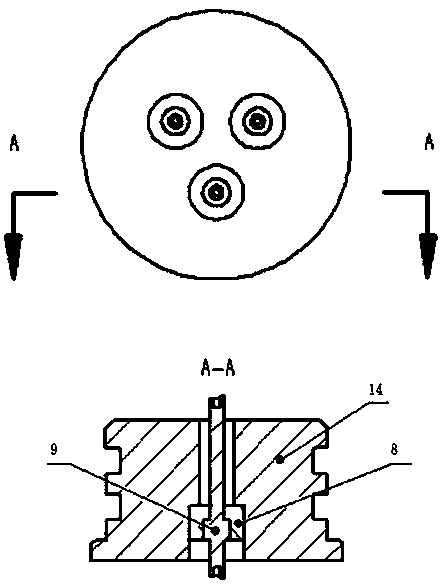

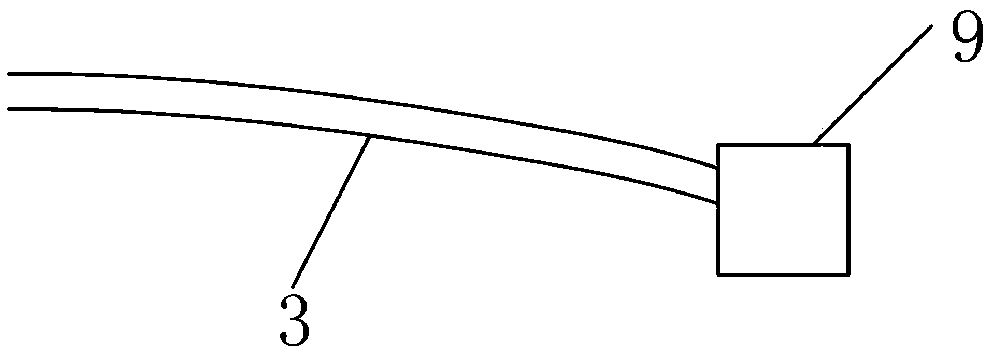

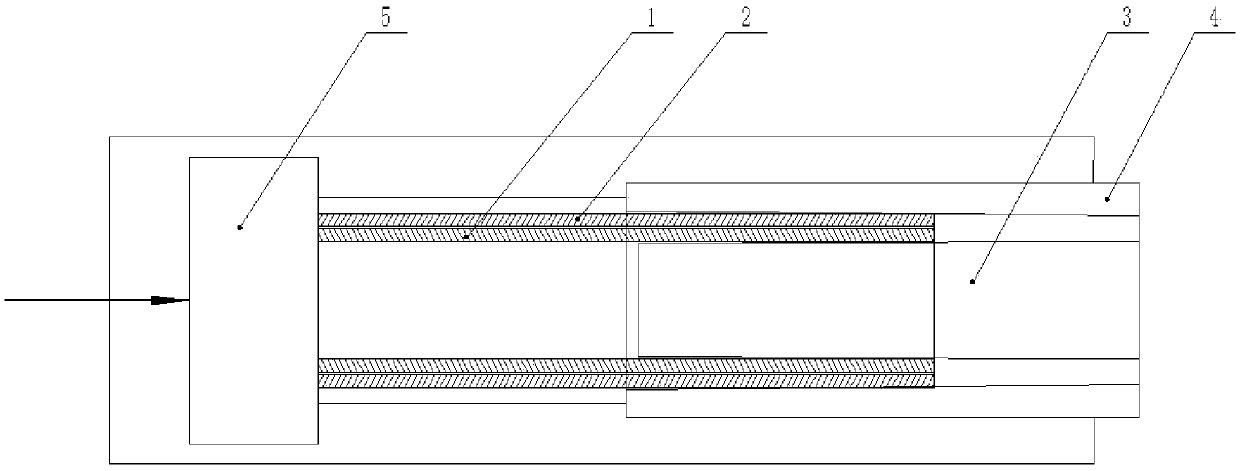

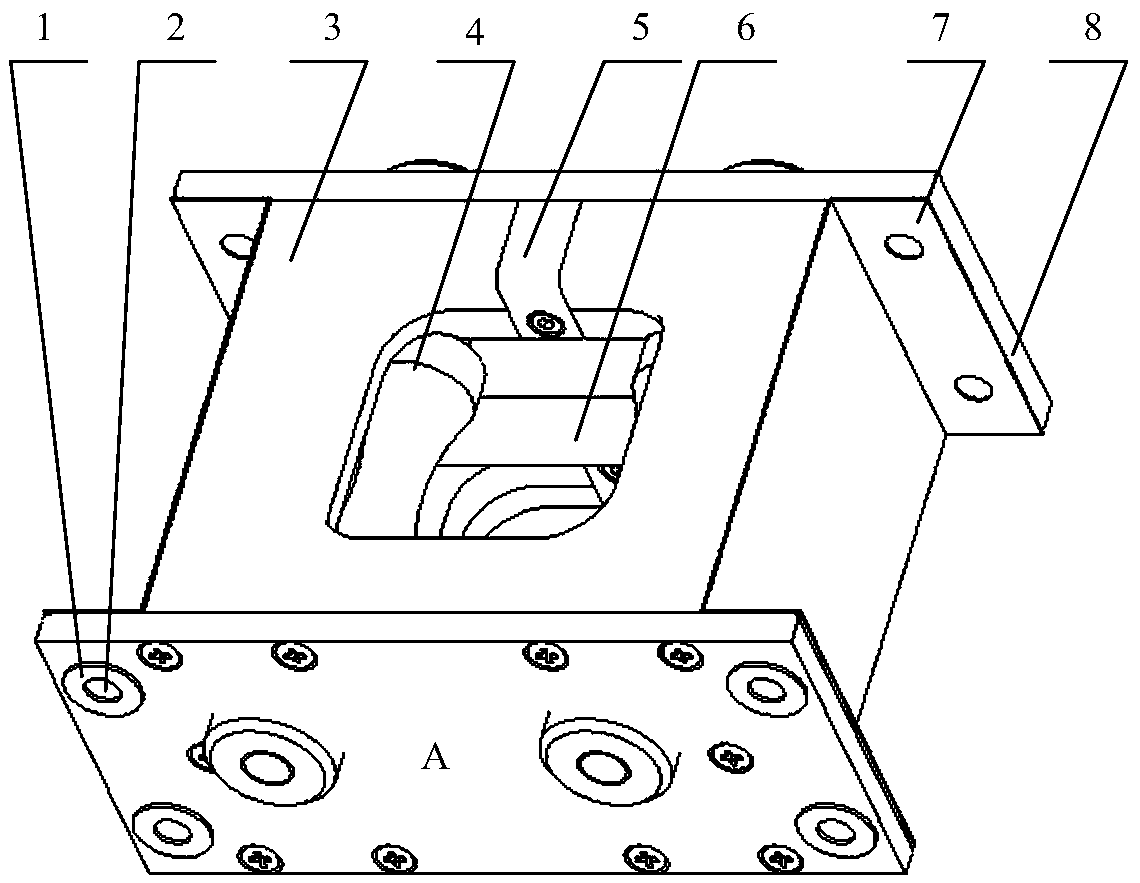

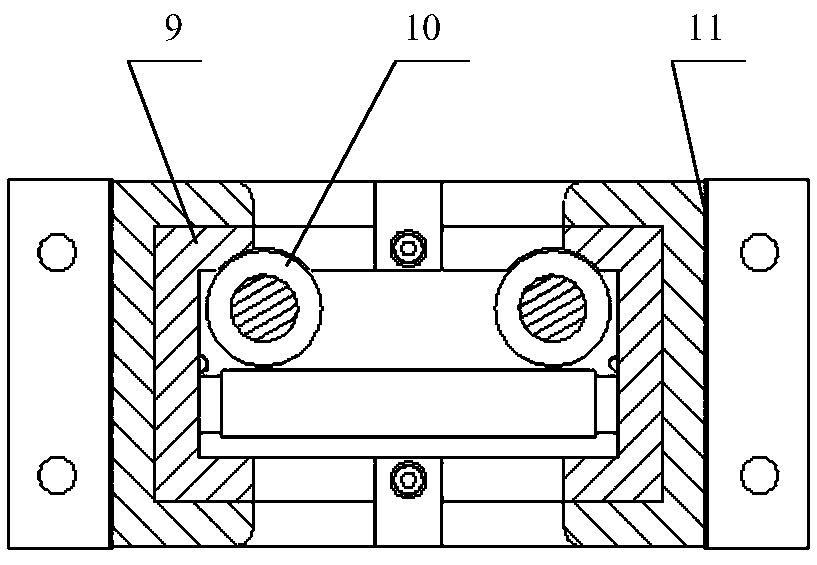

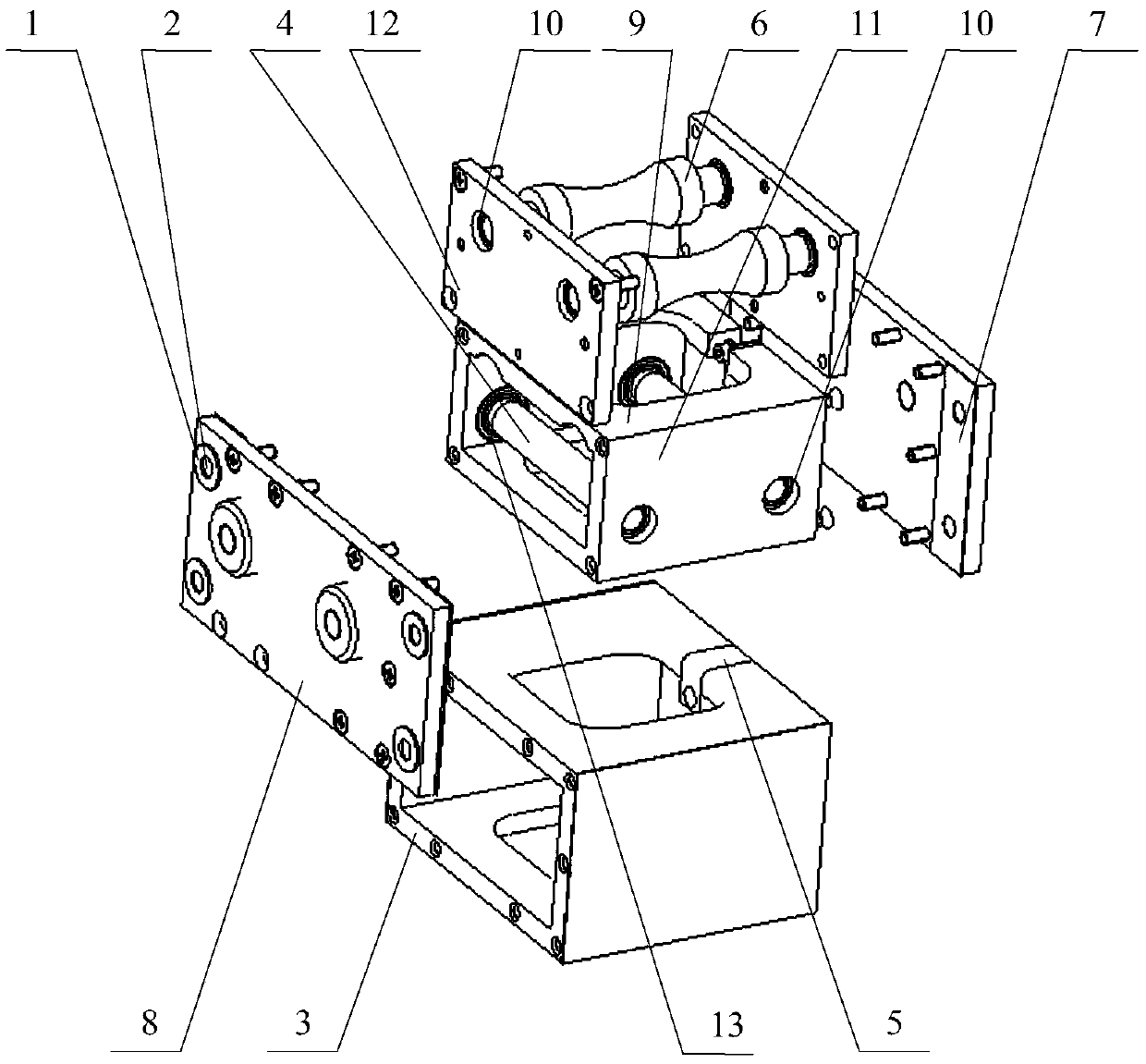

Cable guiding device

InactiveCN105501397AAct as a fixed supportReduce frictionWaterborne vesselsFilament handlingEngineeringFriction force

The invention discloses a cable guiding device. The device comprises a fairlead, a long shaft bracket, two long roll shafts, two short roll shafts, two short shaft brackets and two cover plates, wherein the fairlead and the long shaft bracket are hollow cuboids with openings at two ends and nested with each other, and guiding holes are formed in centers of two opposite end surfaces; the two short shaft brackets are mounted at