Duplex stainless steel pipe used under marine environment and machining method of duplex stainless steel pipe

A duplex stainless steel, marine environment technology, applied in the field of transportation pipelines, can solve the problems of ecological environment damage and short service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

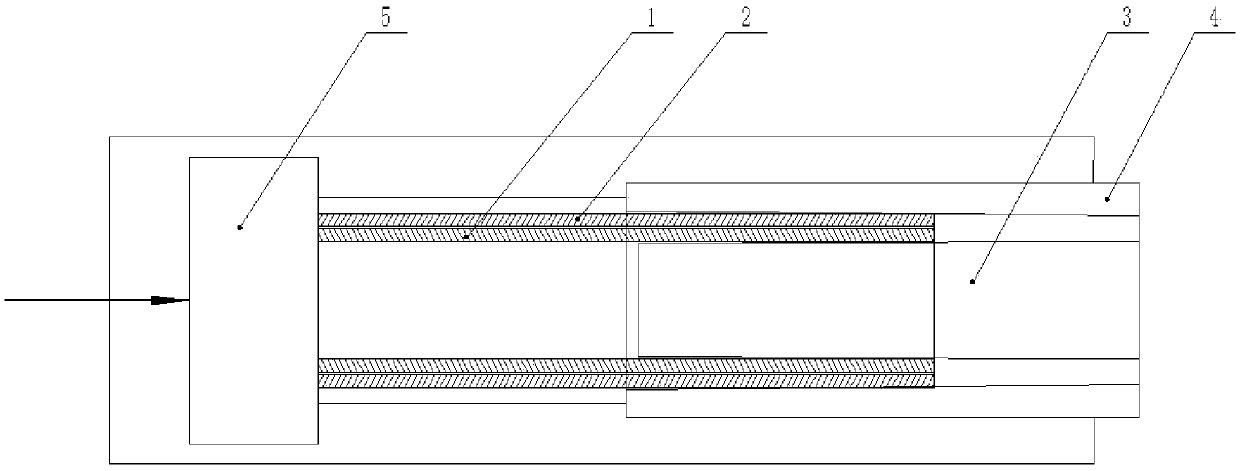

[0056] Embodiment 1: The duplex stainless steel pipe in the marine environment of this embodiment includes a steel pipe formed by integral hot extrusion of the outer duplex stainless steel layer and the inner duplex stainless steel layer, and the outer duplex stainless steel layer is the first ferrite ~Austenitic duplex stainless steel alloy, the specific weight ratio content is:

[0057]C is 0.05%; Si is 0.6%; Mn is 0.04%; Cr is 27%; Ni is 7%; Mo is 0.6%; S is 0.01%; Al is 0.06%; W is 2%; P is 0.03%; Cu is 1.5%; N is 0.2%; the ferrite content is 55%, and the rest is austenite and irremovable impurities; among them, non-metallic inclusions: A≤1.0 level, B, C≤2.0 level, D≤1.5 level; A+B+C+D≤5 level.

[0058] The inner duplex stainless steel layer is the second ferrite-austenite duplex stainless steel alloy, the specific content is:

[0059] C is 0.03%; Si is 0.1%; Mn is 0.06%; Cr is 25%; Ni is 7%; Mo is 1%; S is 0.01%; Al is 0.03%; W is 3%; P is 0.03%; Cu is 2%; N is 0.25%; ...

Embodiment 2

[0076] Embodiment 2: This embodiment is a further improvement on the basis of Embodiment 1. It includes a steel pipe formed by integral hot extrusion of the outer duplex stainless steel layer and the inner duplex stainless steel layer. The outer duplex stainless steel layer is the first Ferritic-austenitic duplex stainless steel alloy, the specific weight ratio content is:

[0077] C is 0.04%; Si is 0.1%; Mn is 0.03%; Cr is 25%; Ni is 5%; Mo is 0.3%; S is 0.008%; Al is 0.03%; W is 1%; P is 0.02%; Cu is 1%; N is 0.18%; the ferrite content is 45%, the rest is austenite and irremovable impurities; among them, non-metallic inclusions: A≤1.0 level, B, C≤2.0 level, D ≤1.5 level; A+B+C+D≤5 level.

[0078] The inner duplex stainless steel layer is the second ferrite-austenite duplex stainless steel alloy, the specific content is:

[0079] C is 0.02%; Si is 0.03%; Mn is 0.03%; Cr is 22%; Ni is 6%; Mo is 0.6%; S is 0.008%; Al is 0.02%; W is 2%; P is 0.02%; Cu is 1.5%; N is 0.2%; ferr...

Embodiment 3

[0080] Embodiment 3: This embodiment is a further improvement on the basis of Embodiment 1, including a steel pipe formed by integral hot extrusion of the outer duplex stainless steel layer and the inner duplex stainless steel layer, and the outer duplex stainless steel layer is the first Ferritic-austenitic duplex stainless steel alloy, the specific weight ratio content is:

[0081] C is 0.045%; Si is 0.4%; Mn is 0.035%; Cr is 26%; Ni is 6%; Mo is 0.5%; S is 0.007%; Al is 0.045%; W is 1.5%; P is 0.025%; Cu is 1.3%; N is 0.19%; the ferrite content is 50%, the rest is austenite and irremovable impurities; among them, non-metallic inclusions: A≤1.0 level, B, C≤2.0 level, D ≤1.5 level; A+B+C+D≤5 level.

[0082] The inner duplex stainless steel layer is the second ferrite-austenite duplex stainless steel alloy, the specific content is:

[0083] C is 0.025%; Si is 0.07%; Mn is 0.05%; Cr is 24%; Ni is 6.5%; Mo is 0.8%; S is 0.009%; Al is 0.025%; W is 2.5%; P is 0.025%; Cu is 1.8%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com