openings in two ends of the long shaft bracket; the two cover plates are mounted outside the fairlead and attached to the two short shaft rackets; the long shaft bracket and the two short shaft brackets form a mounting chamber; in the mounting chamber, the two long roll shafts are mounted in parallel, the two short roll shafts are mounted in parallel, axial directions of the long roll shafts are perpendicular to the axial directions of the short roll shafts, and planes of the two shafts are parallel; through holes are formed in centers of the long roll shafts and the short roll shafts, a cable penetrates from the guiding hole in one end and then penetrates out of the guiding hole in the other end via the through holes. The cable guiding device can be mounted on an underwater buoyancy-driven lifting platform and is small in friction force, simple in structure, reliable in sliding, resistant to seawater corrosion and capable of being applied modularly.

Owner:710TH RES INST OF CHINA SHIPBUILDING IND CORP

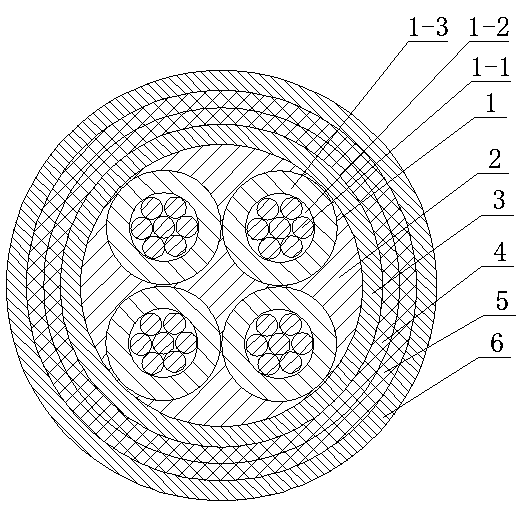

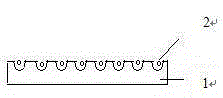

A sea-dedicated special cable

InactiveCN103680691ASeawater corrosion resistantWith high pressureInsulated cablesInsulated conductorsYarnCopper conductor

The invention relates to a sea-dedicated special cable and to cable structural field. The sea-dedicated special cable comprises a plurality of insulating wire cores. Each insulating wire core comprises twisted tin-plated copper conductors. Insulating layers are disposed on the peripheries of the twisted tin-plated copper conductors. Waterproof glue filling layers are disposed between the insulating layers and corresponding twisted tin-plated copper conductors. A waterproof wrapping tape is disposed on the peripheries of the insulating wire cores. A waterproof yarn mixing filling layer is arranged between the waterproof wrapping tape and the insulating wire cores. An aramid yarn weaving layer and a tin-plated alloy wire woven shielding layer are disposed on the periphery of the waterproof wrapping tape. An armor double-layer slurry-preventing outer sheath is disposed on the periphery of the tin-plated alloy wire woven shielding layer. Besides a transverse and vertical waterproof function, the sea-dedicated special cable also has advantages of seawater corrosion resistance, high voltage resistance, oil resistance, slurry resistance, and excellent wear-resistant, tensile, and hauling-resistant performance.

Owner:JIANGSU CHENGUANG CABLE

Sheet laminating preparation method for sisal fiber reinforced polypropylene composite material

The present invention adopts the sisal hemp fiber as fiber raw material, and uses the nonwoven fabric of thermoplastic resin PP, film, powder material and its fiber as resin base body, and adopts the following steps: pretreating sisal hemp fiber and making it into fiber felt, hot-pressing and forming, selecting and using a certain number of fiber felts, delaminating and sand wiching pp nonwoven fabric or film, under the condition of a certain temp. and pressure hot-pressing and forming or mixing PP fiber (PP powder) directly with sisal hemp fibre, making them into fiber felt and then hot-pressing and forming so as to obtain the invented sisal hemp fiber reinforced polypropylene composite material.

Owner:SUN YAT SEN UNIV

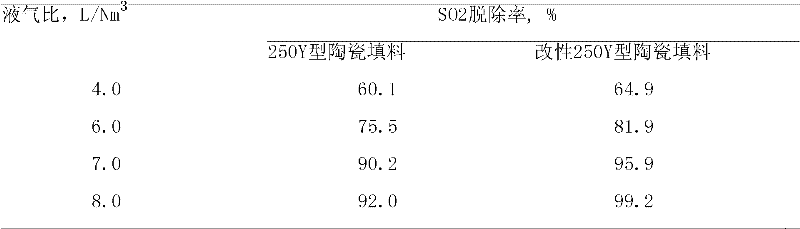

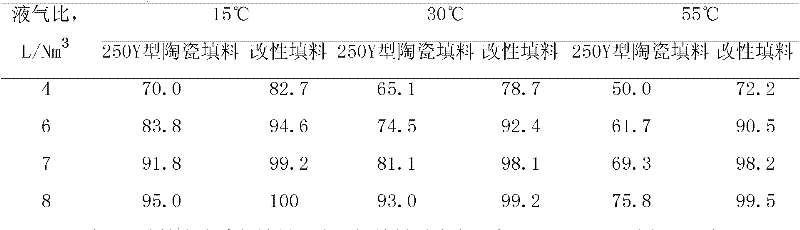

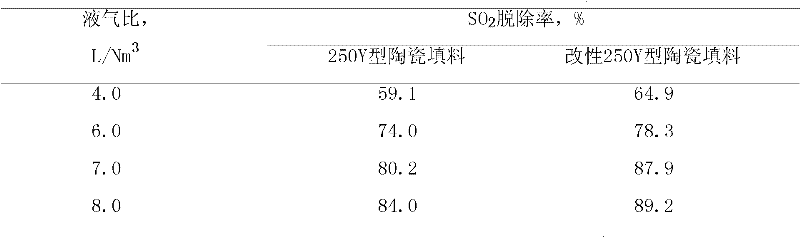

Method for preparing ceramic regulation catalytic filling for sea water desulfuration

InactiveCN101693184BLarge specific surface areaHigh porosityCatalyst carriersDispersed particle separationRoom temperatureSupersaturation

The invention discloses a method for preparing ceramic regulation catalytic filling for sea water desulfuration, which is characterized by comprising the flowing steps: processing ceramic regulation catalytic filling by diluted acid, then dipping the ceramic regulation catalytic filling into mixed solution of MnSO4 solution with the concentration of 0.7-1.5 mol / L or the MnSO4 solution with the concentration of 0.5-1.0 mol / l with the FeSO4 with the concentration of 0.3-0.5 mol / L, and dipping and stirring the filling for eight hours in the constant temperature of 60 DEG C, then dripping supersaturation (NH4)2CO3 solution, taking out the filling which is covered with deposition from deposition solution and aging the filling for 4-8 hours in the temperature of 30 DEG C-50 DEG C, drying the filling for 3-5 hours in the temperature of 120 DEG C after washing the filling by deionized water, processing the filling for 2-4 hours under the condition of room temperature by K2CO3 with the concentration of 0.7-1.2 mol / L, and drying the filling for 2-4 hours in the temperature of 100-150 DEG C, and then baking the filling for 2-4 hours in the temperature of 300-450 DEG C, thereby modified ceramic regulation catalytic filling is prepared.

Owner:OCEAN UNIV OF CHINA

A strain monitoring two-dimensional wound composite underwater vehicle shell and its preparation method

ActiveCN106903948BGuaranteed resistance to damageGuaranteed resistance to deformationWaterborne vesselsSynthetic resin layered productsCarbon fibersResin matrix

The invention discloses a strain monitoring two-dimensional winding composite material underwater vehicle shell and a preparation method thereof. The underwater vehicle shell comprises three parts from inside to outside: a metal sealing layer, a rigid strength layer and a corrosion-resistant layer, wherein the rigid strength layer is prepared by adopting a plurality of carbon fiber mixing and combination modes on the surface of the metal sealing layer, so that the underwater vehicle shell can adapt to different complicated underwater environments; the corrosion-resistant layer is prepared from chopped fiber reinforced resin matrix composite materials, so that the surface not only has the characteristic of resisting seawater corrosion, but also achieves the purpose of promoting the binding strength through the reinforcement action of the chopped fibers so as to effectively guarantee the service life. Through the embedding use of optical fibers or strain gauges or other different forms of strain inductors in the structure of the two-dimensional winding composite material rigid strength layer, the small strain of the whole shell structure or structure inner layer under high external pressure condition can be effectively perceived, and the real-time monitoring on the service status change of the underwater vehicle shell can be achieved.

Owner:山东宽原新材料科技有限公司

An intelligent monitoring three-dimensional composite underwater vehicle shell and its preparation method

ActiveCN106926532BEnsure mechanical stabilityHigh bonding strengthWaterborne vesselsSynthetic resin layered productsIntelligent lightingMechanical stability

The invention discloses an intelligent monitoring three-dimensional composite underwater vehicle shell body and a preparation method of the intelligent monitoring three-dimensional composite underwater vehicle shell body. The underwater vehicle shell body comprises a plurality of layers of structures from exterior to interior and comprises four parts of a corrosion resistance layer, an impact resistance layer, a rigidity layer and a metal sealing layer, one or more strain sensors is / are adopted in the impact resistance layer and the rigidity layer of a three-dimensional composite structure at the same time and introduced into the three-dimensional composite structure, and the stress state of the structure of the shell body is monitored through sensing of the micro-strain of the shell body in the working process. The three-dimensional prefabricated part structure guarantees the mechanical stability of the whole shell body, meanwhile, due to the arrangement of the impact resistance layer and the rigidity layer, the composite underwater vehicle shell body can adapt to different complex underwater environments.

Owner:山东宽原新材料科技有限公司

A kind of strapping for deep sea buoyancy material and preparation method thereof

The invention discloses a strapping tape for a deep sea buoyancy material and a preparation method thereof. The strapping tape material takes ethylene propylene diene monomer rubber as a matrix resin, graphite powder as a reinforcing agent, gamma-chlorine propyl triethoxy silane as a surfactant, multi-alkenyl irradiation sensitizing agent as a cross-linking auxiliary, quad[beta-(3,5-ditertiary butyl-4-hydroxide phenyl) propionic acid] pentaerythritol ester-1010 as an antioxidant, diisodecyl adipate-DDA as a plasticizing agent, zinc stearate-ZnSt2 as a stabilizing agent. A final annular strapping tape product can be obtained by proportioning the components according to a certain ratio, extruding to form an ethylene propylene diene monomer rubber strip and a smooth rubber strip of groove structures by using a double-screw rod extruder, annually winding high-performance fibers on a large rolling shaft with the ethylene propylene diene monomer rubber strip of the groove structure, subsequently attaching the smooth rubber strip, and subsequently forming in a mutual extrusion manner by using the large rolling shaft and the small rolling shaft which can be heated, after extrusion forming, taking down the extruded strapping tape from the large rolling shaft, and subsequently performing normal temperature irradiation cross-linking aftertreatment in a high-energy electronic accelerator.

Owner:北京大敖海洋科技有限公司

Brake gasket and its preparation method

The preparation process of brake gasket includes the following steps: preparing sisal fiber via cutting sisal into 10-20 mm long segment, soaking in anhydrous alcohol plus benzene solution, washing with anhydrous alcohol and deionized water, boiling in NaOH solution, cooling to room temperature, washing with deionized water to neutrality and stoving in stove; mixing sisal fiber, phonetic resin, copper powder, graphite powder, MoS2, pre-polymer, metal oxide, butadiene-acrylonitrile rubber, non-metal compound and barium sulfate in a high speed mixer to form mixture material; making blank with the mixture material; hot pressing the blank to form; and heat treatment at 190-200 deg.c. The present invention makes asbestos-free brake gasket with sisal fiber as reinforcing material, and the brake gasket has stable friction coefficient, less heat degradation, low wear, no couple wear, smooth braking, low noise and no environmental pollution.

Owner:XI AN JIAOTONG UNIV +1

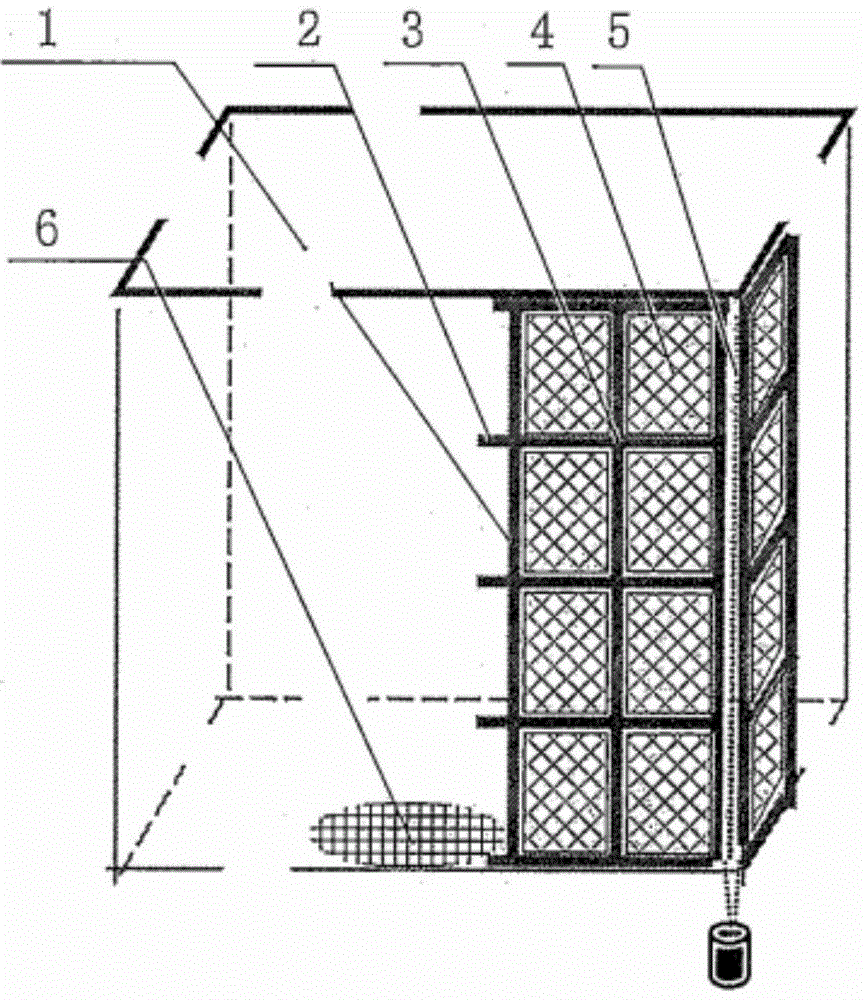

A modularly assembled copper alloy tension net cage and its assembly method

ActiveCN104756904BImprove integrityIncrease elasticityClimate change adaptationPisciculture and aquariaPolyesterMarine culture

The invention relates to a modularly assembled copper alloy tension net cage and an assembly method thereof, comprising a vertically stressed high-strength polyester fiber ribbon, a main skeleton ribbon standard part and a horizontally secondary stressed high-strength polyester fiber ribbon The standard part of the sub-skeleton webbing is fixed at the intersection point of the cross to form a grid-shaped single-side cage box webbing skeleton with flexibility and elasticity; in each frame of the single-side cage box webbing skeleton, Through the assembly of pre-installed quick connectors and prefabricated copper alloy tensile mesh standard modules, a modular assembled net cage box side net is formed; both sides of the unilateral side net are connected by quick connectors or several sheets The side and side nets are equipped with corner flexible transfer standard parts and assembled with the bottom net to form a copper alloy tensile net cage body. The invention can be modularized and standardized for production, and is convenient for rapid installation at sea, and has the performance of well maintaining the marine culture net cages against marine fouling organisms, and maintaining good water exchange inside and outside the net cages.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

A kind of ship antirust paint and preparation method thereof

ActiveCN104277693BImprove water resistanceHigh hardnessAnti-corrosive paintsPolyurea/polyurethane coatingsEthylenediamineHigh resistance

The invention discloses an anti-rust paint for a ship and a preparation method thereof. The anti-rust paint comprises the following components in parts by weight: 8-12 parts of styrene-acrylate emulsions, 16-25 parts of polyurethane emulsions, 2-6 parts of sodium gluconate, 0.8-2.4 parts of polyepoxysuccinic acid, 3-8 parts of film-forming auxiliary agents, 0.5-1.8 parts of defoaming agents, 20-45 parts of water, 6-10 parts of amino acid and 2-5 parts of sodium citrate or disodium ethylene diamine tetraacetate. The anti-rust paint prepared through the interaction of all the components has the advantages of high water resistance, high rigidity, good paint film plumpness, sea water corrosion resistance, high biodegradability, use of safe and non-toxic components and wide application prospect and cannot cause serious pollution to a water body even if blended into sea water.

Owner:江苏悠谷未来科技有限公司

Antioxidation coating material of Nano silicate in use for annealing billet in series

The invention relates to a nano-silicate anti-oxidation coating used for annealing a series of steel billets. The coating is composed of 20-30% composite binder, 8-12% composite phosphate curing Aluminosilicate filler composition. Its characteristics: 1. Temperature resistance 1500 ℃; 2. No surface treatment in any way. The surface of the direct-sprayed steel billet is solidified at room temperature for ten minutes, collides and rubs against each other, making it difficult to be soft and hard; 3. All kinds of steel billets sprayed are quenched in water for a few seconds before annealing and hot rolling. Bell paint is self-detaching, self-departing without leaving paint traces, and improves the surface quality; 4. It can reduce the loss on ignition of various steels; 6. It can also be used for surface protection of refractory materials for furnace linings in various fields; industrial and civil fields as internal and external Wall coatings; bridges, piers, dams and other metal structures in the field of cement construction are waterproof, anti-corrosion, anti-oxidation, and have the unique performance of seawater resistance.

Owner:沁阳市皇甫喷射防腐技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com